Composite process antibacterial ceramic tile and preparation method thereof

A composite process and technology of ceramic tiles, applied in the field of new building ceramic materials, can solve the problems of weak bonding between the antibacterial layer and the glazed surface, affecting the surface decoration effect, poor antibacterial durability, etc., achieve excellent chemical resistance stability, and realize antifouling Good effect of performance and acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

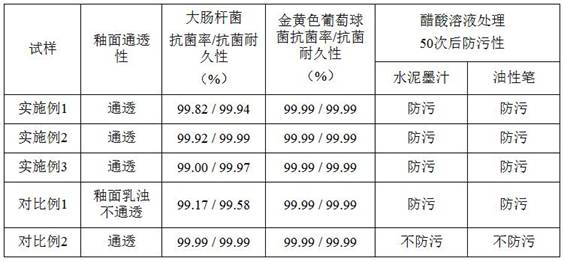

Examples

Embodiment 1

[0043] An antibacterial ceramic brick with composite technology, including a green body layer and an antibacterial glaze layer, wherein: the chemical composition of the raw material of the green body layer, by weight percentage, includes: SiO 2 66.76%, Al 2 o 3 24.87%, Fe 2 o 3 0.71%, TiO 2 0.15%, CaO1.15%, MgO0.32%, K 2 O 3.05%, Na 2 O 2.89%.

[0044] The glaze of the antibacterial glaze layer contains the first antibacterial agent and the basic glaze, the first antibacterial agent is zinc silicate, the addition of zinc silicate is 8 parts, the basic glaze is 92 parts, and the chemical composition of the basic glaze is by mass percentage Gauge includes SiO 2 56.07%, Al 2 o 3 19.77%, Fe 2 o 3 0.24%, TiO 2 0.25%, CaO 10.74%, MgO 4.41%, ZnO 5.13%, K 2 O 0.25%, Na 2 O3.14%.

[0045] The micropores on the surface of the antibacterial glaze layer are filled with an antibacterial and antifouling agent. The antibacterial and antifouling agent contains a second a...

Embodiment 2

[0052] An antibacterial ceramic brick with composite technology, including a green body layer and an antibacterial glaze layer, wherein: the chemical composition of the raw material of the green body layer, by weight percentage, includes: SiO 2 66.76%, Al 2 o 3 24.87%, Fe 2 o 3 0.71%, TiO 2 0.15%, CaO1.15%, MgO0.32%, K 2 O 3.05%, Na 2 O 2.89%.

[0053] The glaze of the antibacterial glaze layer contains the first antibacterial agent and the basic glaze, the first antibacterial agent is zinc aluminate, the addition of zinc aluminate is 5 parts, the basic glaze is 95 parts, and the chemical composition of the basic glaze is by mass percentage Gauge includes SiO 2 56.07%, Al 2 o 3 19.77%, Fe 2 o 3 0.24%, TiO 2 0.25%, CaO 10.74%, MgO 4.41%, ZnO 5.13%, K 2 O 0.25%, Na 2 O3.14%.

[0054] The micropores on the surface of the antibacterial glaze layer are filled with antibacterial and antifouling agents. The antibacterial and antifouling agents contain a second a...

Embodiment 3

[0061] An antibacterial ceramic brick with composite technology, including a green body layer and an antibacterial glaze layer, wherein: the chemical composition of the raw material of the green body layer, by weight percentage, includes: SiO 2 66.76%, Al 2 o 3 24.87%, Fe 2 o 3 0.71%, TiO 2 0.15%, CaO1.15%, MgO0.32%, K 2 O 3.05%, Na 2 O 2.89%.

[0062] The glaze of the antibacterial glaze layer contains the first antibacterial agent and the basic glaze, the first antibacterial agent is zinc silicate and zinc aluminate, the addition of zinc silicate and zinc aluminate is 7 parts, and the basic glaze is 93 parts, The basic polishing glaze chemical composition includes SiO in mass percentage 2 56.07%, Al 2 o 3 19.77%, Fe 2 o 3 0.24%, TiO 2 0.25%, CaO 10.74%, MgO 4.41%, ZnO 5.13%, K 2 O 0.25%, Na 2 O 3.14%.

[0063] The micropores on the surface of the antibacterial glaze layer are filled with antibacterial and antifouling agents, the antibacterial and antif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com