Synthetic wax candle and preparation method thereof

A technology of synthetic wax and Fischer-Tropsch synthetic wax, which is applied in the field of candles, can solve the problems of not being able to know the properties of candles such as combustibility and stability, and not studying F-T Fischer-Tropsch synthetic wax candles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

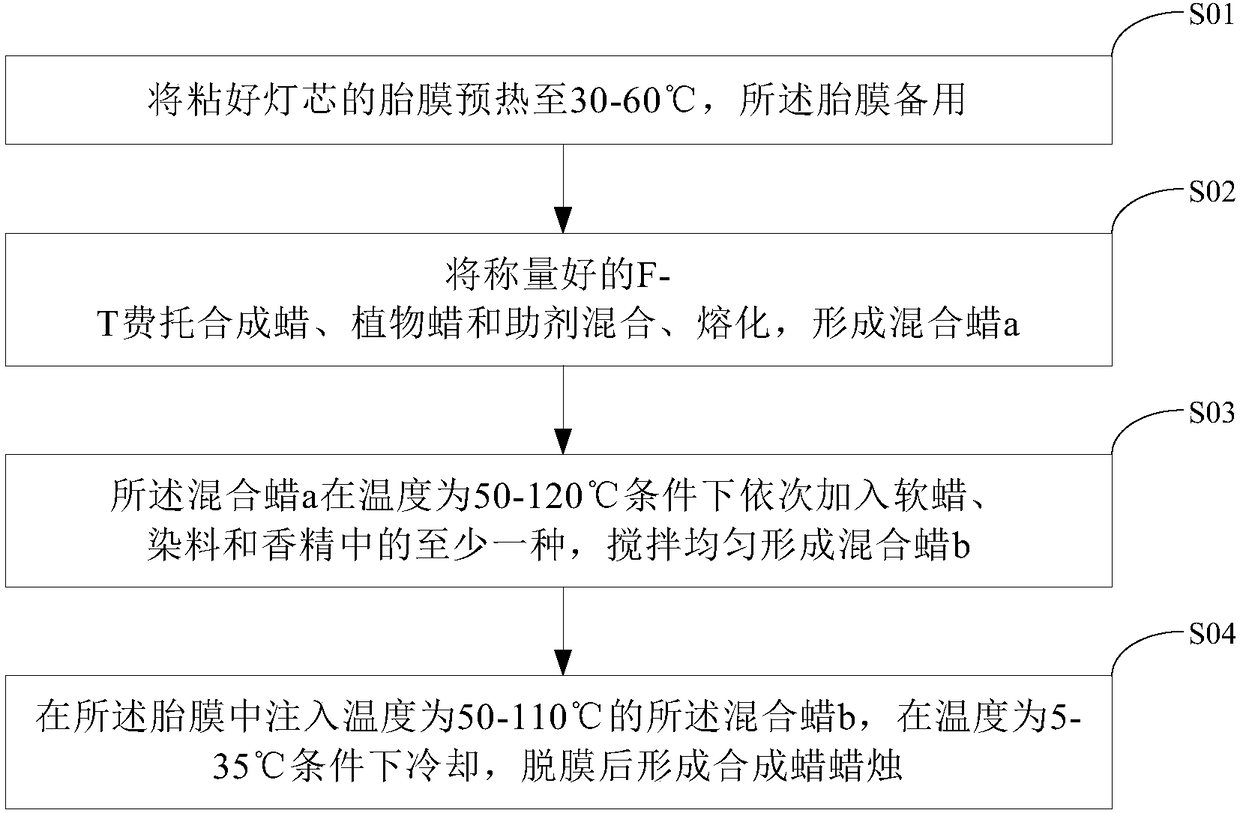

Method used

Image

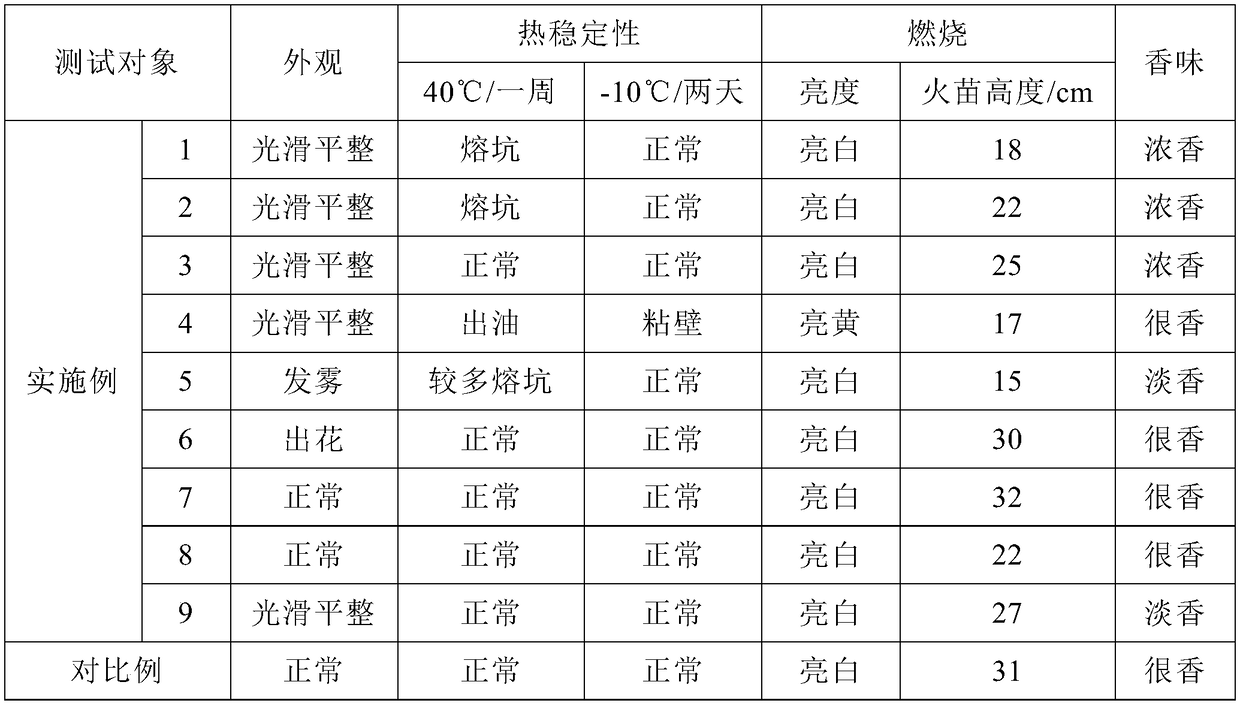

Examples

Embodiment 1

[0025] The preparation raw material of the synthetic wax candle that the embodiment of the present invention provides comprises according to parts by weight: F-T Fischer-Tropsch synthetic wax 45%, hydrogenated palm oil 45%, soft wax 3%, essence 5%, oil-locking agent 1% and anti-ultraviolet Additive 1%. Wherein, the melting point of F-T Fischer-Tropsch synthetic wax is 50° C., and the penetration is 18.

[0026] The synthetic wax candle that the embodiment of the present invention provides is cup wax, and the preparation method of this cup wax comprises:

[0027] S101: preheat the membrane with the wick glued to 30°C, and reserve the membrane for later use;

[0028] S102: Mixing and melting the weighed F-T Fischer-Tropsch synthetic wax, hydrogenated palm oil, soft wax, oil locking agent and anti-ultraviolet additive to form mixed wax a;

[0029] S103: add essence to mixed wax a at a temperature of 50°C, and stir evenly to form mixed wax b;

[0030] S104: Inject the mixed wax...

Embodiment 2

[0032] The preparation raw material of the synthetic wax candle that the embodiment of the present invention provides comprises according to parts by weight: F-T Fischer-Tropsch synthetic wax 60%, half-hydrogenated palm oil 30%, soft wax 3%, essence 5%, oil-locking agent 1% and β - Cyclodextrin 1%. Wherein, the melting point of F-T Fischer-Tropsch synthetic wax is 54° C., and the penetration is 15.

[0033] The synthetic wax candle that the embodiment of the present invention provides is cup wax, and the preparation method of this cup wax comprises:

[0034] S201: Preheat the membrane with the wick attached to 60°C, and reserve the membrane for later use;

[0035] S202: Mix and melt the weighed F-T Fischer-Tropsch synthetic wax, semi-hydrogenated palm oil, soft wax, oil-locking agent and β-cyclodextrin to form mixed wax a;

[0036] S203: add dye to mixed wax a at a temperature of 120°C, add essence at 80°C, and stir evenly to form mixed wax b;

[0037] S204: Inject the mixe...

Embodiment 3

[0039] The raw materials for the preparation of the synthetic wax candle provided by the embodiments of the present invention include: F-T Fischer-Tropsch synthetic wax 45%, hydrogenated soybean oil 45%, soft wax 3%, essence 5%, oil-locking agent 1% and anti-ultraviolet additive according to parts by weight 1%. Wherein, the melting point of F-T Fischer-Tropsch synthetic wax is 54° C., and the penetration is 15.

[0040] The synthetic wax candle that the embodiment of the present invention provides is cup wax, and the preparation method of this cup wax comprises:

[0041] S301: preheat the membrane with the wick attached to 35°C, and reserve the membrane for later use;

[0042] S302: Mixing and melting the weighed F-T Fischer-Tropsch synthetic wax, hydrogenated soybean oil, soft wax, oil-locking agent and anti-ultraviolet additive to form mixed wax a;

[0043] S303: add essence to mixed wax a at a temperature of 60°C, and stir evenly to form mixed wax b;

[0044] S304: Injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com