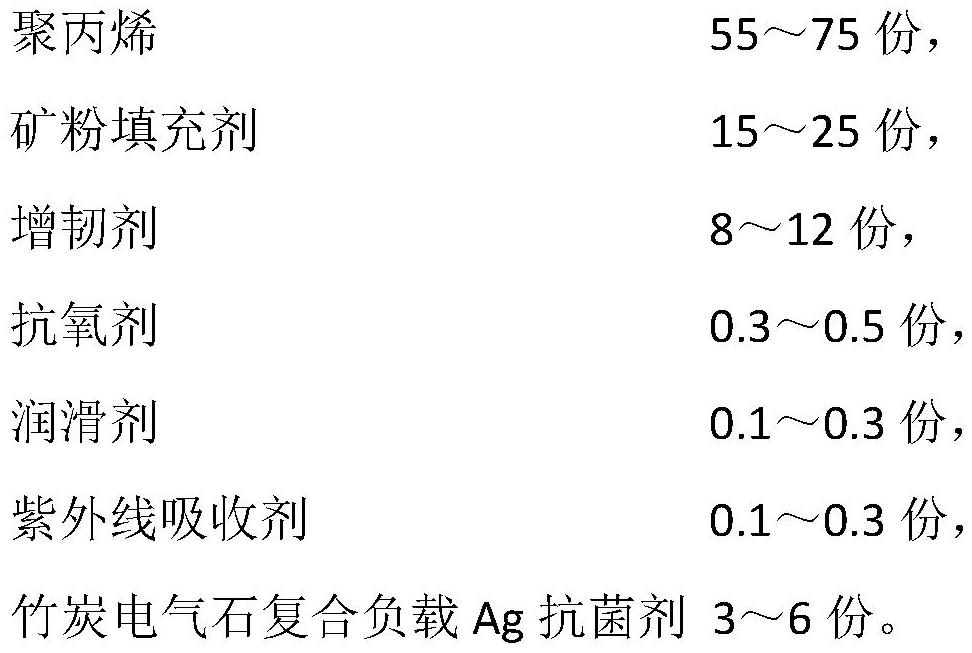

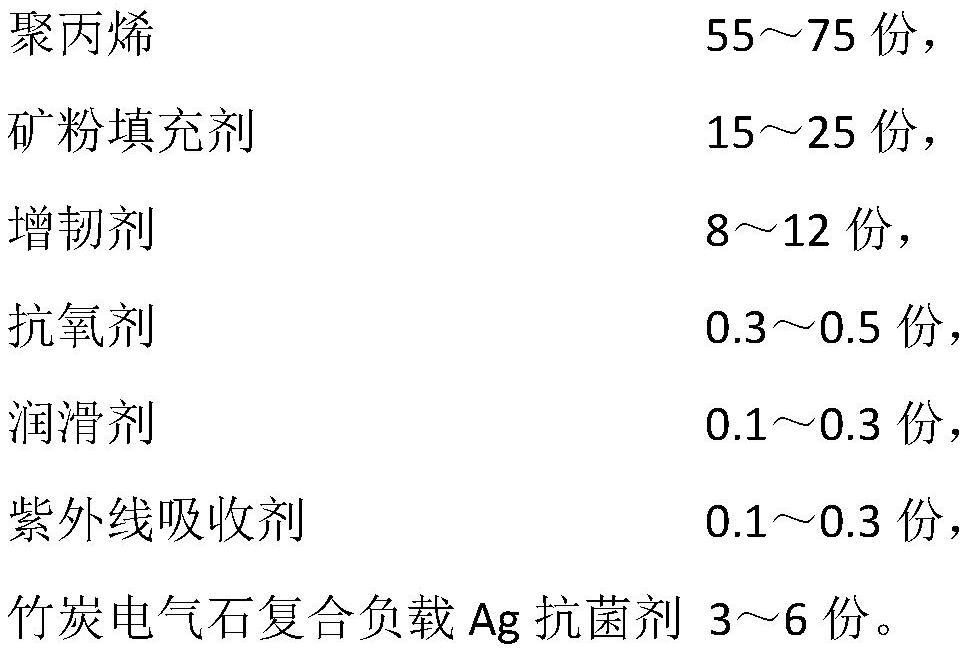

Bamboo charcoal and tourmaline composite Ag-loaded antibacterial agent, antibacterial polypropylene composition and preparation method

An antibacterial polypropylene and antibacterial agent technology, applied in the field of polymer materials, can solve the problems of single antibacterial solution, poor antibacterial durability of antibacterial polypropylene composition, and inability to achieve multiple antibacterials, etc. performance, the effect of improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

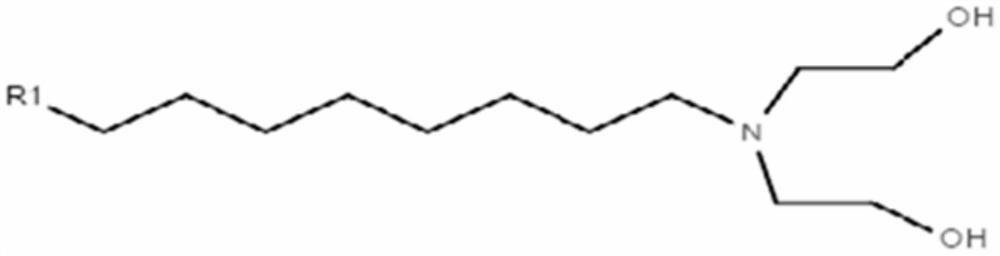

Method used

Image

Examples

Embodiment 1

[0070] First, 15 parts of high toughness copolymerized polypropylene (Qilu Petrochemical SP179), 49 parts of low toughness copolymerized polypropylene (Wuhan Petrochemical K7227), 23 parts of talcum powder (IMIFABI HTPultra5L), 10 parts of toughening agent (Dow POE8150), compound antibacterial Add 2 parts of anti-oxidant (BASF 1076 and BASF 168 compound according to 3:2), 0.25 parts of lubricant (calcium stearate) and 0.25 parts of 0.25 part of absorbent (Xinxiu Chemical 5590) was mixed again; finally added into a twin-screw extruder for melt extrusion to obtain a polypropylene composition.

[0071] The twin-screw extruder is the same as Comparative Example 1.

Embodiment 2

[0073] The preparation method is the same as in Example 1, and the raw materials are: 15 parts of high-toughness copolymerized polypropylene (Qilu Petrochemical SP179), 49 parts of low-toughness copolymerized polypropylene (Wuhan Petrochemical K7227), 20 parts of talcum powder (IMIFABI HTPultra5L), toughening agent (ceramic 10 parts of POE8150), 0.5 parts of antioxidant (BASF 1076 and BASF 168 compounded according to 3:2), 0.25 parts of lubricant (calcium stearate), 0.25 parts of ultraviolet absorber (Xinxiu Chemical 5590), compound antibacterial agent 5 servings.

Embodiment 3

[0075] The preparation method is the same as in Example 1, and the raw materials are: 15 parts of high-toughness copolymerized polypropylene (Qilu Petrochemical SP179), 48 parts of low-toughness copolymerized polypropylene (Wuhan Petrochemical K7227), 20 parts of talcum powder (IMIFABI HTPultra5L), toughening agent (ceramic 10 parts of POE8150), 0.5 parts of antioxidant (BASF 1076 and BASF 168 compounded according to 3:2), 0.25 parts of lubricant (calcium stearate), 0.25 parts of ultraviolet absorber (Xinxiu Chemical 5590), compound 5 parts of antibacterial agent, 1 part of auxiliary agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com