Water-soluble oxidized chitosan and method for finishing fabric by using water-soluble oxidized chitosan

An oxidized chitosan, water-soluble technology, applied in the direction of enzyme/microorganism biochemical treatment, biochemical fiber treatment, fiber treatment, etc., can solve the problems of difficult practical application, large amount of reagents, long processing time, etc. The effect of reaction probability, avoiding long reaction time, and fast catalytic reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

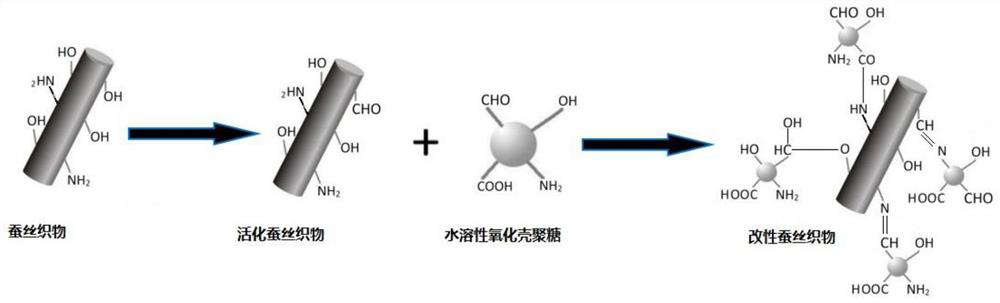

Method used

Image

Examples

Embodiment 1

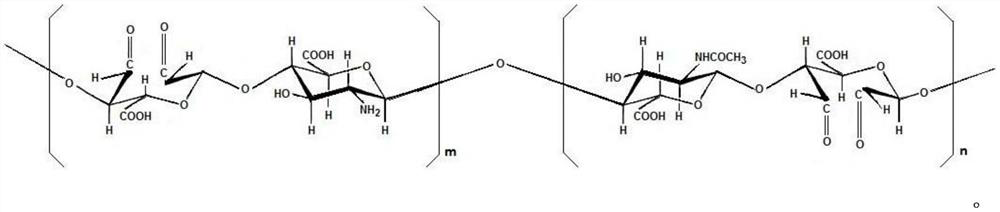

[0040] The water-soluble oxidized chitosan of the present embodiment is prepared according to the following steps:

[0041] (1) Dissolution of chitosan: chitosan with a viscosity-average molecular weight of 825,000 and a deacetylation degree of 95.2% is added to 1-carboxymethyl-3-methylimidazolium bisulfate ionic liquid at 95°C Continue stirring until the chitosan is completely dissolved to obtain a mass concentration of 4% chitosan / ionic liquid solution;

[0042] (2) The preparation of dialdehyde chitosan: in the chitosan / ionic liquid solution of step (1), add dropwise the NaOH solution of 0.5mol / L to adjust its pH value to 4.5, then add sodium periodate oxidizing agent to make it With a concentration of 0.5g / L, the resulting reaction solution was oxidized under microwave radiation conditions (power 200W, radiation temperature 30°C) in the dark and stirred for 30 minutes, adding absolute ethanol to terminate the reaction, and the reaction solution was filtered to remove insol...

Embodiment 2

[0057] The water-soluble oxidized chitosan of the present embodiment is prepared according to the following steps:

[0058] (1) Dissolution of chitosan: chitosan with a viscosity-average molecular weight of 825,000 and a deacetylation degree of 95.2% is added to 1-carboxymethyl-3-methylimidazolium bisulfate ionic liquid at 95°C Continue stirring under continuous stirring and make chitosan dissolve completely, obtain mass concentration and be 4% chitosan / ionic liquid solution;

[0059] (2) The preparation of dialdehyde chitosan: in the chitosan / ionic liquid solution of step (1), add dropwise the NaOH solution of 0.5mol / L to adjust its pH value to 4.5, then add sodium periodate oxidizing agent to make it With a concentration of 1g / L, the reaction solution was stirred and oxidized for 40 minutes under microwave radiation conditions (power 280W, radiation temperature 35°C) in the dark, and absolute ethanol was added to terminate the reaction, and the reaction solution was filtered...

Embodiment 3

[0073] The water-soluble oxidized chitosan of the present embodiment is prepared according to the following steps:

[0074] (1) Dissolution of chitosan: chitosan with a viscosity-average molecular weight of 825,000 and a deacetylation degree of 95.2% is added to 1-carboxymethyl-3-methylimidazolium bisulfate ionic liquid at 95°C Continue stirring under continuous stirring and make chitosan dissolve completely, obtain mass concentration and be 4% chitosan / ionic liquid solution;

[0075] (2) The preparation of dialdehyde chitosan: in the chitosan / ionic liquid solution of step (1), add dropwise the NaOH solution of 0.5mol / L to adjust its pH value to 4.5, then add sodium periodate oxidizing agent to make it With a concentration of 1.5g / L, the reaction solution was stirred and oxidized for 45 minutes under microwave radiation conditions (power 320W, radiation temperature 40°C) in the dark, and absolute ethanol was added to terminate the reaction, and the reaction solution was filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com