Self-antibacterial type high-bonding strength melamine resin adhesive and preparation method thereof

A melamine, adhesive strength technology, applied in the direction of adhesive types, aldehyde/ketone condensation polymer adhesives, adhesives, etc., can solve the problems of mildew deterioration, water absorption and swelling, and achieve excellent water resistance and extremely low formaldehyde release. , The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

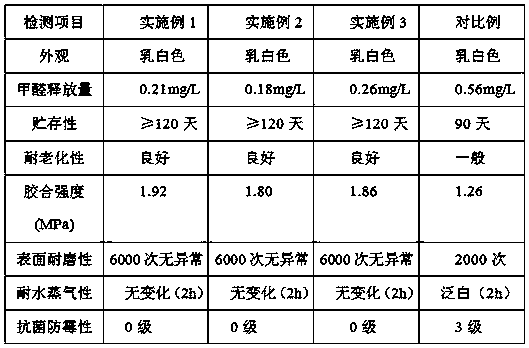

Examples

Embodiment 1

[0027] A kind of self-antibacterial type high adhesive strength melamine resin glue, its preparation process is as follows:

[0028] a. Put 60.0 parts of 37.0% formaldehyde, 16.0 parts of urea, 2.0 parts of acrylamide, 10.0 parts of melamine, and 2.2 parts of polyvinyl alcohol into the reaction kettle in order according to the weight of the formula. Adjust the pH value of the mixture to 7.5-8.0, raise the temperature to 68°C, and keep it warm for 30 minutes;

[0029] b. Cool down to 63°C, add 0.2 parts of ammonium chloride aqueous solution dropwise every 5 minutes, stir evenly, and check the pH value until the pH value of the mixture is adjusted to 4.5, continue the reaction for 10 minutes; then slowly add 0.5 parts of sodium hydroxide aqueous solution dropwise Adjust the pH value of the reaction mixture to 7.2 to 8.0, and at the same time raise the temperature to 78°C, add 5.0 parts of silane coupling agent, 8.0 parts of urea and 10.0 parts of melamine to continue the reactio...

Embodiment 2

[0032] A kind of self-antibacterial type high adhesive strength melamine resin glue, its preparation process is as follows:

[0033] a. Put 56.0 parts of 36.5% formaldehyde, 14.0 parts of urea, 8.0 parts of acrylamide, melamine, and 1.8 parts of polyvinyl alcohol into the reaction kettle in order according to the weight of the formula. Adjust the pH value to 7.5-8.0, raise the temperature to 66°C, and keep it warm for 40 minutes;

[0034] b. Cool down to 62°C, add 0.2 parts of ammonium chloride aqueous solution dropwise every 5 minutes, stir evenly, and check the pH value until the pH value of the mixture is adjusted to 4.5, continue the reaction for 10 minutes; then slowly add 0.4 parts of sodium hydroxide aqueous solution dropwise Adjust the pH value of the reaction mixture to 7.2-8.0 in 2 parts, and raise the temperature to 76°C at the same time, add 6.2 parts of silane coupling agent, 7.0 parts of urea and 8.0 parts of melamine to continue the reaction for 15-20 minutes, a...

Embodiment 3

[0037] A kind of self-antibacterial type high adhesive strength melamine resin glue, its preparation process is as follows:

[0038] a. Put 65.0 parts of 36.0% formaldehyde, 18.0 parts of urea, 2.2 parts of acrylamide, 9.5 parts of melamine and 3.5 parts of polyvinyl alcohol into the reaction kettle in sequence according to the weight of the formula. Adjust the pH value of the mixture to 7.5-8.0, raise the temperature to 70°C, and keep it warm for 30 minutes;

[0039]b. Cool down to 62°C, add 0.2 parts of ammonium chloride aqueous solution dropwise every 5 minutes, stir evenly, and check the pH value until the pH value of the mixture is adjusted to 4.5, continue the reaction for 10 minutes; then slowly add 0.6 parts of sodium hydroxide aqueous solution dropwise Adjust the pH value of the reaction mixture to 7.2 to 8.0, and at the same time raise the temperature to 76°C, add 6.6 parts of silane coupling agent, 9.0 parts of urea and 9.5 parts of melamine to continue the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com