Preparation method of PET (polyethylene terephthalate) weaving material provided with anti-bacterial and mineralization-promoting functional coating

A technology of polyethylene terephthalate and phthalate, which is applied in the field of biomaterials to achieve good antibacterial properties and good mineralization-promoting abilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

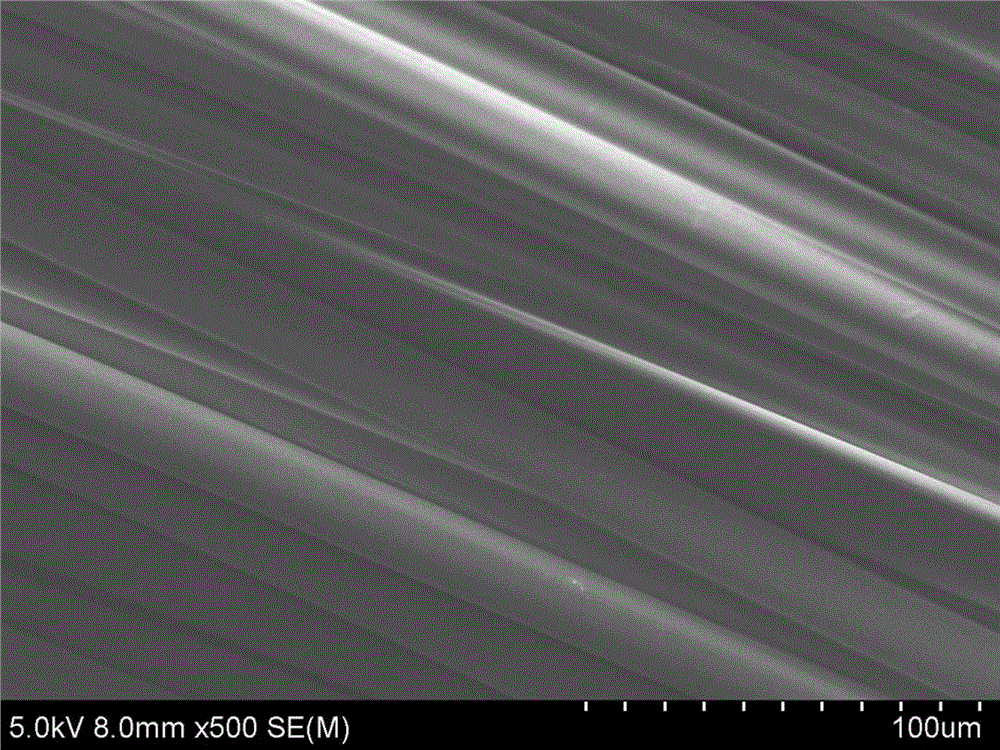

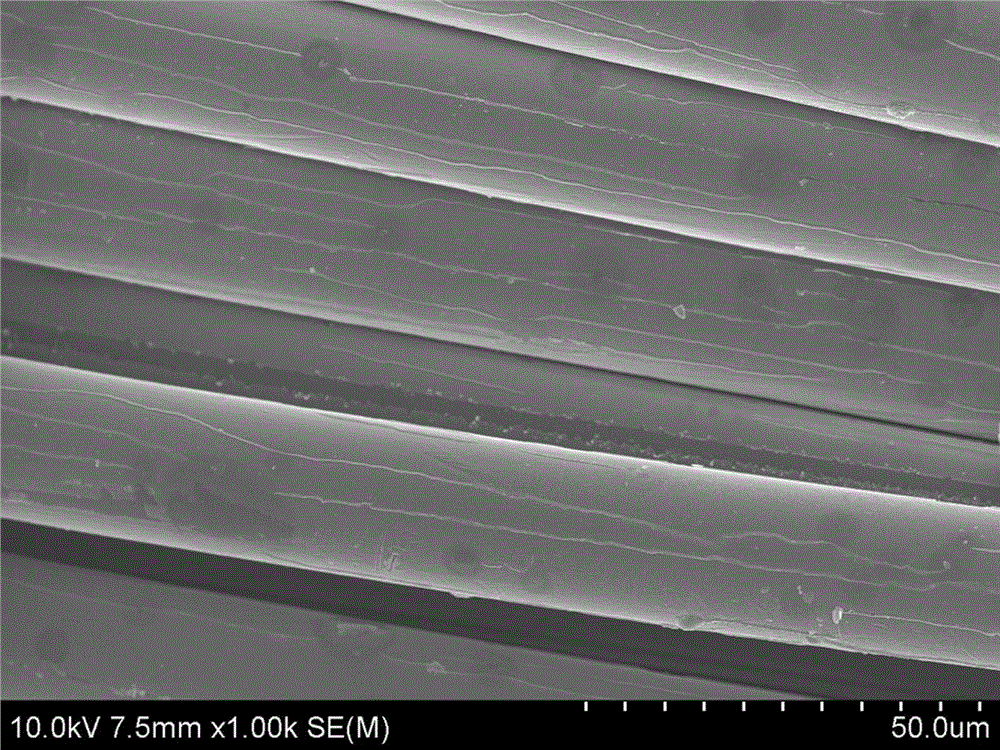

[0018] (1) Preparation of polyethylene terephthalate braided material: weave polyethylene terephthalate (PET) threads into a grid;

[0019] (2) Surface treatment of PET braided materials: At room temperature, soak PET braided materials in acetone, ethanol, and water for 10 minutes, 20 minutes, and 30 minutes to ultrasonically clean them respectively to remove surface impurities, and then place the cleaned PET braided materials in Dry at room temperature to obtain a clean PET braided material;

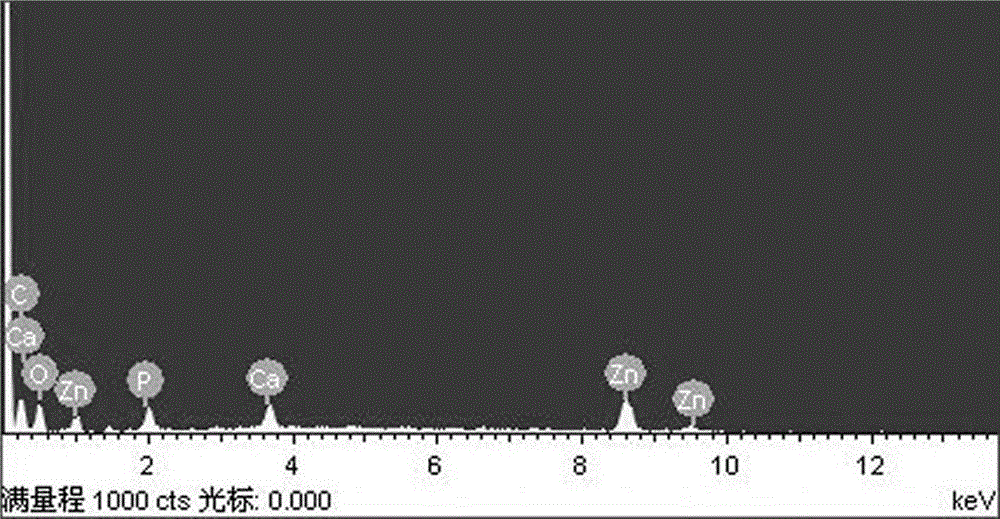

[0020] (3) Atomic layer deposition of zinc oxide on PET woven material: Put the clean PET woven material in the atomic layer deposition equipment, use diethyl zinc and water as zinc source and oxygen source respectively, high-purity nitrogen as cleaning gas, growth temperature After 300 cycles at 200°C, a nano-ZnO deposition with a thickness of 60 nm was obtained.

[0021] The obtained zinc oxide deposited PET woven material has the following properties, the antibacterial rate reaches ...

Embodiment 2

[0023] (1) Preparation of polyethylene terephthalate braided material: weave polyethylene terephthalate (PET) threads into a grid;

[0024] (2) Surface treatment of PET braided materials: At room temperature, soak PET braided materials in acetone, ethanol, and water for 10 minutes, 20 minutes, and 30 minutes to ultrasonically clean them respectively to remove surface impurities, and then place the cleaned PET braided materials in Dry at room temperature to obtain a clean PET braided material;

[0025] (3) Atomic layer deposition of zinc oxide on PET woven material: Put the clean PET woven material in the atomic layer deposition equipment, use diethyl zinc and water as zinc source and oxygen source respectively, high-purity nitrogen as cleaning gas, growth temperature After 500 cycles at 200°C, a nano-ZnO deposition with a thickness of 100 nm was obtained.

[0026] The obtained zinc oxide deposited PET woven material has the following properties, the antibacterial rate reaches...

Embodiment 3

[0028] (1) Preparation of polyethylene terephthalate braided material: weave polyethylene terephthalate (PET) threads into a grid;

[0029] (2) Surface treatment of PET braided materials: At room temperature, soak PET braided materials in acetone, ethanol, and water for 10 minutes, 20 minutes, and 30 minutes to ultrasonically clean them respectively to remove surface impurities, and then place the cleaned PET braided materials in Dry at room temperature to obtain a clean PET braided material;

[0030] (3) Atomic layer deposition of zinc oxide on PET woven material: Put the clean PET woven material in the atomic layer deposition equipment, use diethyl zinc and water as zinc source and oxygen source respectively, high-purity nitrogen as cleaning gas, growth temperature At 200°C, after 200 cycles, nano-ZnO deposition with a thickness of 40nm was obtained.

[0031] The obtained zinc oxide deposited PET woven material has the following properties, the antibacterial rate reaches 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com