Patents

Literature

99 results about "Hydrogenated Palm Oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elaeis Guineensis (Palm) Oil, Elaies Guineensis (Palm) Kernel Oil, Hydrogenated Palm Oil and Hydrogenated Palm Kernel Oil are obtained from the Elaeis guineensis tree. Crude Palm Oil is one of the richest natural sources of beta carotene, which gives crude Palm Oil a deep red color.

Preparation method of high-quality glycerin monostearate

ActiveCN102964245AFully purifiedControl acid valueOrganic compound preparationCarboxylic acid esters preparationHydrogenated Palm OilDistillation

The invention discloses a preparation method of high-quality glycerin monostearate. The method comprises the steps of reacting hydrogenated palm oil and glycerol under strong base catalysis to generate ester, and carrying out four-stage distillation to obtain high-quality glycerin monostearate. The acid value of the product is reduced to below 0.4, the freezing point is raised to 64-66 DEG C, the quality of the product is improved, and the difficulty of the prior art is overcome. Besides, the problems in the prior art that the pipeline is blocked by slag produced in the distillation process, the production efficiency is lowered, the product quality is reduced, the production is discontinuous and the processing efficiency is low resulting from scaling of an evaporating surface and a condensing surface are solved. Glycerol and hydrogenated palm oil can be recycled, so that the cost is low, the yield is high, the product quality is improved, and the whole processing controllability is high. The high-quality glycerin monostearate is suitable for industrial production.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

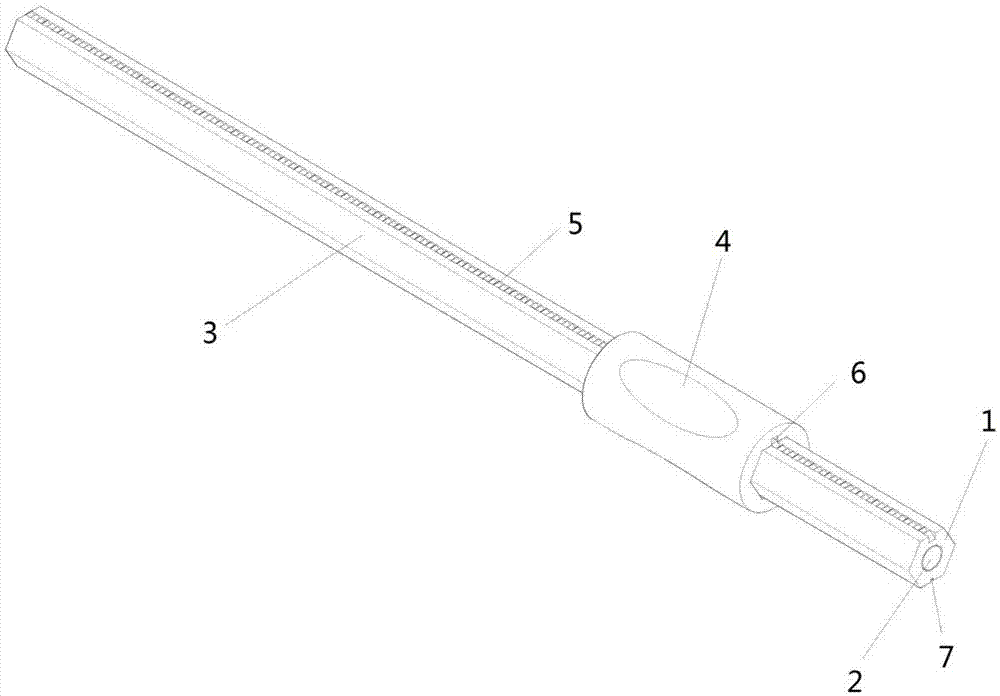

Plastic pencil and preparation method thereof

The present invention relates to a plastic pencil, which comprises a pencil rod, a pencil core and a pencil skin, wherein the components of the pencil rod comprise 30-50 wt% of polystyrene (PS), 10-30 wt% of a synthetic rubber, 2-8 wt% of a nucleating agent, 30-50 wt% of talc powder, and 5-10 wt% of calcium stearate, and are added with polyethylene (PE), the components of the pencil core comprise 20-50 wt% of polystyrene (PS), 2-10 wt% of an organosilicon polymer, 30-60 wt% of graphite powder, 2-10 wt% of hydrogenated palm oil, 2-10 wt% of oleic acid amide, and 5-10 wt% of a synthetic rubber, and the components of the pencil skin comprise 70-90 wt% of polystyrene (PS), 5-20 wt% of color master batch, and 2-10 wt% of hydrogenated palm oil. According to the present invention, the pencil rod and the pencil core are not easily broken, the pencil core has characteristics of good striking degree, good brightness and dreg falling resistance, and the manufacturing cost is low.

Owner:JIANGXI JISHUI GEMSTAR STATIONERY CO LTD

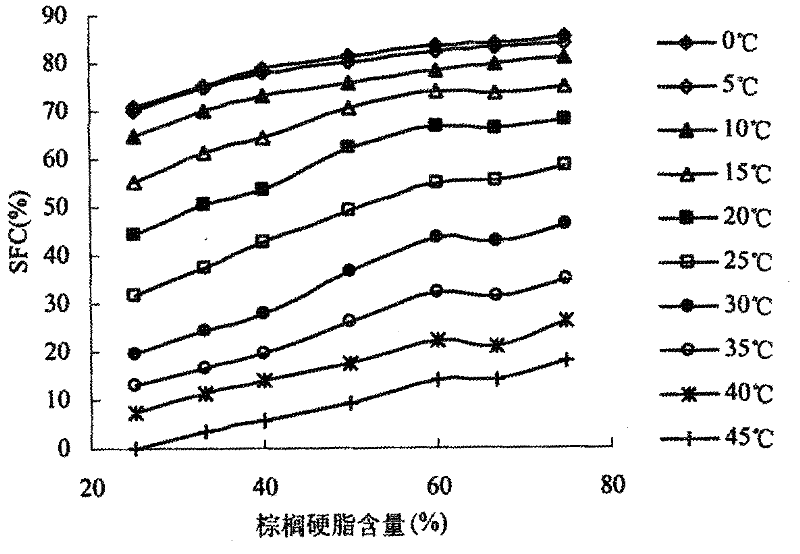

Method for preparing low/zero-trans fatty acid shortening by enzymatic interesterification

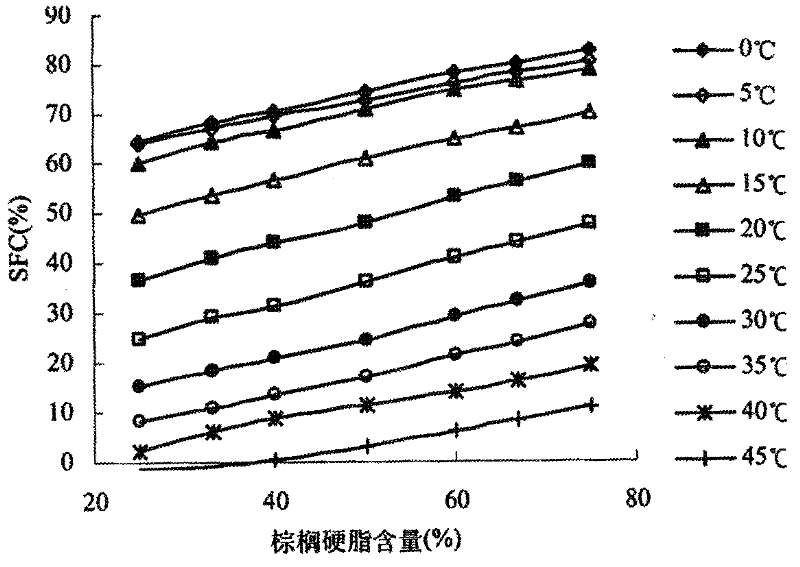

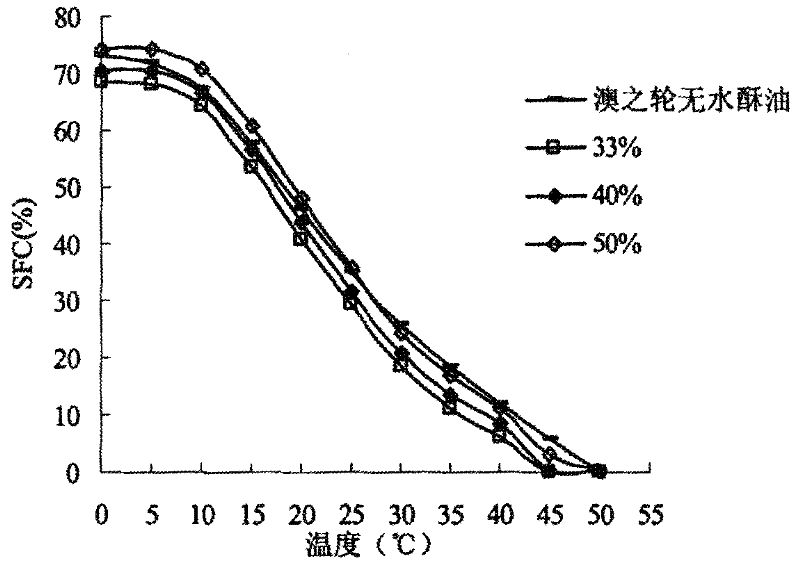

Belonging to the technical field of edible oil processing, the invention relates to a method for preparing low / zero-trans fatty acid shortening by enzymatic interesterification. The method of the invention adopts an immobilized lipase Lipozyme RM IM to catalyze lard and palm stearin or extremely hydrogenated oil (including extremely hydrogenated soybean oil, extremely hydrogenated canola oil, extremely hydrogenated palm oil and extremely hydrogenated cottonseed oil) for interesterification so as to prepare shortening. The solid fat content (SFC) of a reaction product under a temperature of 20DEG C is taken as an index, and by systematically studying the influences of temperature, adding amount of enzyme and time on an interesterification reaction, obtaining ideal technical parameters: a reaction temperature of 60-90DEG C, an enzyme adding amount of 6%-12%, and a reaction period of 1h-3h. In the invention, the compatibility and crystal form of a mixture system before and after an interesterification reaction are studied through an isothermal curve and an X-ray diffraction technology. Results indicate that: after interesterification, the compatibility of the mixture system is obviously improved, the crystal form is converted from beta type into beta' type, and the shortening prepared in the invention is superior to the market shortening in terms of application in bread baking. Widening the range of lard application, the method of the invention brings the abundant lard resources in our country into full play.

Owner:无锡食赫兹未来食品科技有限公司

Lotus-active-ingredient-containing skin cleansing composition and preparation method thereof

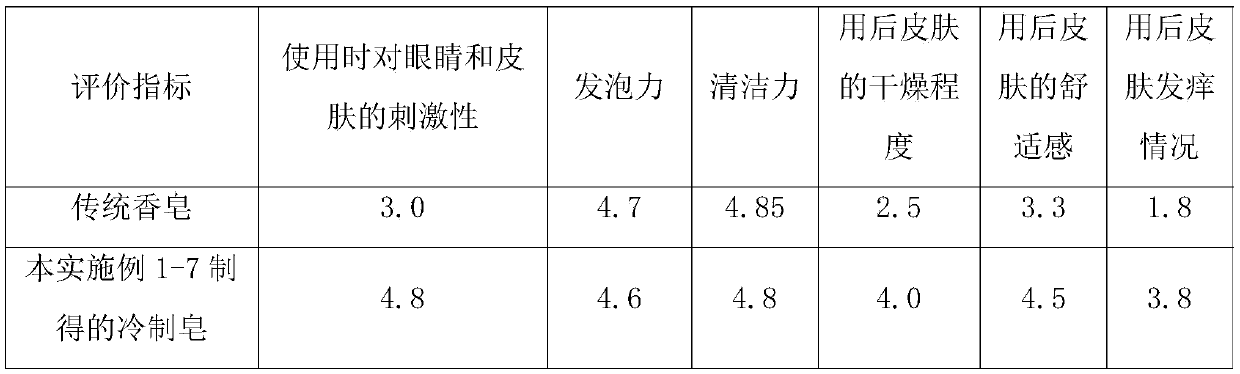

The present invention provides a lotus-active-ingredient-containing skin cleansing composition and a preparation method thereof, and the composition comprises the following ingredients: hydrogenated olive oil, coconut oil, hydrogenated palm oil, hydrogenated almond oil, avocado tree fruit fat oil, avocado oil, hydrogenated soybean oil, wheat germ oil, a tea extract, sodium hydroxide, allantoin, tea powder, nuciferine, lotus pollen, lotus seed powder, and essence and deionized water. The lotus-active-ingredient-containing skin cleansing composition makes full use of natural active ingredients in the lotus, has good skin cleansing effect, also has the effects of conditioning and maintaining the skin, and is mild and low-stimulation, after use of the skin cleansing composition, the skin is not easy to dry, has good comfortable feeling and is not easy to itch.

Owner:CHONGQING PUPU BIOTECH

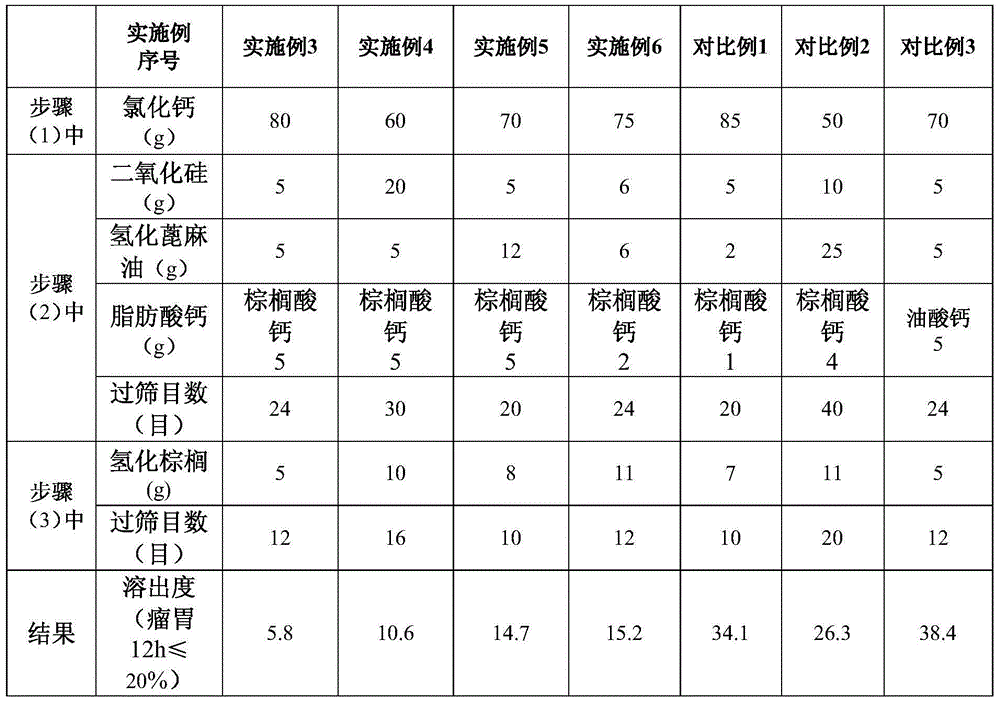

Envelope calcium chloride and preparation method thereof

ActiveCN104585480AEnsure safe passageImprove bioavailabilityAnimal feeding stuffHydrogenated Palm OilChloride

The invention discloses envelope calcium chloride and a preparation method thereof. The envelope calcium chloride is prepared from the following raw materials in parts by weight: 5-20 parts of hydrogenated palm oil, 5-20 parts of hydrogenated castor oil, 4-30 parts of silicon dioxide, 1-20 parts of fatty acid calcium and 60-85 parts of calcium chloride. The preparation method is characterized in that the envelope calcium chloride which can be taken as a feed additive is obtained by taking the hydrogenated palm oil, the hydrogenated castor oil, silicon dioxide and fatty acid calcium as envelope materials and taking the calcium chloride as a core material through a multiple-time pelletizing and enveloping technology. The envelope calcium chloride can make up the defects that the calcium chloride raw material easily absorbs water, and also can guarantee that calcium chloride safely passes through a rumen to smoothly reach the intestinal tract, so that the biological utilization rate of calcium chloride is greatly increased.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

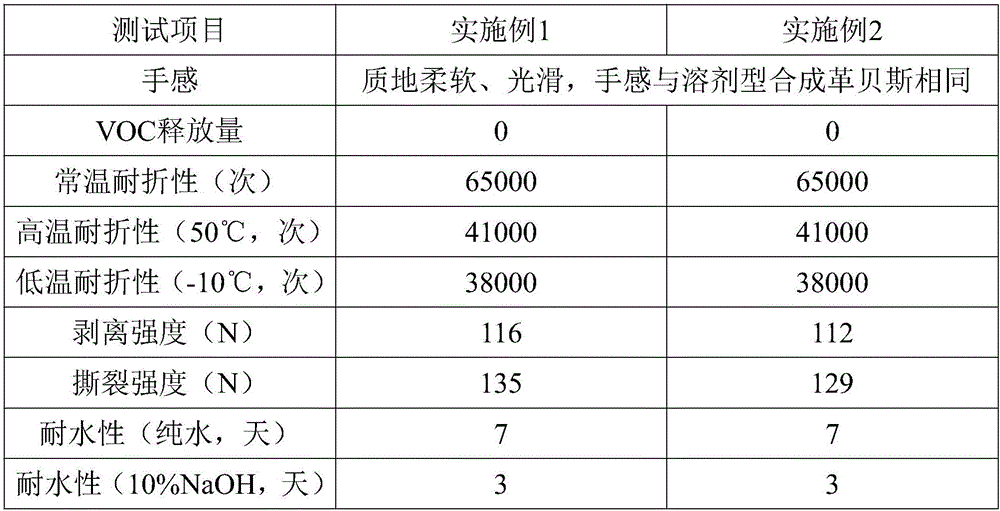

Waterborne polyurethane slurry for producing synthetic leather bass through wet method

The invention discloses waterborne polyurethane slurry for producing a synthetic leather bass through a wet method. The waterborne polyurethane slurry relates to the technical field of synthetic leather processing, and is prepared from the following raw materials in parts by weight: 60 to 70 parts of waterborne polyurethane resin, 5 to 10 parts of waterborne acrylic resin, 5 to 10 parts of hydrogenated ester gum, 4 to 8 parts of polyvinyl alcohol resin, 4 to 8 parts of chlorinated polyethylene, 3 to 6 parts of terpene resin, 3 to 6 parts of microcrystalline cellulose, 2 to 4 parts of C5 petroleum resin, 2 to 4 parts of hydrogenated palm oil, 2 to 4 parts of activated clay, 1 to 2 parts of dipentaerythritol, 1 to 2 parts of sesbania gum, 0.5 to 1 part of tea seed powder, 0.5 to 1 part of molecular sieve raw powder, 0.5 to 1 part of nanometer titanium dioxide, and 200 to 250 parts of water. The waterborne polyurethane slurry provided by the invention adopts the water as a solvent, so that the problems of environmental pollution and harm to human health existed by using an organic solvent are avoided; the curing time of an intumescent coating is short, no harmful gas escapes during a curing process, and the prepared synthetic leather bass and a solvent type synthetic leather bass have close textures and operational performance.

Owner:南平慧薇网知识产权营运有限公司

Efficient and stable anti-light and anti-oxidation composition and application thereof

InactiveCN111557861ARemarkable anti-blue lightImprove antioxidant capacityCosmetic preparationsToilet preparationsPolymer scienceAstaxanthin

The invention discloses an efficient and stable anti-light and anti-oxidation composition, which is prepared from the following components in parts by weight: 0.0001 to 0.2 part of astaxanthin; and 0.01 to 2.0 parts of glucosylrutin. The astaxanthin and the glucosylrutin are compounded, the light stability is high, and good light damage resistance and oxidation resistance effects are achieved. Theefficient and stable anti-light and anti-oxidation composition disclosed by the invention can be applied to preparation of skin care products, including smoothing toner, toner, essence, emulsion, face cream, essence, facial masks, sun cream, spray, essential oil, massage cream and the like. The efficient and stable anti-light and anti-oxidation composition disclosed by the invention can also be compounded with glycerol, glyceryl stearate, hydrogenated palm oil / palm kernel oil PEG-6 esters, lysolecithin, tocopherol and water to form a compound.

Owner:GUANGZHOU BIOHOPE CO LTD

Tasteless nutritional supplement containing free amino acids

A nutritional composition includes proteinaceous material and micronutrients, wherein at least 90 wt % of the proteinaceous material and micronutrients is coated with a fat-containing layer containing at least 90 wt % of edible fat, based on the total weight of the layer, and having a SFC of more than 95% at 30° C., wherein the proteinaceous material includes at least 90 wt % free amino acids, based on its proteinaceous weight content, the micronutrients and proteinaceous material in the coated particulate material forming separate particles, and wherein the coated particulate material and the coating are free from phospholipids. It is preferred that the coating is made from hydrogenated palm oil.

Owner:SHS INTERNATIONAL

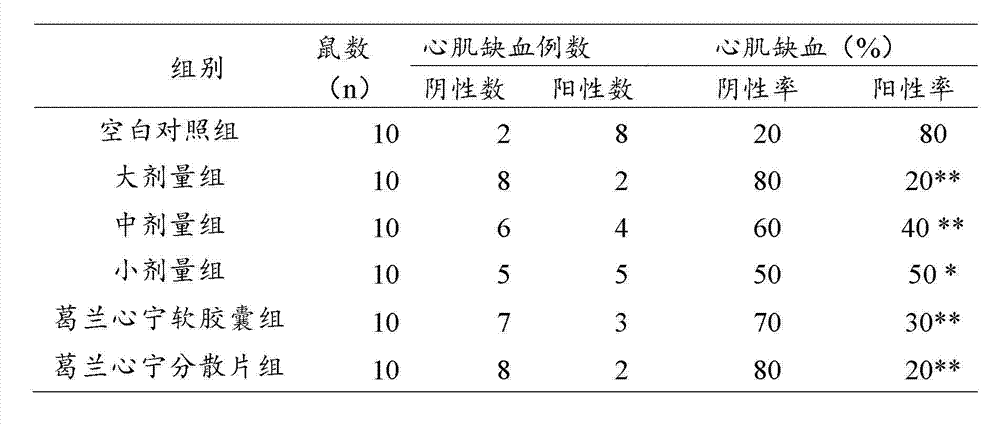

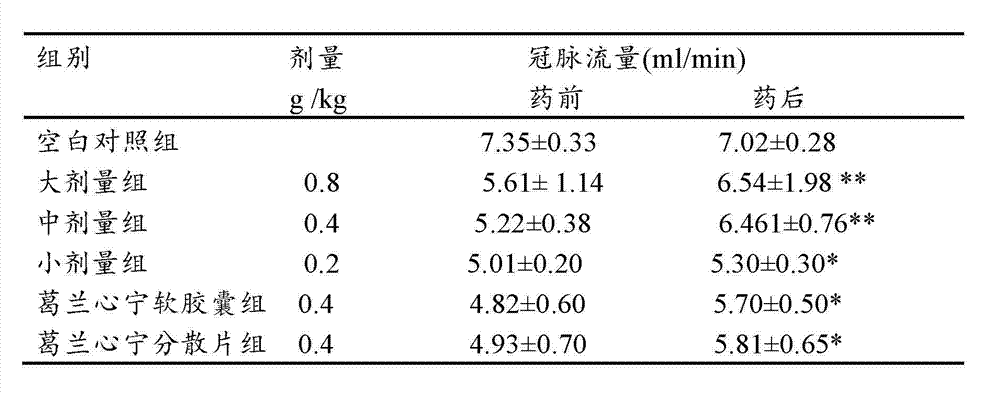

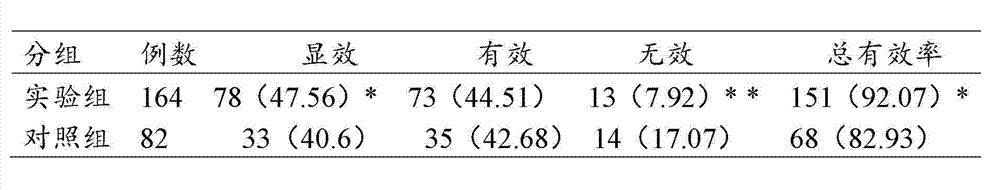

Gelan Xinning soft capsule for treating coronary disease and angina and preparation method thereof

ActiveCN102872227AThe preparation method is simple and controllableShorten the production cycleMetabolism disorderCapsule deliveryCoronary artery diseaseSide effect

The invention provides a Gelan Xinning soft capsule for treating coronary disease and angina and a preparation method of the Gelan Xinning soft capsule. The medicine comprises the following raw materials in parts by weight or is composed of the following raw materials in parts by weight: 4 to 60 parts of radix puerariae general flavones, 1 to 30 parts of fructus crataegi extract, 0.4 to 10 parts of gynostemma pentaphylla general flavones, 5 to 100 parts of soybean oil or salad oil, 0.1 to 3 parts of beewax, 0.4 to 10 parts of hydrogenated palm oil, 0.2 to 5 parts of soyabean lecithin, 0.01 to 0.5 parts of dimeticone, 8 to 150 parts of gelatin, 3 to 80 parts of glycerol, 8 to 150 parts of purified water and 0.01 to 0.8 parts of ethylparaben. The preparation method of the medicine provided by the invention is simple, the processing cost is low, the efficacy is remarkable and the Gelan Xinning soft capsule is free from any toxic and side effects.

Owner:XIAN CHIHO PHARMA

Solid pasty eyebrow pencil

PendingCN111529433AReduce complaintsImprove satisfactionCosmetic preparationsMake-upCaprylyl GlycolHydrogenated Palm Oil

The invention discloses a solid pasty eyebrow pencil. The eyebrow pencil comprises the following components: group a: hydrogenated soybean oil, hydrogenated palm oil, hydrogenated castor oil, hydrogenated castor oil and C10-18 triglyceride; group b: mica powder and toner pigment; and group c: phenoxyethanol, caprylyl glycol and vitamin acetate. A preparation method comprises the following steps: sequentially adding the components in the group a into a melting pot in proportion, heating the components to 105 DEG C, and performing uniform stirring; then keeping stirring and adding the raw materials of the group b and the group c, and performing uniform stirring; and uniformly grinding the mixed raw materials for three times, extruding for color matching, and after the color is confirmed, performing casting to obtain the eyebrow pencil.

Owner:浙江美雪化妆品有限公司

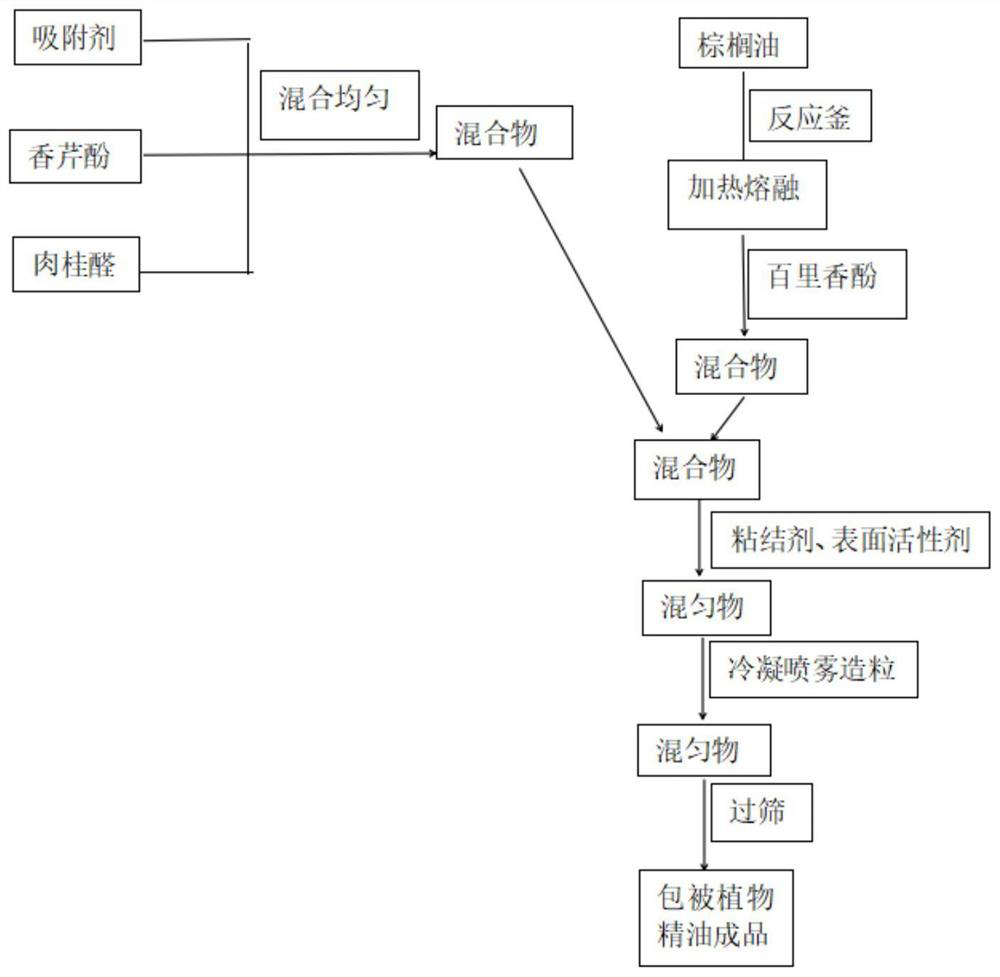

Coated plant essential oil for piglets and preparation method of coated plant essential oil

PendingCN112544808AGood antibacterial effectImprove the bactericidal effectAccessory food factorsWorking-up animal fodderSpray GranulationHydrogenated Palm Oil

The invention discloses coated plant essential oil for piglets and a preparation method of the coated plant essential oil, and belongs to the technical field of animal husbandry feed. The plant essential oil is prepared from the following raw materials in percentage by mass: 3-6% of thymol, 3.5-7% of carvacrol, 3.5-7% of cinnamyl aldehyde, 5-20% of a binder, 1-10% of a surfactant, 5-20% of an adsorbent and 45-62% of hydrogenated palm oil. The preparation method comprises the following steps: stirring the adsorbent, the carvacrol and the cinnamyl aldehyde for uniform adsorption and mixing; taking the hydrogenated palm oil, heating the hydrogenated palm oil until the hydrogenated palm oil is completely molten, adding the thymol while stirring, adding the obtained mixture after the thymol isdissolved, adding the binder and the surfactant, and performing uniform stirring to obtain a mixture; and carrying out condensation spray granulation on the obtained mixture, and finally carrying outscreening to obtain coated plant essential oil finished product particles for piglets. The plant essential oil has the characteristics of volatilization resistance, oxidation resistance and stability,and can protect intestinal health of the piglets.

Owner:WUXI ZHENGDA POULTRY

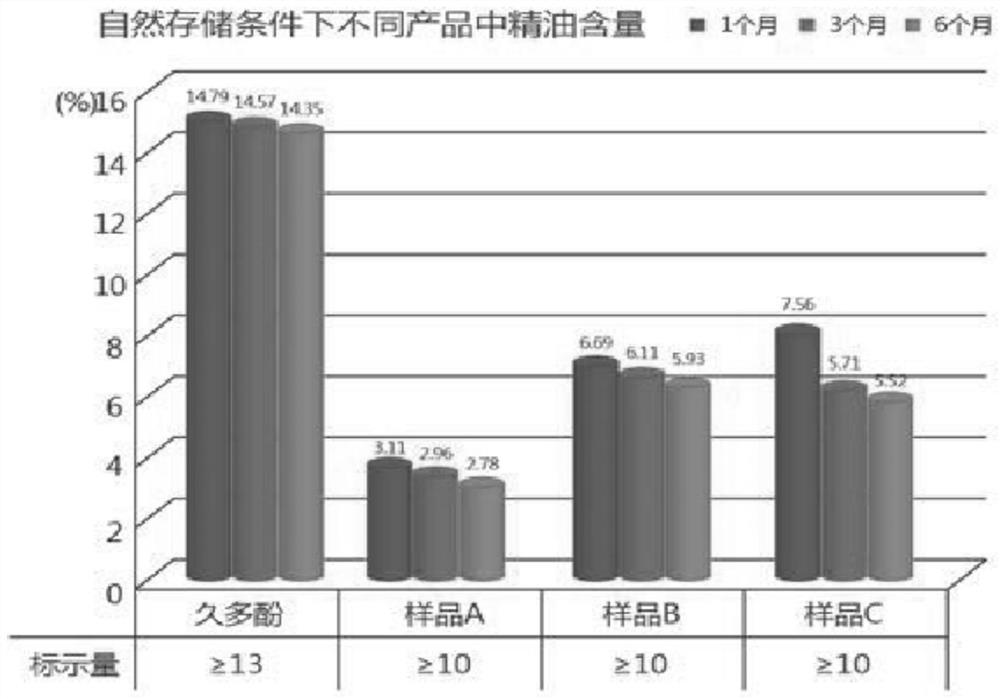

Preparation auxiliary agent of volatile oil obtained by extracting traditional Chinese medicine

InactiveCN107158407AReduce loss rateImprove stabilityOil/fats/waxes non-active ingredientsHydrogenated Palm OilChinese drug

The invention discloses a preparation auxiliary agent of volatile oil obtained by extracting traditional Chinese medicine, which relates to the technical field of a traditional Chinese medicine extract product preparation. The preparation auxiliary agent comprises the following raw materials in parts by weight: 10-15 parts of poloxamer / polyglutamic acid, 3-5 parts of microcrystalline cellulose, 1-3 parts of pregelatinized hydroxypropyl starch / citric acid, 0.5-1 part of sorbitol, and 0.5-1 part of hydrogenated palm oil. The prepared preparation auxiliary agent is used for inclusion of the volatile oil obtained by extracting traditional Chinese medicine, the instant inclusion rate after inclusion can reach 90% and above, the inclusion rate of the preparation after 6 months can reach 85% and above, and the inclusion rate of the preparation after 12 months can reach 80% and the above.

Owner:ANHUI RENZHITANG PHARMA CO LTD

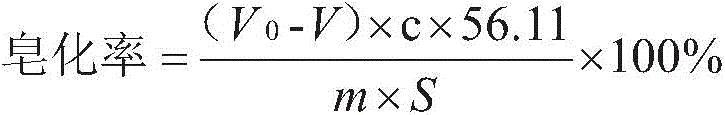

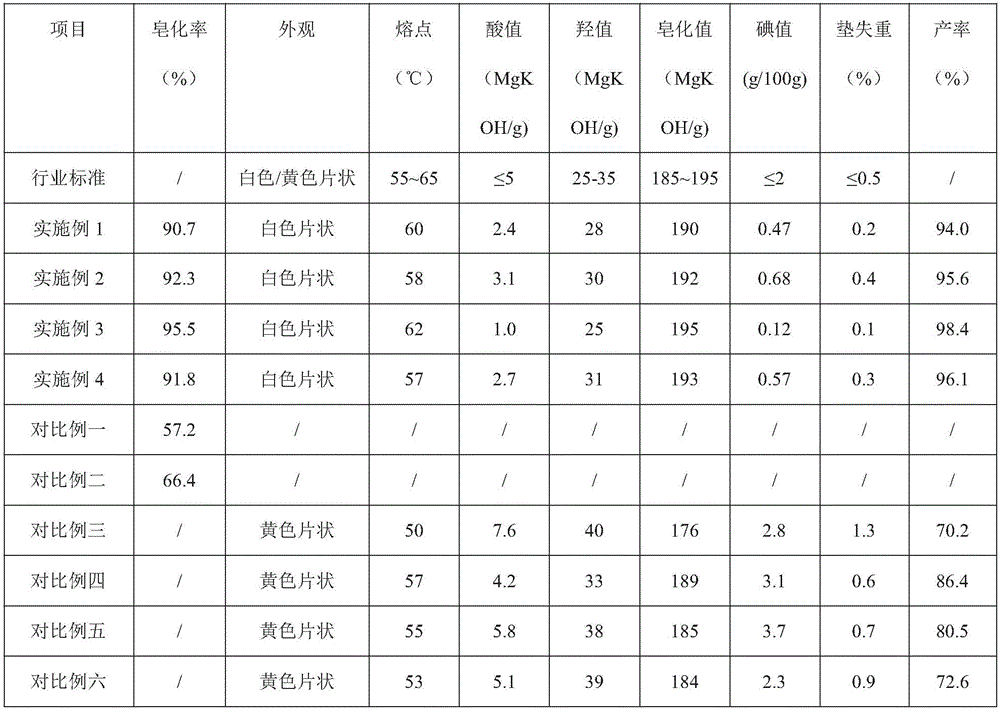

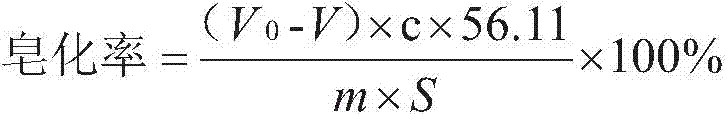

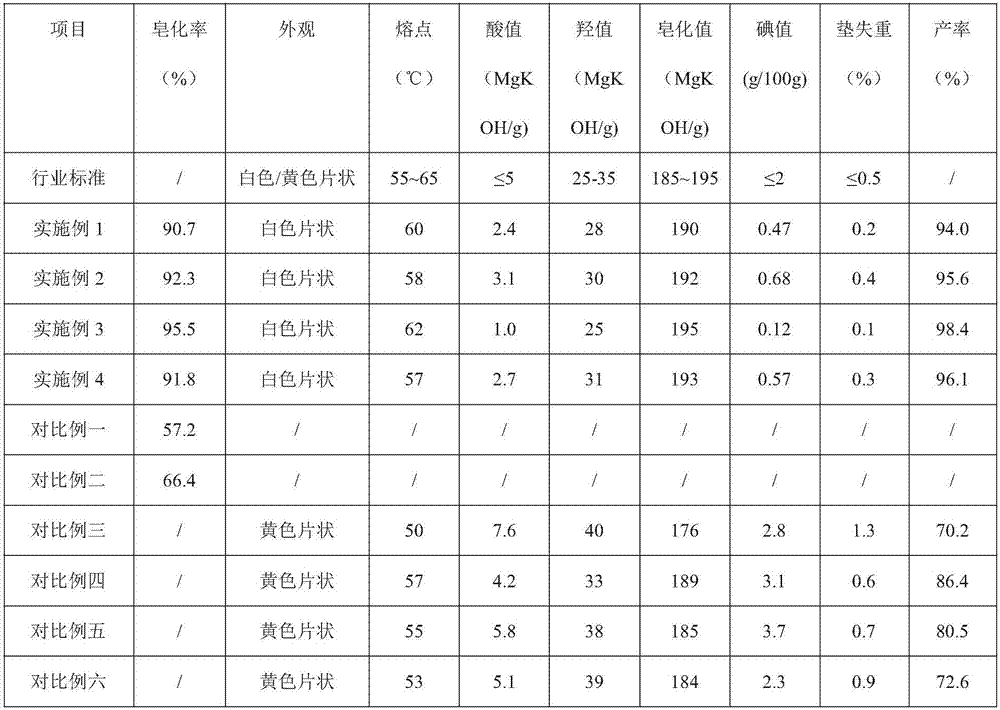

Method for preparing pentaerythritol stearate from hydrogenated oil

ActiveCN105753698AHigh saponification rateHigh acid valuePreparation from carboxylic acid saltsOrganic compound preparationDistillationStearic acid

The invention discloses a method for preparing pentaerythritol stearate from hydrogenated oil.The method includes the following steps that S1, a sodium hydroxide solution is added to hydrogenated palm oil, microwave processing is conducted, a reaction is conducted under stirring, and saponified matter is obtained; S2, a sulfuric acid solution is added to the saponified matter till the pH value is 1 to 2, the material is transferred into a distillation tower, and stearic acid is obtained after distillation is completed; S3, stearic acid, pentaerythritol and a catalyst are put, the material is heated, negative pressure is controlled, and a reaction is conducted; S4, then the vacuum degree is increased to 0.07-0.09 mpa, the material is heated to 155-165 DEG C, and a reaction is conducted for 130-150 min under heat preservation at constant pressure; S5, cooling is conducted after an esterification condensation reaction is completed, kieselguhr is added for decoloration and deordorization, the material enters a plate-and-frame filter press, filter cakes are removed, filtrate is taken and subjected to powder spraying, bead spraying and slicing, and packaging and storage are conducted.The method is stable, reliable, high in yield and capable of achieving industrial production, and the prepared pentaerythrityl tetrastearate product is good in whiteness, low in acid value and high in purity.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

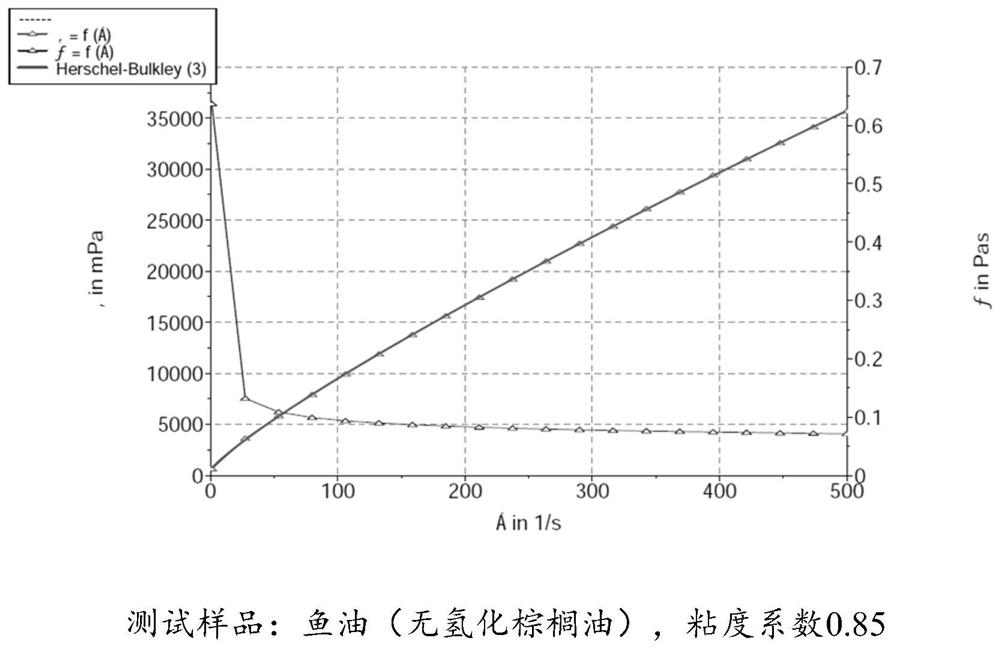

Chewable and edible oil-in-water gel composition and preparation method and application thereof

ActiveCN111803439AHigh fat contentImprove delivery efficiencyFlexible coversWrappersPhospholipinCarrageenan

The invention relates to a chewable and edible oil-in-water gel composition, which is characterized by comprising the following components based on the total weight of the gel composition: (1) 1-15wt%of a first gelling agent selected from one or more of gelatin, carrageenan, pectin, konjac glucomannan and guar gum; (2) 0.1-7wt% of a stabilizer, wherein the stabilizer is a mixture of 2-5wt% of hydrogenated palm oil, palm stearate or beewax and 0.2-1wt% of phospholipid; and (3) 55-70wt% of other grease except hydrogenated palm oil and / or palm stearate. The invention further relates to a preparation method and application of the gel composition.

Owner:SIRIO PHARMA CO LTD

Primary decolorizer for treating high-chromaticity chemical industry wastewater

InactiveCN106587196ANo increase in difficultyEasy to useWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionChemical industryCarrageenan

The invention discloses a primary decolorizer for treating high-chromaticity chemical industry wastewater and relates to the technical field of treatment of pesticide wastewater. The primary decolorizer is prepared from the following raw materials in parts by weight: 10-15 parts of volcanic ash, 10-15 parts of rock flour, 5-10 parts of dry wheat straw powder, 3-5 parts of sodium carboxymethyl cellulose, 2-4 parts of column chromatography silica gel, 1-2 parts of raw molecular sieve powder, 1-2 parts of pregelatinized starch, 0.5-1 part of carrageenan, 0.5-1 part of sodium gluconate, 0.5-1 part of aluminum magnesium silicate, 0.3-0.5 part of calcium propionate, 0.3-0.5 part of hydrogenated palm oil and 0.1-0.2 part of nano zinc oxide. According to the decolorizer disclosed by the invention, the chromaticity reduction rate can reach 95% or more, and the COD value can be lowered by 50% or more; and the decolorizer is precipitated out in a precipitate manner and can be removed from the wastewater through filtering.

Owner:ANHUI SUQI CHEM

Preparation method of monoglyceride particles

InactiveCN103664592AImprove efficiencyGood light colorOrganic compound preparationCarboxylic acid esters preparationPlastics industryMonoglyceride

The invention relates to a preparation method of monoglyceride particles. The preparation method is characterized in that the monoglyceride particles are directly synthesized by adopting hydrogenated palm oil and glycerinum; a proper alkaline substance is added to adjust the acidity; activated clay is added to decolorize; decolorized monoglyceride liquid is conveyed to a spraying granulator with an air cooling function; monoglyceride mist liquid sprinkling from a spray gun from top to bottom forms the monoglyceride particles after being air-cooled. The monoglyceride particles are 0.8-1 micron. By adopting the preparation method, the product is light in color, good in glossiness, and fine in particle, and has better mobility and lubricity. The production equipment is high in efficiency, large in yield, and low in cost. The product produced by the method is especially applicable to being used as a lubricating agent in plastic industry.

Owner:江苏向阳科技有限公司

Polyester fiber treating agent prepared from hydroxyethyl methylacrylate

The invention discloses a polyester fiber treating agent prepared from hydroxyethyl methylacrylate, and relates to the technical field of chemical industries. The polyester fiber treating agent is prepared from the following raw materials in parts by weight: 15-20 parts of hydroxyethyl methylacrylate, 10-15 parts of polyvinyl alcohol, 5-10 parts of glycidyl methacrylate, 3-6 parts of chlorinated polyvinyl chloride, 3-6 parts of polyvinyl acetate, 2-4 parts of hydrogenated ester gum, 2-4 parts of hexamethoxymethylmelamine, 2-4 parts of a static inhibitor, 1-2 parts of rice bran wax, 1-2 parts of lanolin alcohol, 1-2 parts of cetyl alcohol, 0.5-1 part of hydrogenated palm oil, 0.5-1 part of dipentaerythritol, and 0.3-0.5 part of a maleic anhydride grafting compatilizer. On one hand, by adoption of a static electricity eliminating way, the flexibility of a polyester fiber is effectively improved, and the problem of pilling is solved, and on the other hand, the dye-uptake of a dye on the polyester fiber is remarkably improved, and the color fastness of the dye is strengthened.

Owner:CHIZHOU FANGDA SCI & TECH CO LTD

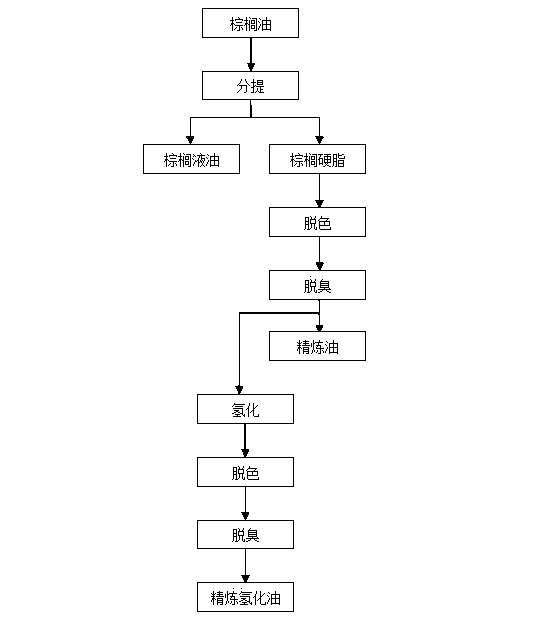

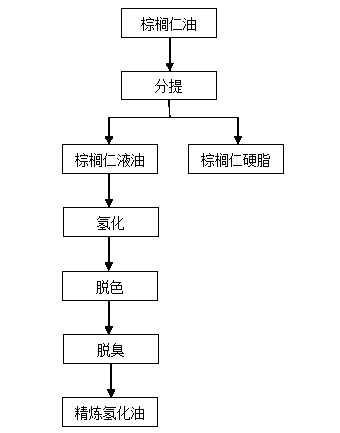

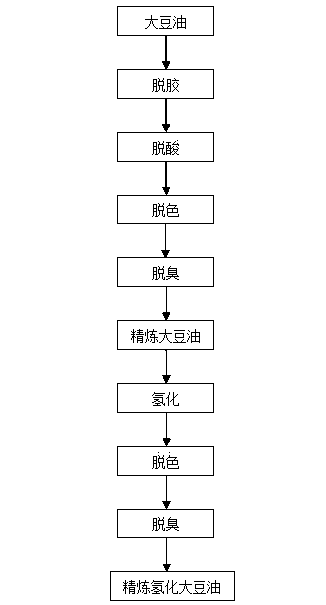

Method for preparing candle base oil by using vegetable oil

The invention discloses a method for preparing candle base oil by using vegetable oil. The method comprises the following steps: i) carrying out fractionation and / or hydrotreating on the vegetable oil; ii) adding a decolorising agent to the vegetable oil processed in the step i), and carrying out vacuum decoloring treatment; iii) carrying out deodorization treatment on the decolorized vegetable oil obtained in the step ii), so as to obtain the candle base oil. The vegetable oil is adopted to carry out fractionation and / or hydrotreating, and then decoloring and deodorization treatment is carried out to obtain palm stearin, hydrogenated palm oil, hydrogenated palm kernel oil and hydrogenated soybean oil with different application performances as the candle base oil. Whole vegetable oil materials are provided for candle production enterprises to produce different candles, the production cost and the export cost are reduced, and the method is environmentally friendly.

Owner:丰益油脂科技(连云港)有限公司

Tea seed contained handmade soap and manufacture process thereof

ActiveCN108485851AGood effectEasy to cleanSurface-active non-soap compounds and soap mixture detergentsBetaineSucrose

The invention provides a tea seed handmade soap, which is prepared from 18-25 parts of camellia oil, 18-20 parts of coconut oil, 10-15 parts of olive oil, 10-18 parts of hydrogenated palm oil, and 00032-0.00036 part of neroli essential oil, 15-20 parts of cocoyl glutamic acid, 10-20 parts of sodium lauroyl glutamate, 10-25 parts of tea seed powder, 10-18 parts of grape seed oil, 15-25 parts of jojoba seed oil, 10-15 parts of propylene glycol, 10-15 parts of betaine, 10-15 parts of sucrose, 10-18 parts of sodium hyaluronate, 10-15 parts of tocopherol acetate, 2-3 parts of essence, 5-8 parts ofhoney wax, and 3 to 5 parts of jasmine pollen. The tea seed handmade soap has clearly visible tea seed pulp particles, is smooth and delicate, has no graininess, is mild and non-irritating, has the functions of diminishing inflammation and deswelling, and is very suitable for face cleaning.

Owner:南平市祥寿茶籽科技有限公司

Nourishing lung-moistening Swiss sugar

InactiveCN105594964AFormulation ScienceReasonable ratio of oil to waterConfectionerySweetmeatsIsomaltooligosaccharideFruit juice

The invention discloses nourishing lung-moistening Swiss sugar comprising the following ingredients: granulated sugar, xylooligosaccharide, isomaltooligosaccharide, gentiooligosaccharide, water, persimmon, lily, pears, duck eggs, traditional Chinese medicines, cream, hydrogenated palm oil, corn starch, gellan gum, konjac gum, citric acid and lysozyme. The product is scientific in formula, good in thermal stability, fragrant, fine, smooth and rich in a variety of nourishing lung-moistening food ingredients and traditional Chinese medicines, is conducive to digestion and absorption, antioxidant and anti-aging, can enhance immunity, is anti-cancer, and can clear lung, reduce phlegm, dispel diseases and relieve cough; juice increases the taste of the Swiss sugar, the Swiss sugar is free of essence and additives, natural and healthy; the nourishing lung-moistening Swiss sugar is obtained by dissolving the sugar, filtering, and decocting in different stages and then adding edible gum, the obtained Swiss sugar is fine, smooth and soft, and does not stick teeth, the obtained Swiss sugar is uniform, fine and close in pores and good in chewiness due to vacuum freeze-drying, work efficiency is improved, and by addition of the lysozyme for natural sterilization and corrosion prevention, the obtained Swiss sugar is long in shelf life, does not contain preservatives, and is safe and healthy.

Owner:界首市奥源食品有限责任公司

Calycanthus praecox petal shower soap and preparation method thereof

InactiveCN106591014AAntioxidantAnti-allergicNervous disorderSurface-active detergent compositionsWrinkle skinSucrose

The invention relates to the technical field of a washing product, in particular to calycanthus praecox petal shower soap and a preparation method thereof. The calycanthus praecox petal shower soap is prepared from the following raw materials in parts by weight: 10 to 20 parts of stearic acid, 5 to 10 parts of sodium chloride, 10 to 20 parts of sucrose, 5 to 10 parts of lauric acid, 8 to 15 parts of hydrogenated olive oil, 10 to 15 parts of water, 3 to 6 parts of sodium lauryl sulfate, 4 to 8 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 1 to 2 parts of sodium hydroxide, 3 to 8 parts of enthanol, 2 to 5 parts of ciruela extracts, 0.1 to 0.5 part of calycanthus praecox petals, 0.3 to 1 part of algae extracts, 1 to 2 parts of camellia seed oil, 0.2 to 1 part of coconut oil, 0.1 to 2 parts of hydrogenated palm oil, 0.1 to 0.8 part of Oolong tea extracts, 0.3 to 1 part of benzophenone, 0.05 to 0.1 part of allantoin and 0.05 to 0.5 part of essence. The product of the calycanthus praecox petal shower soap has a good cleaning effect, and achieves the efficacies of preserving moisture, eliminating wrinkles, moisturizing the skin, maintaining the skin smoothness, resisting senescence, resisting the bacteria, resisting oxidation, resisting the allergy, soothing the nerves and the like.

Owner:CHONGQING PUPU BIOTECH

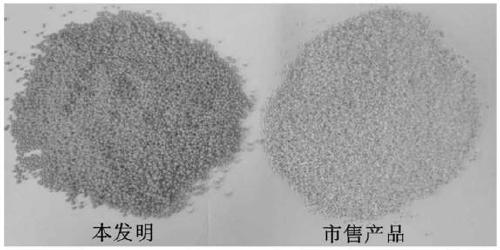

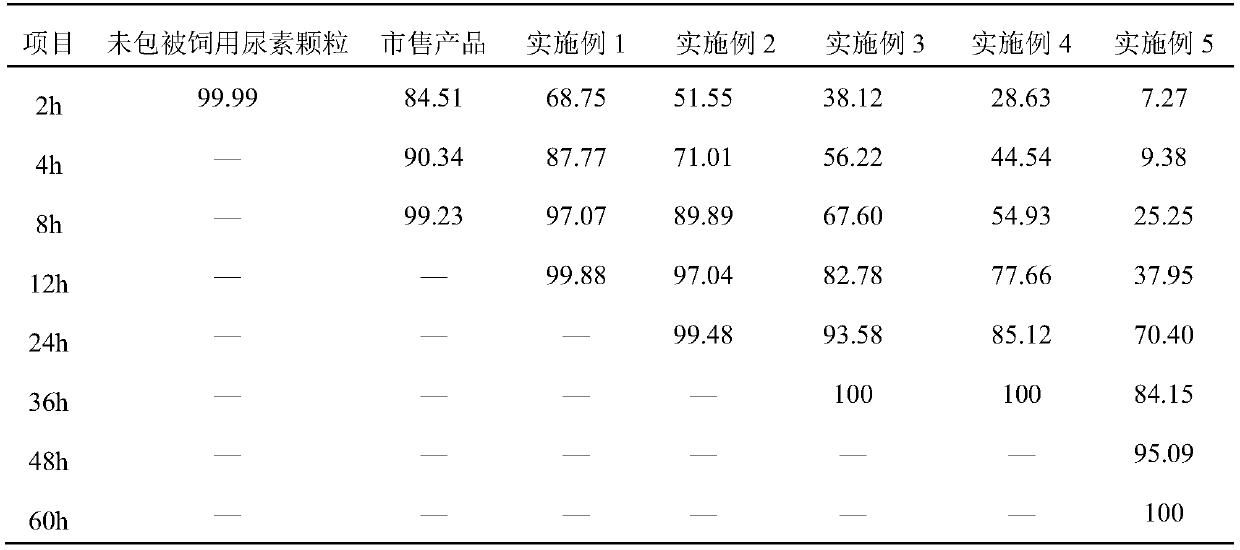

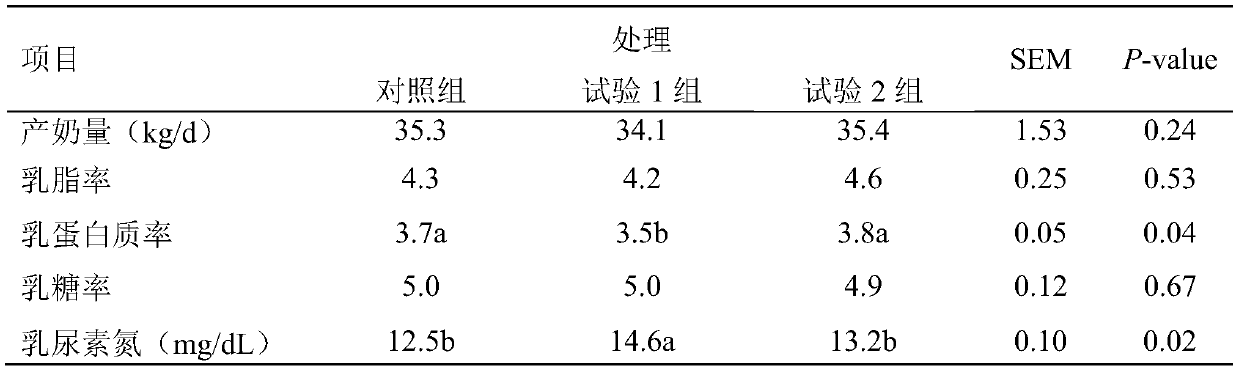

Long-acting slow-release coated urea special for lactating dairy cows, and preparation method and application thereof

PendingCN111513198AImprove palatabilityReduced release rateWorking-up animal fodderBiotechnologyCellulose

The invention belongs to the technical field of ruminant feed, and specifically relates to long-acting slow-release coated urea special for lactating dairy cows, and a preparation method and application thereof. The long-acting slow-release coated urea comprises a core material and a wall material, wherein the core material is a urea particle, the wall material is any one or a combination of two of ethyl cellulose, polyacrylic resin IV, chitosan or hydrogenated palm oil, the long-acting slow-release coated urea comprises 70%-90% of the core material, and 10%-30% of the wall material, and the wall material also comprises an emulsifier, a plasticizer, and an anti-sticking agent. The long-acting slow-release coated urea can effectively replace part of protein feed, saves protein sources, reduces feed cost, and especially improves a protein utilization rate of lactating dairy cows in the feeding environment where protein is scarce in winter and spring. In addition, the long-acting slow-release coated urea can improve the palatability of urea, avoids rumen ammonia poisoning, and effectively slows down a release rate of urea in the rumen of ruminant. Compared with commercially availableproducts, a product prepared by adopting a coating process of the invention has a more uniform coating film and better coating effects.

Owner:JILIN ACAD OF AGRI SCI +1

Polyurethane resin functional additive for processing hydrolysis-resistant sofa leather

InactiveCN106752261AImprove hydrolysis resistanceIncrease elasticityCoatingsTextiles and paperPolyethylene oxidePolyvinyl alcohol

The invention discloses a polyurethane resin functional additive for processing hydrolysis-resistant sofa leather, and relates to the technical field of processing of sofa leather. The polyurethane resin functional additive is prepared from the following raw materials in parts by weight: 10-15 parts of chlorinated polyvinyl chloride, 5-10 parts of polyvinyl butyral, 5-10 parts of polyvinyl acetate, 3-6 parts of polyethylene oxide, 3-6 parts of pentaerythritol stearate, 2-4 parts of hydrogenated palm oil, 2-4 parts of nanometer gelatine powder, 1-2 parts of C5 hydrogenated petroleum resin, 1-2 parts of cross-linking polyvidone, 1-2 parts of asbestos wool, 0.5-1 part of cation polyacrylamide, 0.5-1 part of a glass fiber powder and 0.3-0.5 part of a maleic anhydride grafting compatilizer. After the functional additive is assisted with polyurethane resin, excellent hydrolysis resistance, excellent elasticity and excellent intensity of the polyurethane resin can be completely reserved, the plasticity of the polyurethane resin can also be notably improved, and requirements of kneading patterns and embossing are met.

Owner:南平慧薇网知识产权营运有限公司

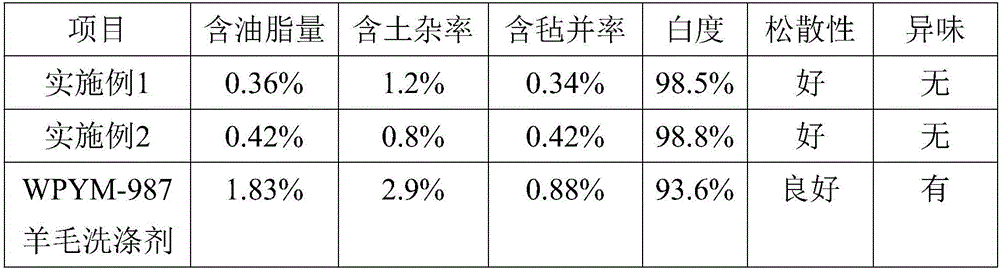

High-efficiency low-foam wool washing agent and preparation method thereof

InactiveCN106566664AEasy to cleanHigh whitenessInorganic/elemental detergent compounding agentsCationic surface-active compoundsPolyethylene glycolSesbania gum

The invention discloses a high-efficiency low-foam wool washing agent and a preparation method thereof, belonging to the technical field of the breeding industry. The high-efficiency low-foam wool washing agent is prepared from the following raw materials by weight: 15 to 20 parts of pregelatinized starch, 10 to 15 parts of microcrystalline cellulose, 6 to 11 parts of polyoxyethylene, 4 to 8 parts of cold-soluble type polyvinyl alcohol, 3 to 6 parts of sweet rice flour, 3 to 6 parts of polyethylene glycol 4000, 2 to 4 parts of polyquaternary ammonium salt, 2 to 4 parts of powdered dregs of tea-oil tree fruit, 2 to 4 parts of an adsorption aid, 1 to 2 parts of polyvinyl alcohol resin, 1 to 2 parts of hydrogenated palm oil, 1 to 2 parts of rice bran wax, 0.5 to 1 part of sesbania gum, 0.5 to 1 part of sodium bicarbonate powder, 0.5 to 1 part of disodium hydrogen phosphate and 100 to 200 parts of water. The washing agent provided by the invention carries out high-efficiency cleaning on wool in virtue of wetting, adsorption, flocculation and settlement effect, has good cleaning effect, is free of toxicity and harm and enhances the whiteness of wool without influence of usage security of wool. The washing agent also has sterilization effect and can carry out preliminary sterilization on wool.

Owner:MAANSHAN JINNONG ANIMAL HUSBANDRY

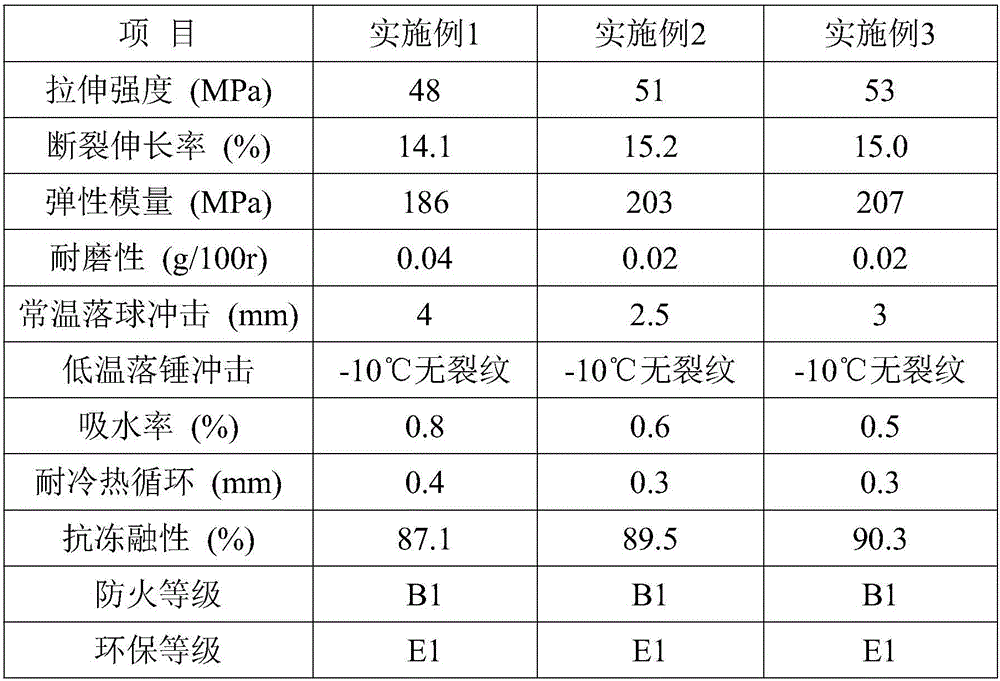

Wood-plastic composite material for processing road signs and preparation method thereof

The invention discloses a wood-plastic composite material for processing road signs and a preparation method thereof, relating to the technical field of wood-plastic composite materials. The wood-plastic composite material is prepared from the following raw materials in parts by weight: 20 to 25 parts of plastic particles recycled from beverage bottles, 15 to 20 parts of wood flour, 5 to 10 parts of chlorinated polyethylene, 5 to 10 parts of polyvinyl alcohol resin, 4 to 8 parts of rubber powder, 4 to 8 parts of coconut chaff, 3 to 6 parts of polyoxyethylene, 3 to 6 parts of activated clay, 2 to 4 parts of macroporous adsorption resin, 2 to 4 parts of pigments, 1 to 2 parts of dodecyl trimethyl ammonium chloride, 1 to 2 parts of nano rubber powder, 1 to 2 parts of hydrogenated palm oil, 0.5 to 1 part of trimellitic anhydride, 0.5 to 1 part of nano aluminium oxide and 0.5 to 1 part of 2-imidazolidone. The wood-plastic composite material disclosed by the invention is specially used for processing and preparing the road signs, and is good in processing formability; and additionally, the prepared road signs not only can be closely adhered to reflective films, but also have excellent mechanical properties, wear resistance, impact resistance and freeze-thaw resistance.

Owner:SHUCHENG ANTAI PLASTIC PROD

A kind of method utilizing hydrogenated oil to prepare pentaerythritol stearate

ActiveCN105753698BHigh saponification rateHigh acid valuePreparation from carboxylic acid saltsOrganic compound preparationDistillationStearic acid

The invention discloses a method for preparing pentaerythritol stearate from hydrogenated oil.The method includes the following steps that S1, a sodium hydroxide solution is added to hydrogenated palm oil, microwave processing is conducted, a reaction is conducted under stirring, and saponified matter is obtained; S2, a sulfuric acid solution is added to the saponified matter till the pH value is 1 to 2, the material is transferred into a distillation tower, and stearic acid is obtained after distillation is completed; S3, stearic acid, pentaerythritol and a catalyst are put, the material is heated, negative pressure is controlled, and a reaction is conducted; S4, then the vacuum degree is increased to 0.07-0.09 mpa, the material is heated to 155-165 DEG C, and a reaction is conducted for 130-150 min under heat preservation at constant pressure; S5, cooling is conducted after an esterification condensation reaction is completed, kieselguhr is added for decoloration and deordorization, the material enters a plate-and-frame filter press, filter cakes are removed, filtrate is taken and subjected to powder spraying, bead spraying and slicing, and packaging and storage are conducted.The method is stable, reliable, high in yield and capable of achieving industrial production, and the prepared pentaerythrityl tetrastearate product is good in whiteness, low in acid value and high in purity.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Preparation method of glycerin monostearate alpha crystal

ActiveCN102993009AIncrease contentLow costOrganic compound preparationCarboxylic acid esters separation/purificationMonoglycerideDistillation

The invention discloses a preparation method of glycerin monostearate alpha crystal. The method comprises the steps of enabling material hydrogenated palm oil and glycerol to react to generate crude monoglyceride under alkali catalysis, and then carrying out four-stage distillation to obtain the high-quality glycerin monostearate alpha crystal, wherein the content exceeds 90%. The acid value of the product disclosed by the invention is reduced to below 0.4; the freezing point is increased to 64-66 DEG C; the quality of the product is improved, and the difficult point of the prior art is overcome. Meanwhile, slag block of a pipe generated in the distillation process and the problems of disconnected production and low treatment efficiency caused by scale formation of an evaporating surface in an early technology are completely eradicated by the preparation method; and recovered glycerin and intermediate materials can be recycled. Therefore, the preparation method is low in cost, high in yield, high in controllability of the entire process, and suitable for industrial production.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Quick cleaning agent for eggs and preparation method thereof

InactiveCN106591006AAffect qualityQuick washInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPolyethylene oxidePolyvinyl alcohol

Relating to the technical field of livestock breeding industry, the invention discloses a quick cleaning agent for eggs and a preparation method thereof. The quick cleaning agent is prepared from the following raw materials by weight: 15-20 parts of dry wheat straw powder, 10-15 parts of bamboo powder, 8-12 parts of activated clay, 6-9 parts of polyvinyl alcohol resin, 4-8 parts of acrylic macroporous adsorption resin, 3-6 parts of polyethylene oxide, 3-6 parts of lotus leaf powder, 3-6 parts of pine needle meal, 2-4 parts of rice wine lees, 2-4 parts of sesbania gum, 2-4 parts of glutinous rice flour, 1-2 parts of hydrogenated palm oil, 1-2 parts of asbestos wool, 0.5-1 part of litsea cubeba oil, 0.5-1 part of citionella oil, 0.5-1 part of bone black, and 100-150 parts of water. The cleaning agent for eggs prepared by the method provided by the invention quickly cleans dirt attached to the egg surfaces by means of wetting, adsorption and flocculation, has high cleaning efficiency, consumes short time, and is conducive to reducing the amount of labor. At the same time, sterilization treatment is carried out on egg surfaces to prevent bacterial reproduction from affecting egg quality.

Owner:MAANSHAN JINNONG ANIMAL HUSBANDRY

Wood plastic floor additive prepared from bottle body recycled plastic particle of recycled plastic bottle

The invention discloses a wood plastic floor additive prepared from a bottle body recycled plastic particle of a recycled plastic bottle, and relates to the technical field of plastic recycling. The wood plastic floor additive is prepared from the following raw materials by weight: 25-30 parts of the bottle body recycled plastic particle, 4-8 parts of polyvinyl alcohol resin, 4-8 parts of superfine polytetrafluoroethylene powder, 3-6 parts of tephra, 3-6 parts of hydrogenated palm oil, 2-4 parts of rice bran wax, 2-4 parts of bamboo powder, 1-2 parts of lanoline, 1-2 parts of hydrogenated ester gum, 1-2 parts of sulfuretted lard oil, 0.5-1 part of epoxy coal pitch, 0.5-1 part of dipentaerythritol, 0.5-1 part of nano titanium dioxide, and 0.5-1 part of trithiocyanuric acid. The prepared additive fully improves the blending of raw material wood powder prepared from the recycled plastic particle and the wood plastic floor, so as to be favorable for the sufficient blending of the raw materials, and the extrusion and use performances of the wood plastic floor are prevented from being affected by the accumulation of the wood flour.

Owner:肇庆高新区飞越信息科技有限公司

Cleaning method of wind turbine main gearbox oil cooling radiator, cleaning agent and preparation method thereof

InactiveCN109675860AHigh removal rateGood removal effectInorganic/elemental detergent compounding agentsCationic surface-active compoundsFreeze-dryingThermal insulation

The invention discloses a cleaning method of a wind turbine main gearbox oil cooling radiator. The cleaning method comprises the following steps: heating and compressing a cleaning agent and then flushing; and blowing greasy dirt between every two adjacent cooling fins out. The cleaning agent comprises the following components: 25-30 parts of modified starch, 5-10 parts of bean dreg freeze-dried powder, 2-3 parts of grape skin dreg freeze-dried powder, 1-2 parts of buckwheat bran flour, 0.5-1 part of bamboo powder, 0.5-1 part of hydrogenated palm oil, 0.3-0.5 part of polyoxyethylene, 0.3-0. 5part of asbestos wool, 0.1-0.3 part of poly dimethyl diallyl ammonium chloride, 0.1-0.3 part of nano titanium dioxide and 100-200 parts of water. A preparation method of the cleaning agent comprises the following steps: adding bamboo powder, hydrogenated palm oil and asbestos wool into buckwheat bran flour, warming to 50-55 DEG C, and carrying out thermal insulation and mixing; adding polyoxyethylene, poly dimethyl diallyl ammonium chloride and nano titanium dioxide, warming to 80-85 DEG C, and carrying out thermal insulation and mixing; adding modified starch and water of 80-85 DEG C, and mixing; and adding bean dreg freeze-dried powder and grape skin dreg freeze-dried powder, and refining.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com