Mold release agent and preparation method thereof

A release agent and emulsifier technology, applied in the food field, can solve the problems of settlement, high cost, storage and transportation, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

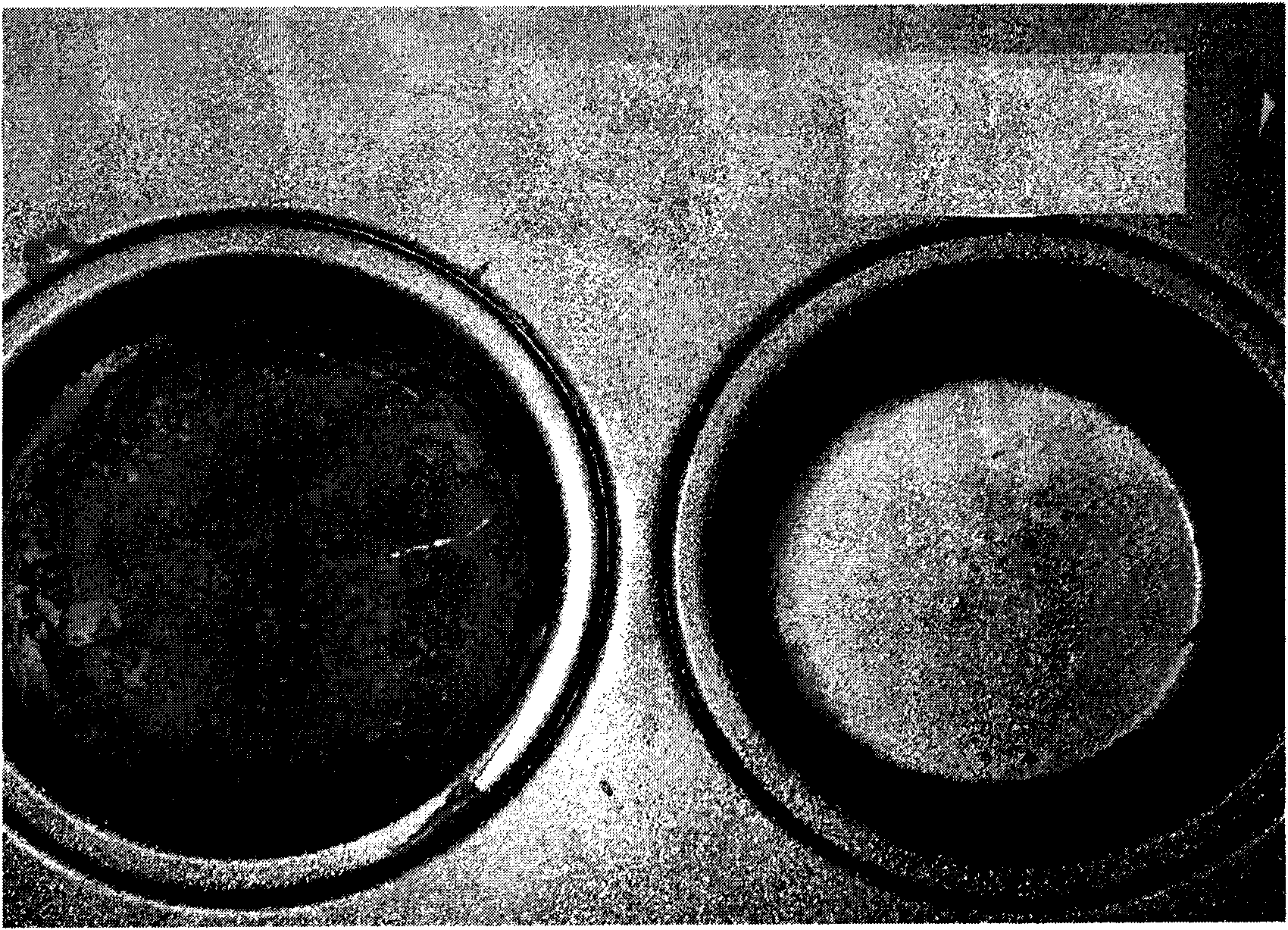

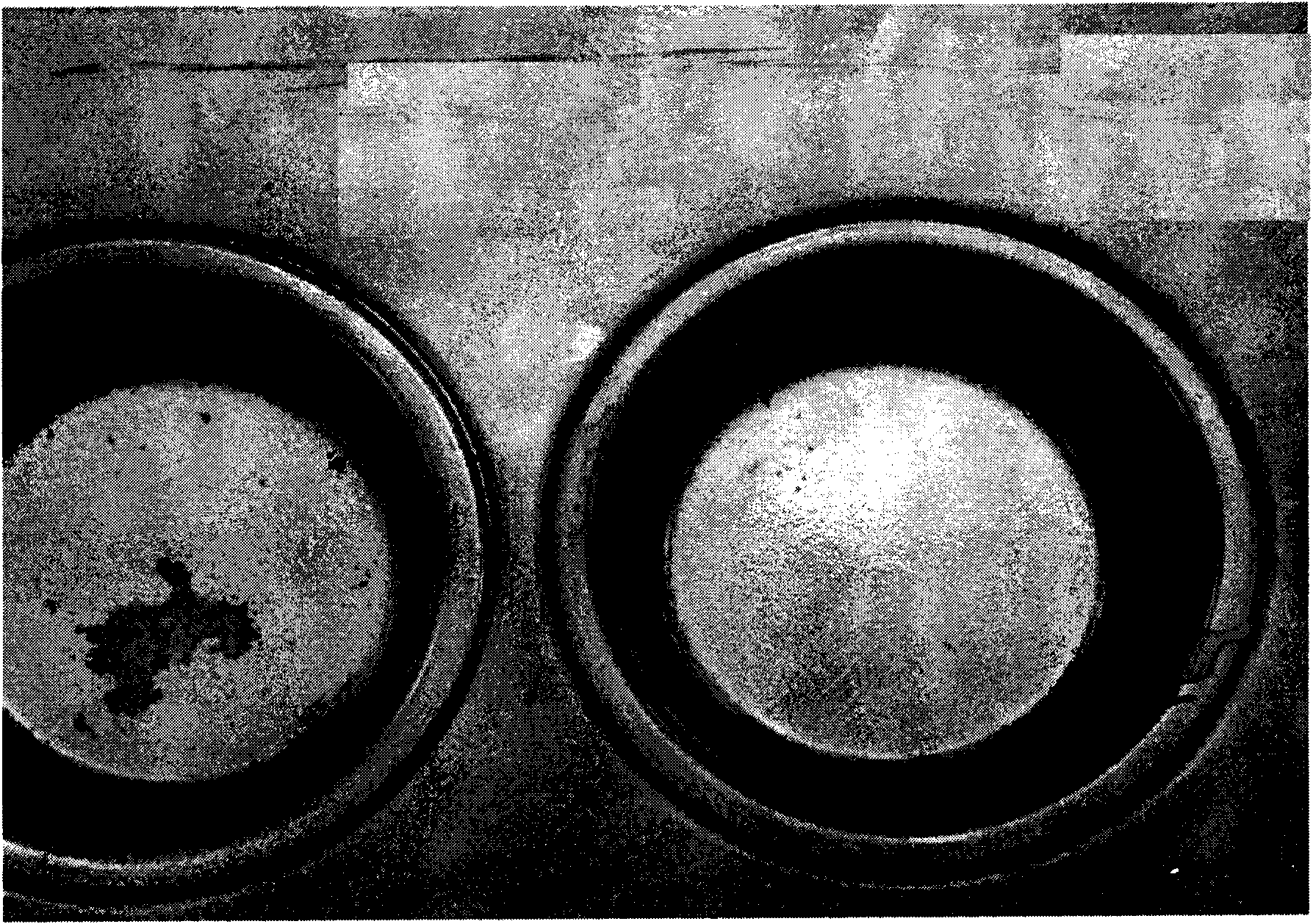

Image

Examples

preparation example Construction

[0052] Another aspect of the present invention also relates to a method for preparing a release agent, the method comprising: mixing the components of the release agent to obtain a homogeneous mixture; quenching the mixture to below about 30° C., kneading; and returning the temperature to the quenched Above the temperature, aging is carried out, so as to obtain the finished mold release agent.

[0053] The components of the release agent can be mixed in a conventional manner. For example, the components can be melted and mixed together, stirring well.

[0054] The quenching step can be carried out using various devices existing in the art, for example, shortening production equipment can be used. During rapid cooling and kneading, the outlet temperature of the equipment is controlled below about 30°C, such as below 25°C, 20°C, 15°C, etc., such as 10-25°C, 10-20°C or 15-20°C.

[0055] The step of returning to temperature and aging can be realized by placing the quenched and k...

Embodiment 1

[0071] Ingredients: get 300g of rice bran wax and melt, add 1300g of fractionated coconut oil liquid oil (iodine value 16g I2 / 100g), and add 400g of lecithin, stir and mix evenly. Then add this mixed oil in 8000g rapeseed oil, and add 2g vitamin E, mix evenly.

[0072] Process: Use shortening production equipment (Danish G&A Company) to knead the blended oil that has been prepared above, and control the outlet temperature below 20°C, pack it in a food-grade container, and then place it in a warehouse at 25°C to warm up Aging for 1 day is the finished product.

[0073] The liquid oil of the above fractionated coconut oil is obtained by fractionating coconut oil at normal pressure and growing crystals at 5-15°C.

Embodiment 2

[0075] Ingredients: Take 500g of rice bran wax and 500g of extremely hydrogenated canola oil (Nanhai Oil Industry (Chiwan) Co., Ltd., the product name is Golden Oriole brand extremely hydrogenated rapeseed oil) and melt, add 4000g of medium-chain fat triglycerides (MCT , Shanghai Heyi Food Additive Co., Ltd., product name is medium-chain fatty triglyceride GCTT), and add 400g polyglycerol polyricinoleate, stir and mix. Add this mixed oil in 4600g rapeseed oil again, and add 2g vitamin E, mix well.

[0076] Process: Use shortening production equipment to knead the mixed oil prepared above, control the outlet temperature below 20°C, pack it in a food-grade container, and then place it in a warehouse at 30°C for 1 day. finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com