Nano coating and preparation method thereof

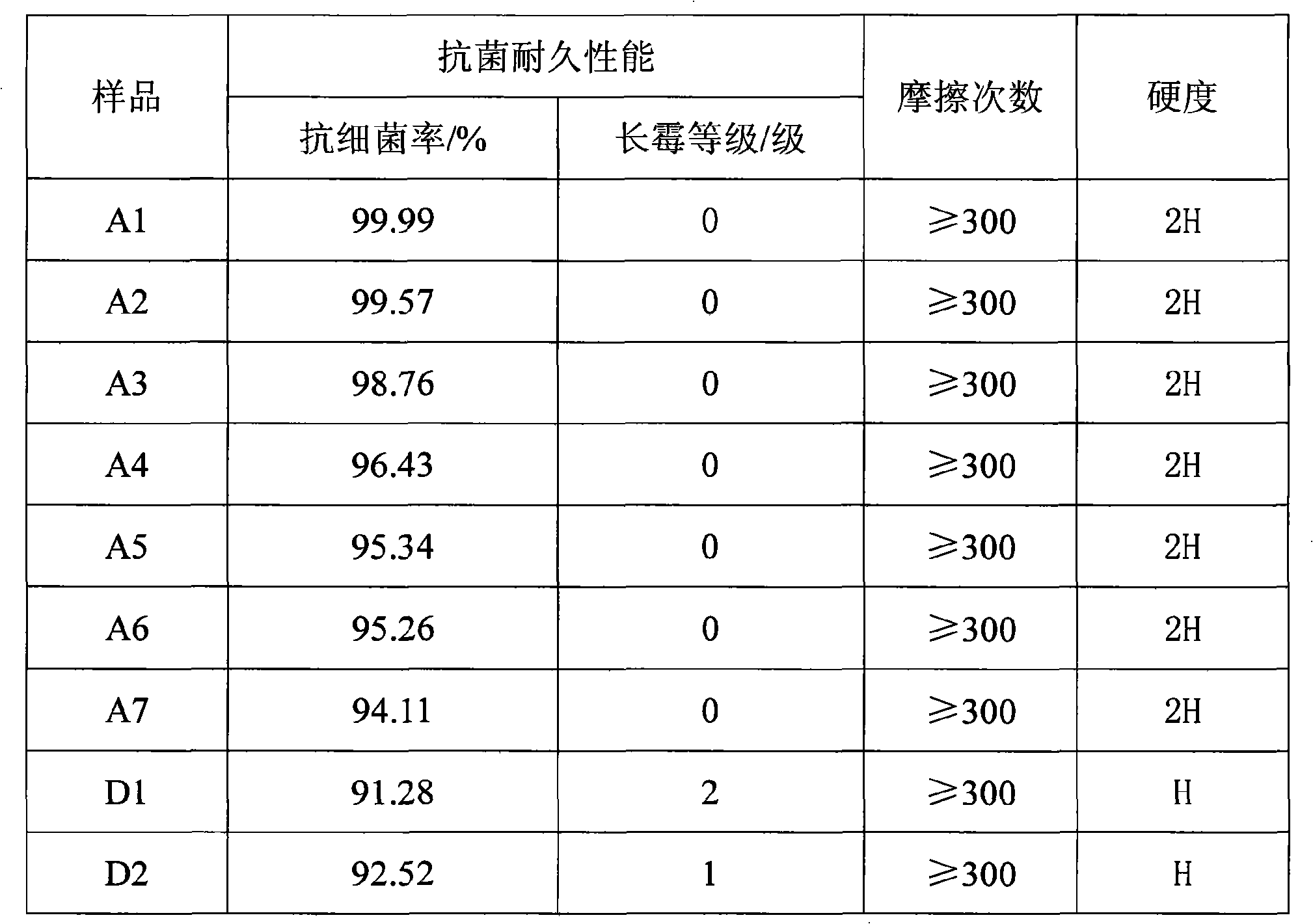

A nano-coating and nano-silver technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor antibacterial durability, and achieve the effect of reducing agglomeration reaction, high efficiency and long-lasting antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a kind of preparation method of above-mentioned nano-coating, comprises the following steps:

[0025] (1) Nano-silver and nano-titanium dioxide are mixed in a weight ratio of 1:5 to 8 to prepare nano-TiO 2 Silver-loaded composite materials;

[0026] (2) In the nano-TiO 2 Add additives to the silver-loaded composite material, disperse evenly, and grind to obtain a mixed slurry;

[0027] (3) Add emulsion into the mixed slurry, and disperse evenly to obtain nano coating.

[0028] In the preparation method provided by the present invention, the nano-titanium dioxide is acid-treated nano-titanium dioxide, and the acids used in the acid treatment are various inorganic acids known to those skilled in the art. In the present invention, nitric acid with a volume concentration of 63-68% is preferably used. The acid treatment method is a variety of acid treatment methods known to those skilled in the art, which will not be repeated here.

...

Embodiment 1

[0045] This embodiment is used to illustrate the nano-coating provided by the present invention and its preparation method.

[0046] (1) Solution preparation: Weigh 0.4g nano-silver powder and add it to 100mL ethanol. After fully stirring for 45min, grind at high speed with a sand mill to make a nano-silver-ethanol mixture; weigh 0.5g rutile titanium dioxide powder, 1.0g Anatase titanium dioxide powder, added to 50mL HNO with a volume concentration of 65% 3 solution, fully stirred for 45 minutes, and then rinsed and filtered the titanium dioxide with distilled water until the filtrate was neutral to obtain acid-treated titanium dioxide.

[0047] (2) Nano-TiO 2 Preparation of silver-loaded composite material: Get 50g of prepared nano-silver-ethanol mixed solution and add it to acid-treated nano-titanium dioxide, add 0.02g fatty acid sodium methyl ester sodium sulfonate surfactant, stir and heat to fully react, and prepare Nanometer TiO 2 Silver loaded composites.

[0048] (...

Embodiment 2

[0050] This embodiment is used to illustrate the nano-coating provided by the present invention and its preparation method.

[0051] Adopt the same mode as embodiment 1 to prepare nano-coating, difference is:

[0052] Addition of emulsion: In step (3), 200 g of polyurethane was used to replace 600 g of hydroxyacrylic resin in Example 1.

[0053] The nano-coating that makes by above-mentioned method is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com