Patents

Literature

64results about How to "Efficient and durable antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

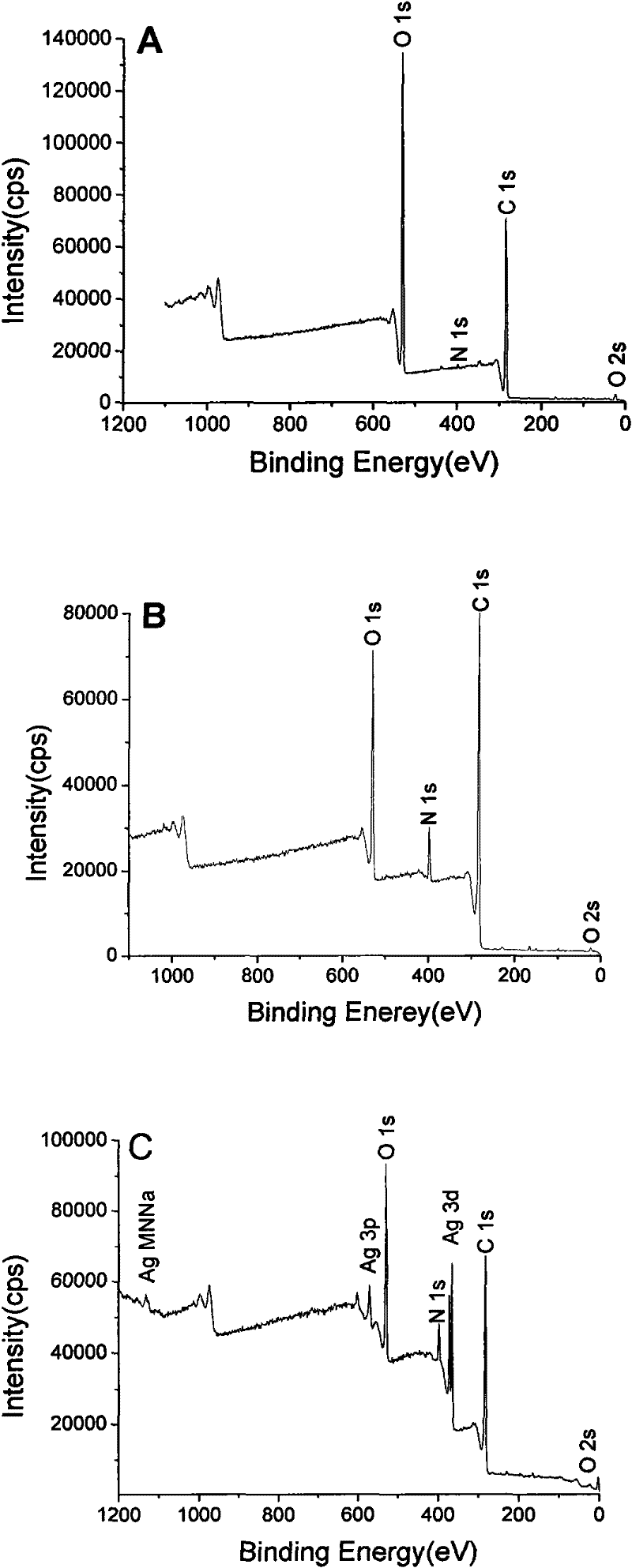

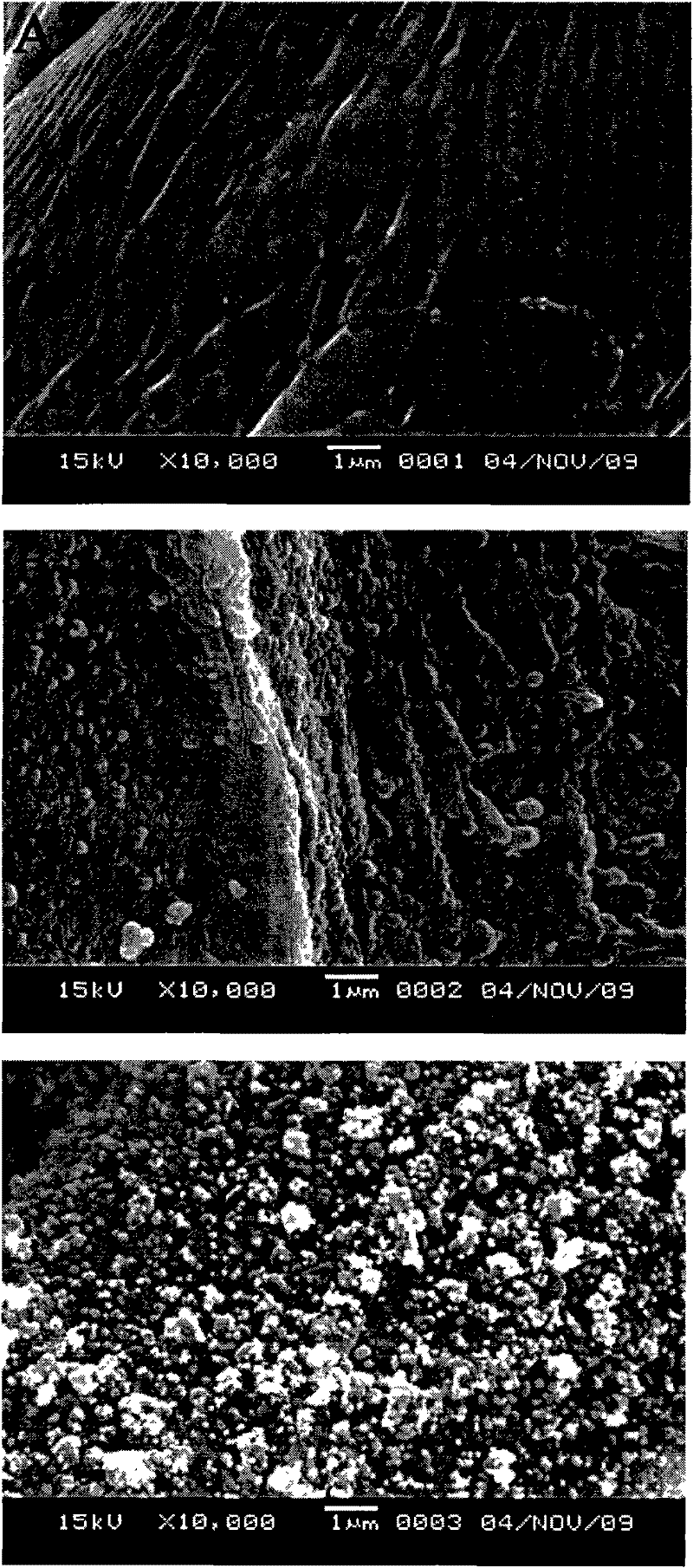

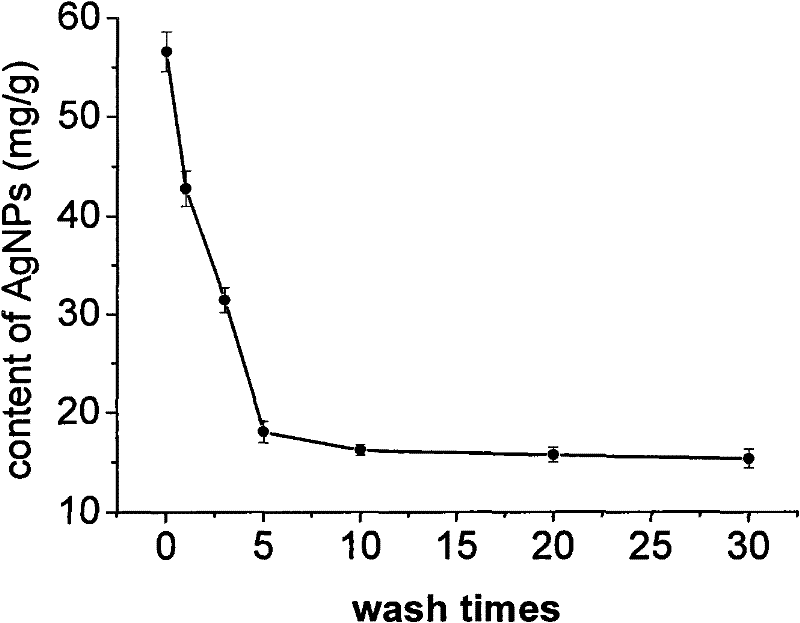

Method for preparing nano silver-containing anti-bacterial fabric by immersion process

ActiveCN101864670AGood soaping fastnessEfficient and durable antibacterialVegetal fibresAnimal fibresChemistryAnti bacterial

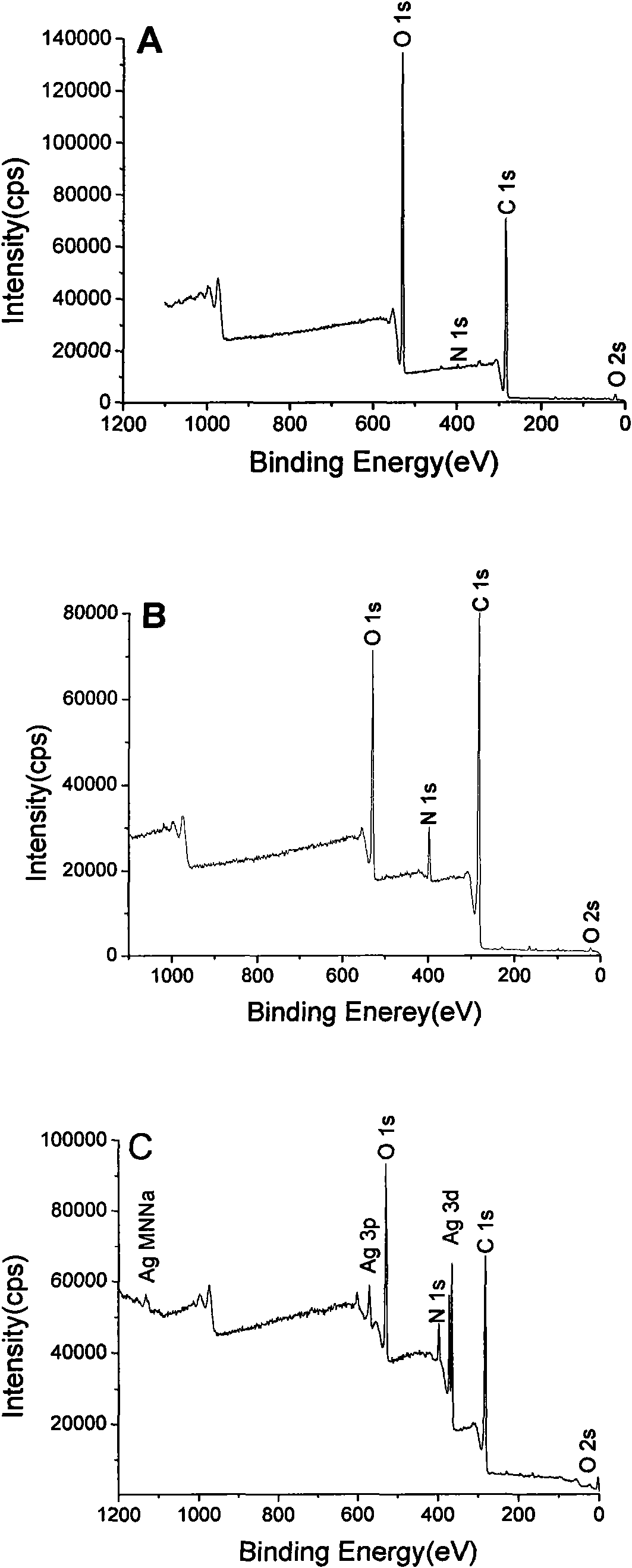

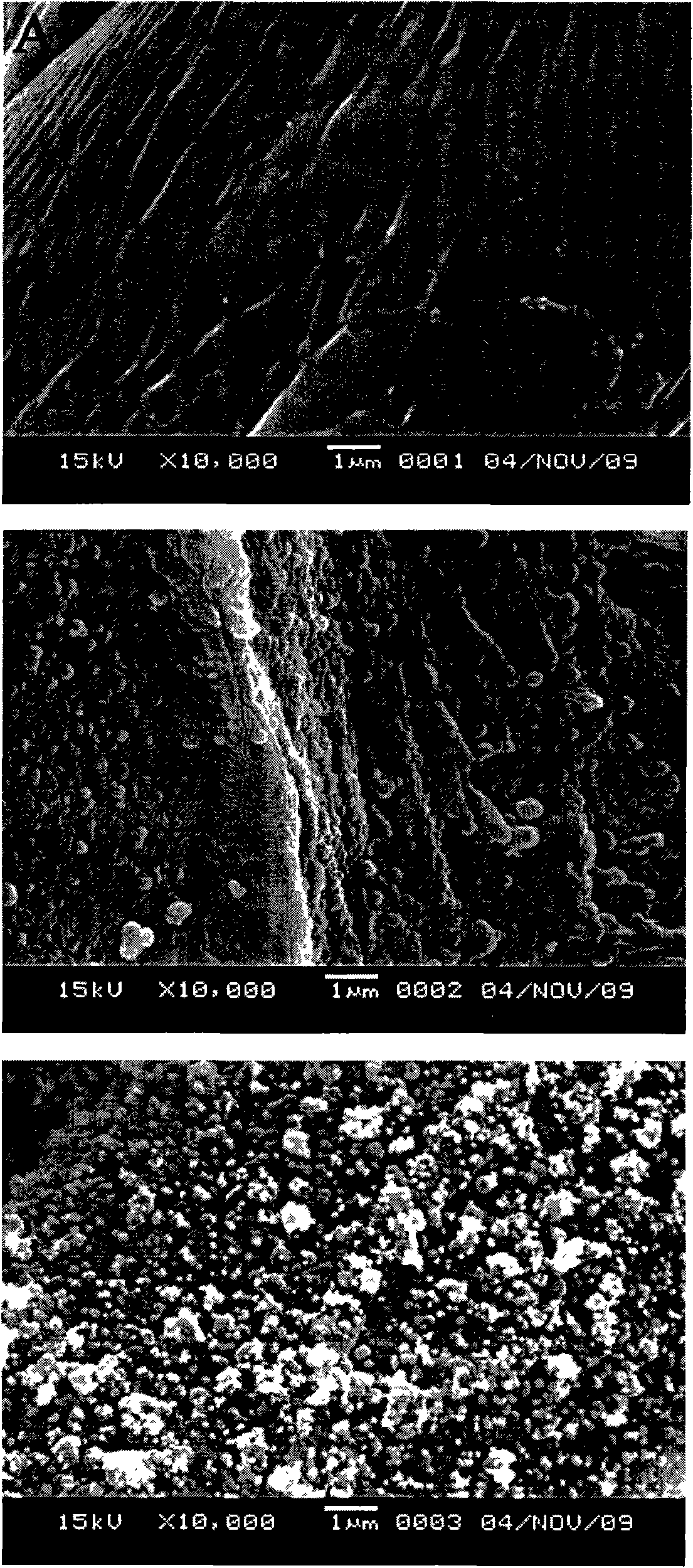

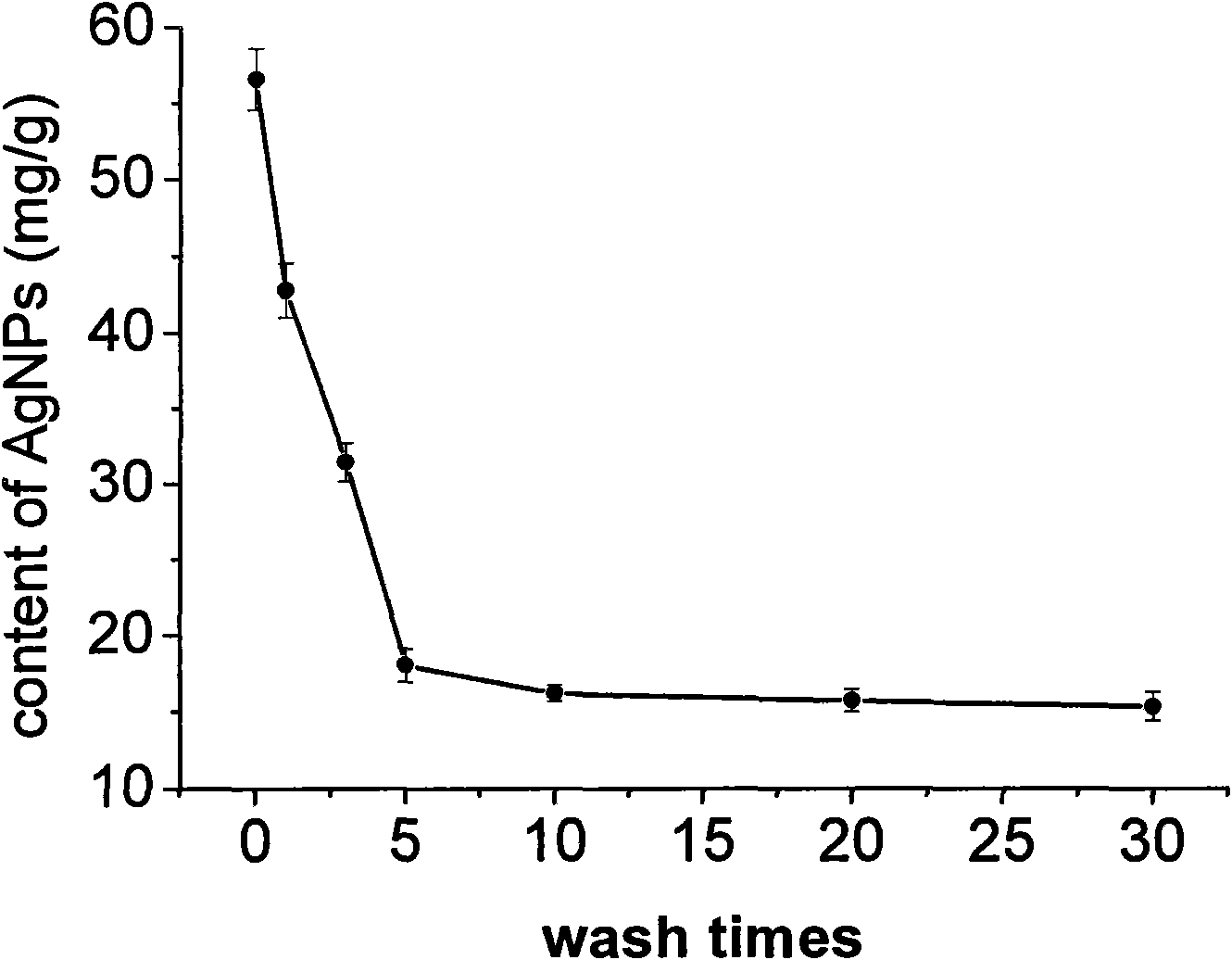

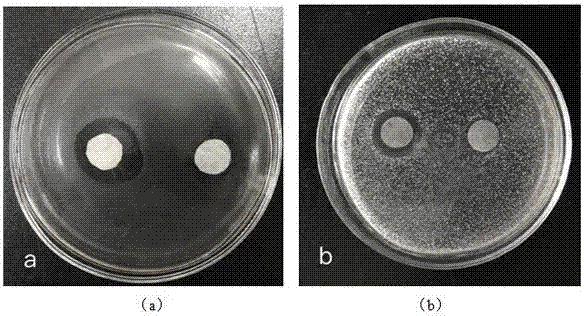

The invention relates to a method for preparing a nano silver-containing anti-bacterial fabric by an immersion process. The method comprises the following steps: dissolving dopamine hydrochloride in Tris buffer solution; adjusting the pH value of solution to be between 7 and 10 by using hydrochloric acid; immerging a fabric into prepared dopamine solution in a bath ratio of 1:30; after stirring for reacting at the temperature of between 20 and 40 DEG C for 20 to 30 hours, taking the fabric out and washing to obtain a poly dopamine film-coated fabric; putting the fabric into silver nitrate aqueous solution; and after immerging for 8 to 10 hours, washing and drying the fabric to obtain the nano silver-containing fabric. The nano silver-containing fabric prepared by the method has the characteristics of high soaping fastness resistance and lasting antibiotic property; a sterilizing rate is still up to 100 percent after the fabric is washed with water for 30 times; and the preparation method has the characteristics of simple process, no pollution to the environment, low cost and large-scale production.

Owner:DONGHUA UNIV

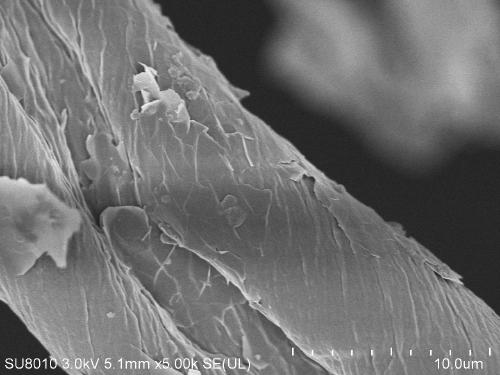

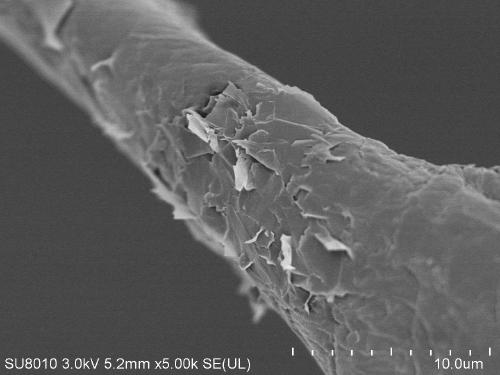

Preparation method for composite antibacterial cellulose fiber filler of metal organic frame

ActiveCN107142538AEasy to introduceImprove antibacterial propertiesMonocomponent cellulose artificial filamentArtifical filament manufactureEscherichia coliHydrogen

The invention relates to a preparation method for composite antibacterial cellulose fiber filler of a metal organic frame. The method comprises the following steps: firstly, enabling fiber to be subjected to carboxymethylation to introduce more carboxyl anion groups, secondly, stirring and blending a metal salt solution and the fiber, then adding organic ligands to perform in-situ preparation of composite antibacterial cellulose fiber of the metal organic frame, utilizing the composite fiber, and taking the composite fiber as filler to form intermolecular hydrogen bonding with natural plant fiber to prepare paper for daily use, medical dressings, product packages and textiles which are rich in an antimicrobial property. The preparation method is simple and high in accessibility; the problem about bonding between the metal organic frame as filler and the fiber is fully solved; the prepared novel antibacterial cellulose fiber has excellent structural stability and an efficient and durable antibacterial property; and the antibacterial rate specific to staphylococcus aureus and escherichia coli can be 99% or more; and the preparation method can be widely applied to the relevant fields of medical apparatus and instruments, the medical dressings, the product packages and textiles and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of polyphenol modified nano-silver carrying antibacterial fabric

ActiveCN105839419ANot easy to loseGood soaping resistanceBiochemical fibre treatmentTextile technologyEnvironmental resistance

The invention discloses a preparation method of polyphenol modified nano-silver carrying antibacterial fabric and belongs to the technical field of textiles. According to the method, after being soaked in a polyphenol compound water solution for a reaction, fabric is air-dried to obtain fabric with the surface coated with a polyphenol compound, and then the fabric is soaked in a silver nitrate water solution for a reaction to obtain the polyphenol modified nano-silver carrying antibacterial fabric. According to the method, the polyphenol compound is used for modifying the fabric, nano-silver particles are generated on the surface of the fabric in an in-situ reduction mode through a redox reaction of polyphenol and silver ions, and meanwhile nano-silver can adhere to the surface of the fabric without loss under the coordination effect of the polyphenol compound on the nano-silver particles. The antibacterial fabric has good soaping resistance and efficient and lasting antibacterial properties, and is not prone to fall off; after 30 times of washing, the sterilizing rate can still reach 95-100%; the fabric is diversified in type, wide in application range, simple in preparation process, environmentally friendly, low in cost and suitable for large-scale production, and selected materials are cheap and easy to obtain.

Owner:DONGGUAN YIMAO FILTER MEDIA

Nano coating and preparation method thereof

InactiveCN101654572AEfficient and durable antibacterialReduce agglomeration reactionAntifouling/underwater paintsPaints with biocidesEmulsionNanometre

The invention provides a nano coating and a preparation method thereof. The nano coating contains an emulsion, nano titanium dioxide and nano silver, wherein the nano silver is loaded on the surface of the nano titanium dioxide, and the weight ratio of te nano silver to the nano titanium dioxide is 1:5-8. In the preparation method of the nano coating, the nano silver is loaded on the surface of the nano titanium dioxide to reduce the agglomeration reaction of the nano silver so that the nano coating has efficient and lasting antibacterial performance.

Owner:BYD CO LTD

Antimicrobial bacterial cellulose and preparation method thereof

ActiveCN103724568AGood chemical stabilityImprove antibacterial propertiesProsthesisWound healingChemical stability

The invention provides antimicrobial bacterial cellulose and a preparation method thereof. According to the antimicrobial bacterial cellulose provided by the invention, a large number of hydroxyl functional groups existing on the bacterial cellulose are utilized, a quaternary ammonium salt antimicrobial group is introduced by surface modification, the structure of the bacterial cellulose is not damaged, the shape of hydrated gel is maintained, the effect of promoting healing of a wound is realized, and the antimicrobial bacterial cellulose prepared by the preparation method provided by the invention simultaneously has the advantages of good chemical stability and lasting antimicrobial effect.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of photosensitive antibacterial fabric

ActiveCN104313889AImprove deformation resistanceImprove stabilityVegetal fibresChemical LinkageAlcohol

The invention discloses a preparation method of a photosensitive antibacterial fabric. The method comprises the steps of soaking the fabric in dopamine aqueous solution to generate a fabric with a polydopamine layer on the surface, taking out the fabric, sequentially washing the fabric by utilizing the deionized water and absolute ethyl alcohol, and drying the fabric in the air to obtain the fabric with the polydopamine layer on the surface; soaking the fabric with the polydopamine layer on the surface in an ethanol and water mixed solution of BAPDPP compound, taking out the fabric after reacting for 6 to 24 hours, washing the fabric by sequentially utilizing the deionized water and absolute ethyl alcohol, vacuum drying the fabric for 5 to 10 hours at the temperature of 40 DEG C, and obtaining the photosensitive antibacterial fabric which is chemically bonded with a porphyrin compound by adopting the polydopamine as a bridging base. The photosensitive antibacterial fabric is good in soap washing resistance and high-efficient and lasting in antibacterial property, the sterilizing rate still can reach 95 to 100 percent after the fabric is washed for 20 times, the variety of the fabric is diversified, and the application range is wide; moreover, the preparation process is simple, environmentally friendly, low in cost and applicable to mass production.

Owner:WUHAN TEXTILE UNIV

Semen Cassiae Composite Antibacterial Finishing Agent, Preparation Method, Fiber Treatment Method and Application

The invention discloses a cassia seed composite antibacterial finishing agent which is prepared from a cassia seed extract or nano-cassia seed, a finishing agent and TW-80 (Tween-80). The cassia seed composite antibacterial finishing agent is convenient to use and stable; by adopting the technology of applying the cassia seed composite antibacterial finishing agent on fiber, a product has high-efficient, lasting and safe antibacterial performance; the natural cassia seed is introduced into the traditional home textile industry, thereby avoiding the safety problem during the application of an organic antibacterial agent; and the problems of dispersion, uniformity, firm combination and the like between the antibacterial agent and the fiber can be solved, and the high-efficient lasting antibacterial effect can be achieved in the real sense. The invention further discloses a preparation method of the cassia seed composite antibacterial finishing agent, a method for processing the fiber byutilizing the cassia seed composite antibacterial finishing agent and an application of the cassia seed composite antibacterial finishing agent in home textile products.

Owner:SHANGHAI SHUIXING HOME TEXTILE

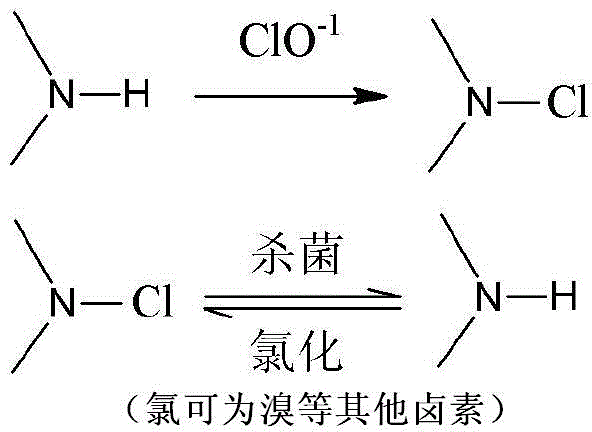

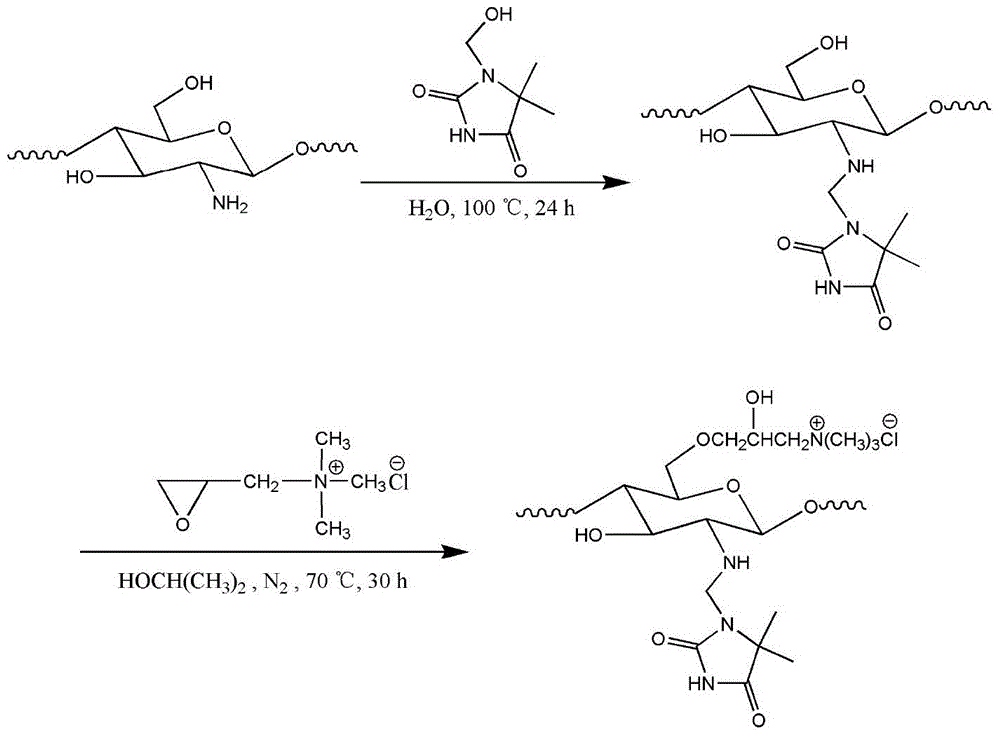

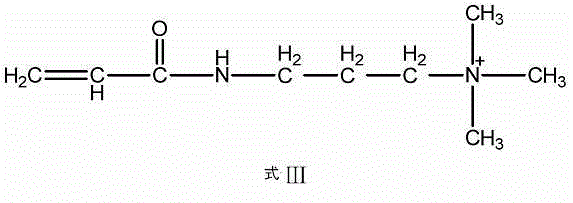

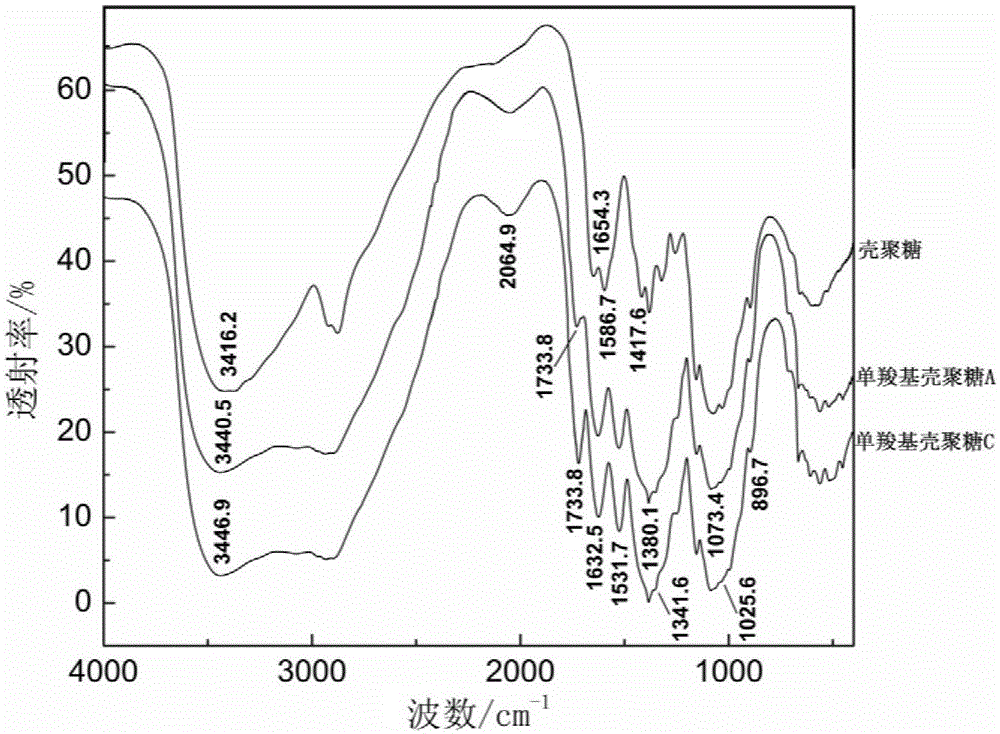

Quaternization hadegen amide modified chitosan and method for preparing antibacterial cotton fabric

ActiveCN104628888AImprove antibacterial propertiesReduce the impact of forceVegetal fibresPolymer scienceFiltration

The invention discloses a method for preparing quaternization hadegen amide modified chitosan. The method comprises the following specific steps: (1) hydroxymethyl hydantoin and chitosan in water, reacting at the temperature of 80-100 DEG C for 24-30 hours, cooling to room temperature after the reaction is ended, performing vacuum filtration, and drying the obtained solids; and (2) mixing the dried solids and 2,3-epoxypropyltrimethylammonium chloride in an isopropanol solution, reacting at the temperature of 60-80 DEG C for 24-32 hours, cooling to room temperature after the reaction is ended, performing vacuum filtration, and drying the obtained solids, thereby obtaining the quaternization hadegen amide modified chitosan. The method disclosed by the invention is easy to operate and low in cost, and the prepared antibacterial cotton fabric has excellent and high-efficiency antibacterial performance and also has good service performance.

Owner:JIANGNAN UNIV

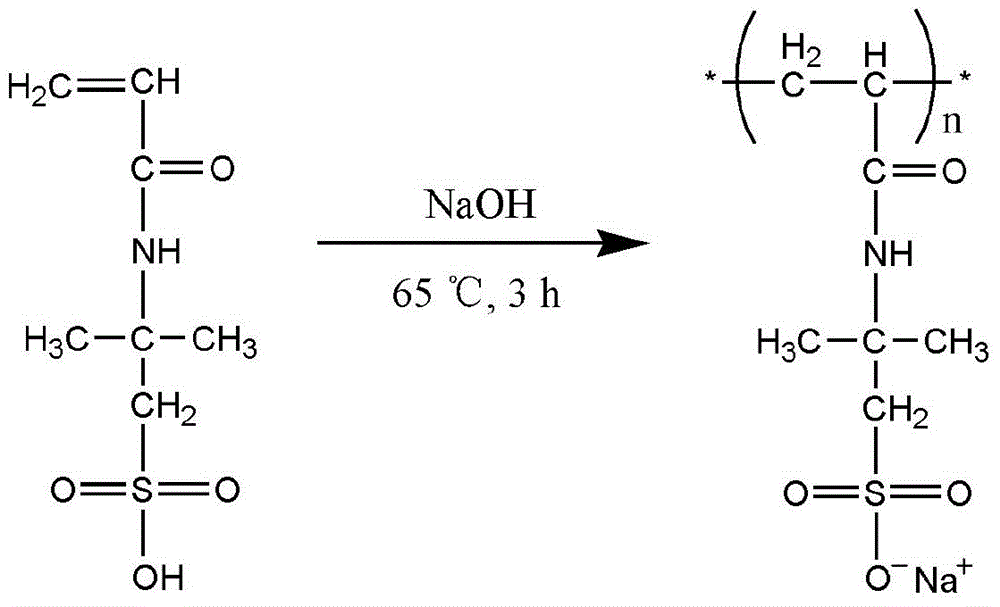

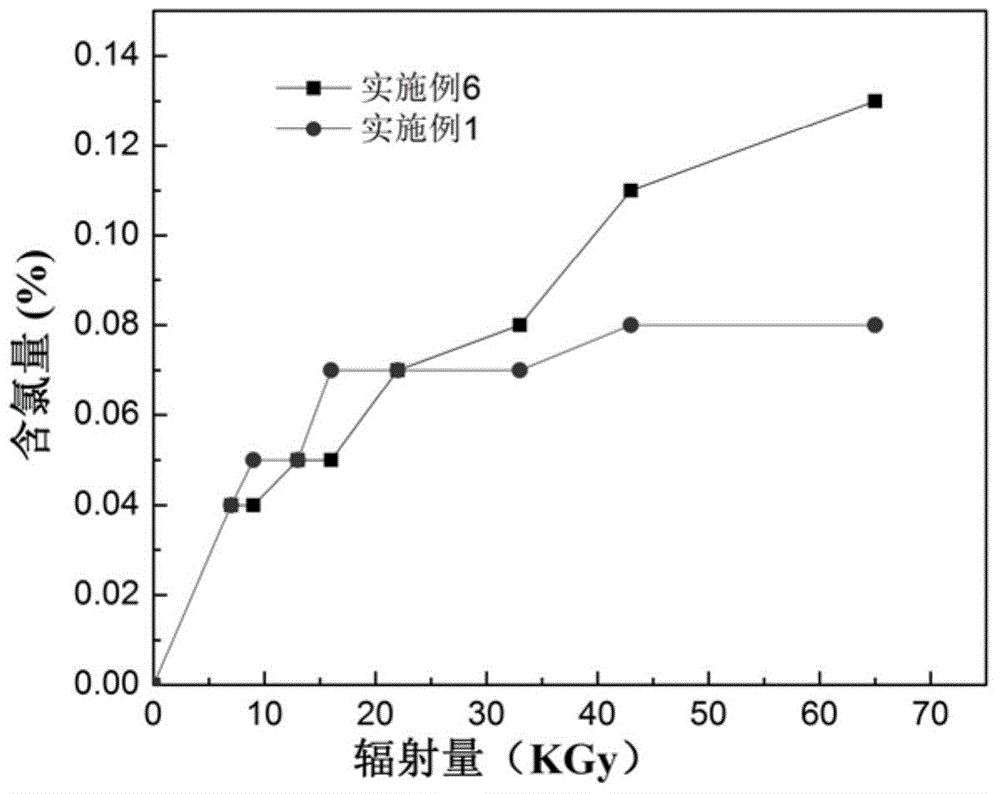

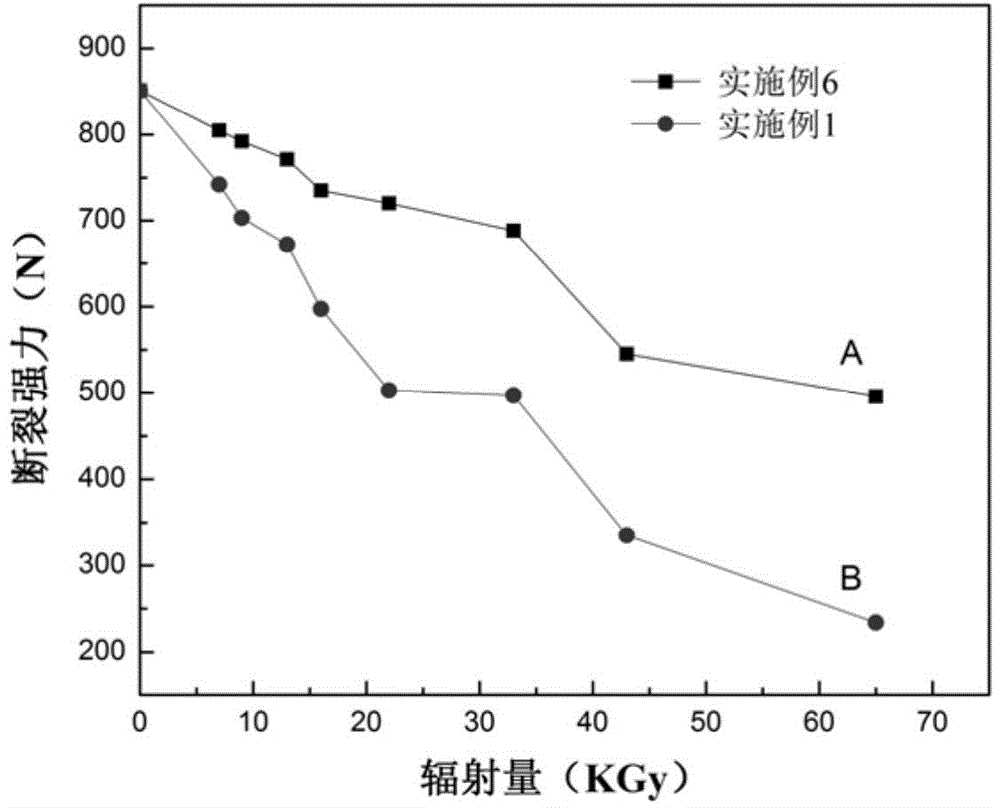

Method for preparing antimicrobial textiles by using electronic radiation technology

ActiveCN104358104AWill not polluteImprove efficiencyPhysical treatmentVegetal fibresAfter treatmentAntibacterial property

The invention discloses a method for preparing antimicrobial textiles by using an electronic radiation technology. The method comprises the following steps: dipping textiles or coating textiles by antibacterial finishing liquid and then carrying out electronic radiation; or firstly, carrying out electronic radiation on the textiles and then dipping or coating the antibacterial liquid; and baking, washing and carrying out after treatment, so as to prepare antibacterial textiles, wherein the radiation range of electronic radiation is 0-500KGy and corresponding other radiation unit conversion value; an antibacterial agent precursor in the antibacterial finishing liquid can generate free radical through electronic radiation, and can react with other substances through the free radical; and the antibacterial agent precursor can be independently used or used in a mixing manner. According to the method, the reaction can be carried out at normal temperature; the treatment process is simple, and easy to control; the antibacterial agent is high in utilization rate and low in energy consumption; and the antimicrobial textiles prepared by the method are excellent in antibacterial property, and good in wearability.

Owner:JIANGNAN UNIV

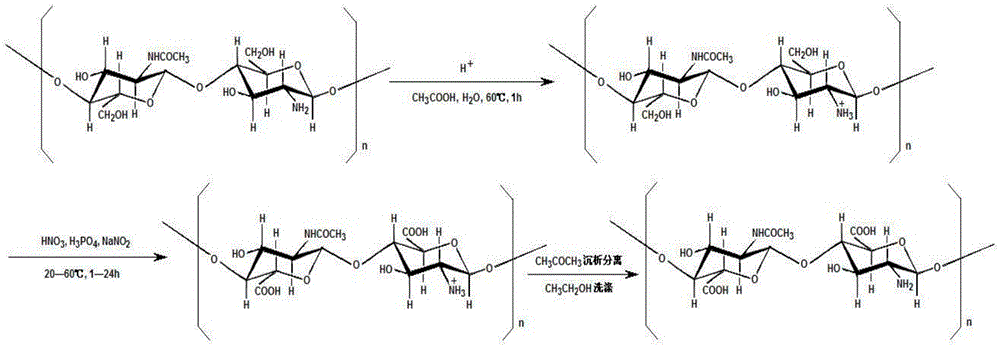

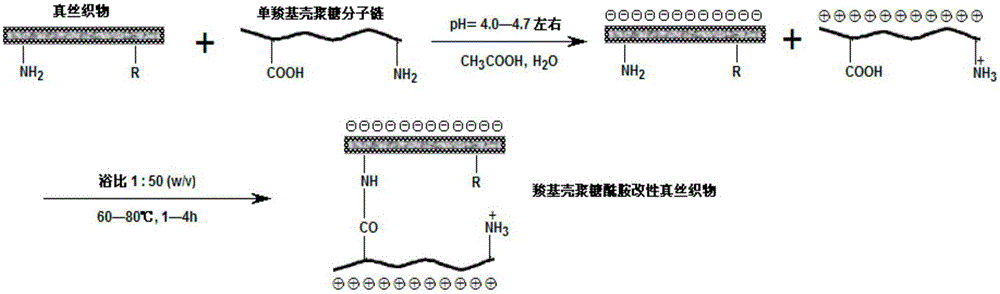

Water-soluble antibacterial monocarboxylic chitosan as well as preparation method and application thereof

ActiveCN105061637AHigh oxidation selectivityQuick responseAnimal fibresPhosphoric acidAntibacterial activity

The invention discloses a water-soluble antibacterial monocarboxylic chitosan as well as a preparation method and application thereof. The preparation method of the monocarboxylic chitosan is characterized by comprising the following steps: dissolving macromolecular chitosan in a diluted acetic acid solution, and then selectively oxidizing part or all of hydroxyl groups at the C6 site of the chitosan into carboxyl groups by utilizing a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system, thereby obtaining the monocarboxylic chitosan. The water-soluble antibacterial monocarboxylic chitosan disclosed by the invention can be used for carrying out amide modification on real silk fabrics so as to obtain monocarboxylic chitosan amide modified real silk fabrics. The method disclosed by the invention is simple in operation, high in reaction speed and easy to control, the prepared monocarboxylic chitosan amide modified real silk fabrics have lasting and efficient antibacterial activity and good wearability and are environment-friendly, and the negative effects on good real silk characteristics and human health caused by using chemical crosslinking agents in conventional chitosan modification are overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

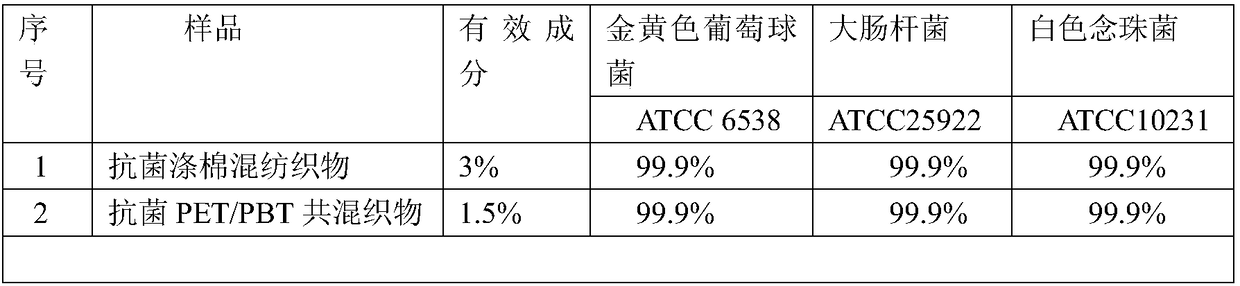

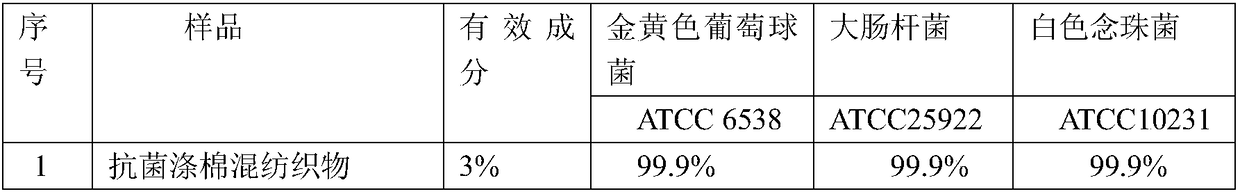

Clothing fabric based on one-dimensional nanometer zinc oxide polyester antibacterial masterbatch

InactiveCN108411402AChemically stableFully dispersed effectConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsEnvironmental resistanceChemistry

The invention relates to a clothing fabric based on a one-dimensional nanometer zinc oxide polyester antibacterial masterbatch, belonging to the technical field of high-tech functional composite materials. Polyester resin which is prepared by blending the polyester antibacterial masterbatch in proportion is subjected to conventional pre-crystallization, drying and melt spinning successively to prepare antibacterial polyester fibers, and the antibacterial polyester fibers are woven or are blended and interwoven with cotton, hemp and other chemical fibers to form an antibacterial fabric; and theantibacterial fabric undergoes printing, dyeing and finishing so as to prepare the clothing fabric with antibacterial functions. According to the invention, one-dimensional nanometer zinc oxide is fully and effectively dispersed, so the one-dimensional nanometer zinc oxide is prevented from failures due to agglomeration and allowed to maintain long-lasting antibacterial effect, and can be effectively applied to the polyester resin. The clothing fabric provided by the invention has the characteristics of broad-spectrum antibacterial performance, high efficiency, durability, washing resistance,excellent performance, safety to the body, no toxicity, no harm, no allergenicity, environment protection performance, etc.

Owner:浙江中迪纺织新材料科技有限公司

Multipurpose antibacterial non-woven fabric and production process thereof

InactiveCN110117910AEfficient and durable antibacterialStable appearanceTextiles and paperNonwoven fabricAntibacterial agent

The invention discloses a multipurpose antibacterial non-woven fabric and a production process thereof and belongs to the technical field of fiber products and composite materials. According to the technical scheme, the multipurpose antibacterial non-woven fabric comprises a base fabric layer, and the surface of the base fabric is coated with an antibacterial coating, which is composed of, by weight part, 0.1-0.2 part of natural antibacterial agent, 0.5-1.5 parts of defoaming agent, 1-2 parts of water absorbent, 1-2 parts of dispersing agent, 3-6 parts of binding agent and water as balance. The multipurpose antibacterial non-woven fabric has the advantages of being efficient and durable in antibacterial performance, stable in appearance and free from toxicity and pollution. The invention also discloses the production process of the multipurpose antibacterial non-woven fabric. The production process mainly comprises performing a spunlacing procedure and applying the antibacterial coating. The production process avoids affecting the original features of fibers and damaging the fibers, the produced non-woven fabric has the advantages of high strength, low fluffiness, soft hand feelingand the like, besides, the production process is high in production efficiency and utilization rate of raw materials.

Owner:HANGZHOU XINFUHUA NONWOVENS

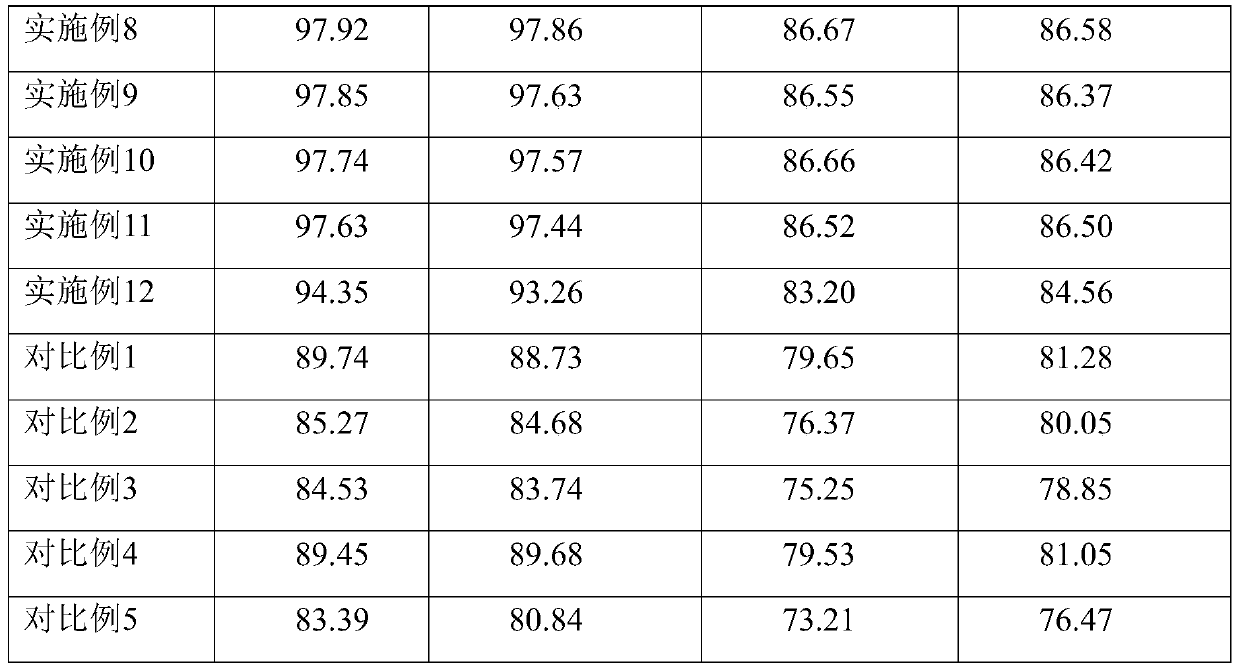

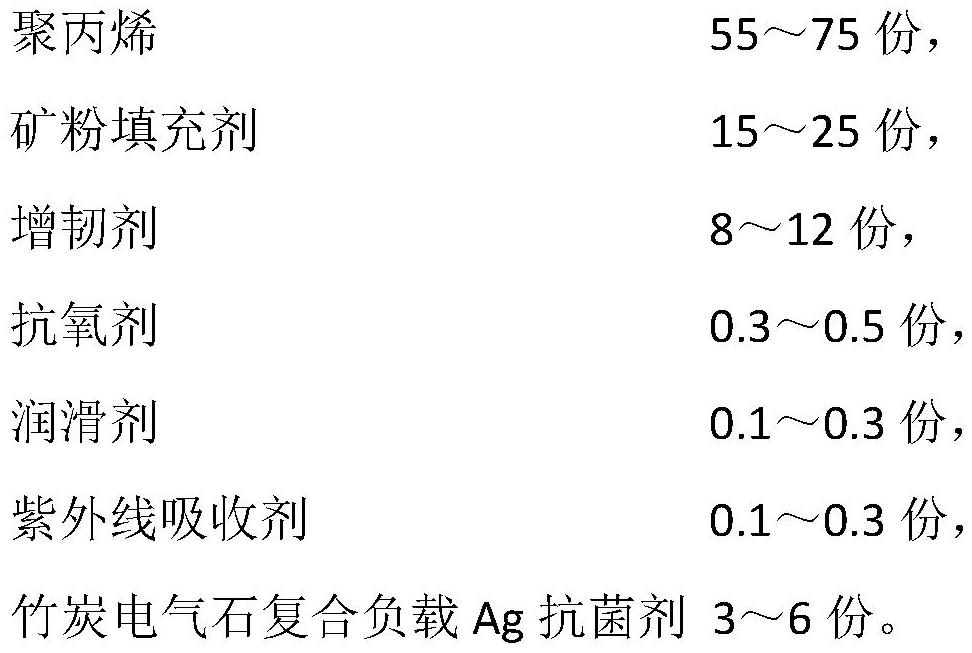

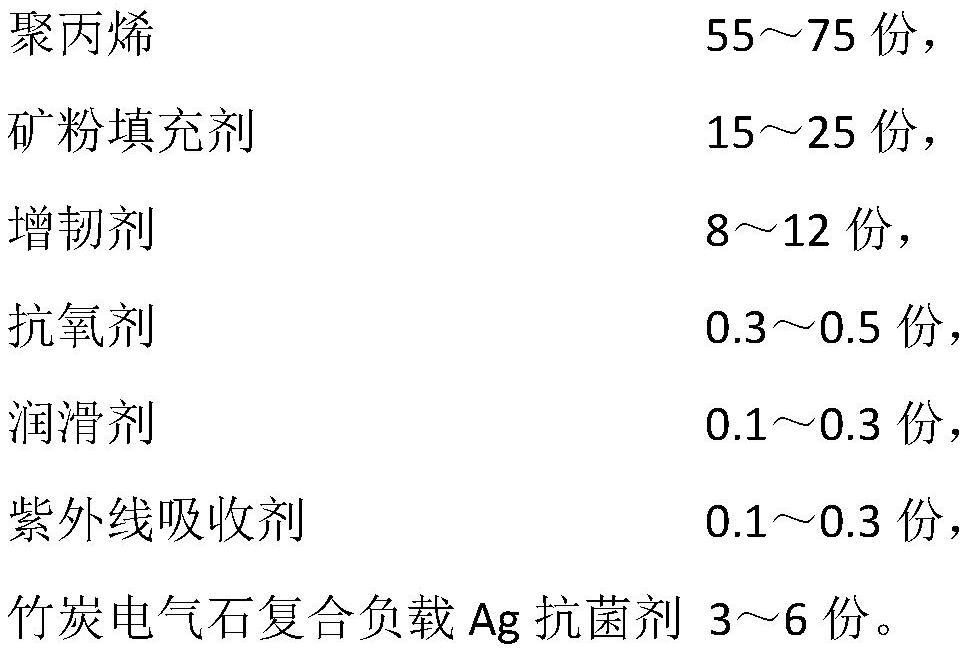

Bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent, antibacterial polypropylene composition and preparation method

ActiveCN112694677ALong-lasting antibacterial effectFacilitated releaseEscherichia coliStaphylococcus aureus

The invention provides a bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent, an antibacterial polypropylene composition and a preparation method. The bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent is prepared from bamboo charcoal and tourmaline powder through Ag loading modification. The preparation method comprises the following steps that bamboo charcoal powder is loaded with Ag, tourmaline powder is loaded with Ag, and a bamboo charcoal powder Ag-loaded antibacterial agent and a tourmaline powder Ag-loaded antibacterial agent are mixed according to the ratio of (1-3): 1. The prepared composite antibacterial agent is added into a polypropylene composition, and through the mutual auxiliary effect of Ag, bamboo charcoal and tourmaline, multiple antibacterial modes such as silver ion slow release, bamboo charcoal adsorption and negative ion sterilization are achieved, and the efficient and lasting antibacterial effect on common bacteria such as escherichia coli and staphylococcus aureus is achieved.

Owner:ORINKO NEW MATERIAL CO LTD

Method for preparation of inorganic nano copper antibacterial agent and dipping treatment of cotton chitosan blended antibacterial fabric

InactiveCN104762810AHighly effective and long-lasting UV protectionPromote the field of applicationVegetal fibresIonNH3 compound

The invention discloses a preparation method of copper-ion antibacterial and anti-ultraviolet finishing agent. The method is characterized in that the reagent dosage, namely the adding ratios of copper sulfate and sodium hydroxide reacting in preparation can be determined according to the ratios of alkaline copper ammonia and salt copper ammonia in an antibacterial agent. A fiber reaction interval is easy to operate by the alkaline copper ammonia, so that copper ammonia chelate ions are easily provided for complex reaction by the salt copper ammonia; and due to the introduction of the copper ammonia ions, the fabric easily develops the antibacterial property. The chitosan and cotton blended fabric are complexly finished by employing the obtained copper ion finishing agent with the optimal ratio; and the parameter conditions of a complexing process are explored to control the complex condition of the copper ions, so that the current situations that the spinnability of a chitosan fiber is poor and the antibacterial property is easily interfered are solved.

Owner:TIANJIN POLYTECHNIC UNIV

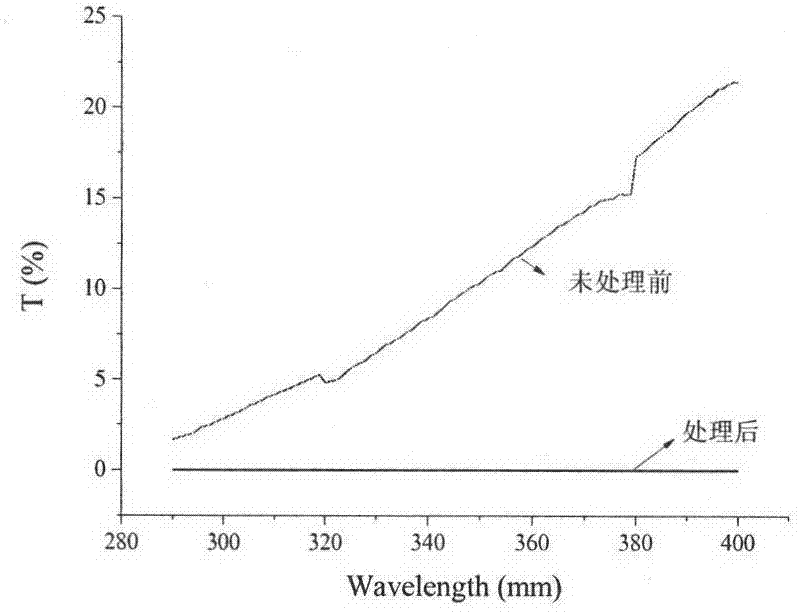

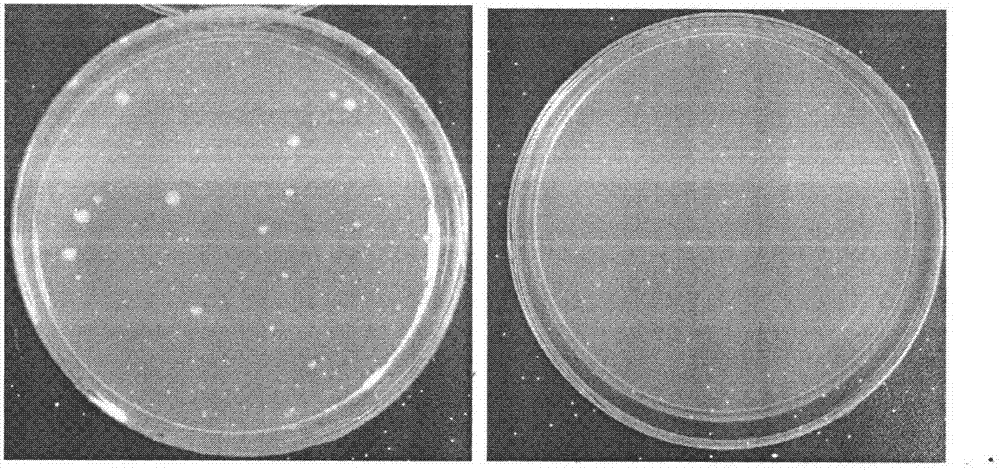

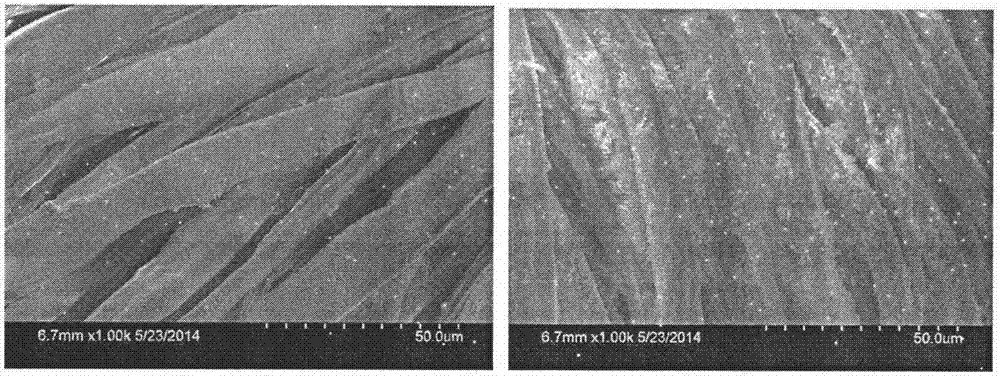

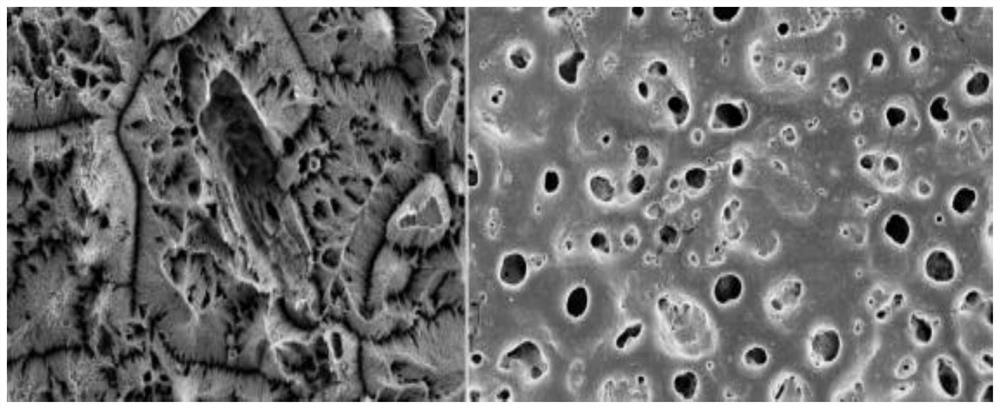

Preparation method and application of titanium alloy surface iodine-loaded antibacterial coating

ActiveCN111719172ALong release timePrevent explosive releaseAntifouling/underwater paintsSurgeryElectrophoresesBACTERIAL INFECTIOUS DISEASES

The invention discloses a preparation method and application of a titanium alloy surface iodine-loaded antibacterial coating and belongs to the technical field of preparation of medical and biologicalmaterials. The preparation method comprises the following steps: deoiling, blasting sand and grinding, carrying out ultrasonic washing, washing with acid, washing with water, carrying out micro-arc anodic oxidation treatment, washing with water, carrying out electrophoresis, washing with water and sealing pores. A non-metallic material with an antibacterial effect is deposited in a porous bioactive film layer prepared on the surface of a titanium alloy; the risk of dissolving metal ions in the using process is avoided; the antibacterial coating is semi-closed; the explosive release of the iodine material of the antibacterial coating is prevented; the slow release time of the iodine material is obviously prolonged; a more efficient and lasting antibacterial effect can be achieved; the antibacterial sterilization rate of the in-vitro coating reaches 100%; the bonding strength between the antibacterial coating and a titanium alloy substrate is greater than 53MPa; the antibacterial effects of medical apparatus and instruments are ensured; the bacterial infectious diseases caused by the medical apparatus and instruments are reduced; and the inflammations of implants are reduced.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

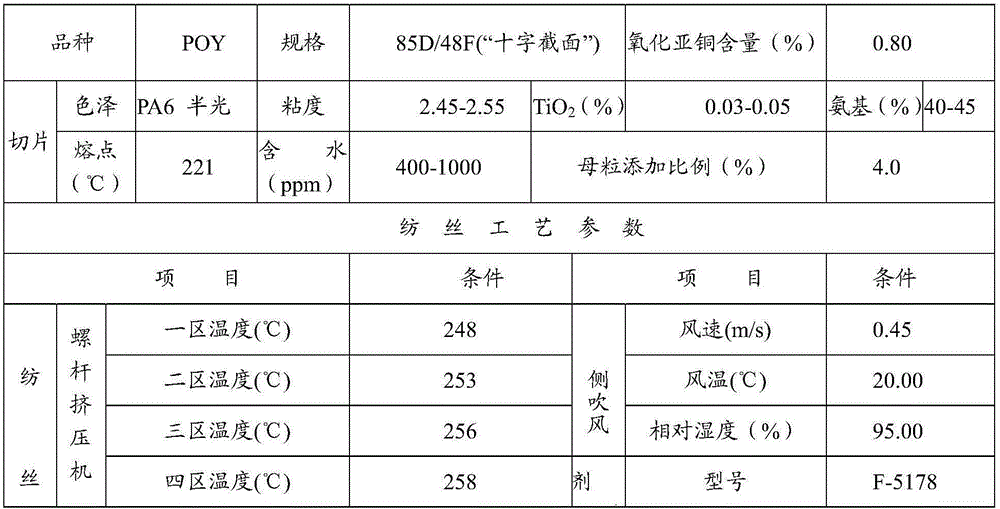

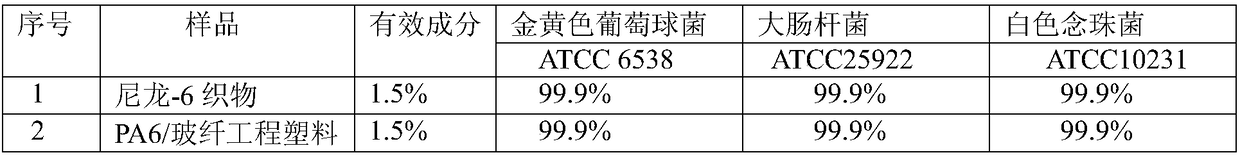

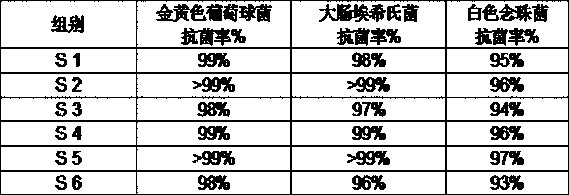

Polyamide6 fiber and preparing method thereof

InactiveCN106319669AEfficient and durable antibacterialFilament/thread formingArtifical filament manufactureFiberEscherichia coli

The invention provides a polyamide6 fiber with the antibacterial and moisture absorption and sweat releasing functions. The polyamide6 fiber is prepared from cuprous-oxide antibacterial master batches and sliced polyamide6, wherein the weight ratio of the cuprous-oxide antibacterial master batches to the sliced polyamide6 is (2-10):(90-98); the mixture is mixed, melted, extruded and spun through a deformed section spinneret plate, and the polyamide6 fiber is prepared. The invention also provides a preparing method of the polyamide6 fiber. The polyamide6 fiber and the preparing method thereof have the advantages that the polyamide6 fiber is modified through the cuprous-oxide antibacterial master batches, the cuprous-oxide antibacterial master batches and the sliced polyamide6 are mixed to be spun through the deformed section spinneret plate, and the prepared polyamide6 fiber has the antibacterial and moisture absorption and sweat releasing functions at the same time, the antibacterial rate of the polyamide6 fiber to candida albicans reaches 95% or above, the antibacterial rates to staphylococcus aureus and escherichia coli reach 99% or above, the fabric woven by the polyamide6 fiber can rapidly absorb and guide moisture, and the polyamide6 fiber has the lasting and efficient antibacterial performance.

Owner:FUJIAN JINJIANG TECH

Method for preparing nano silver-containing anti-bacterial fabric by immersion process

ActiveCN101864670BGood soaping fastnessEfficient and durable antibacterialVegetal fibresAnimal fibresDopamineAnti bacterial

The invention relates to a method for preparing a nano silver-containing anti-bacterial fabric by an immersion process. The method comprises the following steps: dissolving dopamine hydrochloride in Tris buffer solution; adjusting the pH value of solution to be between 7 and 10 by using hydrochloric acid; immerging a fabric into prepared dopamine solution in a bath ratio of 1:30; after stirring for reacting at the temperature of between 20 and 40 DEG C for 20 to 30 hours, taking the fabric out and washing to obtain a poly dopamine film-coated fabric; putting the fabric into silver nitrate aqueous solution; and after immerging for 8 to 10 hours, washing and drying the fabric to obtain the nano silver-containing fabric. The nano silver-containing fabric prepared by the method has the characteristics of high soaping fastness resistance and lasting antibiotic property; a sterilizing rate is still up to 100 percent after the fabric is washed with water for 30 times; and the preparation method has the characteristics of simple process, no pollution to the environment, low cost and large-scale production.

Owner:DONGHUA UNIV

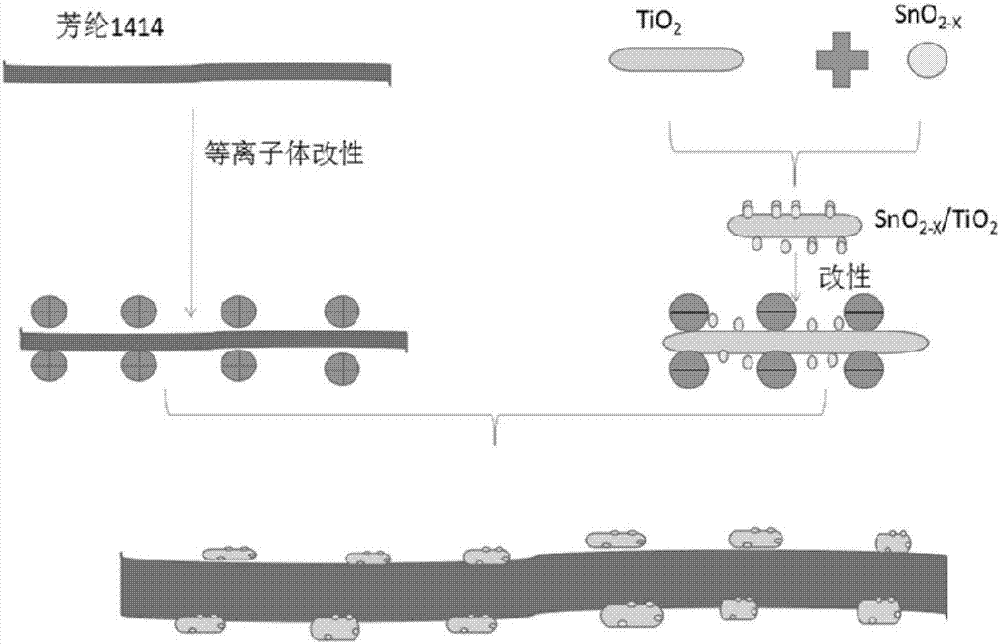

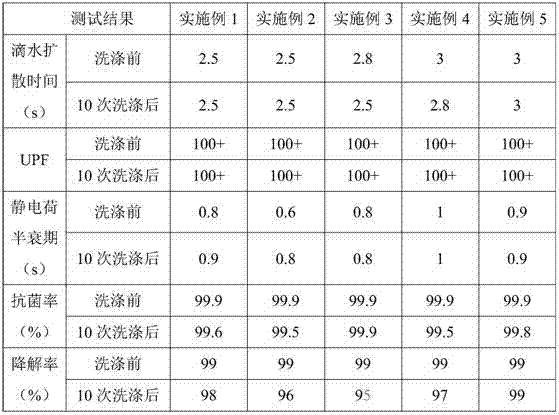

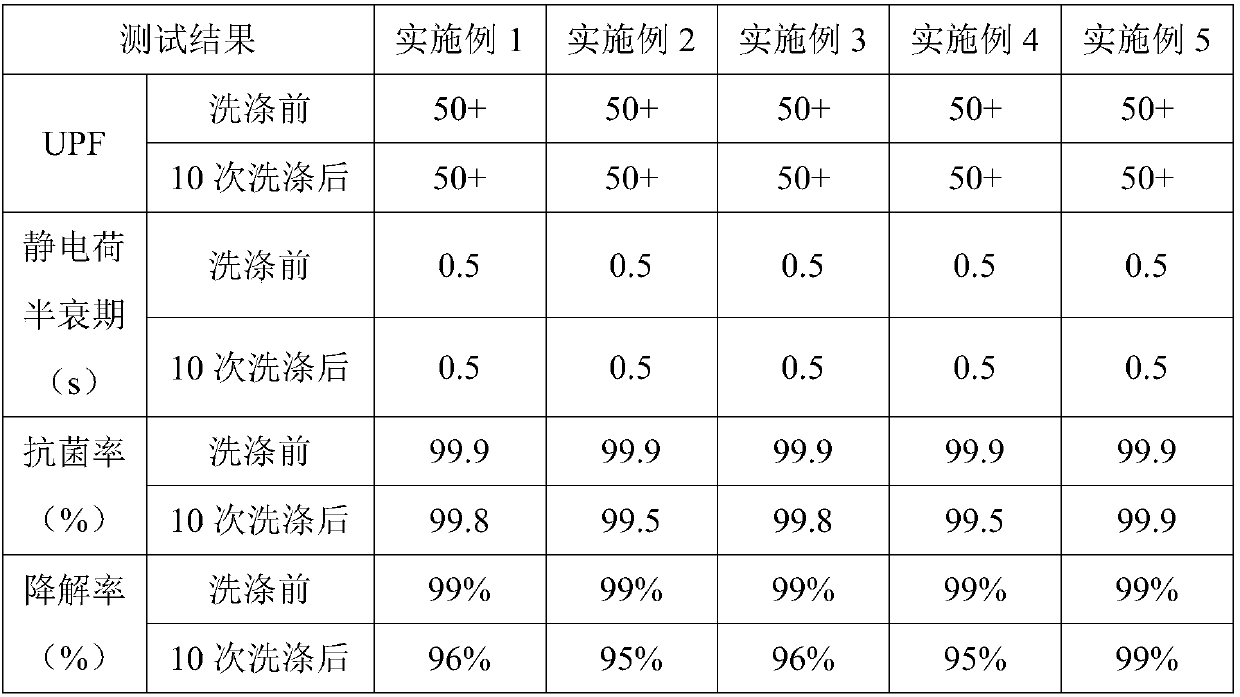

Preparation method of visible light composite photocatalyst and finishing method for fabric by visible light composite photocatalyst

ActiveCN107377005AImprove energy efficiencyHigh activityStain/soil resistant fibresOrganic-compounds/hydrides/coordination-complexes catalystsMoisture absorptionMaterials science

The invention discloses a preparation method of a visible light composite photocatalyst and a finishing method for fabric by the visible light composite photocatalyst. The preparation method comprises the following steps: step 101): preparing a titanium dioxide nanobelt; step 102): preparing a self-doped stannic oxide precursor solution; step 103): preparing the visible light composite photocatalyst with a heterostructure doped with the stannic oxide and the titanium dioxide nanobelt; step 104): carrying out surface modification on the visible light composite photocatalyst prepared in the step 103) to obtain a visible light composite photocatalyst modified by anion. According to the visible light composite photocatalyst prepared by the method, energy efficiency and activity of the photocatalyst can be improved; in addition, the self-cleaning property, ultraviolet resistance, antibacterial property, antistatic property and moisture absorption property of the fabric are improved by the visible light composite photocatalyst.

Owner:苏州安蓝纺织科技有限公司

High-molecular polymer antibacterial masterbatch based on one-dimensional nanometer Ag/C composite material and preparation method thereof

InactiveCN108410141AEfficient and long-lasting antibacterial effectChemically stableMicro nanoPelletizing

The invention relates to a high-molecular polymer antibacterial masterbatch based on a one-dimensional nanometer Ag / C composite material and a preparation method thereof, belonging to the technical field of high-tech functional composite materials. The high-molecular polymer antibacterial masterbatch is prepared from 36 to 88 parts of a high-molecular polymer, 5 to 25 parts of micro-nano inorganicpowder, 5 to 20 parts of a one-dimensional nanometer Ag / C composite material, 5 to 19 parts of an auxiliary agent and the like through blending, plasticizing, mixing, extruding, drawing, cooling andgranulation. According to the invention, the one-dimensional nanometer Ag / C composite material is fully and effectively dispersed, so the one-dimensional nanometer Ag / C composite material is preventedfrom failures due to agglomeration and allowed to maintain long-lasting antibacterial effect, and can be effectively applied to the high-molecular polymer. The high-molecular polymer antibacterial masterbatch of the invention has the characteristics of no toxicity and no harm to the body, environmental protection performance, high-efficiency and long-lasting antibacterial performance, excellent performance, a wide application scope, etc., and can be applied to bacterium prevention, bacteriostasis and anticorrosion of high-molecular polymers.

Owner:浙江中迪纺织新材料科技有限公司

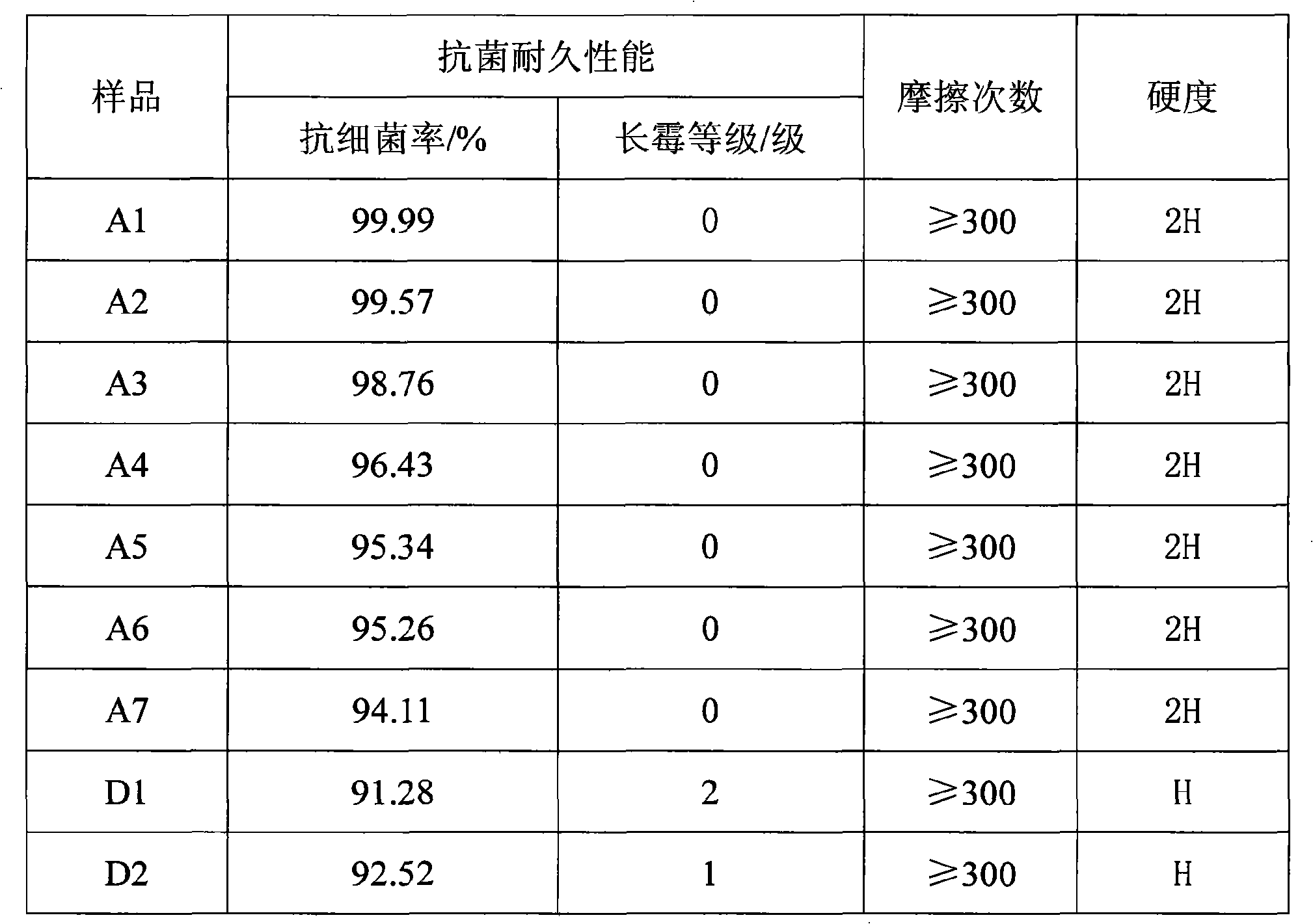

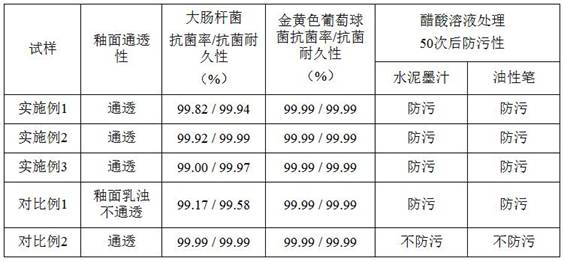

Composite process antibacterial ceramic tile and preparation method thereof

The invention relates to the technical field of new building ceramic materials, and particularly discloses a composite process antibacterial ceramic tile and a preparation method thereof. The composite process antibacterial ceramic tile comprises a green body layer and an antibacterial glaze layer, glaze of the antibacterial glaze layer contains a first antibacterial agent, and surface micropores of the antibacterial glaze layer are filled with an antibacterial antifouling agent; and the first antibacterial agent comprises zinc silicate and / or zinc aluminate, the antibacterial antifouling agent contains a second antibacterial agent, and the second antibacterial agent comprises nano zinc phosphate and / or nano zinc zirconate. The preparation method comprises the following steps: preparing the green body layer, preparing the antibacterial glaze slip, spraying the antibacterial glaze slip on the surface of the green body layer, sintering to obtain a semi-finished product, polishing the semi-finished product, and polishing the surface of the semi-finished product by using an antibacterial antifouling agent to obtain the antibacterial ceramic tile. According to the antibacterial ceramic tile, a composite antibacterial technology combining in-glaze antibacterial and glaze layer surface micropore antibacterial is adopted, efficient and lasting antibacterial of a ceramic tile product is achieved, antibacterial components do not affect permeability of a glaze surface, and the antifouling performance of the glaze surface can be achieved.

Owner:FOSHAN OCEANO CERAMICS +1

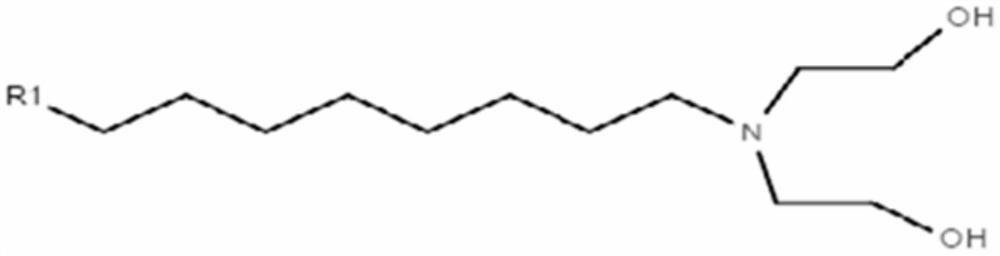

Fragrant detergent for household textiles

InactiveCN104845758AEfficient and durable antibacterialGood cleanlinessAnionic-cationic-non-ionic surface-active compoundsDetergent perfumesChemistryActive agent

The invention discloses a fragrant detergent for household textiles. The fragrant detergent for the household textiles is prepared from the following raw materials in parts by weight: 2-4 parts of rose essence, 7-14 parts of zinc sulfate, 8-16 parts of methyl acrylate, 1.2-2 parts of essence, 6-12 parts of fatty alcohol-polyoxyethylene ether, 10-16 parts of a petroleum emulsion, 7-10 parts of cetyltrimethylammonium chloride, 8-13 parts of lauryl polyoxyethylene ether sodium sulfate, 2.4-4.6 parts of honeysuckle essential oil, 1-2.1 parts of sodium sulfate, 6-9 parts of a compound surfactant, 8-13 parts of ethyl alcohol and 2-5 parts of hydroxyethyl cellulose. The fragrant detergent for the household textiles is efficient and durable in antibacterial property, excellent in cleaning property, free of influence on the hand feeling of textiles, free of toxicity and harm to the human body and free of pollution to the environment, and is capable of durably scenting fragrant smell.

Owner:青岛千帆高新技术有限公司

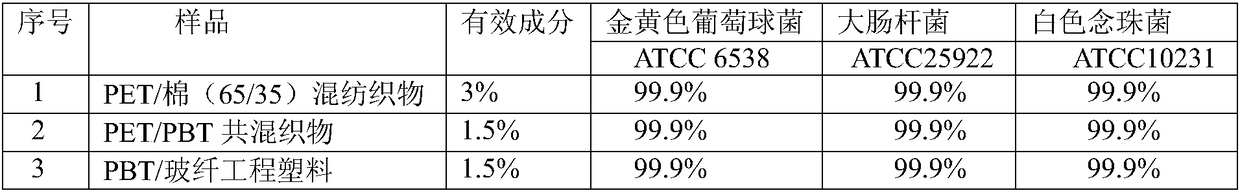

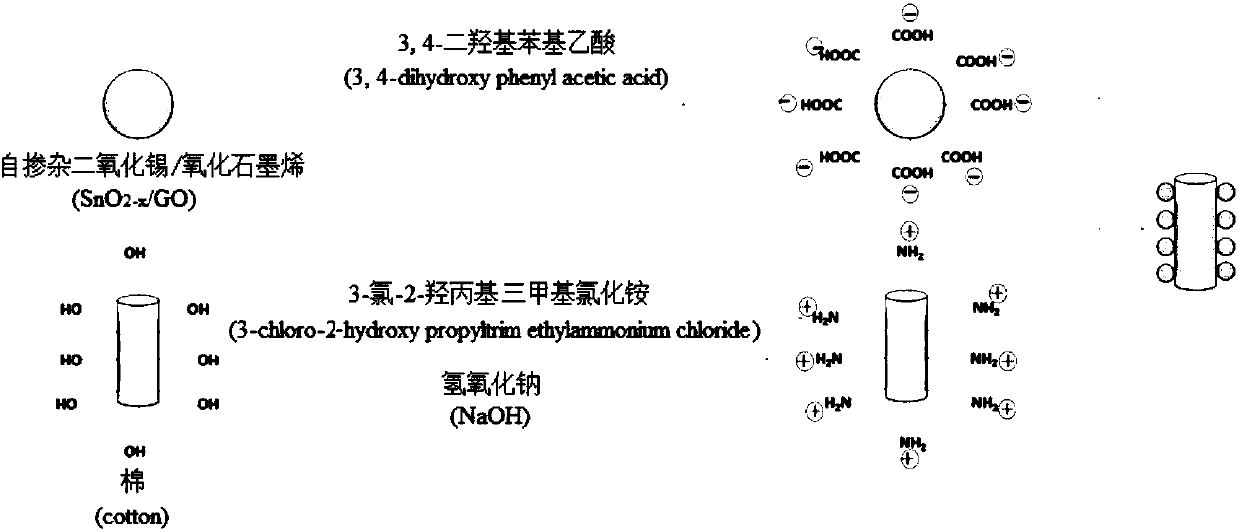

Preparation method of visible light compound photocatalyst and finishing method of cotton fabric by use of visible light compound photocatalyst

InactiveCN107552037AEasy to operateNo pollution in the processOrganic-compounds/hydrides/coordination-complexes catalystsVegetal fibresTin dioxideUltraviolet

The invention discloses a preparation method of a visible light compound photocatalyst and a finishing method of cotton fabric by use of the visible light compound photocatalyst. The preparation method comprises steps as follows: step 101), preparing self-doped tin dioxide; step 102), preparing a visible light compound photocatalyst by use of graphene oxide and self-doped tin dioxide; step 103), performing a carboxylation reaction on the prepared visible light compound photocatalyst, and preparing a carboxylic visible light compound photocatalyst. The visible light compound photocatalyst has high efficiency and high activity, and the cotton fabric has efficient and durable anti-ultraviolet, anti-static, antibacterial and self-cleaning performance after being finished with the visible lightcompound photocatalyst.

Owner:YANCHENG INST OF TECH

Bedding prepared from polyester antibacterial masterbatch based on one-dimensional nanometer Ag/C composite material

InactiveCN108411399AChemically stableFully dispersed effectMonocomponent polyesters artificial filamentArtifical filament manufactureMicro nanoMasterbatch

The invention relates to bedding prepared from a polyester antibacterial masterbatch based on a one-dimensional nanometer Ag / C composite material, belonging to the technical field of high-tech functional composite materials. According to the invention, polyester resin which is prepared by blending the polyester antibacterial masterbatch in proportion is subjected to conventional pre-crystallization, drying and melt spinning successively to prepare antibacterial polyester fibers, and the antibacterial polyester fibers are woven or are blended and interwoven with cotton, hemp and other chemicalfibers to form an antibacterial fabric. The polyester antibacterial masterbatch is prepared from polyester, a one-dimensional nanometer Ag / C composite material, micro-nano inorganic powder, an auxiliary agent and the like through blending, plasticizing, mixing, extruding, drawing, cooling and granulation. According to the invention, the one-dimensional nanometer Ag / C composite material is fully and effectively dispersed, so the one-dimensional nanometer Ag / C composite material is prevented from failures due to agglomeration and allowed to maintain long-lasting antibacterial effect; and the prepared bedding fabric has the characteristics of broad-spectrum antibacterial performance, high efficiency, durability, washing resistance, excellent performance, safety to the body, no toxicity, no harm, no allergenicity, environment protection performance, etc.

Owner:浙江中迪纺织新材料科技有限公司

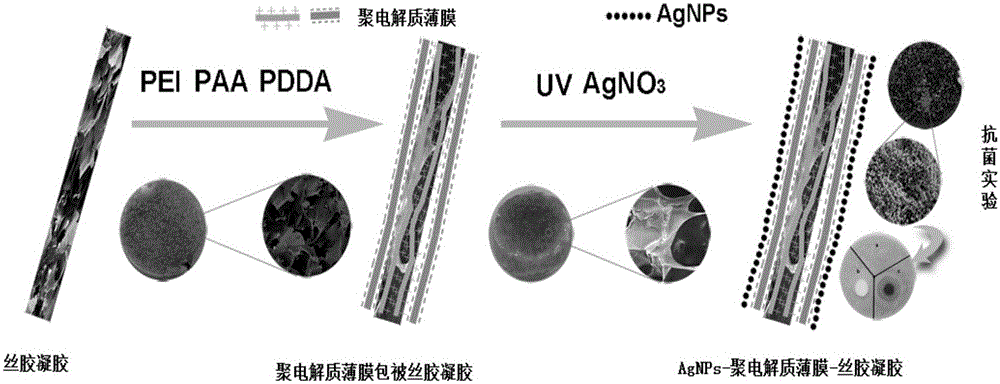

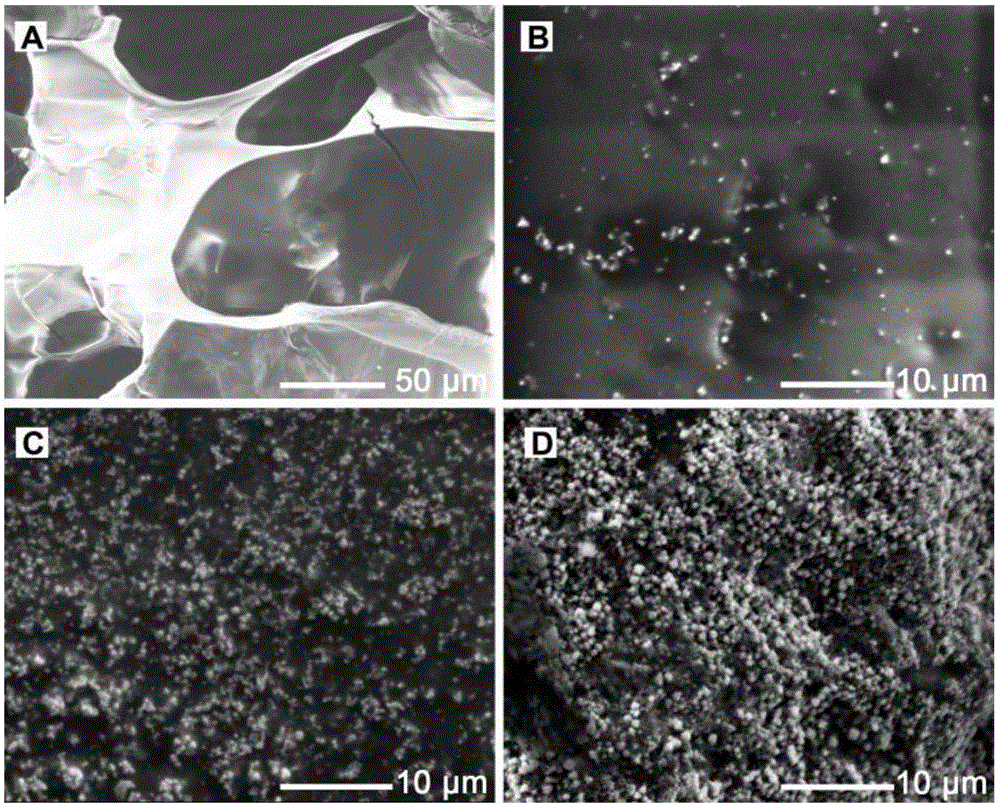

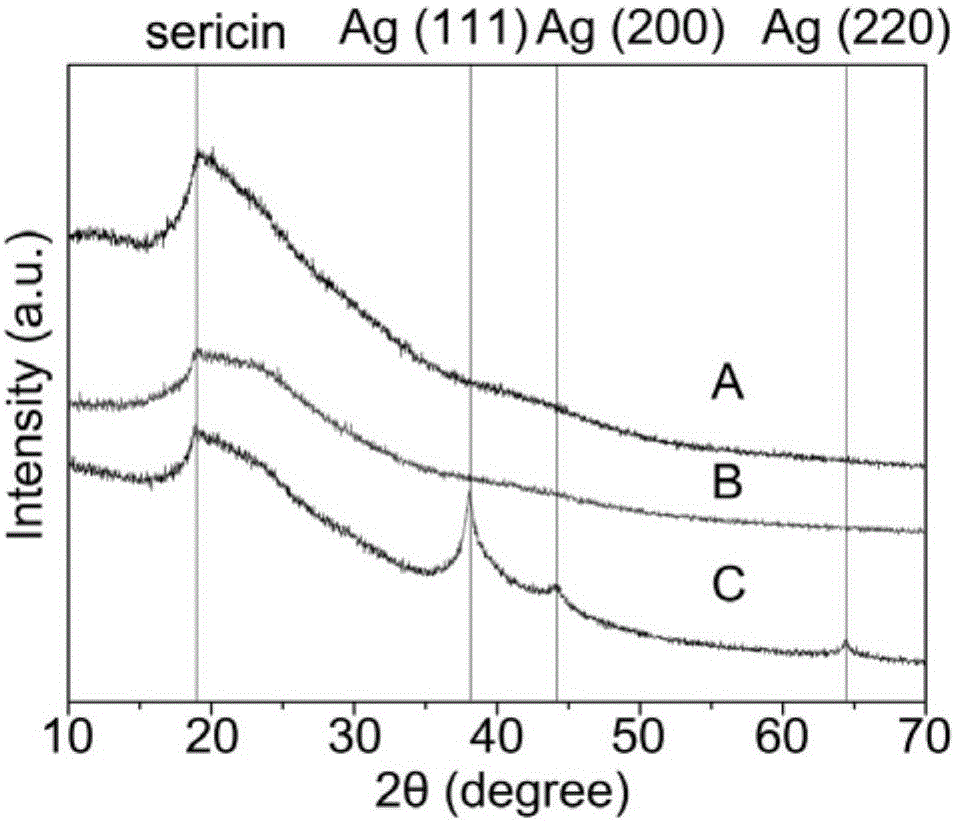

Method of modifying polyelectrolyte thin film coated sericin gel with nano-silver and product and application thereof

ActiveCN105854066AGood biocompatibilityGood hygroscopicityAbsorbent padsBandagesPolyelectrolyteBiocompatibility Testing

The invention discloses a method of modifying polyelectrolyte thin film coated sericin gel with nano-silver and a product and application thereof. The method of modifying polyelectrolyte thin film coated sericin gel with nano-silver includes the steps that sericin powder is prepared, sericin porous gel is prepared, then the surface of the sericin porous gel is coated with a polyelectrolyte thin film, and then the surface of the polyelectrolyte thin film-coated sericin gel is modified with nano-silver. The prepared polyelectrolyte thin film coated sericin gel modified with nano-silver is high in biocompatibility, hygroscopicity, moisture retentivity and efficient and durable in antifungal property, can be used for preparing an antifungal material and has excellent application prospects.

Owner:SOUTHWEST UNIV

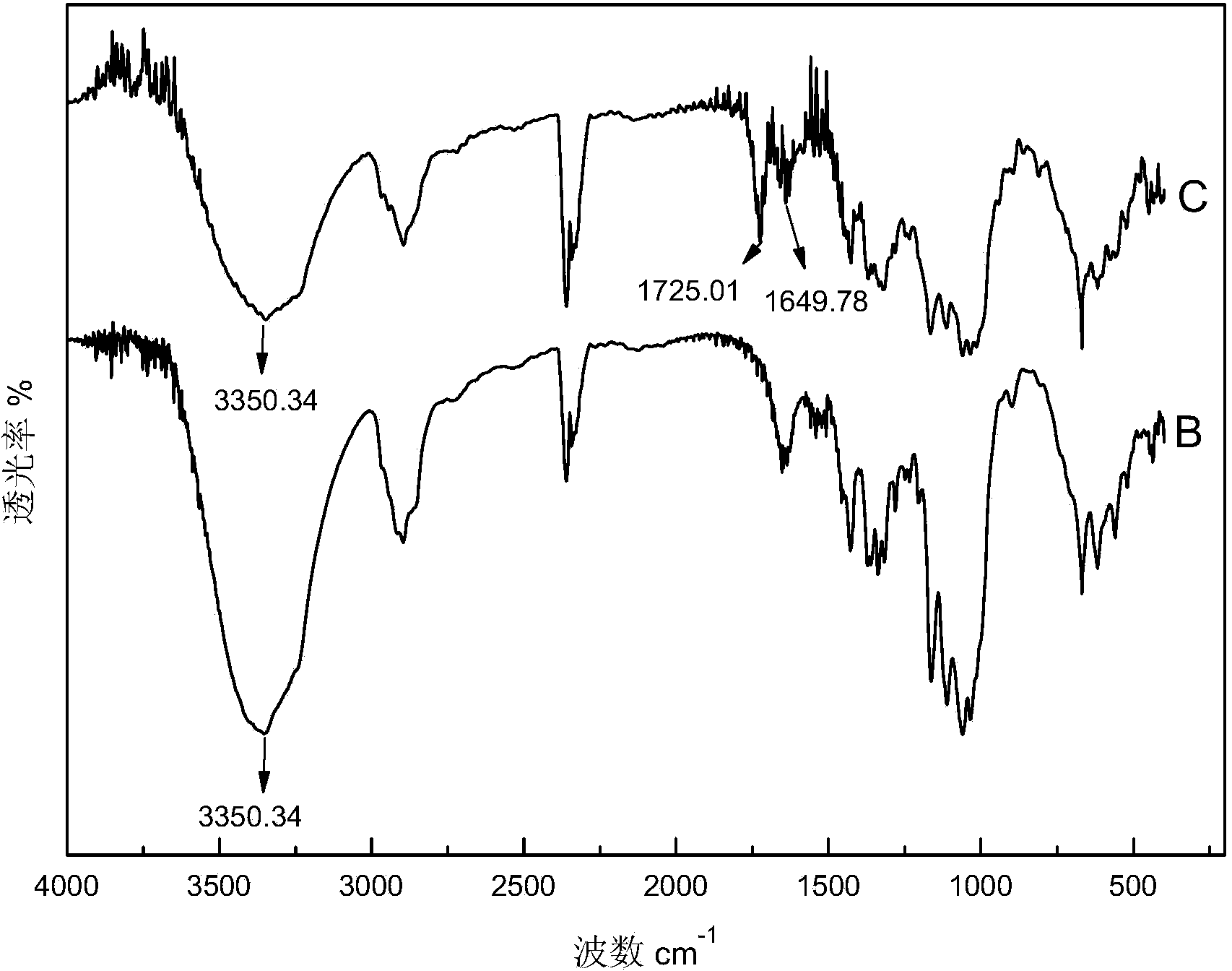

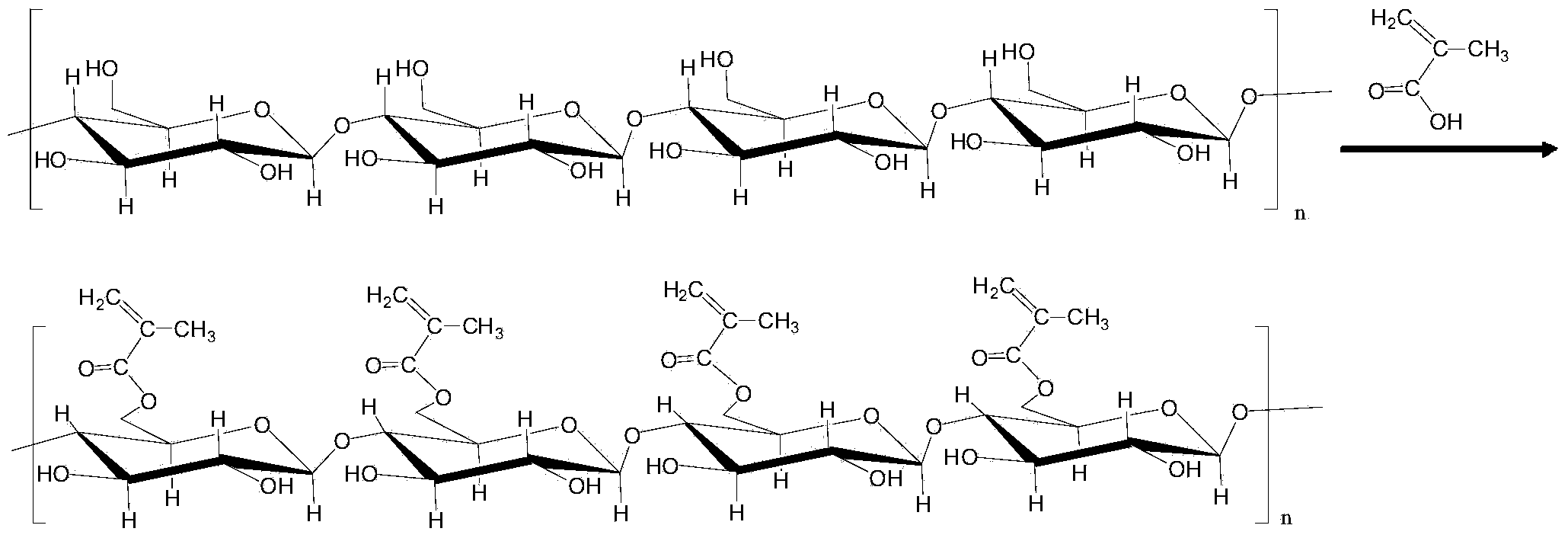

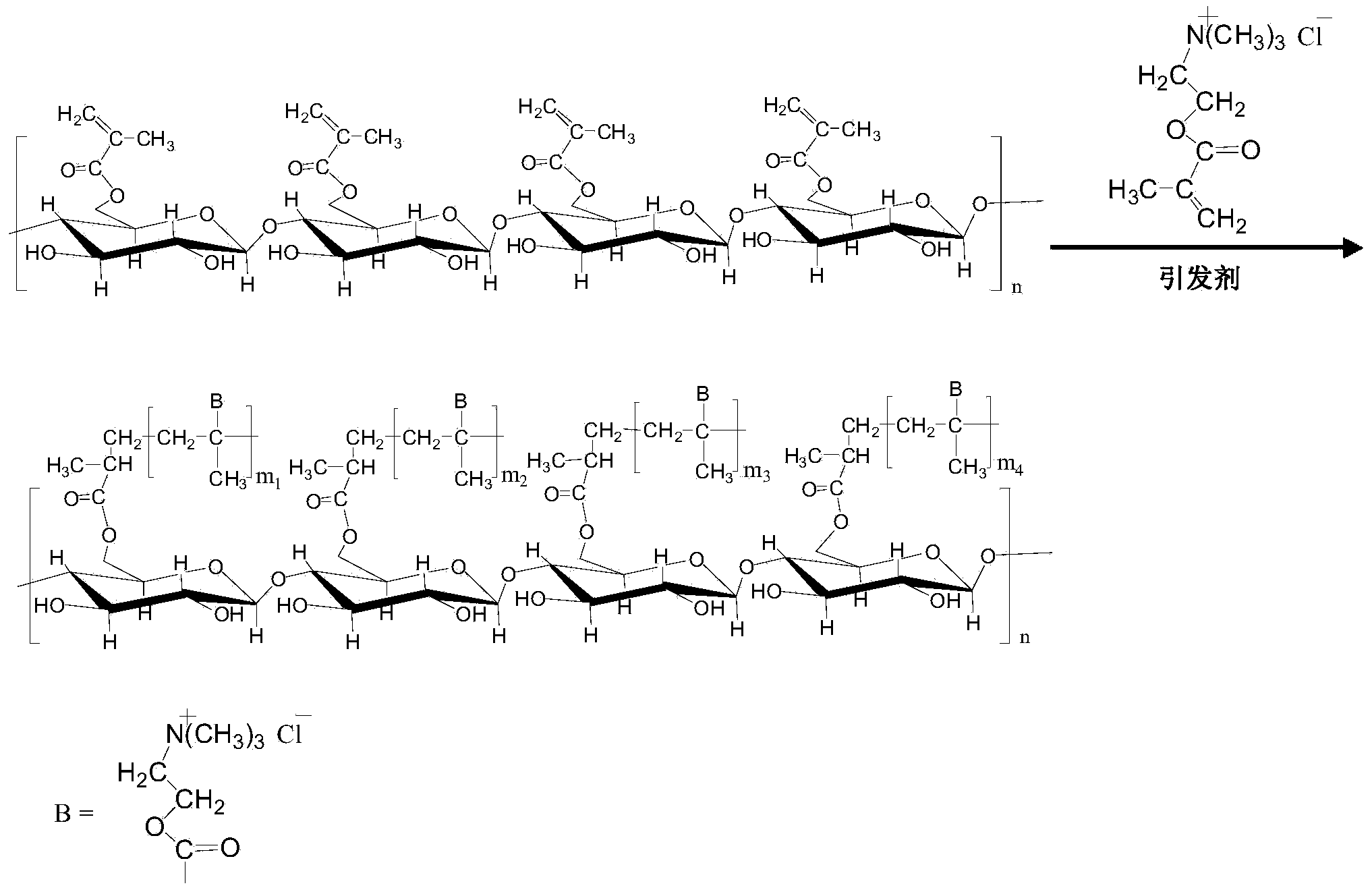

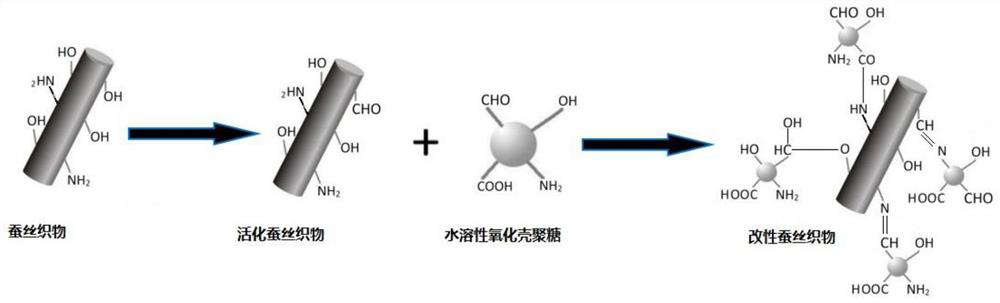

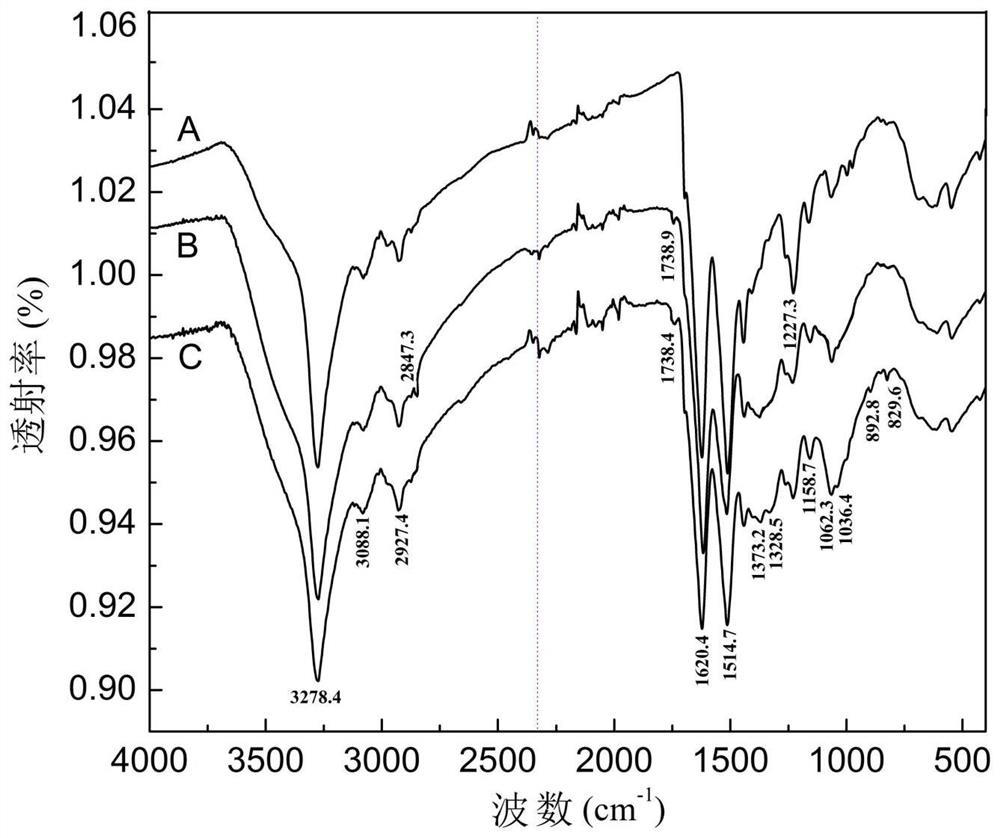

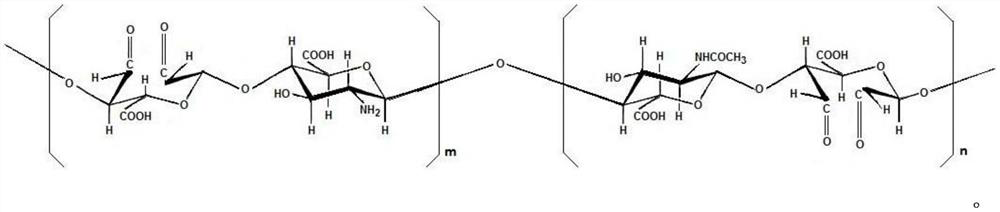

Water-soluble oxidized chitosan and method for finishing fabric by using water-soluble oxidized chitosan

ActiveCN114000350AShort and uniform reaction timeIncrease oxidation rateWrinkle resistant fibresBiochemical treatment with enzymes/microorganismsHydrogen SulfateO-Phosphoric Acid

The invention discloses water-soluble oxidized chitosan and a finishing method of the water-soluble oxidized chitosan on a fabric. The water-soluble oxidized chitosan is prepared by the following steps: dissolving chitosan in a 1-carboxymethyl-3-methylimidazolium hydrogen sulfate aqueous solution, oxidizing C2 and C3 sites of the chitosan by sodium periodate under microwave radiation to generate aldehyde groups, and then oxidizing primary hydroxyl at C6 site of the dialdehyde chitosan in an ionic liquid by concentrated nitric acid-concentrated phosphoric acid to generate carboxyl. The water-soluble oxidized chitosan can be used for modifying fabrics. Compared with a traditional chemical cross-linking agent modified fabric, the method has the advantages that the grafting efficiency of the oxidized chitosan is high, the enzyme treatment condition is mild, the reaction process is simple, the fabric is crease-resistant, antibacterial, efficient and lasting, the fabric is comfortable to wear, and the requirements of people on lasting functional ecological textiles are met.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Antimicrobial yarn and preparation method thereof

InactiveCN111206418AEnable color selectivityColor options comply withBiochemical fibre treatmentDyeing processYarnBiochemical engineering

The present invention provides an antimicrobial yarn and a preparation method thereof. The anti-bacterial yarn has the safety, the non-toxicity and the efficient and lasting antibacterial performanceof graphene while realizing the yarn color selectivity and meeting the textile diversity demand. The preparation method of the antibacterial yarn comprises the steps of firstly, ultrasonically dispersing graphene, inserting hydrophilic groups and dyeing groups into graphene groups under the action of hydrogen bonds, covalent bonds and the like, and uniformly implanting antimicrobial graphene groups into a general yarn in situ under the action of soaking and dyeing; secondly, enhancing combination between the antibacterial graphene groups and the dyeing groups and the yarn again under the action of soaping and color fixing; and finally, performing dewatering and drying to obtain the antibacterial yarn. The preparation method has the advantages of simple process, energy saving and high efficiency, can be used for preparing a product with good consistency and stability, is environment-friendly, fully realizes the sustainable development idea of fine chemical engineering and environmentalprotection, and is suitable for large-scale popularization and application.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

Nano antibacterial corrosion-resistant ceramic and preparation method thereof

PendingCN111517830AImprove adhesionDoes not affect the decorative effect of the appearanceGlazeNanostructured carbon

The invention discloses a nano antibacterial corrosion-resistant ceramic which comprises an antibacterial glaze layer on the surface of corrosion-resistant ceramic; the antibacterial glaze layer is composed of a ground glaze layer and an antibacterial layer; the antibacterial layer is formed by loading a composite antibacterial agent on nano calcium carbonate; wherein the nano calcium carbonate loaded composite antibacterial agent comprises a nano calcium carbonate carrier and a composite antibacterial agent, the nano calcium carbonate loaded composite antibacterial agent is accumulated at theupper part of a glaze layer, the antibacterial effective component of the composite antibacterial agent is nano antibacterial oxide, and the nano antibacterial oxide is nano magnesium oxide and nanozinc oxide. According to the invention, the nano antibacterial material is added to the outermost surface of the ceramic, excellent antibacterial effect is achieved; the nano calcium carbonate is introduced into the antibacterial layer to serve as a porous carrier of the nano antibacterial agent, so that the adhesive force of the nano antibacterial agent can be remarkably improved, the antibacterial performance is more durable and efficient, meanwhile, the surface appearance decoration effect of the ceramic is not affected, and the antibacterial ceramic can be widely applied to the fields of architectural decoration, domestic ceramics and the like.

Owner:GUANGDONG PROVINCE CERAMIC RES INST

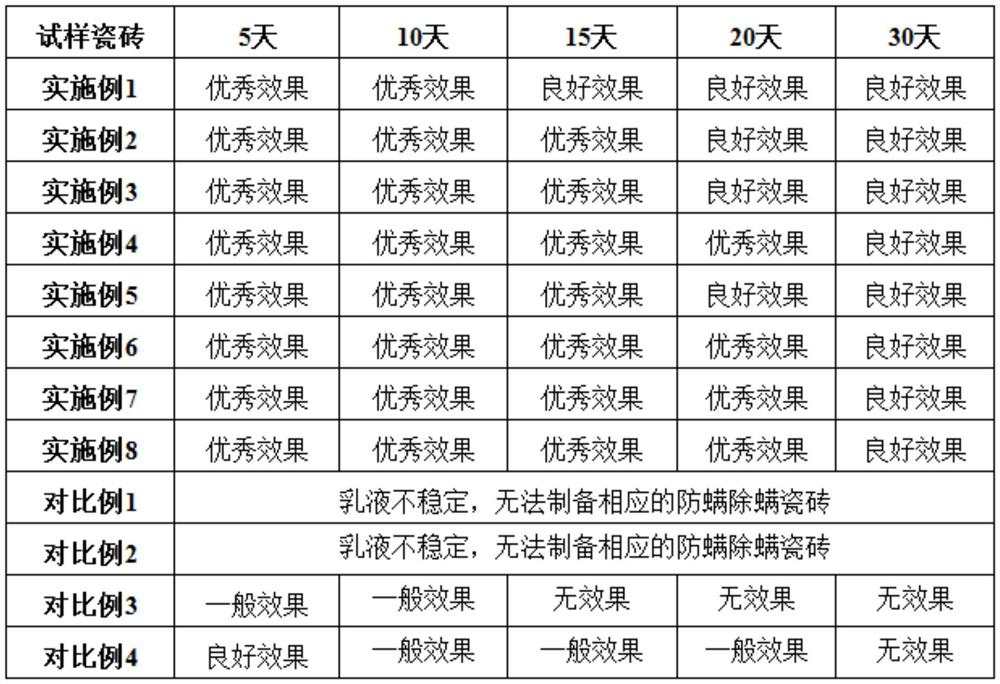

Anti-mite and mite-killing ceramic tile and preparation method thereof

ActiveCN111807868AEfficient and durable anti-miteEfficient and durable antibacterialBiocideAnimal repellantsPolymer scienceEmulsion

The invention discloses an anti-mite and mite-killing ceramic tile which is composed of a ceramic tile body and an anti-mite mite-killing slow-release film layer, the anti-mite mite-killing slow-release film layer is formed by atomizing an anti-mite mite-killing emulsion, spraying the atomized anti-mite mite-killing emulsion onto the ceramic tile body, drying and curing; the anti-mite mite-killingemulsion is prepared from the following raw material components in percentage by weight: 5 to 15 percent of an anti-mite mite-killing effective substance, 3 to 12 percent of a film-forming agent, 2 to 5 percent of an emulsifier, 0.5 to 2 percent of an antifouling agent, 0.2 to 0.5 percent of a preservative and the balance of water. By adjusting the raw material components and proportion of the anti-mite mite-killing emulsion, the anti-mite mite-killing emulsion is suitable for forming the anti-mite mite-killing slow-release film layer on the surface of the ceramic tile body, and the anti-mitemite-killing slow-release film layer has efficient and lasting anti-mite, anti-fouling and antibacterial effects, so that the ceramic tile surface is endowed with efficient, stable and lasting anti-mite, anti-fouling and antibacterial properties. The invention further discloses a preparation method of the anti-mite and mite-killing ceramic tile. The preparation method is simple in operation stepand high in controllability.

Owner:FOSHAN OCEANO CERAMICS

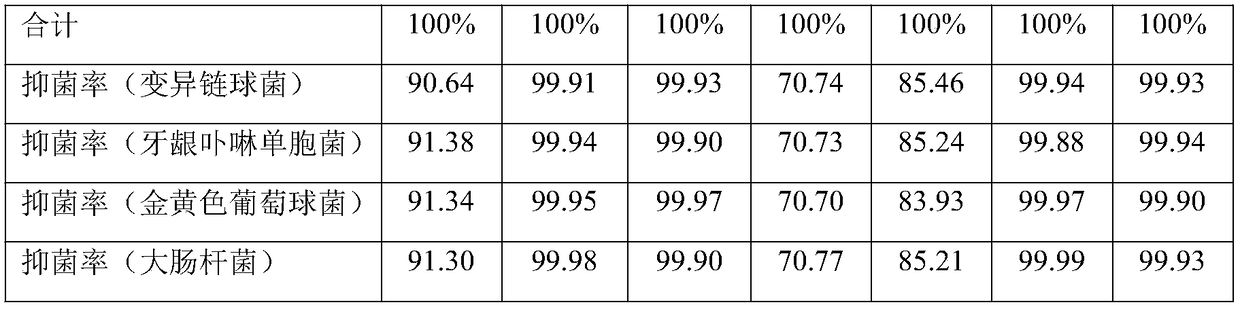

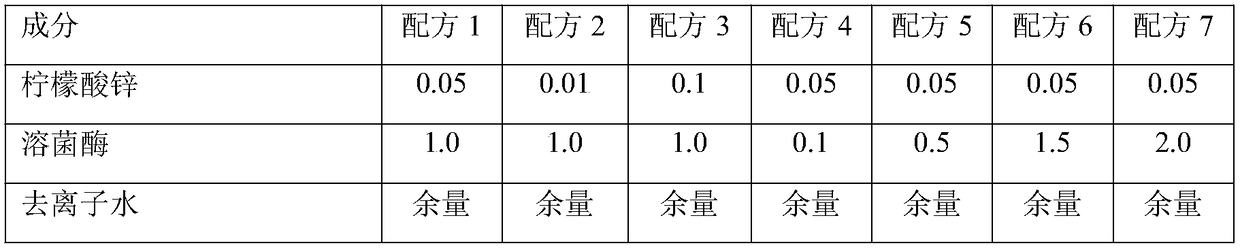

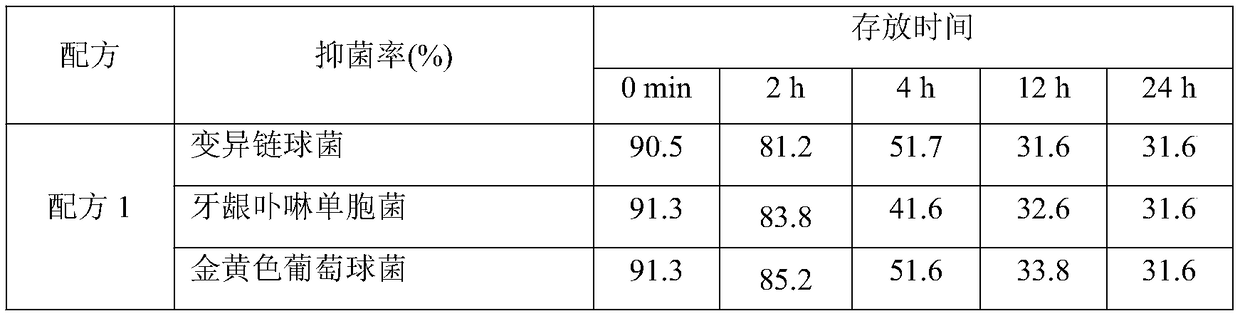

Oral-care health-care liquid containing lysozyme

InactiveCN108652996AGood antibacterial effectHigh bactericidal activityCosmetic preparationsToilet preparationsCell wallSerum zinc

The invention discloses oral-care health-care liquid containing lysozyme. The oral-care health-care liquid is prepared from the following components in percentage by mass: 1 to 20 percent of humectant, 0.01 to 1 percent of sodium chloride, 0.1 to 2 percent of emulsifier, 0.01 to 1 percent of chelating agent, 0.01 to 2 percent of the lysozyme, 0.01 to 0.1 percent of zinc-containing compound, 0.01 to 1 percent of essence, 0.01 to 0.5 percent of sweetener and the balance of de-ionized water. According to the oral-care health-care liquid disclosed by the invention, the zinc-containing compound andthe lysozyme are compounded; on one hand, the concentration of serum zinc of a local part of an oral cavity can be improved, and zinc ions are used for reducing bacterial colonization in the oral cavity through inhibiting the glucose metabolism of bacteria and a mutual effect between cell walls of the bacteria; the sterilization and bacterium-inhibition effect of the lysozyme also can be reinforced in the presence of the zinc ions; on the other hand, the zinc-containing compound and the lysozyme are combined to use so that a metal taste and a bitter taste, caused by zinc salt, can be coveredand reduced very well. Furthermore, sodium chloride, the humectant and other components are added and are compounded, so that the bitter taste of the lysozyme can be improved and the sterilization activity of the lysozyme also can be effectively improved, and furthermore, the aim of efficiently and persistently inhibiting bacteria is realized.

Owner:HAOYIKANG BIOLOGICAL TECH(GUANGZHOU) CO LTD

Nano-coating for container wall body

InactiveCN107903792AReasonable compositionReduce agglomeration reactionAntifouling/underwater paintsPaints with biocidesHardnessPolyresin

The invention relates to the field of coatings, in particular to a nano-coating for a container wall body for a building surface. The nano-coating is characterized by being prepared from the followingraw materials in parts by weight: 1 to 3 parts of nano-titanium dioxide, 1 to 3 parts of nano-zirconium oxide, 50 to 150 parts of aluminum silicate, 30 to 50 parts of glass fibres, 30 to 50 parts ofgypsum powder, 6 to 8 parts of a thickening agent, 6 to 8 parts of a defoaming agent, 1 to 3 parts of a dispersing agent, 15 to 35 parts of propylene glycol, 80 to 150 parts of acrylic acid derivativeresin, 100 to 200 parts of polyurethane and 100 to 300 parts of water.In the nano-coating for the container wall body, provided by the invention, the nano-titanium dioxide is specially added, so thatan agglomeration reaction is reduced, and the nano-coating for the container wall body has the high-efficiency persistent antibacterial property. Meanwhile, in the nano-coating for the container wallbody, provided by the invention, the glass fibres and the gypsum powder is also added, so that the water repellency, the hardness and the adhesive force of the coating are improved, and water volatilizes quickly.

Owner:山东蓝盟防腐科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com