Preparation method for composite antibacterial cellulose fiber filler of metal organic frame

A metal-organic framework and cellulose fiber technology, which is applied in the field of preparation of antibacterial fiber fillers, can solve the problems of little research on metal-organic framework composite antibacterial cellulose fibers, and achieve simple preparation methods, high accessibility, and strong antibacterial properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

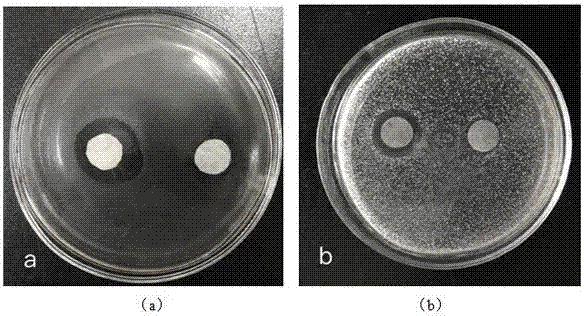

Image

Examples

Embodiment 1

[0029] The fiber used in this experiment was fully bleached bamboo pulp.

[0030] A method for preparing a metal-organic framework composite antibacterial cellulose fiber filler, comprising the following steps:

[0031] Firstly, the whole bleached bamboo pulp is beaten, and when the pulp concentration reaches 2%, the temperature is controlled at 25°C, the pH value is 5, and the concentration is 0.03mol / L of CaCl 2 Add 20mg of CMC to the solution and react for 2h; make carboxymethyl cellulose;

[0032] Next, weigh 0.20g of AgNO 3 Add the above carboxymethyl cellulose, and add 10mL of deionized water, magnetically stir for 30min, then add 0.1g of 3,5-pyridinedicarboxylic acid to mix with it, and adjust the pH value of the system to 6 with NaOH, pour the mixture Put it into a polytetrafluoroethylene high-pressure reaction kettle with a volume of 25mL, seal it, put it into an electric heating constant temperature drying box at 100°C and heat it, react for 24 hours, place the rea...

Embodiment 2

[0036] The fiber used in this experiment was fully bleached bamboo pulp.

[0037] Firstly, the whole bleached bamboo pulp is beaten, and when the pulp concentration reaches 2%, the temperature is controlled at 75°C, the pH value is 6, and the CaCl concentration is 0.04mol / L. 2 Add 30 mg of CMC to the solution and react for 8 hours; make carboxymethyl cellulose;

[0038] Next, weigh 0.20 g of CuNO 3 Add the above carboxymethyl cellulose, and add 10mL deionized water, 3ml ethanol, 3ml acetic acid, magnetically stir for 15min, then add 0.1g trimesic acid to mix with it, and adjust the pH value of the system to 5 with NaOH, and Pour the mixture into a polytetrafluoroethylene high-pressure reactor with a volume of 25mL, seal it, heat it in a 60°C electric constant temperature drying oven, and react for 10 hours. Place the reactor under cooling water and quickly cool it to room temperature, and centrifuge the product After separation, washing with deionized water and absolute etha...

Embodiment 3

[0042] The fiber in this experiment was cotton dissolving pulp.

[0043] First, the cotton dissolving pulp is beaten, and when the pulp concentration reaches 4%, the temperature is controlled at 120°C, the pH value is 7, and the concentration is 0.05mol / L CaCl 2 Add 60 mg of CMC to the solution and react for 12 hours to obtain carboxymethyl cellulose;

[0044] Then weigh 1.0 g of Cu(OAc) 2 H2O and add it to the carboxymethyl cellulose, and add 12 mL of deionized water, 4 ethanol, 4 ml of acetic acid, magnetically stir for 15 min, and then add 0.50 g of trimesic acid to mix with it , and use KOH to adjust the pH value of the system to 4, pour the mixture into a polytetrafluoroethylene high-pressure reactor with a volume of 50mL, seal it, put it into a 40°C electric constant temperature drying oven to heat, and react for 4 hours. Cool quickly to room temperature under cooling water. The product was centrifuged, washed three times with deionized water and absolute ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com