An antibacterial polycarbonate material and a preparing method thereof

A technology of polycarbonate and antibacterial agent, applied in the field of antibacterial polycarbonate material and its preparation, can solve the problems of poor antibacterial performance, low shrinkage and rigidity, etc., and achieve the effect of excellent antibacterial property, high rigidity and improved antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

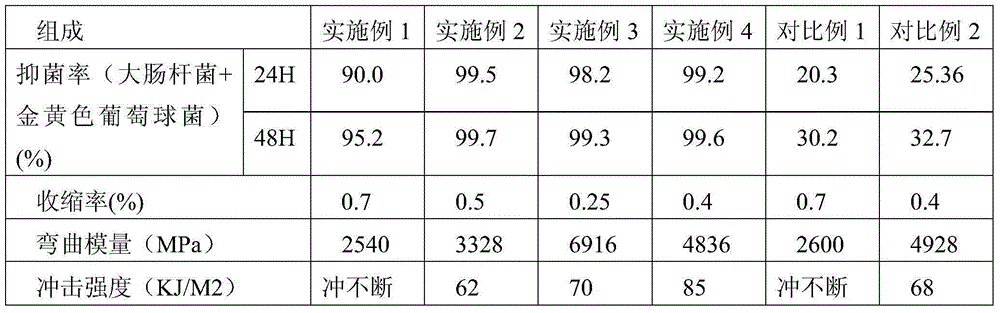

Embodiment 1

[0025] 100 parts of PC resin, 5 parts of toughening agent MBS, 1 part of Ag 1+ Silicate, 0.4 part of dispersant PE wax and 0.4 part of antioxidant (antioxidant 1076 / antioxidant 168=1 / 2), add to high mixer and mix at high speed, control the speed of high mixer to be 500rmp, mix The temperature is 80°C, mix for 3 minutes and mix well;

[0026] Put the mixed material and 10 parts of glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feed port to the die head of the extruder) to 220°C, 230°C, 240°C, 255°C, and 265°C , The antibacterial polycarbonate material is obtained by extruding strands and pelletizing.

[0027] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 265° C. The injection-molded strips were placed at 50% relative humidity at 23°C for 24 hours before performing a performance test. T...

Embodiment 2

[0029] With 100 parts of PC resin, 3 parts of toughening agent EMA-GMA, 0.7 part of antibacterial agent (polyhexamethylene guanidine phosphate / nanometer silver oxide=2 / 1), 0.6 part of dispersant PETS and 0.6 part of antioxidant ( Antioxidant 1010 / antioxidant 168=1 / 2), added to the high-speed mixer and mixed at high speed, controlled the speed of the high-mixer to 700rmp, the mixing temperature was 40°C, and mixed for 3 minutes to mix evenly;

[0030] Put the mixed material and 20 parts of glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feed port to the die head of the extruder) to 220°C, 230°C, 240°C, 250°C, and 260°C , The antibacterial polycarbonate material is obtained by extruding strands and pelletizing.

[0031] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 265° C. The injection-m...

Embodiment 3

[0033] With 100 parts of PC resin, 10 parts of toughening agent LLDPE-g-MAH, 2 parts of nano titanium dioxide, 1.0 parts of dispersant EBS and 1.2 parts of antioxidant (antioxidant 1010 / antioxidant 168=2 / 3), add Go to the high-speed mixer for high-speed mixing, control the speed of the high-speed mixer to 600rmp, the mixing temperature to 60°C, and mix for 10 minutes to mix evenly;

[0034] Put the mixed material and 50 parts of glass fiber into the twin-screw extruder to extrude and granulate, and control the temperature of each zone (from the feed port to the die head of the extruder) to 230°C, 245°C, 250°C, 265°C, and 255°C , The antibacterial polycarbonate material is obtained by extruding strands and pelletizing.

[0035] The above product was dried at 85° C. for 5 hours in a blast oven and then injection molded with an injection molding machine, and the injection molding temperature was 265° C. The injection-molded strips were placed at 50% relative humidity at 23°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com