High-efficiency low-foam wool washing agent and preparation method thereof

A detergent and high-efficiency technology, applied in the field of aquaculture, achieves good cleaning effect, saves water consumption, and enhances whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Heat 3 parts of glutinous rice flour to 70-80°C and mix for 5 minutes, then add 10 parts of microcrystalline cellulose, 2 parts of tea dry powder, 1 part of rice bran wax and 1 part of kale gum, and continue heating to 100-110 Insulate and mix at ℃ for 15 minutes, place the resulting mixture in an environment of -5-0℃ and freeze for 5 hours, and then make it into a powder through an ultrafine pulverizer to obtain powder I;

[0020] (2) Add 4 parts of cold-soluble polyvinyl alcohol and 3 parts of polyethylene glycol 4000 to 8 parts of polyethylene oxide, mix well, and then microwave for 5 minutes at a microwave frequency of 2450MHz and a power of 700W, then add 2 parts of polyvinyl alcohol resin and 1 part of hydrogenated palm oil, mix evenly and continue microwave treatment for 3 minutes to obtain powder II;

[0021] (3) Add 15 parts of pregelatinized starch and 2 parts of polyquaternium to 200 parts of water, mix to dissolve completely, then add powder I and powder...

Embodiment 2

[0024] (1) Heat 3 parts of glutinous rice flour to 70-80°C and mix for 5 minutes, then add 15 parts of microcrystalline cellulose, 2 parts of tea dry powder, 2 parts of rice bran wax and 0.5 part of kale gum, and continue heating to 100-110 Insulate and mix at ℃ for 15 minutes, place the resulting mixture in an environment of -5-0℃ and freeze for 5 hours, and then make it into a powder through an ultrafine pulverizer to obtain powder I;

[0025] (2) Add 4 parts of cold-soluble polyvinyl alcohol and 5 parts of polyethylene glycol 4000 to 10 parts of polyethylene oxide, mix well, and then microwave for 5 minutes at a microwave frequency of 2450 MHz and a power of 700 W, then add 1 part of polyvinyl alcohol resin and 1 part of hydrogenated palm oil, mix evenly and continue microwave treatment for 3 minutes to obtain powder II;

[0026] (3) Add 20 parts of pre-gelatinized starch and 2 parts of polyquaternium to 200 parts of water, mix to dissolve completely, then add powder I and ...

Embodiment 3

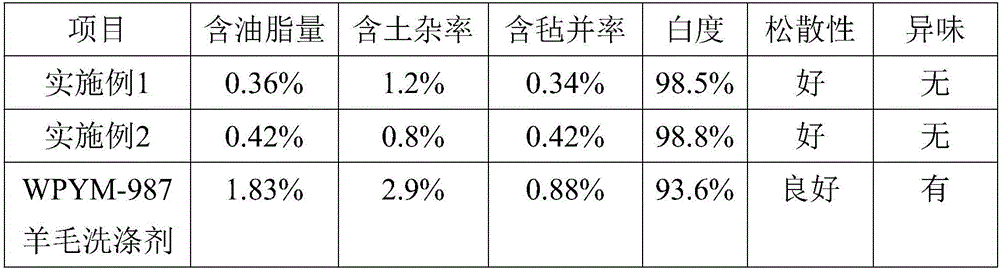

[0029] The detergents prepared in Examples 1 and 2 were used for wool washing, and the quality of the washed wool was tested, and compared with the commercially available WPYM-987 wool detergent, the results are shown in Table 1.

[0030] Table 1 The quality results of wool after washing

[0031]

[0032] It can be seen from Table 1 that the cleaning effect of the detergents prepared in Examples 1 and 2 of the present invention on wool is significantly better than that of the commercially available WPYM-987 wool detergent, and the oil content, dirt content and matting rate are lower, and the white High density, good looseness and no peculiar smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com