Method for preparation of inorganic nano copper antibacterial agent and dipping treatment of cotton chitosan blended antibacterial fabric

An antibacterial agent and fabric technology, applied in the field of textile functional finishing, can solve the problems of high price and low reaction rate, and achieve the effects of low product cost, simple process, efficient and durable anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

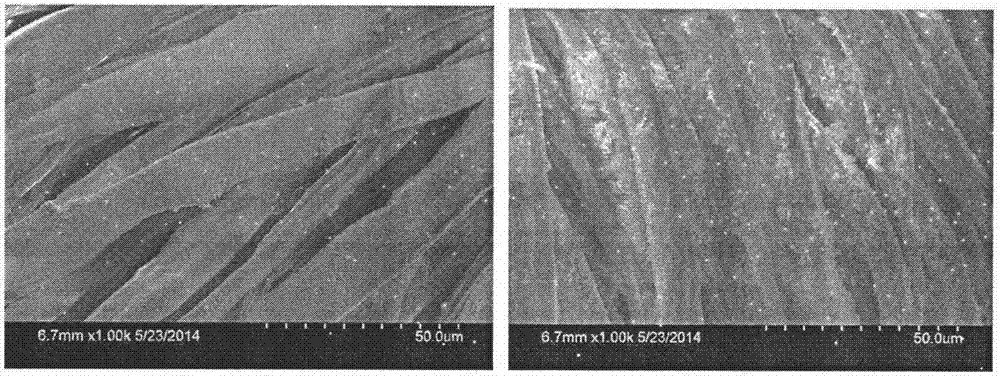

[0016] Prepare NaOH and CuSO4 solutions of equal volume and concentration, and slowly add NaOH to the CuSO4 solution to seal and let it stand for 5 minutes. Then the blue precipitate obtained by the reaction is suction filtered, rinsed with absolute ethanol several times during the suction filtration process, and finally the amount of the substance is 1 / 2 of Cu and the volume ratio is 1:3 ammonia water to dissolve the suction filtration solid PH≈12 , that is, A([Cu(NH 3 ) 4 ](OH) 2 ) and B([Cu(NH 3 ) 4 ] SO 4 ) is a copper-carrying ligand finishing agent with a similar proportion as the main component.

[0017] The copper-loaded ligand finishing agent prepared above was used to impregnate and complex the semi-bleached pure cotton fabric with a bath ratio of 1:30, a time of 20 minutes, and a copper concentration of 0.025M / L. Then wash with warm water and cold water several times until the washing water becomes neutral, then dry it naturally and then soap it (soap flakes 2...

Embodiment 2

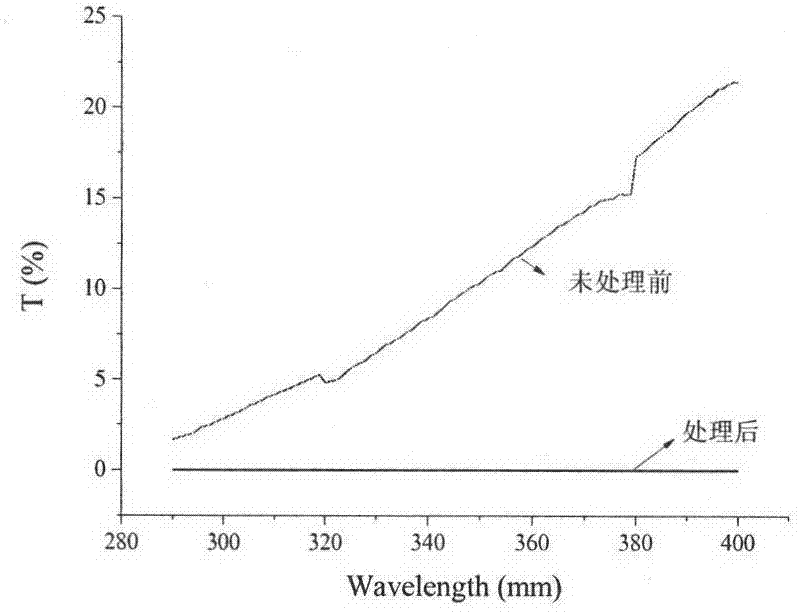

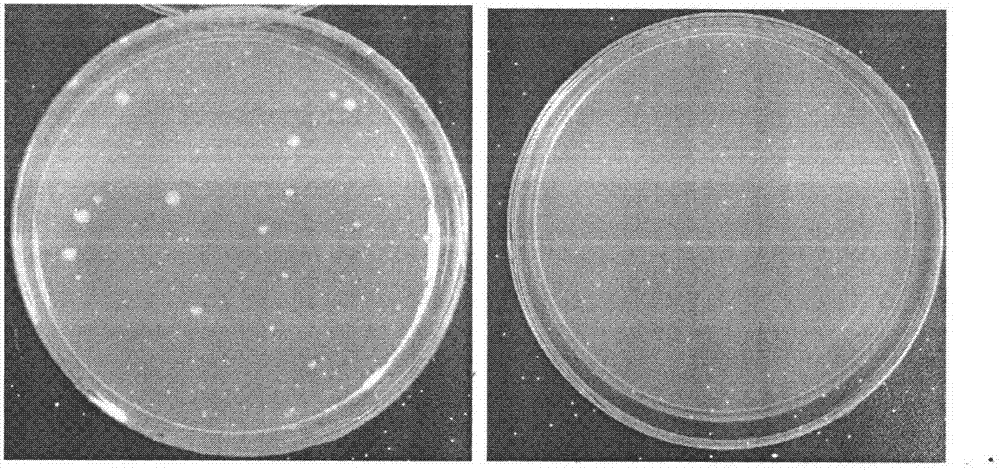

[0019] The pretreated 10 / 90 chitosan / cotton blended fabric was impregnated and complexed with the copper-loaded ligand finishing agent prepared above at a bath ratio of 1:30, for 20 minutes, and with a copper concentration of 0.025 M / L. Then wash with warm water and cold water several times until the washing water becomes neutral. After natural drying, use soap flakes 2g / L, 95°C, 10min, bath ratio 1:30 process parameters to soap the complex blended fabric, and use the same washing method to wash the fabric. The antibacterial rate of the fabric against Escherichia coli and Staphylococcus aureus is close to 100% when tested by shaking method, and the bactericidal rate is only reduced by 1% after 50 times of simulated washing. In addition, after the UV protection performance test, its UDF value can reach 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com