Full-automatic rationing machine

A quantitative feeder, fully automatic technology, used in conveyors, rotary conveyors, loading/unloading, etc., can solve the problem that the residue cannot be completely discharged, the bearing sealing structure is not ideal, and the accuracy of measurement is affected, etc. problems, to achieve the effect of long working life, simple and compact structure, and stable feeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

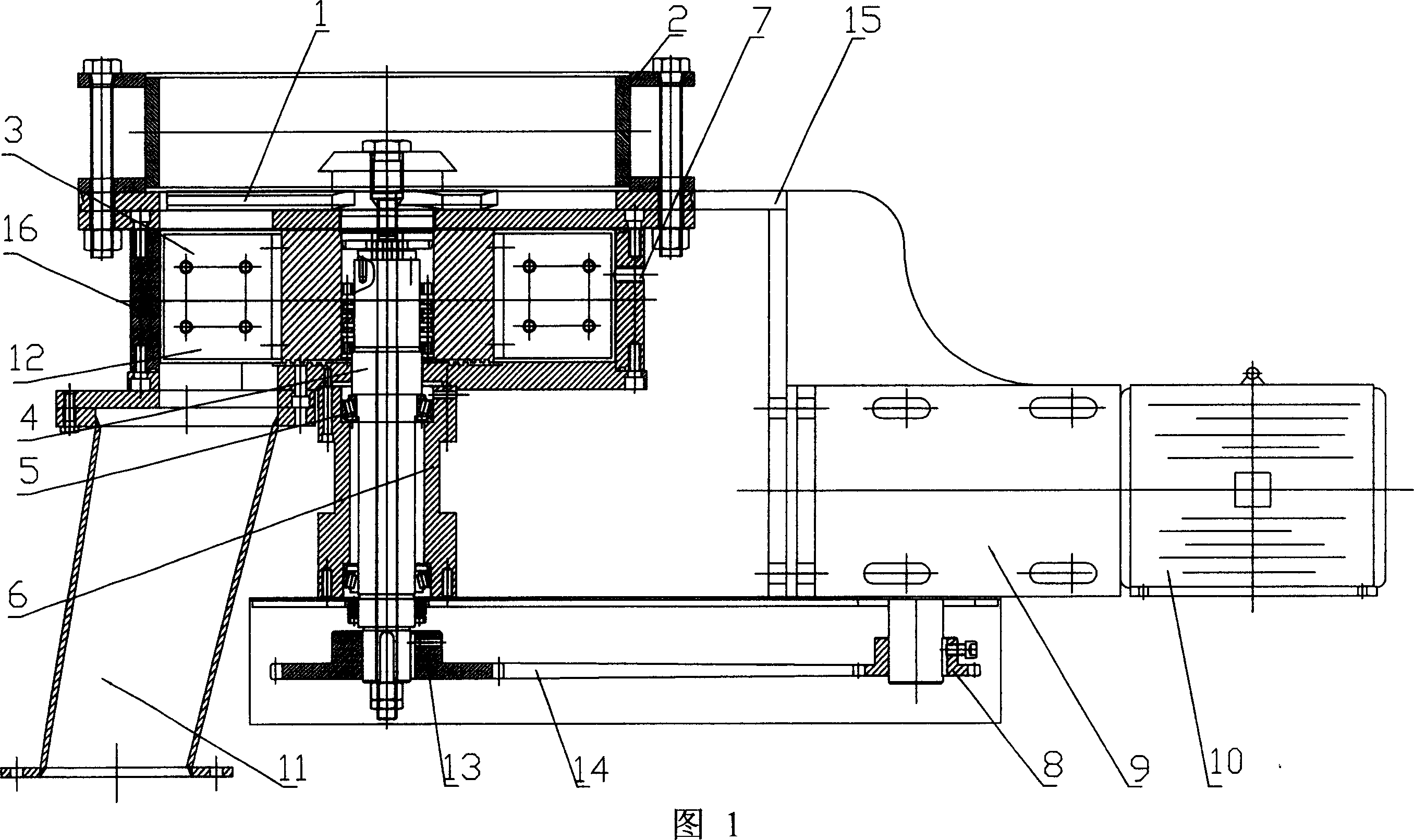

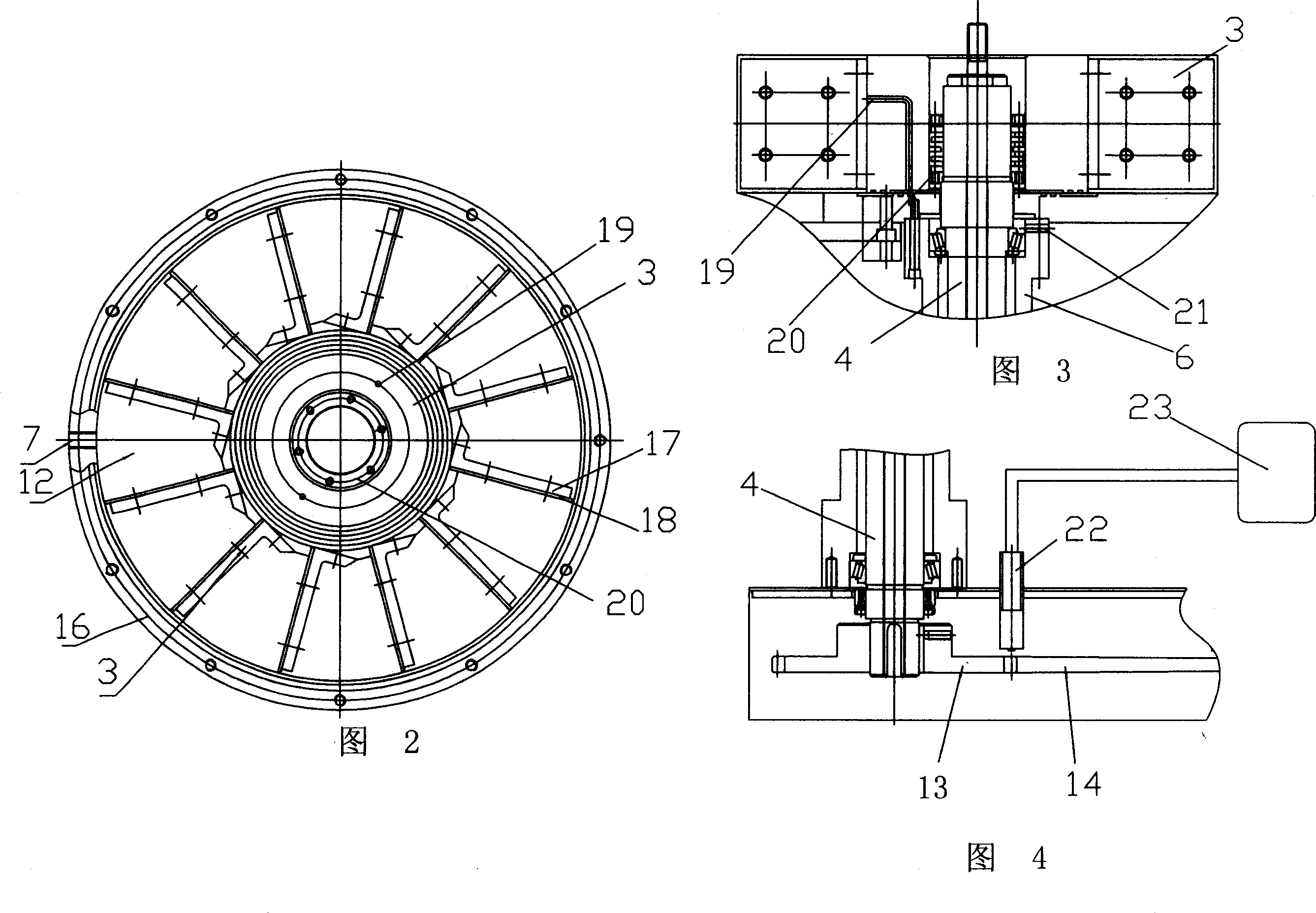

[0013] In the figure: 1. Scraper, 2. Hopper, 3. Impeller, 4. Main shaft, 5. Bearing, 6. Air-sealed bearing seat, 7. Purge assembly, 8. Transmission wheel, 9. Reducer, 10. Motor, 11. Discharge port, 12. Material storage space, 13. Driven wheel, 14. Transmission belt, 15. Rack, 16. Housing, 17. Metering vane, 18 Regulating vane, 19. Pipeline, 20. Self-locking adjustment center Device, 21, bearing air seal air intake hole, 22, speed measurement and low speed protection assembly, 23, console.

[0014] As shown in the figure: install the bearing seat 6 under the housing 16, install the main shaft 4 with the bearing 5 in the bearing housing 6, install the hopper 2 on the top of the housing 16, the upper end of the main shaft 4 is located in the hopper 2, and the main shaft 4 The scraper 1 is installed on the upper end of the hopper, the impeller 3 is installed on the main shaft 4 below the hopper 2, and several blades are installed on the impeller 3, and a storage space 12 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com