Patents

Literature

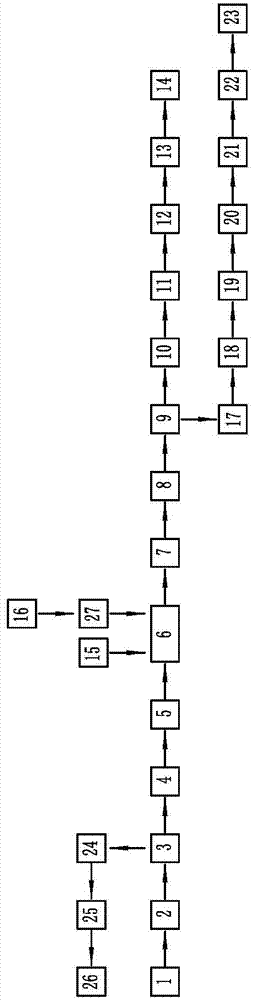

202 results about "Rice bran wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice bran wax is the vegetable wax extracted from the bran oil of rice (Oryza sativa).

Policosanol composition and its use in treatment of hypercholesterolemia

InactiveUS20050220868A1Improved serum cholesterol lowering activityHigh activityBiocideHydroxy compound active ingredientsMedicinePolicosanol

A composition is provided containing at least 90% of policosanols obtained from rice bran wax, wherein the policosanols contain from about 25 to about 35% of octacosanol, and its use in providing significant improvements in total cholesterol and / or LDL reduction in subjects in need thereof.

Owner:MARCOR DEV +1

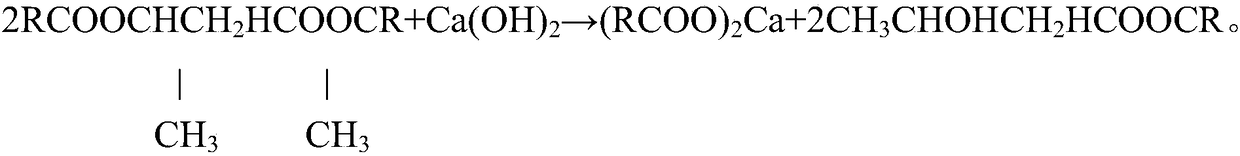

Rice bran calcium cerotate soap wax and preparation method thereof

ActiveCN108191602AHigh glossReduce manufacturing costOxygen-containing compound preparationOrganic compound preparationAcetic acidPolyol

The invention provides a preparation method of a rice bran calcium cerotate soap wax. The preparation method comprises the following steps: deoiling, soaking the deoiled but undecolorized rice bran wax into ethyl acetate, heating to melt, cooling, and cutting into slices for later use; oxidizing, heating the sliced rice bran wax and dilute sulphuric acid together to melt the rice bran wax, addinga sodium bichromate solution, constantly stirring and oxidizing, heating the oxidized rice bran wax into a liquid, then adding the dilute sulphuric acid, stirring, standing, layering, stirring while adding water, raising the temperature until the wax is completely melted, continuing to stir, standing and layering to obtain the rice bran wax cerotate; esterifying, heating and melting the rice branwax cerotate, raising the temperature, adding a polyhydric alcohol to have esterification reaction to obtain rice bran cerotate ester wax; saponifying, heating and melting the rice bran cerotate esterwax, and adding a calcium hydroxide solution to implement partial saponification to obtain the rice bran calcium cerotate soap wax. The invention further provides the rice bran calcium cerotate soapwax. The preparation method provided by the application is low in production cost, and the product is harder and has the performances of high temperature resistance and high gloss, and can substitutemouton wax soap.

Owner:重庆合才化工科技有限公司

Special composite emulsifier for wax emulsion, and preparation method thereof

The present invention provides a special composite emulsifier for a wax emulsion. The special composite emulsifier is characterized by comprising, by weight, 45-50 parts of peregal, 20-25 parts of stearic acid, and 25-30 parts of fatty alcohol polyoxyethylene ether. The process comprises: sequentially adding peregal, stearic acid and fatty alcohol polyoxyethylene ether to a reaction kettle, heating to achieve a temperature of 60-70 DEG C until completely melting the material, and stirring to achieve a uniform state so as to discharge the material. According to the present invention, during preparation of various wax emulsions, the emulsifier having the amount of 8-10% of the mass of wax and the wax are co-melted and then uniformly stirred, and hot water with a temperature of 90-95 DEG C is added until the solid content is 50% so as to obtain the corresponding wax emulsion, or deionized water can be added according to requirements so as to adjust the wax emulsion content to 5-50% and the like. The special composite emulsifier can be provided for emulsifying paraffin wax, polyethylene wax, palm wax, montan wax, beeswax, rice bran wax, candelilla wax, shellac wax, and other types of waxes, such that material preparation of wax emulsion manufacturers is simply, and the prepared emulsion is translucent, has blue light , and has characteristics of good stability and small particle size; and the emulsifying system is consistent, such that various wax emulsions can be compounded according to any ratios without generation of phenomena such as precipitation, flocculation, layering and the like, and the special composite emulsifier can be conveniently used in various fields.

Owner:山东力厚轻工新材料有限公司

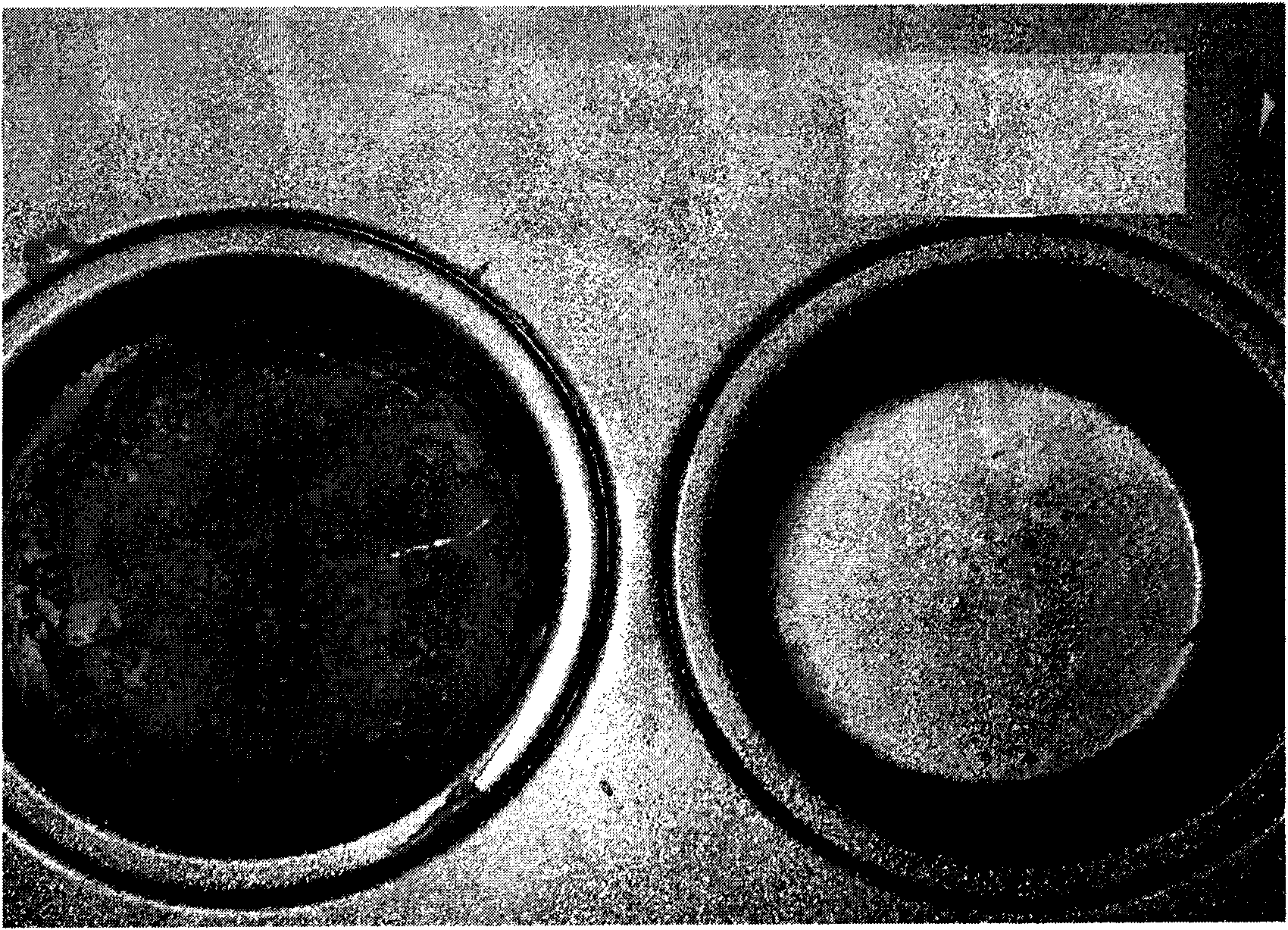

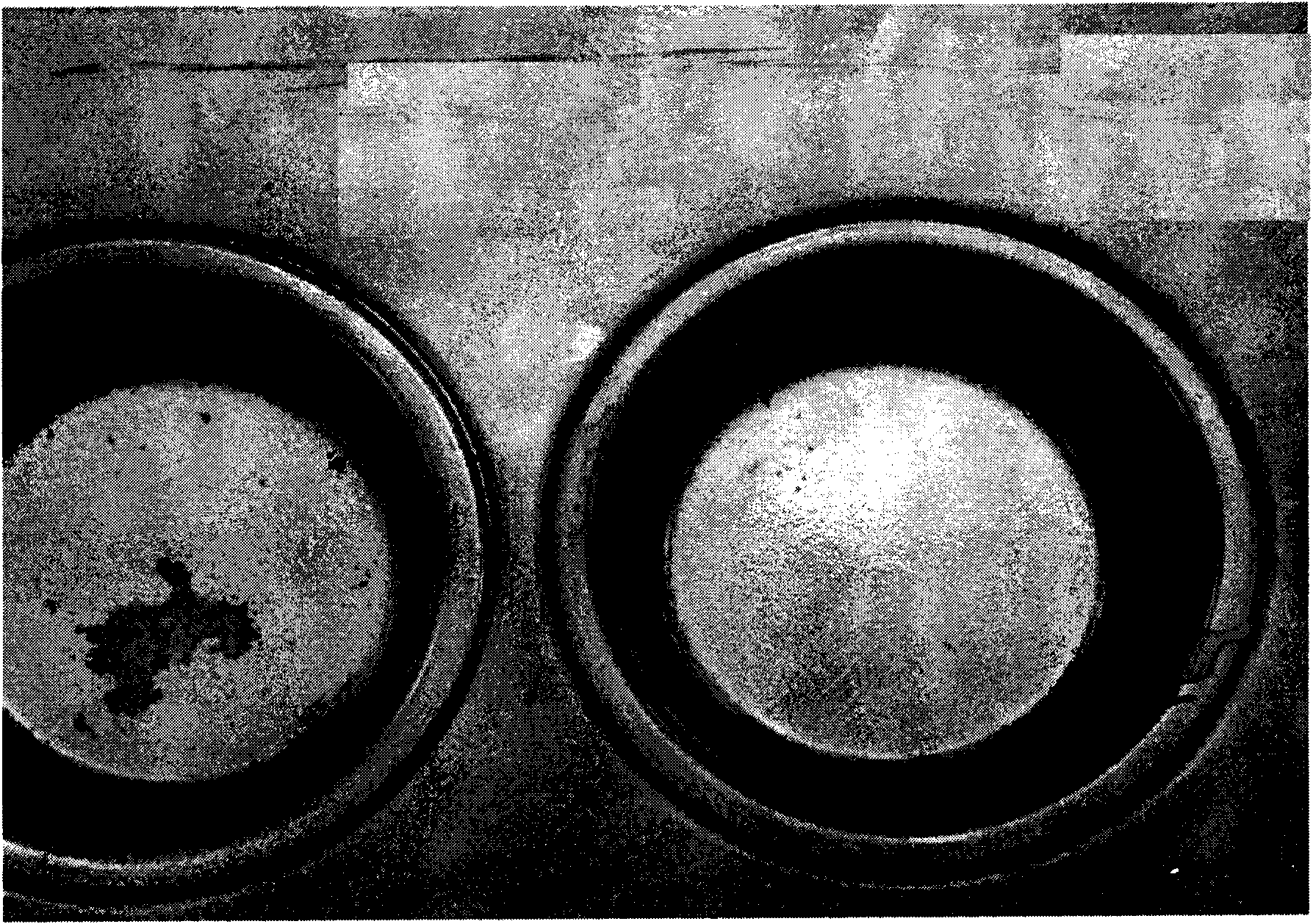

Mold release agent and preparation method thereof

The invention relates to a mold release agent for demolding various bakeware, molds, steel strips and other appliances used in the food industry and a preparation method thereof. The mold release agent contains grease, a wax and an emulsifier, wherein the wax is selected from rice bran wax, soy wax and sunflower seed wax. The method for preparing the mold release agent comprises the process stepsof first rapid cooling and then annealing. The mold release agent is uniform in the storage process, does not settle, and has excellent model release performance. The invention also relates to a method for producing baked food by using the mold release agent.

Owner:嘉里特种油脂(上海)有限公司

Manufacturing technology of plant fiber synthetic resin powder and plant fiber product

The invention relates to the field of chemical materials, in particular to a manufacturing technology of plant fiber synthetic resin powder and a plant fiber product. The manufacturing technology comprises the following steps: grinding plant fiber into plant fiber powder with molecules, putting the plant fiber powder into a high-speed mixer, adding rice bran wax and starch, evenly mixing, putting into a reaction kettle, evenly stirring into pulp by added water, heating up by adding natural resin powder into pasty materials, and injecting into a flash streaming drier to prepare into the plant fiber synthetic resin powder. The manufacturing technology is the recycle derived from the plant fiber residue. The product of the manufacturing technology has the natural color and fragrance of the plant fiber per se, has super-strong water resisting property, further has the characteristics of being hard, high-density, smooth, non-toxic, low-cost, environment-friendly and the like, and can be automatically degraded into organic fertilizer in the natural world, and can return to nature, and the product produced by the manufacturing technology is freezing-resistant, high temperature-resistant, good in intensity, density and hardness, and long in service life, thereby being an environment-friendly material, and wide in market prospect.

Owner:XIAMEN HUSKS NEW MATERIAL TECH CO LTD

Rice bran wax acid ester wax and preparation method thereof

InactiveCN108129302AStable structureHigh hardnessOrganic compound preparationCarboxylic acid esters preparationAcetic acidPolyol

The invention provides a preparation method of a rice bran wax acid ester wax. The method comprises the following steps of deoiling, soaking a deoiled and non-discolored rice bran wax through ethyl acetate, heating for melting, cooling, and slicing for standby use; oxidizing: heating the sliced rice bran wax and dilute sulphuric acid for melting the rice bran wax, then adding a sodium bichromate solution, and continuously stirring and oxidizing; heating the oxidized rice bran wax into a liquid, then feeding a dilute sulphuric acid for stirring, standing for layering, then adding water while stirring while heating until the wax is completely melted, then continuously stirring, and standing for layering to obtain a rice bran wax acid wax; preparing and melting: heating and melting the rice bran wax acid wax, then heating, and adding polyhydric alcohols and the rice bran wax acid wax for carrying out esterification reaction to obtain the rice bran wax acid ester wax. The invention also provides the rice bran wax acid ester wax. The rice bran wax is oxidized through the sodium bichromate so as to generate the rice bran wax acid wax, the rice bran wax acid wax is esterified with the polyhydric alcohols to generate the rice bran wax acid ester wax with a longer chain, and the rice bran wax acid ester wax is low in production cost, high in product hardness and glossiness, and capableof effectively replacing a montan E wax.

Owner:重庆合才化工科技有限公司

Lipstick

InactiveCN104546644AIncrease elasticityKeep hydrated and prevent cracksCosmetic preparationsToilet preparationsJojoba esterCarnuba wax

The invention discloses a lipstick. The lipstick contains grease, a pure natural auxiliary material and wax. The lipstick is characterized in that the wax is pure plant extracted wax and the grease is natural extracted grease; the weight parts are as follows: 35-40 parts of the pure plant extracted wax, 55-65 parts of the natural extracted grease and 2.5-5.5 parts of natural auxiliary material; the pure plant extracted wax is as least one selected from beewax, candelilla wax, carnauba wax, rice bran wax, jojoba ester and olive ester.

Owner:易思成

Method for decolorizing rice bran wax

ActiveCN103981032ALow costReduce manufacturing costFatty substance recovery/refiningEvaporationWastewater

The invention discloses a method for decolorizing rice bran wax. The method comprises the steps of dehydrating rice bran wax paste, adding an industrial hexane solvent for removing oil, then adding an adsorption decolorizing agent for decolorizing in the presence of the industrial hexane solvent, and finally performing solid-liquid separation and evaporation to remove the solvent, thus obtaining decolorized rice bran wax. Compared with the prior art, the method has the advantages that the method does not adopt any oxidant, no heavy metals are left, a large amount of wastewater is not produced, the production cost is reduced, and the pollutants are reduced; and meanwhile, a white rice bran wax product with the whiteness of nearly 32 can be obtained by adopting the method, the purity of the product is high, and the application range of the product is expanded.

Owner:舒城县金禾油脂科技开发有限公司

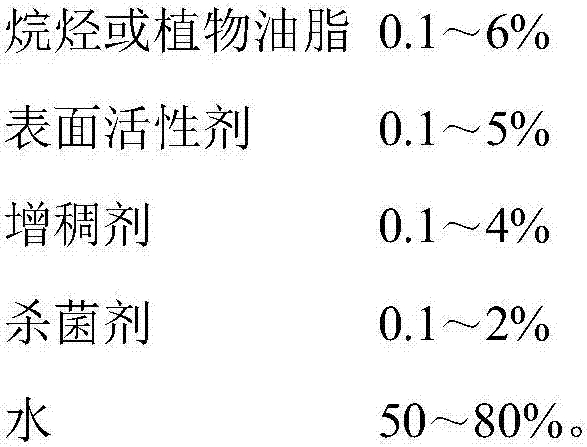

Higher aliphatic alcohol emulsion antifoaming agent

ActiveCN107059474ASuitable for defoamingSuitable for degassingDefoamers additionNon-macromolecular organic additionEmulsionActive component

The invention provides a higher aliphatic alcohol emulsion antifoaming agent. The antifoaming agent is prepared from rice bran wax, ax, alkane or vegetable fat, a surfactant, a thickening gent, a bactericide and water, and the rice bran wax is the active component of the emulsion antifoaming agent. The rice bran wax takes higher aliphatic acid, higher aliphatic alcohol and higher aliphatic alcohol ester as main components and contains abundant hexacosanol, octacosanol, triacosanol and corresponding alcohol ester. The higher aliphatic alcohol emulsion prepared from the rice bran wax is applicable to foam control in each section of pulping and papermaking, particularly a papermaking system and foam control of papermaking wet-ends.

Owner:济宁南天农科化工有限公司

Method of preparing long-chain fatty alcohol from rice bran wax

InactiveCN1389445AReduce generationEasy to shapeOxygen-containing compound preparationOrganic compound preparationSolventFatty acid

The method for preparing long-chain aliphatic alcohol by utilizing rice bran wax includes the following steps: using fine rice bran wax or crude rice bran wax as raw material, adopting dry saponification process, using wet calcium oxide or calcium hydroxide, the ratio of it and water is 1:0.5-10, the dosage of calcium oxide or calcium hydroxide is 10-30% of weight of rice bran wax, its saponification reaction temp. is 95-180 deg.C and reaction time is 2-10 hr. after the reaction and cooled obtaining mixture of aliphatic acid calcium and long-chain aliphatic alcohol, pulverizing said mixture to make into powder, making solvent extraction, fully mixing powder and solvent, filtering to remove insoluble aliphatic acid calcium, recovering solvent from mother liquor and obtaining the long-chain aliphatic alcohol.

Owner:许仁溥 +2

Nanometer titania reinforced concrete mold release agents

ActiveCN105345919AExcellent mold releaseSmooth demouldingCeramic shaping apparatusForm treatmentReinforced concreteRosin

The invention discloses nanometer titania reinforced concrete mold release agents, and relates to the technical field of concrete mold releasing. The nanometer titania reinforced concrete mold release agents comprise, by weight, 5-8 parts of nanometer titania, 80-90 parts of glycerol ester of rosin, 50-60 parts of polyether modified silicone, 15-20 parts of zeolite powder, 15-20 parts of volcanic soil, 12-18 parts of octadecanamide, 10-15 parts of polyamide resin, 10-15 parts of saponin powder, 10-15 parts of emulsified oil, 8-12 parts of spans, 6-10 parts of lubricating grease, 6-10 parts of rice bran wax, 4-7 parts of tartaric acid, 30-40 parts of mandarin oil and 300-350 parts of water. The nanometer titania reinforced concrete mold release agents have good mold release performance, enable a mold plate and concrete to be smoothly released, keep the surface of concrete smooth and keep edges tidy and undamaged.

Owner:滁州京安工贸有限责任公司

Light rice bran cerotic acid wax and preparation method thereof

PendingCN108048222AEffective oxidation removalGood emulsifying effectFatty substance recovery/refiningFatty substance recoveryAcetic acidEthyl ester

The invention provides a preparation method of light rice bran cerotic acid wax. The method includes the following steps of deoiling, oxidation and acid pickling and water scrubbing. During deoiling,deoiled rice bran wax to be discolored is soaked in ethyl acetate, heated for melting and then cooled and sliced for use. During oxidation, the sliced rice bran wax and dilute sulphuric acid are heated to enable the rice bran wax to be melted, then the rice bran wax is added into a sodium bichromate solution and then constantly stirred, the color of the rice bran wax turns light from brown, and natural cooling and standing are conducted to make the wax delaminated from a chromium slurry solution. During acid pickling and water scrubbing, the oxidized rice bran wax is heated into a liquid thenput into dilute sulphuric acid and stirred, standing is carried out to make the wax delaminated from a water scrubbing liquid, then the mixture is added with water, stirred and heated at the same timetill the wax is totally melted, stirring continues to be conducted, standing is carried out to make the wax delaminated from the water scrubbing liquid, and the oxidized rice bran wax at the upper layer is sliced and packed after being cooled. The invention further provides the light rice bran cerotic acid wax. According to the method, the rice bran wax is oxidized by sodium bichromate to generate the rice bran cerotic acid wax which is light in color, odorless and hard in texture, micromolecular materials are effectively removed, the emulsibility and the luster are obviously improved, and deep processing is facilitated.

Owner:重庆合才化工科技有限公司

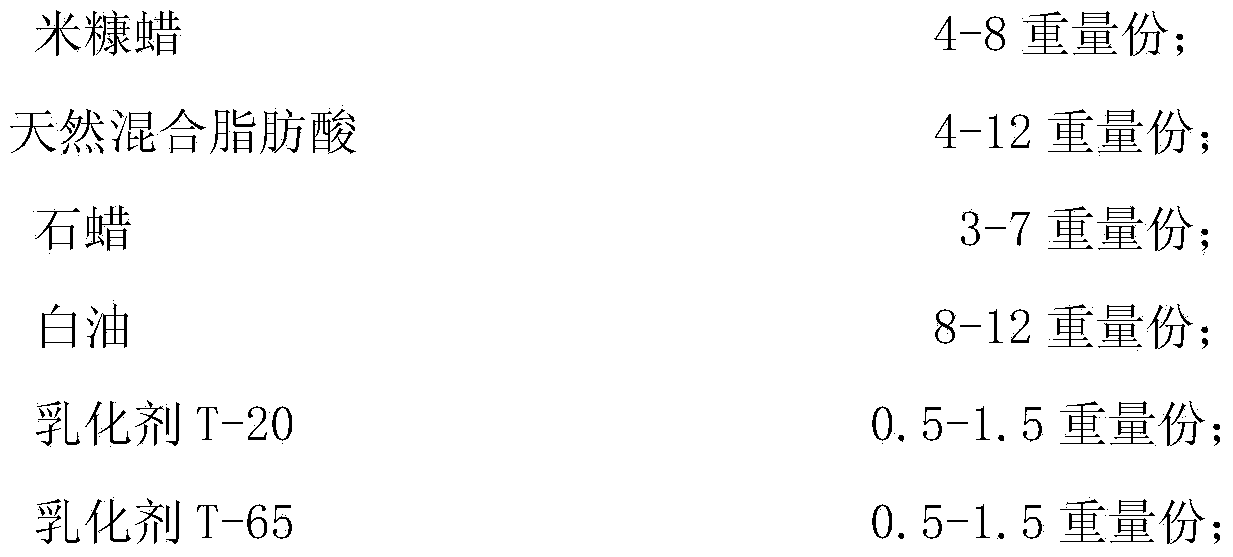

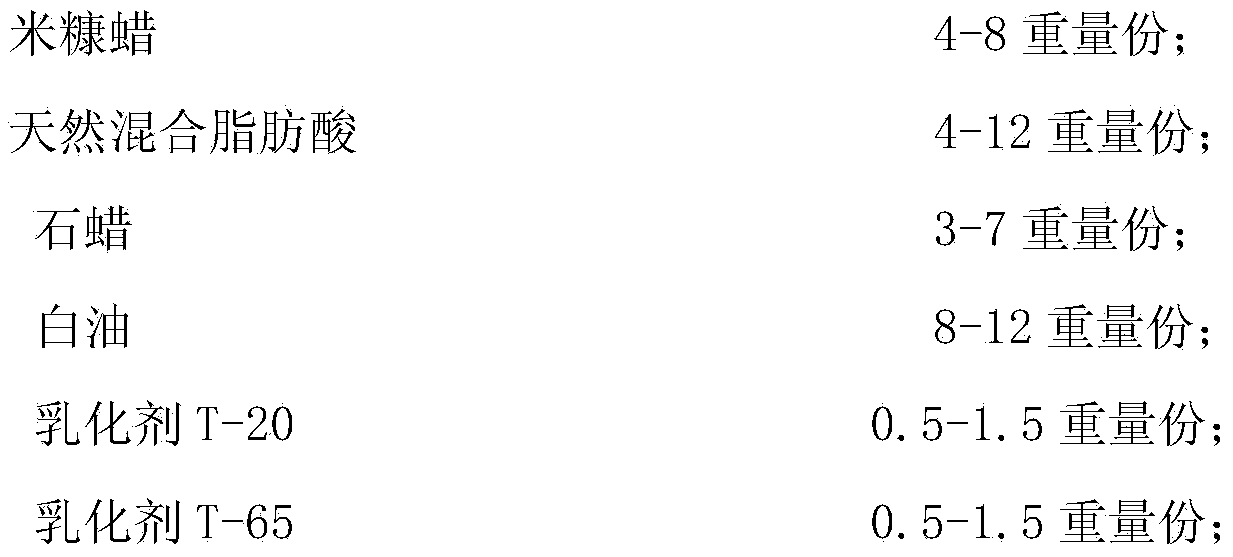

Multi-functional liquid plant protection film agent

The invention discloses a multi-functional liquid plant protection film agent. Natural raw materials such as fulvic acid, rice bran wax and mixed fat are emulsified to form thick water emulsion, and the emulsion belongs to green, low-carbon and environmentally-friendly products which are developed in a sustainable mode. The emulsion with water is sprayed on the full surfaces of plants to form a liquid film, before the liquid film is solidified, the film can paste pathogenic bacteria, spores of the bacteria, soft pests and ova of the pests and block pest air holes to enable the pests to be inactivated and stifle, the pathogenic bacteria, the spores of the bacteria, the soft pests and the ova of the pests are attached to the surfaces of the plants, after the film is naturally solidified, a solid protective micro film layer which can not be seen by naked eyes is formed on the surfaces of the plants, and seals and protects the plants, the film layer repels and isolates encroaching of multiple diseases and pests on crops and has the functions of conserving water, resisting drought, preventing freezing, preventing dry hot (cold) wind, preventing rain and preventing lodging, the use number of pesticides and the use amount of chemical fertilizer can be reduced, environment and food safety can be protected, meanwhile, labor intensity of farmers can be reduced, investment by the farmers can be reduced, and the aim that the production and income are greatly increased is achieved.

Owner:SHAANXI KAIXINYU AGRI SCI & TECH

Method for preparing octacosanol and triacontanol from rice bran wax

InactiveCN102311307ALow toxicityLow priceOxygen-containing compound preparationOrganic compound preparationDistillationHydrolysis

The invention discloses a method for preparing octacosanol and triacontanol from rice bran wax, which comprises the steps of: adopting an oxide or a hydroxide of alkaline-earth metal as a hydrolyst; hydrolyzing the rice bran wax through ultrasonic waves; separating and extracting fatty alcohol with the adoption of ethanol as an extracting agent; and separating the octacosanol and the triacontanol through a molecular distillation technology. The alkaline-earth metal is the hydrolyst; the time of the ultrasonic hydrolysis reaction can be shortened for 10 hours or higher than that of the general method, specifically from 12-16 hours to 2 hours or lower; the hydrolysis ratio is improved by 2 times; and the hydrolysis product is easily separated from impurities and the mother liquid. The invention has the characteristics of low requirement on reaction condition, normal temperature and pressure, low toxicity of auxiliary raw materials, low production cost, short reaction time and high purity and is easy to industrialized production.

Owner:HEILONGJIANG WANHEYUAN GREASE

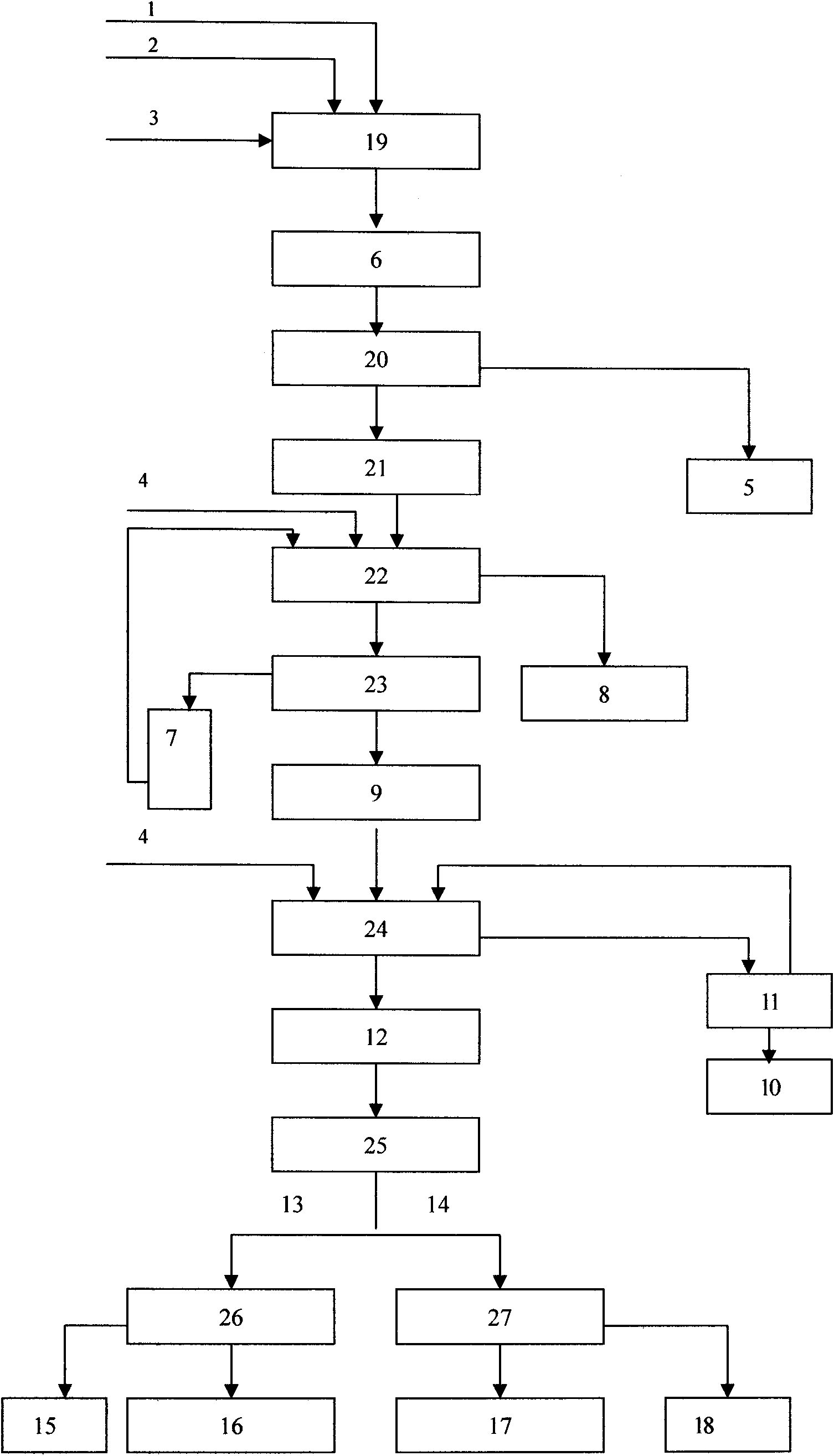

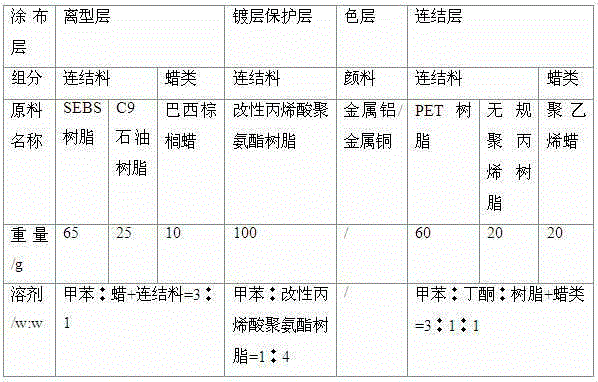

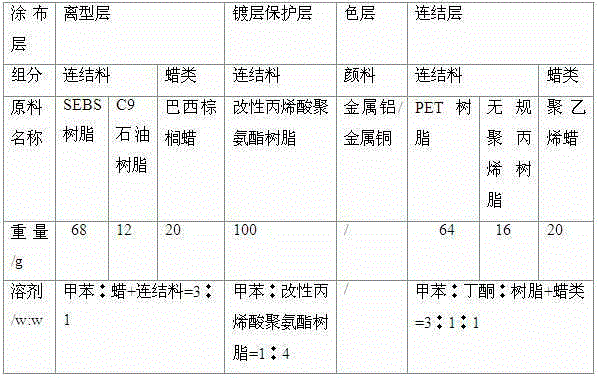

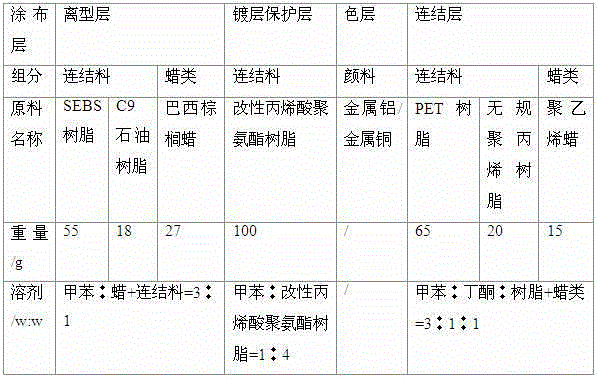

Thermal transfer ribbon for printing golden and silver bar codes and preparation method thereof

ActiveCN105216461AReasonable designEasy to prepareInk ribbonsSynthetic resin layered productsEngineeringPolypropylene

The invention discloses a thermal transfer ribbon for printing golden and silver bar codes and a preparation method thereof, and belongs to the technical field of thermo-printing material. The thermal transfer ribbon for printing the golden and silver bar codes is composed of a ribbon base, a back coating and a thermal transfer printing layer, wherein the back coating and the thermal transfer printing layer are arranged on the two sides of the ribbon base in a coating mode. The thermal transfer printing layer is divided into four parts, namely the release layer, the coating protection layer, the color layer and the connecting layer, wherein the release layer, the coating protection layer, the color layer and the connecting layer are sequentially arranged on the surface of one side of the ribbon base from inside to outside. The release layer is composed of, by weight, connecting material of 73-90% and wax of 10-27%, the connecting material is composed of SEBS resin and petroleum resin, the SEBS resin accounts for 55-80% in total mass of the release layer, the petroleum resin accounts for 0-25% in total mass of the release layer, and the wax can be rice bran wax or polyethylene wax or carnauba wax. The coating protection layer is composed of modified acrylic acid polyurethane resin, wherein the softening point of the modified acrylic acid polyurethane resin ranges from 110 DEG C to 115 DEG C. The color layer is plated to be golden or silver through the vacuum evaporation process. The connecting layer is composed of, by weight, saturated polyester resin of 50-71%, atactic polypropylene resin of 10-30% and polyethylene wax of 10-28%.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

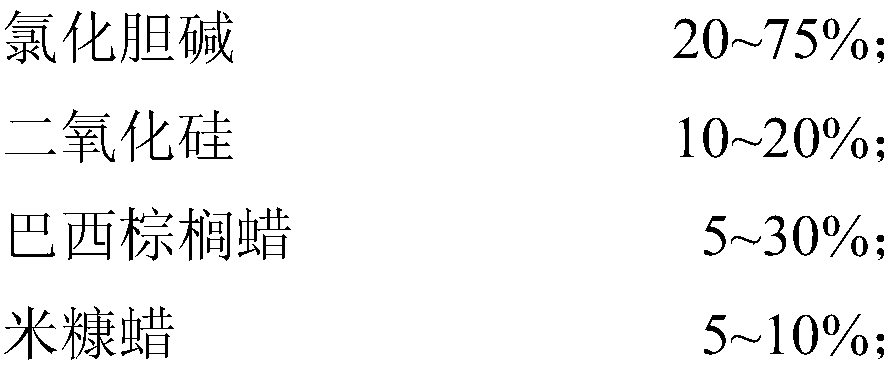

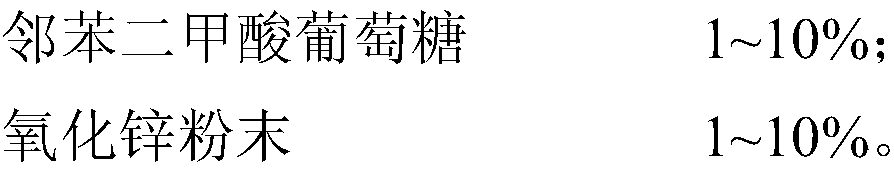

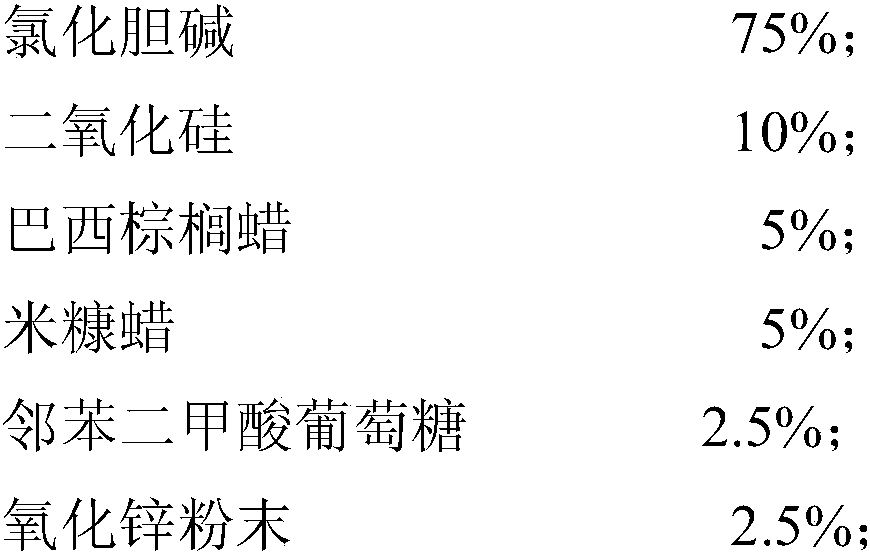

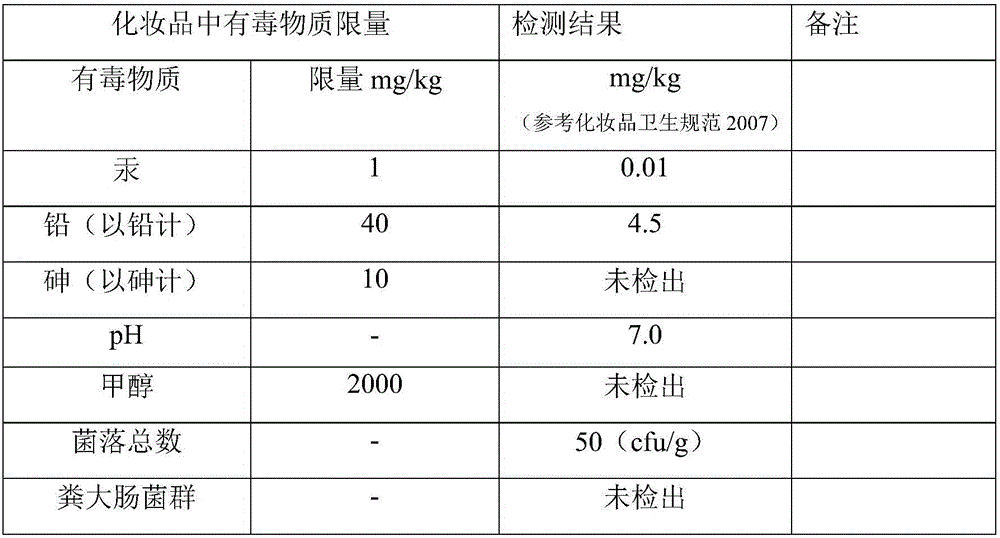

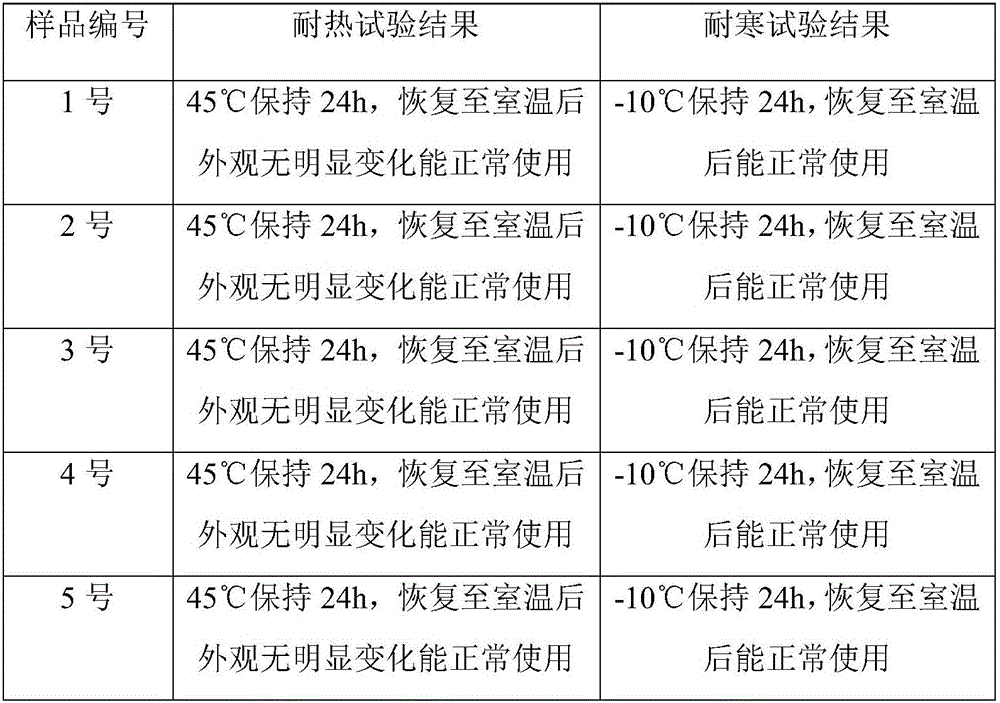

By-pass rumen choline chloride microcapsules and preparation method thereof

ActiveCN109362950AImprove rumen passing rateIncrease release rateAnimal feeding stuffAccessory food factorsPolyethylene glycolGlucose polymers

The invention discloses by-pass rumen choline chloride microcapsules and a preparation method thereof. The microcapsules comprise a core material consisting of choline chloride and a carrier, an innerlayer envelope and an outer layer envelope, wherein the inner layer envelope comprises one or more vegetable fat of which the melting point is higher than 60 DEG C; and the outer layer envelope comprises the following raw materials of rice bran wax, zinc oxide powder and a film-forming material, the film-forming material is phthalate glucose, polyethylene glycol or sodium alginate, the content ofthe rice bran wax is 5-10%, and the mass ratio of the rice bran wax to the zinc oxide powder to the film-forming material is (1-5) to (0.1-1) to (0.1-1 ). The rice bran wax, the zinc oxide powder andthe film-forming material are used as raw materials of the outer layer envelope, so that the by-pass rumen rate of the by-pass rumen choline chloride microcapsules in ruminant animal rumens and the release rate of the by-pass rumen choline chloride microcapsules in small intestines are notably increased, the hygroscopicity of products during storage and usage can also be reduced, and the utilization efficiency of the choline chloride by ruminant animals can also be effectively improved.

Owner:HANGZHOU KINGTECHINA FEED CO LTD

Lipstick containing teas and traditional Chinese medicines and preparation method of lipstick

InactiveCN106727227ATake advantage of natural scentsImprove securityCosmetic preparationsMake-upButter cocoaSide effect

The invention belongs to the technical field of daily necessities, and particularly relates to a lipstick containing teas and traditional Chinese medicines and a preparation method of the lipstick. The lipstick is prepared from the teas, traditional Chinese medicine leaching oil, refined carnauba wax, natural beewax, refined sunflower seed wax, refined soybean wax, refined rice bran wax, macadimia nut butter, cocoa butter, shea butter, refined olive oil, hydrogenated castor oil isostearate, polyglycerol-2-isostearate / dimer dilinoleic acid copolymer, diisostearyl malate, plant-based wool grease, D&C red 21#, Ve oil and BHT. Various teas and traditional Chinese medicines having health care effects on the lip are selected, leaching oil of oil soluble ingredients is prepared, and the lipstick has the advantages of being good in safety, nutrient, full in health care function and free of side effects in common use, and has good effects on beautifying and caring the lip and preventing contact cheilitis.

Owner:ZHENGZHOU JIABEILI BIOLOGICAL SCI & TECH

Sesame cake

InactiveCN105519632AGreat tasteReduce formationDough treatmentBakery productsFiberShiitake mushrooms

The invention relates to a sesame cake comprising a wrapper, a pastry wrapper and filling. The wrapper comprises cooked flour, corn flour, barley flour, water, sesame oil, xylitol, egg and shortening; the pastry wrapper comprises flour, sesame oil, wheat bran and rice bran; the filling comprises mushroom, buckwheat, sweet potato powder, raisin, cheese, mint and plant oil. The corn flour and the barley flour added into the wrapper contain rich crude fibers which like a dental care 'toothbrush' and generate mechanical friction with the dental faces during chewing, the effect of cleaning teeth can be achieved, and formation of dental plaque is reduced; the wheat bran and the rice bran added into the pastry wrapper contain rich crude fibers which can effectively clean the tooth surfaces; the mushroom added into the filling contains plenty of lentinan which can inhibit growth of pathogenic bacteria in the oral cavity, stop formation of dental plaque and prevent dental caries, and the raisin, cheese, mint, sweet potato powder and the like added into the filling can all achieve the effect of preventing dental caries.

Owner:YULIN XINYUE FOOD CO LTD

Valve hand wheel coating

InactiveCN105295571AExtended service lifeImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsFiberNano al2o3

The invention discloses a valve hand wheel coating, and relates to the technical field of valve manufacturing. The valve hand wheel coating is prepared from, by weight, 70-80 parts of high chlorinated polyethylene resin, 40-50 parts of bisphenol A epoxy resin, 15-20 parts of gypsum powder, 13-17 parts of expansive cement, 11-15 parts of hydroxypropyl starch ether, 9-13 parts of jute fibers, 7-10 parts of nano aluminum oxide, 5-8 parts of rice bran wax, 5-8 parts of sorbitol, 4-6 parts of polyoxyethylene polyoxypropylene ether, 3-5 parts of cobaltous hydroxide, 15-20 parts of ethyl acetoacetate, 35-45 parts of glycerin and 50-60 parts of water. The coating can be firmly attached to a hand wheel, the compact and hard coating can be quickly formed after spraying, the coating layer has excellent abrasive resistance, weather resistance, corrosion resistance, ageing resistance and the like, and therefore the hand wheel can be controlled conveniently and the service life of the hand wheel can be prolonged.

Owner:HEXIAN KEJIA VALVE CASTING

Environmentally-friendly shopping paper bag water-proof outer film

InactiveCN105885165AAvoid pollutionImprove waterproof performanceLow-density polyethyleneMicrocrystalline wax

The invention discloses an environmentally-friendly shopping paper bag water-proof outer film, and relates to the technical field of plastic films. The environmentally-friendly shopping paper bag water-proof outer film is prepared from the following raw materials in parts by weight: 35-40 parts of low-density polyethylene, 10-15 parts of polypropylene, 6-10 parts of hydrogenated rosin, 6-10 parts of chitosan, 5-8 parts of filling mineral powder, 5-8 parts of hydrogenated castor oil, 4-6 parts of soybean protein gel, 4-6 parts of rice bran wax, 3-5 parts of sodium carboxymethyl starch, 2-3 parts of glyceryl stearate, 2-3 parts of polyether, 1-2 parts of butadiene rubber, 1-2 parts of microcrystalline wax, 0.5-1 part of urea and 0.5-1 part of antimonous oxide. The environmentally-friendly shopping paper bag water-proof outer film can be attached to the outside of a shopping bag to make an environmentally-friendly shopping bag, so that the water resistance, aging resistance and mechanical performance of the shopping bag are improved, and the problems of tendency to breakage and moisture absorption due to use of paper bags are solved; moreover, the film is biodegradable, so that environmental pollution caused by use of the plastic bag is avoided.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

Ceramic tile adhesive and preparation method thereof

The invention discloses a ceramic tile adhesive and a preparation method thereof. The ceramic tile adhesive is prepared from the following raw materials in parts by weight: 30-40 parts of cement, 35-40 parts of quartz sand, 10-15 parts of vinyl acetate-ethylene copolymer rubber powder, 5-7 parts of zeolite powder, 0.3-0.6 part of nano titanium dioxide, 6-10 parts of modified gypsum powder, 1-3 parts of cellulose ether, 5-10 parts of fly ash, 0.3-0.6 part of setting retarder, 0.5-0.8 part of defoaming agent, 0.3-0.5 part of organic silicon water repellent, 4-7 parts of citric acid, 5-8 parts of guar gum, 3-7 parts of eucalyptus oil, 2.6-3.5 parts of rice bran wax and 50-70 parts of water. The ceramic tile adhesive has the advantages of favorable water resistance, favorable cold / heat abrupt change resistance, favorable aging resistance and favorable long-term durability, and has high binding force with ceramic tiles when being used for bonding ceramic tiles.

Owner:安庆市凯瑞建材有限公司

Leather lustering agent

The invention relates to the technical field of leather care, in particular to a leather brightener. It consists of the following components by mass: 15-20 parts of rice bran wax, 10-15 parts of beeswax, 5-8 parts of polydimethylsiloxane, 10-15 parts of cetearyl polyoxyethylene ether, 12 parts 8-10 parts of sodium alkylbenzene sulfonate, 5-8 parts of tripolyglycerol sodium monostearate, 5-8 parts of silicone modified polyurethane resin, 5-10 parts of mineral oil, 3-5 parts of lanolin, hard 3-5 parts of fatty acid, 80-100 parts of water, 10-15 parts of isopropanol, 0.1-0.3 parts of benzyl alcohol, and 0.1-0.5 parts of methylchloroisothiazolinone. The leather brightener of the present invention contains vegetable wax and animal wax, and water is not easy to penetrate into the leather; small molecule fat and alcohol can penetrate deep into the leather fiber to replenish oil, making the leather plump and flexible; the silicone-modified polyurethane resin can A breathable film is formed on the surface of the leather, which is smooth to the touch, and can increase the brightness and wear resistance of the leather.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Lubricating grease for centrifugal pump sliding bearing

InactiveCN105316096AReduce manufacturing costReduce coefficient of frictionLubricant compositionDiethanolamideCetyl alcohol

The invention discloses a lubricating grease for a centrifugal pump sliding bearing, and relates to the technical field of centrifugal pump manufacturing. The lubricating grease is prepared from the following raw materials in parts by weight: 50-60 parts of mineral base oil, 20-25 parts of modified lard, 13-16 parts of sodium rosin soap, 12-15 parts of sodium bentonite, 10-14 parts of rice bran wax, 7-12 parts of coconut oil fatty acid diethanolamide, 7-12 parts of cetyl alcohol, 6-10 parts of a hydrogenated styrene diene copolymer, 5-8 parts of turpentine oil, 5-8 parts of an oxidation and corrosion inhibitor, 4-7 parts of N, N'-di-salicylidene propanediamine and 3-5 parts of maltodextrin. According to the lubricating grease, mineral base oil and modified lard are used as main raw materials, various functional additives are added in an assistant manner, and the prepared lubricating grease is uniform and transparent and low in manufacturing cost, so that bearing friction coefficients and surface abrasion are greatly reduced, and the service life of the centrifugal pump sliding bearing is prolonged.

Owner:ESKE PUMP

Novel soil modifier

InactiveCN106365852ALower pHReduce the impact of germinationBiocideCalcareous fertilisersRare earthPotassium

The invention discloses a novel soil modifier. The novel soil modifier is prepared from, by weight, 5-25 parts of vinegar residues, 3-20 parts of potassium feldspar, 80-110 parts of straw, 1-15 parts of rare earth silico-calcium mineral substance, 1-10 parts of asparagus residues, 5-25 parts of pomace, 3-20 parts of saw dust, 3-20 parts of bean pulp, 1-12 parts of charcoal, 1-14 parts of yellow cinnamon leaves, 1-10 parts of polymerization amino acid, 1-6 parts of citric acid, 1-15 parts of garden burnet roots, 0.1-3 parts of water-retaining agent, 1-10 parts of rice bran wax, 1-10 parts of sodium silicate and 0.1-5 parts of polymaleic acid. The novel soil modifier has the functions of reducing the pH of soil, improving the physical structure of the soil and increasing soil fertility; when the novel soil modifier is applied in the plant growth earlier stage, the desalting effect is remarkable, the influence of salt damage on plant seedling emergence can be effectively reduced, the production cost can be reduced, the nutrient substances of the soil modifier are effectively enriched, and the growth needs of crops are met.

Owner:云南云创数字生态科技有限公司

Soil insecticide prepared from sapindus mukorossi gaertn.

InactiveCN105794878AAffect normal growthWill not polluteBiocideDead animal preservationFissidens bryoidesPollen

The invention discloses soil insecticide prepared from sapindus mukorossi gaertn.and relates to the technical field of forest plantation.The soil insecticide is prepared from, by weight, 8-13 parts of sapindus mukorossi gaertn., 15-20 parts of leaves of clausena dunniana levl., 15-20 parts of leaves of lllicium anisatum, 10-15 parts of Chinese honeylocust fruit powder, 10-15 parts of rapeseed dregs, 7-11 parts of volcanic ash, 6-10 parts of rice bran wax, 6-10 parts of tobacco stems, 5-8 parts of tea-oil tree fruit dregs, 5-8 parts of eucalyptus oil, 4-6 parts of calamine, 3-5 parts of Chinese honeylocust spines, 3-5 parts of asbestos powder, 3-5 parts of semen raphani, 2-4 parts of rhizoma cimicifugae, 2-4 parts of rosin, 1-2 parts of resina liquidamberis, 1-2 parts of cattail pollen, 0.5-1 part of mirabilite and 60-80 parts of water.The soil insecticide has the advantages of being small in using dosage, quick in effectiveness and long in insecticide effect, insets in soil can be effectively killed, the soil cannot be polluted, the physical and chemical properties of the soil cannot be destroyed, normal growth of plants cannot be influenced, when used, the soil insecticide can be directly mixed into the soil, and certain water retention and fertilizer retention effects can be achieved.

Owner:ANHUI LINHAI LANDSCAPING CO LTD

Packing leather cup rubber for brake wheel cylinder of automobile and preparation method thereof

The invention discloses packing leather cup rubber for a brake wheel cylinder of an automobile. The packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 20-30 parts of fast extruding furnace black N550, 10-15 parts of modified white carbon black, 3-4 parts of graphite, 8-10 parts of modified wood ash, 4-6 parts of talcum powder, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of N,N'-m-phenylene bismaleimide, 0.5-1 part of vulcanizing agent BP, 0.2-0.4 part of accelerant M, 0.3-0.6 part of accelerant TT, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of rice bran wax, 1-2 parts of triphenyl phosphite, 1-2 parts of anti-aging agent RD, 2-3 parts of N-2-(aminoethyl)-3-aminopropyl trimethoxysilane and 16-18 parts of butyl epoxy oleate. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

Soil improvement agent for improving saline-alkali land into cryptotympana atrata fabricius farm

InactiveCN105733598AImprove adsorption capacityReduce heavy metal contentAgriculture tools and machinesOrganic fertilisersRare earthChaff

A soil improver for improving saline-alkali land into golden cicada farms, which relates to the technical field of golden cicada artificial breeding. 12 parts of coconut bran, 15 parts of pomace, 8 parts of camellia oil, 6 parts of soybean meal, 12 parts of jasmine leaves, 3 parts of camphor leaves, 2 parts of maltodextrin, 3 parts of Burnet, 5 parts of silkworm chrysalis powder, 4 parts of rice bran wax 1.5 parts of zeolite powder, 1.5 parts of sodium silicate, 0.2 parts of rare earth, and 15 parts of traditional Chinese medicine composition. The invention uses a soil improver to improve the saline-alkali land into an environment for the growth of the golden cicada. After the improvement, the period for cultivating the golden cicada is greatly shortened, and the cultivated golden cicada can be unearthed within 1-2 years.

Owner:蚌埠海上明珠农业科技发展有限公司

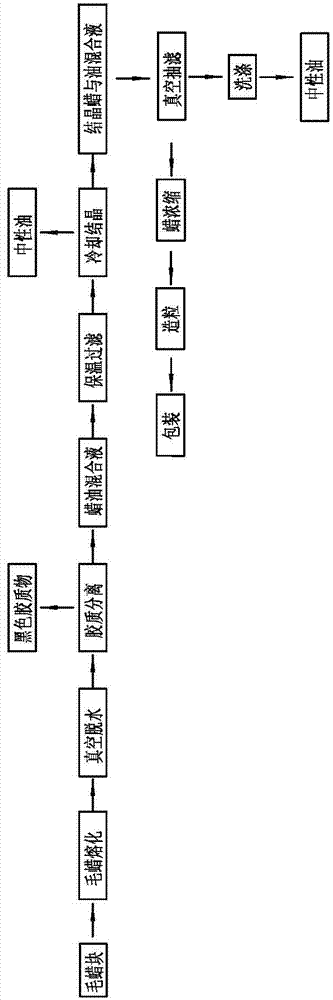

Production method of refined rice bran wax

InactiveCN107118849ASolve refined technical problemsDevelop economic valueFatty substance recovery/refiningFatty substance recoveryReflux extractionChemical reaction

The invention relates to a production method of refined rice bran wax and can effectively solve problem about preparation of the refined rice bran wax from crude rice bran wax through industrial squeezing. The method comprises the following steps: the crude rice bran wax is melted into wax liquor, the wax liquor is dried in vacuum for water removal and pumped into an extraction tank, a solvent and an adsorbent are added, the mixture is subjected to reflux extraction, a product is left to stand for layering, a colloidal material on the lower layer is for other use, wax oil mixed liquor on the upper layer is subjected to heat preservation and filtered, trace impurities are removed, cooling crystallization and crystal growing are performed, the solvent is recovered from mixed oil on the upper layer through an evaporation system, neutral oil is obtained, crystal mixed wax liquor on the lower layer enters a rotary drum vacuum filter, solid wax and oil are separated out, the oil is recycled, the solid wax is heated, evaporated in vacuum and concentrated, trace solvent and water are removed, liquid rice bran wax is obtained and subjected to cooling granulation, and the refined rice bran wax is obtained. The method is novel, unique, high in production efficiency, low in cost, energy-saving and environment-friendly, physical and chemical reactions are integrated, the technical problems about industrial rice bran wax refining are solved effectively, and the economic value of the rice bran wax is exploited.

Owner:河南华泰粮油机械股份有限公司

High-adhesiveness anti-cracking composite material and preparation method thereof

InactiveCN106366944AGood adhesionEasy to cleanNon-ionic surface-active compoundsSurface-active non-soap compounds and soap mixture detergentsBetaineAutomotive paint

The invention discloses a high-adhesiveness anti-cracking composite material. The high-adhesiveness anti-cracking composite material comprises the following raw materials in parts by weight: modified rice bran wax 15-25 parts, palm wax 2-5 parts, paraffin 3-5 parts, saponin extract 1-4 parts, mineral oil 1-3 parts, methyl-silicone oil 2-5 parts, cocinic acid alkanolamide 3-6 parts, coconut fatty diethanolamide 2-5 parts, aluminum silicate 1-4 parts, triethanolamine 3-5 parts, laurel alcohol ether phosphate 2-6 parts, oleic acid 1-4 parts, ethylene glycol 2-4 parts, dodecyl betaine 1-4 parts, essence 2-5 parts and water 3-6 parts. The invention further provides a preparation method of the high-adhesiveness anti-cracking composite material. The composite material prepared by the invention is high in adhesiveness, cracking of automotive paint can be avoided, and the service life of paint of the surface of an automobile is prolonged.

Owner:ANHUI SKY EYE INTELLIGENT TECH

Edible releasing agent

The invention relates to an edible releasing agent comprising the following main raw material components according to parts by weight: 100 parts of maize oil, 3 parts of polyacrylate sodium, 1 to 2 parts of lecithin and 3 to 4 parts of rice bran wax. The edible releasing agent has the main characteristics that: (1), the releasing capability is strong, the surfaces of foods are flat and smooth, grease is distributed uniformly, and the taste of the foods can not be influenced; (2), all the raw materials are edible materials or food additives; and (3), no oil fume is generated when the foods are baked, and the ambient environment is not polluted.

Owner:BEIJING BRIDGECOM SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com