Coated plant essential oil for piglets and preparation method of coated plant essential oil

A plant essential oil and encapsulation technology, which is applied in application, animal feed, additional food elements, etc., can solve the problems of large differences in antibacterial effects of essential oils, discounted use effects, and easy oxidation, etc., to protect intestinal health and cooling speed Fast, simple and convenient production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

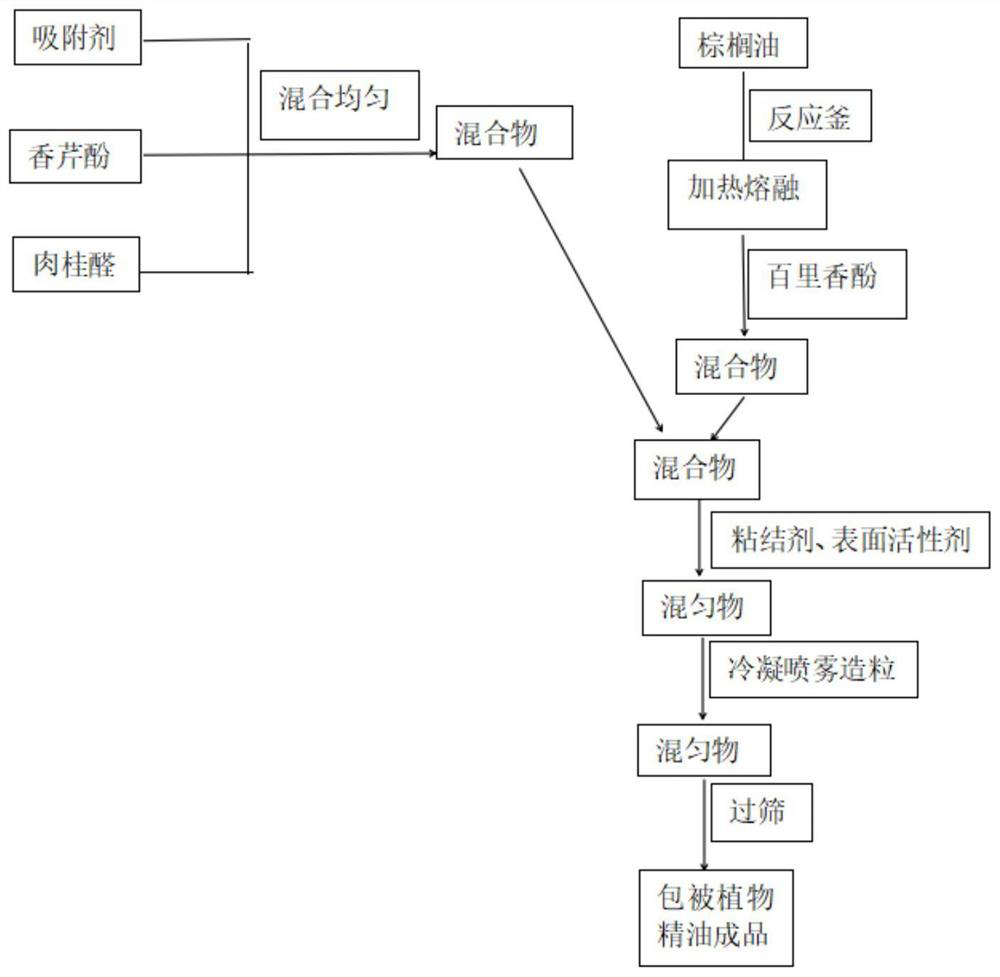

[0025] The preparation method comprises the following steps:

[0026] (1), take by weighing 5% of silicon dioxide, join in the mixer, then add carvacrol 3.5%, cinnamaldehyde 3.5%, absorb and mix evenly;

[0027] (2) Weigh 62% of hydrogenated palm oil and put it in the reaction kettle, raise the temperature to 80°C, after it is completely melted, turn on the agitator, add 3% of thymol, after it is dissolved, then add the silicon dioxide in step 1 , carvacrol and cinnamaldehyde mixture, then add carboxymethylcellulose 20% and Tween 80 3%, stir evenly;

[0028] (3) The homogenate obtained in step (2) is subjected to spray granulation using a condensation spray granulator. The cylinder temperature of the condensing spray granulator is kept at 2°C, and the flow rate of the feed pump is kept at 2 rpm. The obtained granules are passed through a 20-mesh sieve to obtain a finished product.

Embodiment 2

[0030] The preparation method comprises the following steps: each raw material is calculated by mass percentage;

[0031] (1), take by weighing 14% of dextrin, join in the mixer, then add carvacrol 5%, cinnamaldehyde 5%, absorb and mix evenly;

[0032] (2), Weigh 55% of hydrogenated palm oil and put it in the reaction kettle, heat up to 85°C, after it is completely melted, turn on the agitator, add 5% of thymol, and after dissolving, add the dextrin in step 1, Carvacrol and cinnamaldehyde mixture, then add acrylic resin 15% and polysorbate 1%, stir well;

[0033] (3) The homogenate obtained in step (2) is subjected to spray granulation using a condensation spray granulator. The cylinder temperature of the condensing spray granulator is kept at 5°C, and the flow rate of the material pump is kept at 4 rpm. The obtained particles pass through a 40-mesh sieve to obtain a finished product.

Embodiment 3

[0035] The preparation method comprises the following steps: each raw material is calculated by mass percentage;

[0036] (1), take carboxymethyl cellulose 20%, join in the mixer, then add carvacrol 7%, cinnamaldehyde 7%, adsorption mixes evenly;

[0037] (2), Weigh 50% of hydrogenated palm oil and put it in the reaction kettle, heat up to 90°C, after it is completely melted, turn on the agitator, add 6% of thymol, after it dissolves, then add the carboxymethyl in step 1 Cellulose, carvacrol and cinnamaldehyde mixture, then add vinyl acetate resin 8% and sodium dodecylbenzene sulfonate 2%, stir evenly;

[0038] (3) The homogenate obtained in step (2) is subjected to spray granulation using a condensation spray granulator. The cylinder temperature of the condensing spray granulator is kept at 10°C, and the flow rate of the material pump is kept at 7 rpm. The obtained particles pass through a 60-mesh sieve to obtain a finished product.

[0039] In the present invention, hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com