Antimicrobial bacterial cellulose and preparation method thereof

A bacterial cellulose, unsaturated technology, used in medical science, prosthesis and other directions, can solve the problems of low efficiency and stability of bactericide adsorption, bacterial cellulose does not have antibacterial function, harmful microorganism pollution, etc., to achieve high efficiency and long-lasting Bactericidal effect, high-efficiency and long-lasting antibacterial effect, long-lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] First aspect, the present invention provides a kind of preparation method of antibacterial bacterial cellulose, comprises the following steps:

[0030] (1) Provide bacterial cellulose;

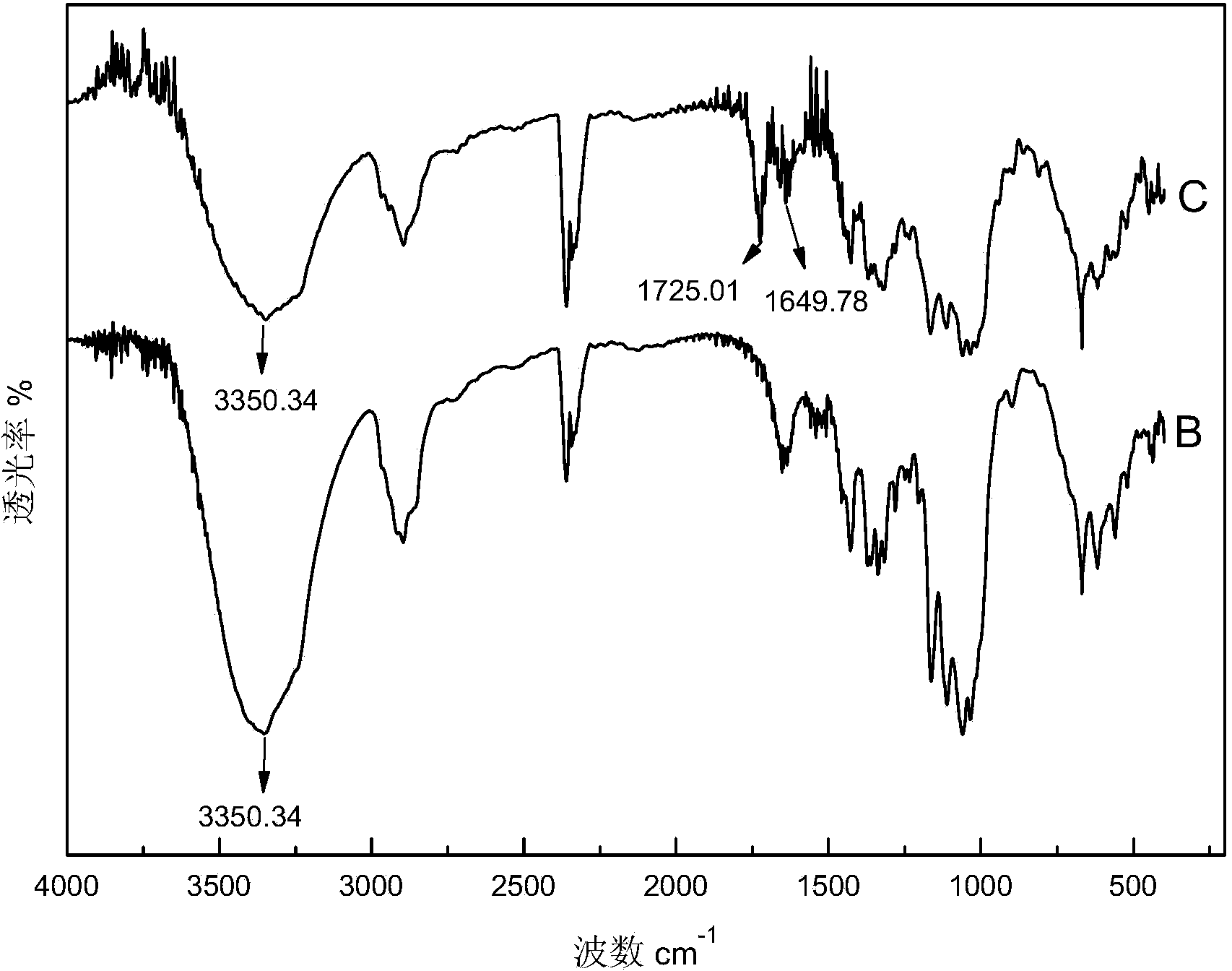

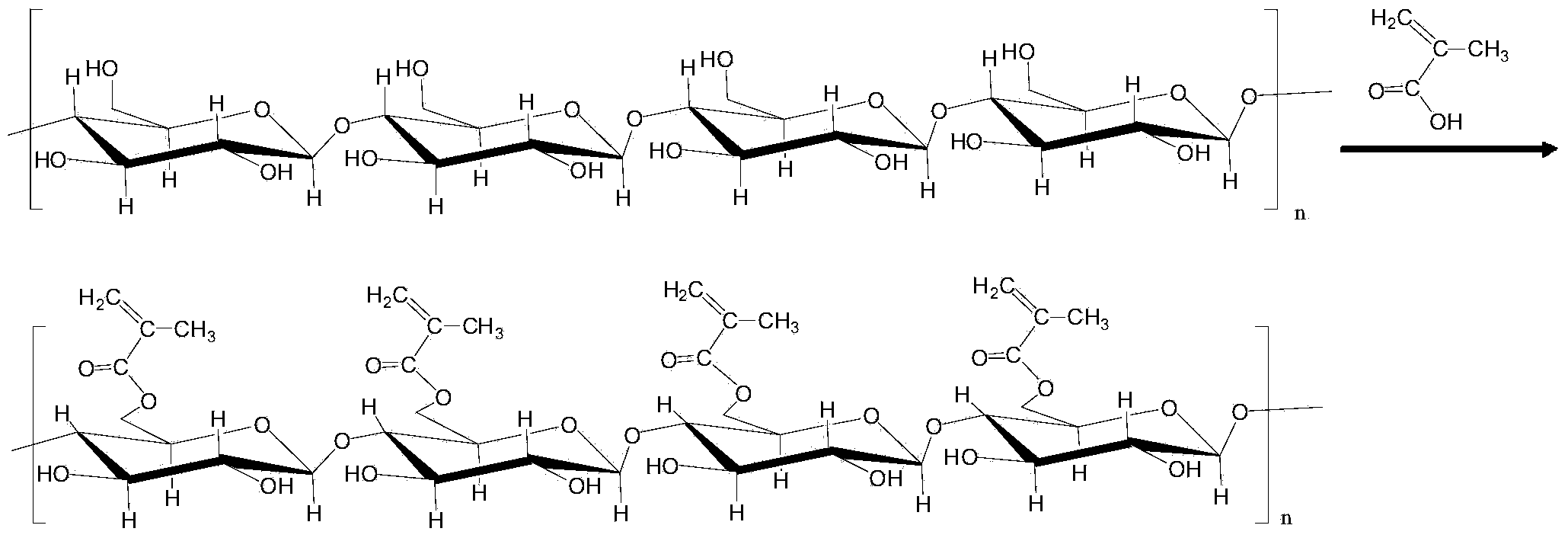

[0031] (2) Soak the bacterial cellulose in an unsaturated carboxylic acid, then add a polymerization inhibitor to obtain a mixed solution, add a catalyst to the mixed solution, and conduct an esterification reaction at room temperature for 1 to 4 hours to obtain a mixed solution containing Unsaturated bond esterified bacterial cellulose solution, after purification, to obtain dry esterified bacterial cellulose containing unsaturated bonds;

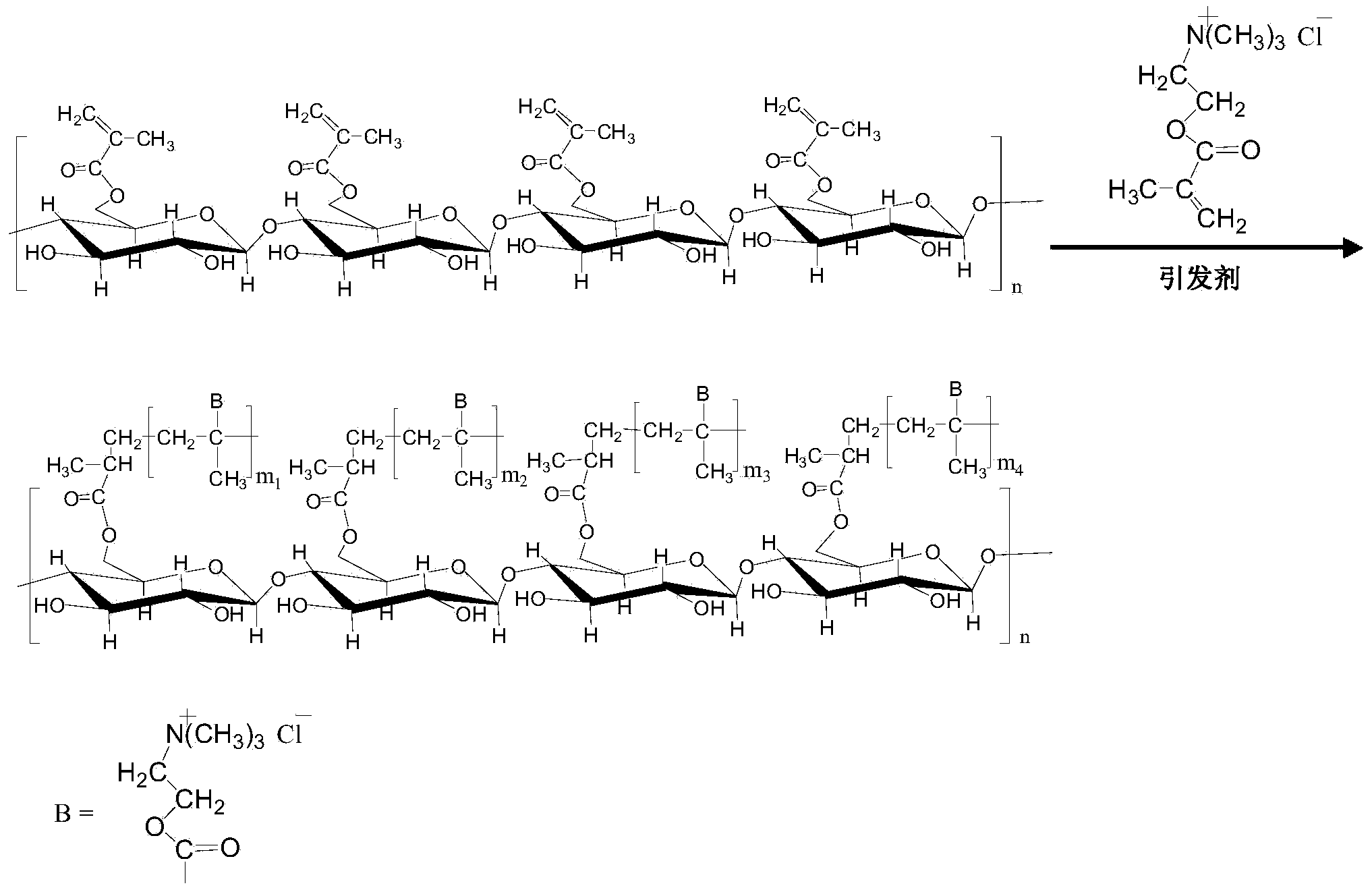

[0032] (3) After soaking the dried esterified bacterial cellulose containing unsaturated bonds in deionized water, under an inert atmosphere, add an unsaturated quaternary ammonium salt monomer and an initiator to obtain a reaction solution, and the reaction solution is Addition reaction and polymerization reaction are carried out at 50°C to 60°C f...

Embodiment 1

[0071] (1) Inoculate 1mL of Acetobacter xylinum into 100mL of culture medium, culture statically at 30°C until a bacterial cellulose film with a thickness of 5mm is obtained, and place the bacterial cellulose film in a sodium hydroxide solution with a concentration of 0.1mol / L. Shake and break the cells at 80°C for 30 minutes. After repeated three times, use deionized water to wash away the broken cells and sodium hydroxide until the surface pH of the bacterial cellulose membrane is neutral. After steam sterilization, freeze-dry for later use; the culture medium The ingredients are: 0.1g / mL glucose, 0.03g / mL peptone, 0.02g / mL yeast powder, 0.01g / mL disodium hydrogen phosphate, 0.005g / mL magnesium sulfate, 0.005g / mL ammonium sulfate, 0.005mL / mL corn syrup extract;

[0072] (2) Take 0.5 g of the bacterial cellulose membrane obtained in step (1), soak it in 20 mL of methacrylic acid for 2 hours, and add a polymerization inhibitor terephthalic acid whose mass is 0.1% of the total...

Embodiment 2

[0079](1) Inoculate 1mL of Acetobacter xylinum into 100mL of culture medium, culture statically at 30°C until a bacterial cellulose film with a thickness of 5mm is obtained, and place the bacterial cellulose film in a sodium hydroxide solution with a concentration of 0.1mol / L. Shaking and breaking the cells at 80°C for 30 minutes, repeated three times, washing the broken cells and sodium hydroxide with deionized water until the surface pH of the bacterial cellulose membrane was neutral, steam sterilized, freeze-dried for later use; The composition of the culture medium is: 0.4g / mL glucose, 0.06g / mL peptone, 0.03g / mL yeast powder, 0.02g / mL disodium hydrogen phosphate, 0.015g / mL magnesium sulfate, 0.01g / mL ammonium sulfate, 0.015mL / mL corn syrup extract;

[0080] (2) Take 0.4 g of the bacterial cellulose membrane obtained in step (1), soak it in 20ml of acrylic acid for 1 hour, add a polymerization inhibitor hydroquinone whose mass is 0.2% of the total mass of the bacterial cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com