Bedding prepared from polyester antibacterial masterbatch based on one-dimensional nanometer Ag/C composite material

An antibacterial masterbatch and composite material technology, applied in the direction of single-component polyester rayon filament, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of waste function, insufficient long-term antibacterial performance, and not easy to disperse, etc. Achieve the effect of improving stability and durability, efficient and durable antibacterial effect, avoiding aggregation and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

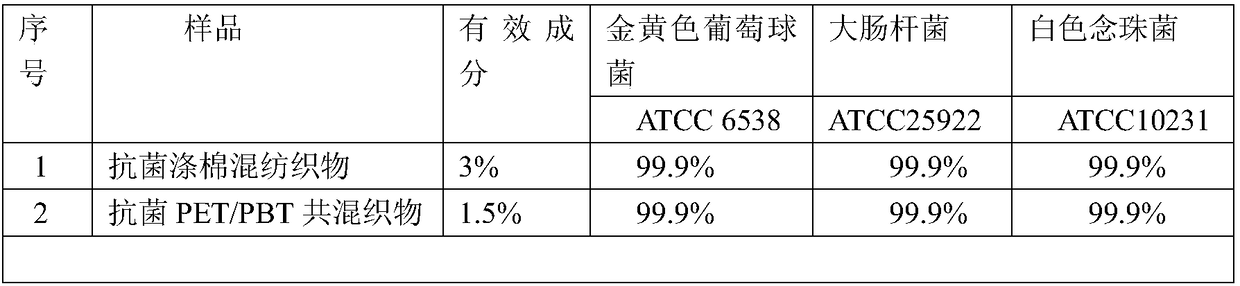

Examples

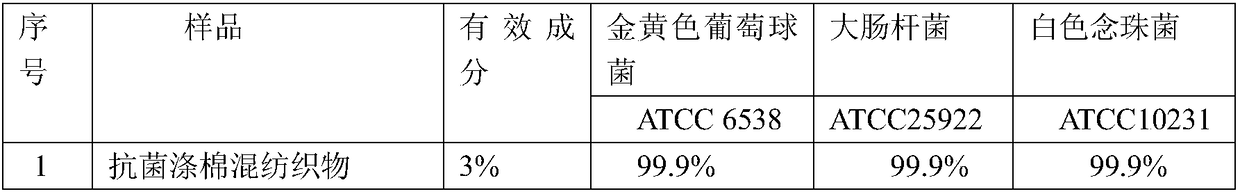

Embodiment 1

[0043] A bedding prepared from polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite material, the preparation method comprising:

[0044] Step 1: Preparation of a polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite:

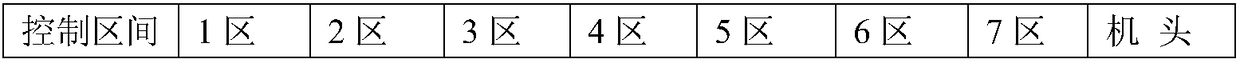

[0045] The raw materials include the following components calculated by weight: 62 parts of polybutylene terephthalate (PBT), 15 parts of one-dimensional nano-Ag / C composite material, 15 parts of inorganic powder, 1.3 parts of surface modifier, dispersion 4 parts of agent, 0.8 part of antioxidant, 1.2 parts of lubricant and 0.7 part of stabilizer.

[0046] PBT resin is fiber grade PBT resin;

[0047] One-dimensional nano-Ag / C composite material: This scheme is self-made.

[0048] The inorganic powder is 3000 mesh calcium carbonate powder, which has been hybridized by this scheme.

[0049] The surface modifier of inorganic powder is a compound of aluminate coupling agent and titanate in a mass ratio of 1:...

Embodiment 2

[0069] A bedding prepared from polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite material, the preparation method comprising:

[0070] Step 1: Preparation of a polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite:

[0071] Preparation of polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite material, raw materials include the following components calculated by weight: 56.2 parts of polytrimethylene terephthalate resin, 20 parts of one-dimensional nano Ag / C composite material , 15 parts of inorganic powder, 1.5 parts of surface modifier, 5 parts of dispersant, 0.9 part of antioxidant, 1.4 parts of lubricant, and 0.5 part of stabilizer.

[0072] Polytrimethylene terephthalate resin is conventional commercially available polytrimethylene terephthalate resin;

[0073] One-dimensional nano-Ag / C composite material: This scheme is self-made.

[0074] The inorganic powder is 2500 mesh calcium carbo...

Embodiment 3

[0095] A bedding prepared from polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite material, the preparation method comprising:

[0096] Step 1: Preparation of a polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite:

[0097] Preparation of polyester antibacterial masterbatch based on one-dimensional nano Ag / C composite material, raw materials include the following components calculated by weight: 88 parts of polyethylene terephthalate resin, one-dimensional nano Ag / C composite material 20 parts, 25 parts of inorganic powder, 0.6 parts of surface modifier, 1 part of dispersant, 2 parts of antioxidant, 4 parts of lubricant, 5 parts of stabilizer.

[0098] Polyethylene terephthalate is conventional commercially available polyethylene terephthalate;

[0099] One-dimensional nano-Ag / C composite material: This scheme is self-made.

[0100] The inorganic powder is a mixture of 2500 mesh calcium carbonate powder and 3000 mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com