Antimicrobial yarn and preparation method thereof

A technology of yarn and graphene, which is applied in the field of antibacterial yarn and its preparation, can solve the problems of single color tone, limited use range, and inability to realize the diversity of color optional textiles, and achieve simple process, reduce the difficulty of soaking, and realize The effect of color selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

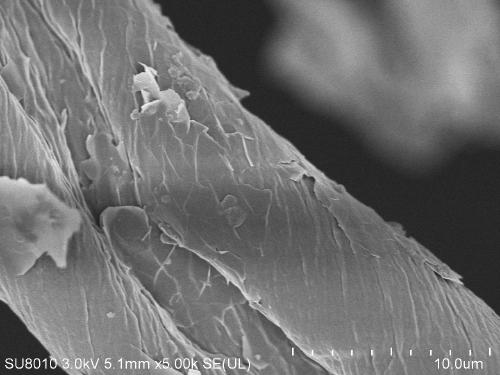

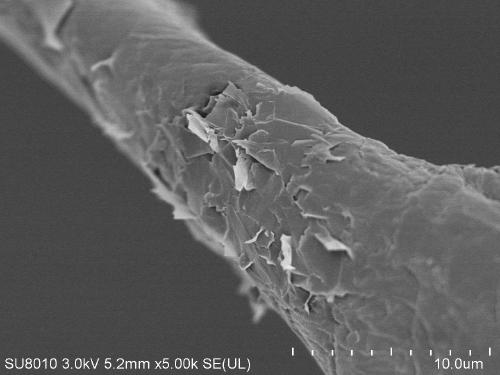

Image

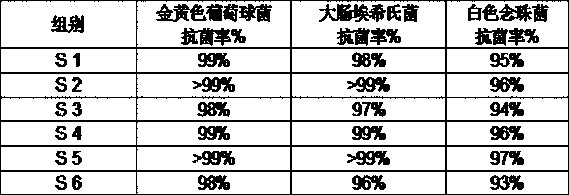

Examples

Embodiment 1

[0033] Embodiment 1: a kind of preparation method of antibacterial yarn is characterized in that, comprises the following steps:

[0034] S01. Weigh the graphene material, dispersant, wetting agent, and dyeing agent in proportion to water, and ultrasonically disperse them evenly. The composition of each component by weight percentage is: graphene oxide 0.2%, dispersant dodecylbenzene Sodium sulfonate 0.6%, dyeing agent 0%, wetting agent dioctyl sodium sulfosuccinate 0.02%;

[0035] S02. After loosening and removing impurities from the cotton yarn, mix the yarn and the slurry at a mass ratio of 1:10, soak in the slurry at 60° C. for 1 hour, and continuously stir during the soaking process;

[0036] S03, soaping the soaked yarn, then adding color-fixing agent dialkylamino ethyl methacrylate to fix the color, and then dehydrating, the moisture content of the dehydrated yarn is 20%, and finally put it in the Dry at 95°C to obtain antibacterial yarn.

Embodiment 2

[0037] Embodiment 2: a kind of preparation method of antibacterial yarn is characterized in that, comprises the following steps:

[0038] S01. Weigh the graphene material, dispersant, wetting agent, and dyeing agent in proportion to water, and ultrasonically disperse them evenly. The composition of each component by weight percentage is: graphene 0.1%, dispersant sodium lauryl sulfate 0.1%, dyeing agent reactive dye 5%, wetting agent acetylene glycol ethoxylate 0.05%;

[0039] S02. After loosening the cotton yarn and removing impurities, mix the yarn and the slurry at a mass ratio of 1:12, soak in the slurry at 85°C for 3 hours, and continuously stir during the soaking process. After 2.5 hours, add salt dyeing accelerator to accelerate dyeing;

[0040] S03, soaping the soaked yarn, then adding the color-fixing agent polydimethyldiallylammonium chloride to fix the color, then dehydrating, the moisture content of the dehydrated yarn is 35%, and finally It is dried at 100°C to ob...

Embodiment 3

[0041] Embodiment 3: a kind of preparation method of antibacterial yarn is characterized in that, comprises the following steps:

[0042] S01. Weigh the graphene material, dispersant, wetting agent, and dyeing agent in proportion to water, and ultrasonically disperse them uniformly, wherein the composition of each component by weight percentage is: modified graphene 2%, dispersant polyvinylpyrrolidone 0.5 %, dyeing agent acid dye 10%, wetting agent polyether modified siloxane copolymer 0.5%;

[0043] S02. After loosening and removing impurities from the polyester yarn, mix the yarn and the slurry at a mass ratio of 1:18, soak in the slurry at 90°C for 5 hours, and stir continuously during the soaking process. After 4 hours, add acetic acid dyeing accelerator to accelerate dyeing;

[0044] S03, soaping the soaked yarn, then adding color-fixing agent diethylenetriamine-dimethylamine-epichlorohydrin copolymer to fix the color, and then dehydrating, the moisture content of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com