Polyamide6 fiber and preparing method thereof

A technology of polyamide and fiber, applied in the field of polyamide 6 fiber and its preparation, can solve the problem of lack of antibacterial function and the like, and achieve the effect of lasting and efficient antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of polyamide 6 fiber, comprises the steps:

[0028] Step 1. Prepare 20-35 parts of cuprous oxide antibacterial powder, 0.5-1.8 parts of aluminate, 0.5-1.8 parts of stearic acid, tris(2,4-di-tert-butylphenyl)phosphorous acid in the following weight parts 0.05-0.15 parts of ester, 0.05-0.15 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 61-79 parts of polyamide 6 slices are mixed and then ground and melted , kneading and extrusion, then water-cooled, pelletized and dried to obtain cuprous oxide antibacterial masterbatch;

[0029] Step 2. Mix the antibacterial cuprous oxide masterbatch and polyamide 6 chips prepared in step 1 in a weight ratio of 2 to 10:90 to 98, melt and extrude, and spin through a spinneret with a special-shaped cross-section to obtain polyamide 6. Amide 6 fiber.

[0030] Further, in step 2, the temperature during mixing, melting and extrusi...

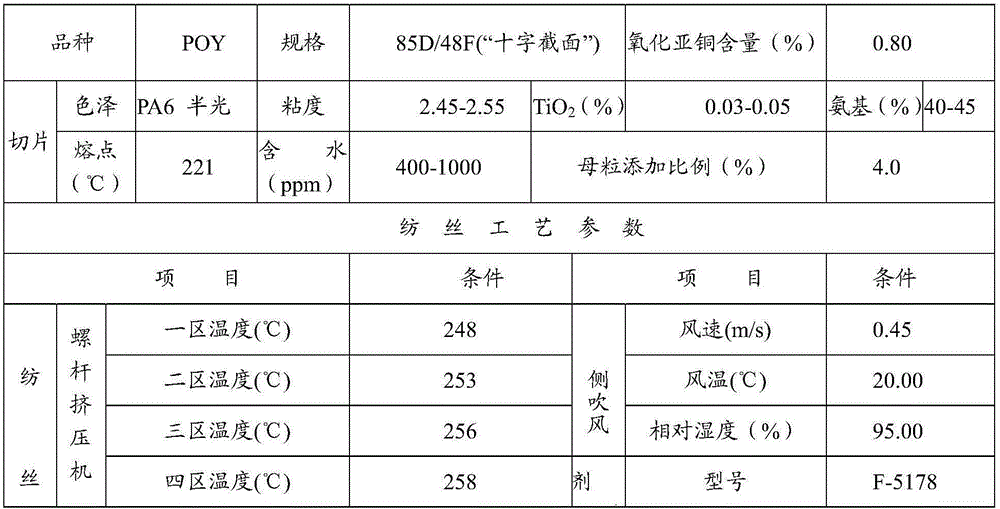

Embodiment 1

[0040] The preparation method of polyamide 6 fiber, comprises the steps:

[0041] Step 1. 20 parts of cuprous oxide antibacterial powder, 0.5 part of aluminate, 0.5 part of stearic acid, 0.05 part of tris(2,4-di-tert-butylphenyl) phosphite, 0.05 part of tetra[ 0.05 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 78.9 parts of polyamide 6 slices were mixed by a high-speed mixer, and then sent to a twin-screw extruder for grinding, melting, After kneading and extruding, water cooling, pelletizing, and drying are performed to obtain cuprous oxide antibacterial masterbatches with a water content of 600 ppm, wherein the average particle diameter of the cuprous oxide antibacterial powder is 150-250 nm;

[0042] Step 2. Mix the cuprous oxide antibacterial masterbatch prepared in step 1 with polyamide 6 slices after being measured by a metering feeder, and then send it into the screw extruder, and control the temperature of each zone of the screw a...

Embodiment 2

[0045] The preparation method of polyamide 6 fiber, comprises the steps:

[0046] Step 1. 35 parts of cuprous oxide antibacterial powder, 1.0 part of aluminate, 1.0 part of stearic acid, 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite, 0.1 part of tetra[ 0.1 part of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 62.8 parts of polyamide 6 slices were mixed by a high-speed mixer, and then sent to a twin-screw extruder for grinding, melting, After kneading and extruding, water cooling, pelletizing, and drying are performed to obtain cuprous oxide antibacterial masterbatches with a water content of 800 ppm, wherein the average particle diameter of the cuprous oxide antibacterial powder is 150-250 nm;

[0047] Step 2. Mix the cuprous oxide antibacterial masterbatch prepared in step 1 with polyamide 6 slices after being measured by a metering feeder, and then send it into the screw extruder, and control the temperature of each zone of the screw and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com