Novel in-situ cleaning agent and preparation method thereof

A cleaning agent and in-situ technology, which is applied in the field of new in-situ cleaning agent and its preparation, can solve the problems of bacteria and microorganisms breeding, hidden safety hazards, troublesome operation process, etc., and achieve strong antibacterial corrosion, efficient antibacterial performance, The effect of overcoming technical deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

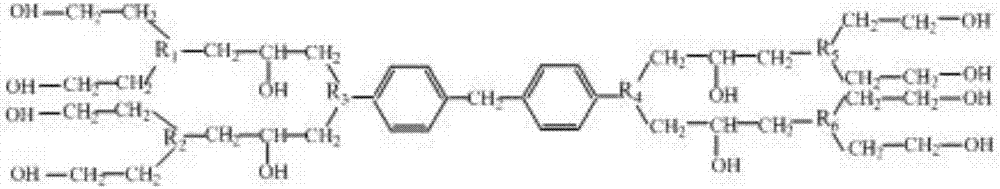

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~4

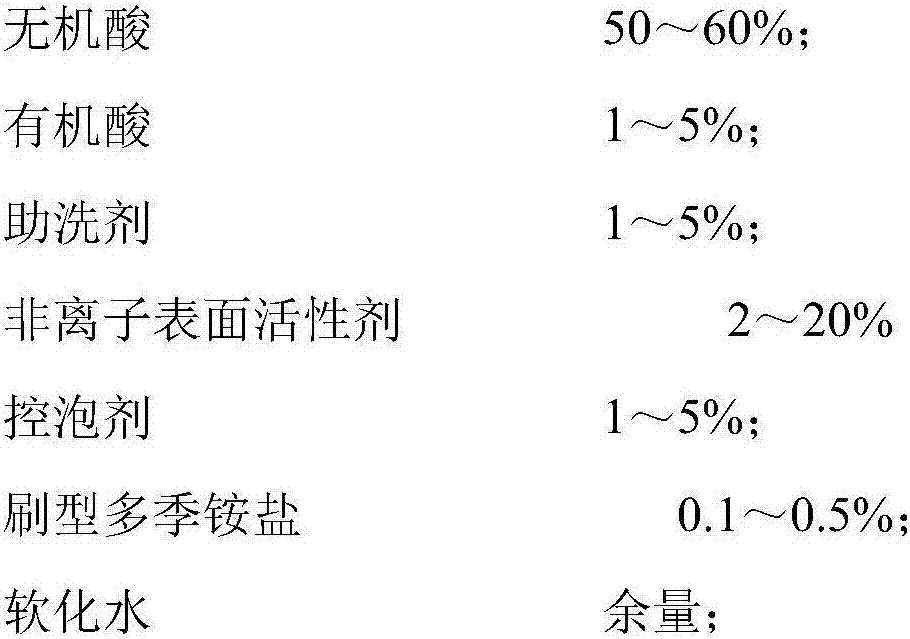

[0051] Examples 1-6 and Comparative Examples 1-4 A kind of acidic in-situ cleaning agent

[0052] The formulations of the in-situ cleaning agents provided in Examples 1-6 and Comparative Examples 1-4 are shown in Table 1 below.

[0053] Table 1 Formulas of in-situ cleaning agents provided by Examples 1-6 and Comparative Examples 1-4 (wt / %)

[0054]

[0055] Note: The nitric acid or phosphoric acid in the above table is pure nitric acid or pure phosphoric acid, which is converted from industrial nitric acid or industrial phosphoric acid.

[0056] In the above table, Comparative Example 4 is a commercially available common acidic in-situ cleaning agent.

[0057] The preparation method of the in-situ cleaning agent provided by Examples 1-6 and Comparative Examples 1-4 is as follows:

[0058] (1) Add detergent builder, foam control agent, brush-type cation, non-ionic surfactant into softened water, stir and dissolve evenly;

[0059] (2) Add mineral acid slowly and stir evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com