Cationic type aqueous polyurethane dispersoid and preparation method thereof

A water-based polyurethane and cationic technology, which is applied in the field of cationic water-based polyurethane dispersion and its preparation, can solve problems affecting the production, development and application of cationic water-based polyurethane, insufficient solvent resistance, product application restrictions, etc., and achieve good appearance , Excellent solvent resistance, reasonable ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

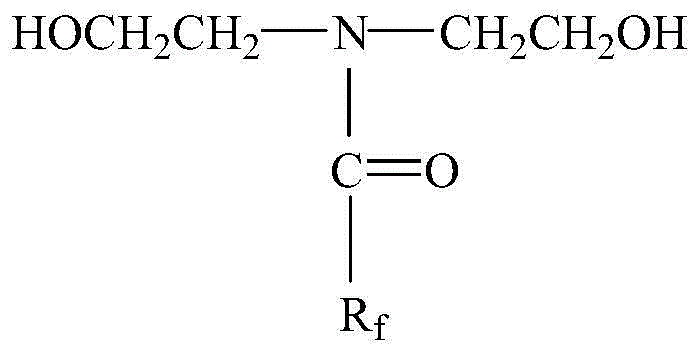

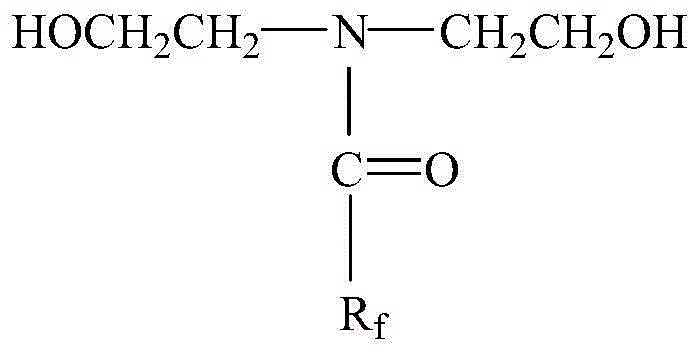

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 concrete operation is as follows:

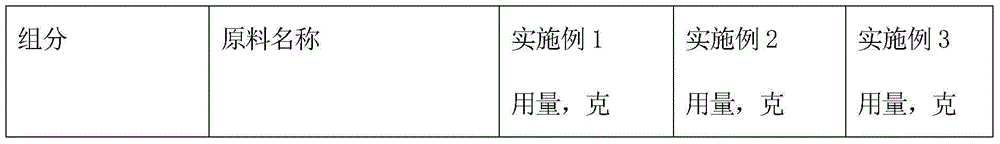

[0042] ① Prepare the raw materials according to the formula in Table 1;

[0043] ② Preparation of isocyanate-terminated polyurethane prepolymer solution

[0044] In a four-necked flask equipped with a stirrer, a thermometer and a condenser tube, mix the isocyanate prepared in step ①, polymer diol, small molecule chain extender, crosslinking agent, catalyst and 543 grams of solvent acetone, and heat at 90°C The reaction was carried out for 5 hours to obtain an isocyanate-terminated polyurethane prepolymer solution with a solid content of 50 wt%, which was stored for future use;

[0045] ③ Prepare the primer solution

[0046] The dihydroxyl compound containing the tertiary amino group prepared by step 1, the dihydroxyl compound containing aliphatic hydrocarbon group in the side chain are mixed with 119 grams of solvent acetone as the primer solution, and its solid content is 50wt%.

[0047] ④Preparation of cationic water...

Embodiment 2

[0049] Embodiment 2 concrete operations are as follows:

[0050] The preparation method is basically the same as in Example 1, the difference is: polycaprolactone diol is used as the polymer diol, and the specific formula is shown in Table 1; when step 2. prepares the isocyanate-terminated polyurethane prepolymer solution, the amount of solvent acetone 518 grams; step ④ when preparing the cationic water-based polyurethane dispersion, the viscosity of the obtained polyurethane prepolymer solution was 11171mPa·s, and during emulsification, the amount of deionized water was 1488 grams.

Embodiment 3

[0051] Embodiment 3 concrete operations are as follows:

[0052] The preparation method is basically the same as in Example 1, except that toluene diisocyanate is used as the isocyanate, and oleic acid diethanolamide is used as the dihydroxy compound containing aliphatic hydrocarbon groups in the side chain. The specific formula is shown in Table 1; step ② prepares isocyanate-terminated polyurethane During prepolymer solution, solvent acetone consumption is 495 grams; Step 3. when preparing primer solution, solvent acetone consumption is 118 grams; Step 4. when preparing cationic waterborne polyurethane dispersion, the viscosity of the polyurethane prepolymer solution that obtains is 16710mPa ·s, when emulsifying, the amount of deionized water is 1432 grams.

[0053] (2) The specific formula for preparing the comparative cationic waterborne polyurethane dispersion is shown in Table 2.

[0054] Table 2

[0055]

[0056]

[0057] Note: The grade of polytetrahydrofuran e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com