Preparation method of visible light compound photocatalyst and finishing method of cotton fabric by use of visible light compound photocatalyst

A composite light and catalyst technology, applied in the field of textile materials, can solve the problems of photogenerated carrier instability, low quantum efficiency, and low energy efficiency, and achieve antibacterial self-cleaning performance, fast degradation rate, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

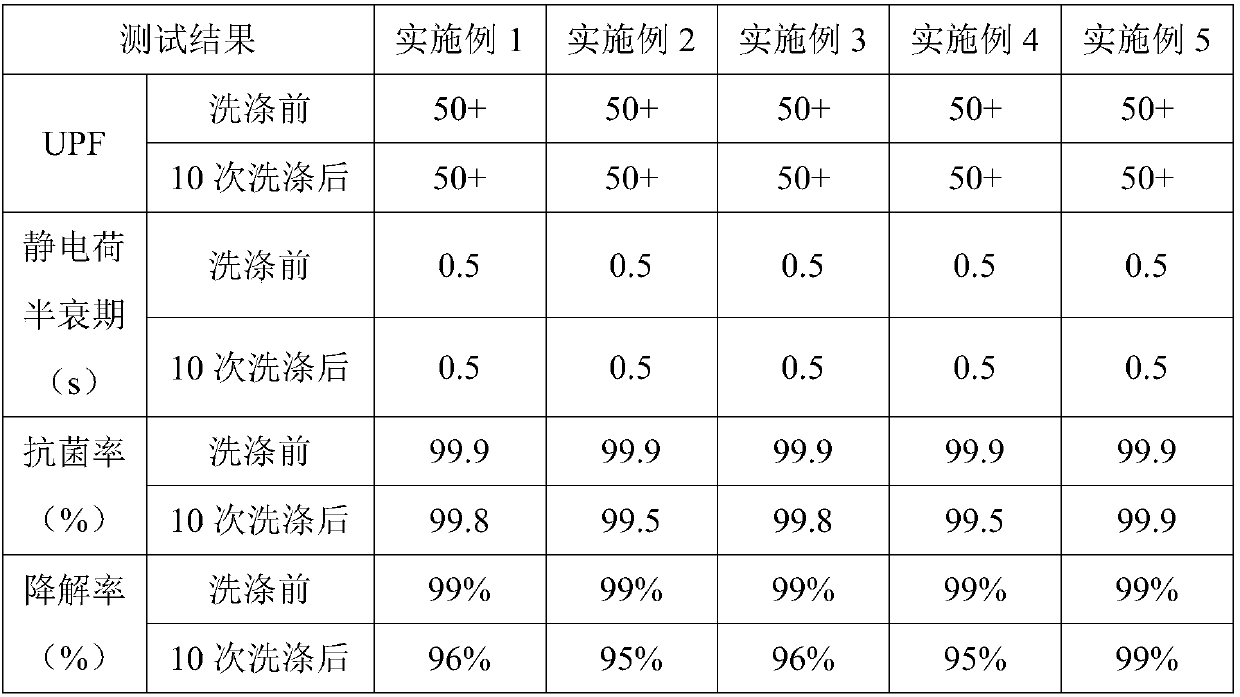

Examples

preparation example Construction

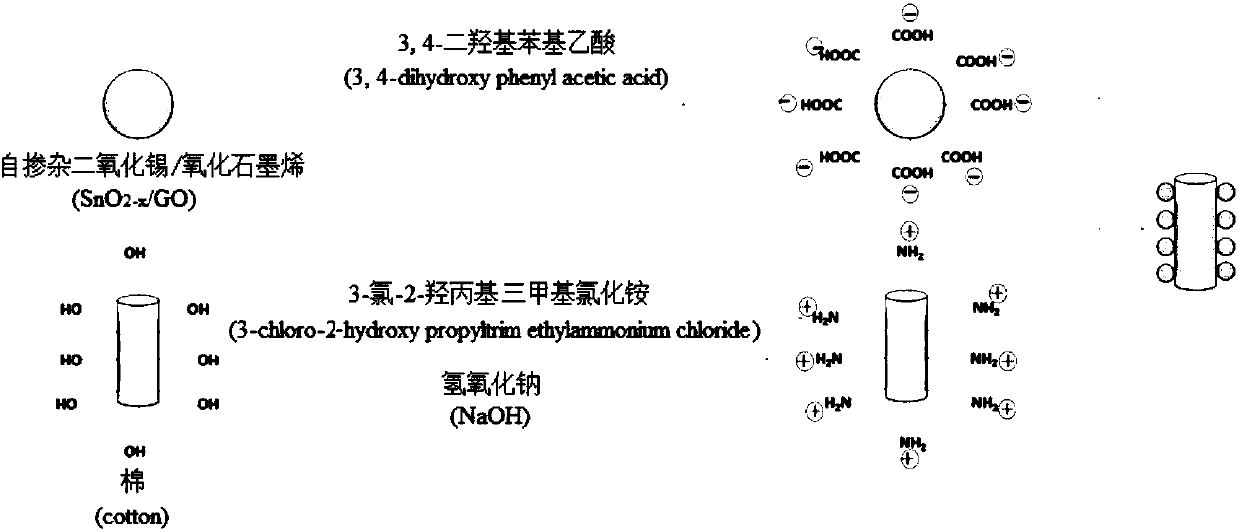

[0027] An embodiment of the present invention provides a method for preparing a visible light composite photocatalyst, comprising the following steps:

[0028] Step 101): preparing self-doped tin dioxide; the chemical formula of said self-doped tin dioxide is SnO 2-x , x represents the doping ratio of divalent tin, and the value of x ranges from 0 to 1. The value of x can be 0, 1 or a value between 0 and 1.

[0029] Step 102): preparing a visible light composite photocatalyst of graphene oxide and self-doped tin dioxide.

[0030] Step 103): Carrying out hydroxyl reaction on the visible light composite photocatalyst prepared in step 102) to make a carboxylated visible light composite photocatalyst.

[0031] Wherein, preferably, the process of step 101) is: adding tin tetrachloride pentahydrate and metal tin powder into water, stirring to form a transparent yellow solution. Preferably, in the transparent yellow solution, the molar ratio of tin tetrachloride pentahydrate to me...

Embodiment 1

[0044] A method for finishing cotton fabrics, comprising the steps of:

[0045] Step 1): preparing a visible light composite photocatalyst, including:

[0046] Step 101): Prepare self-doping tin dioxide: add tin tetrachloride pentahydrate and metal tin powder into water, stir to form a transparent yellow solution; in the transparent yellow solution, tin tetrachloride pentahydrate and metal tin powder The molar ratio is 1:10. Put the transparent yellow solution in a reaction kettle, react at 150°C for 24 hours, take out the reacted solution, cool to room temperature, and centrifuge to obtain a dark yellow precipitate; then wash the dark yellow precipitate with deionized water to remove impurities; finally, put The dark yellow precipitate was dried in a vacuum oven at 60°C for 24 hours to obtain self-doped tin dioxide doped with divalent tin.

[0047] Step 102): preparing a visible light composite photocatalyst of graphene oxide and self-doped tin dioxide; adding the self-dope...

Embodiment 2

[0052] A method for finishing cotton fabrics, comprising the steps of:

[0053] Step 1): preparation of visible light composite photocatalyst, including

[0054] Step 101): Prepare self-doping tin dioxide: add tin tetrachloride pentahydrate and metal tin powder into water, stir to form a transparent yellow solution; in the transparent yellow solution, tin tetrachloride pentahydrate and metal tin powder The molar ratio is 1:8. Put the transparent yellow solution in a reaction kettle, react at 120°C for 20 hours, take out the reacted solution, cool to room temperature, and centrifuge to obtain a dark yellow precipitate; then wash the dark yellow precipitate with deionized water to remove impurities; finally, put The dark yellow precipitate was dried in a vacuum oven at 50°C for 22 hours to prepare self-doped tin dioxide doped with divalent tin.

[0055] Step 102): preparing a visible light composite photocatalyst of graphene oxide and self-doped tin dioxide; adding the self-do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com