Rice bran calcium cerotate soap wax and preparation method thereof

A technology of rice bran wax ester and rice bran wax, which is applied in the preparation of carboxylate, the preparation of carboxylate/lactone, and the preparation of carboxylic acid by oxidation, can solve problems such as supply stoppage, and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

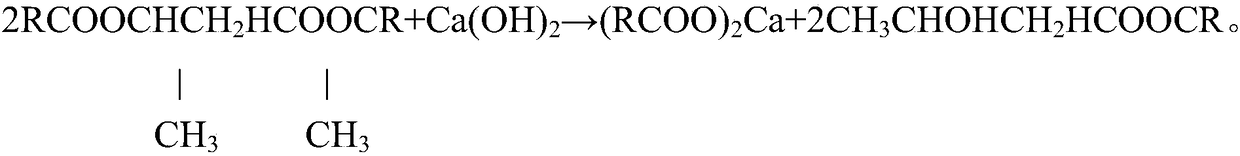

Method used

Image

Examples

Embodiment 1

[0020] The invention provides a method for preparing light-colored rice bran wax acid wax, comprising the following steps:

[0021] Deoiling: Put the deoiled and unbleached rice bran wax into a stainless steel reactor and soak it in ethyl acetate with a concentration of 99.7% for 4 hours, then open the valve under the stainless steel reactor to pump the ethyl acetate into the storage tank for distillation and recovery , the deoiled rice bran wax is heated to 90°C and melted, then cooled and sliced for later use;

[0022] Oxidation: Put 600kg of sliced rice bran wax and 2000ml of 50% dilute sulfuric acid into the enamel reaction kettle, heat to 90°C to melt the rice bran wax, then add 1900ml of 50% red alum sodium solution for oxidation, and keep the temperature at 90 ℃ and kept stirring for 6 hours, the color of rice bran wax changed from brown to light, cooled naturally, and allowed to stand for 1 hour to separate the wax and chromium slurry solution. Pump into another e...

Embodiment 2

[0027] The invention provides a method for preparing light-colored rice bran wax acid wax, comprising the following steps:

[0028] Deoiling: Put the deoiled and unbleached rice bran wax into a stainless steel reactor and soak it in ethyl acetate with a concentration of 99.7% for 4 hours, then open the valve under the stainless steel reactor to pump the ethyl acetate into the storage tank for distillation and recovery , the deoiled rice bran wax is heated to 95°C and melted, then cooled and sliced for later use;

[0029] Oxidation: Put 650kg of sliced rice bran wax and 2200ml of 50% dilute sulfuric acid into an enamelled reaction kettle, heat to 95°C to melt the rice bran wax, then add 2000ml of 50% red alum sodium solution for oxidation, and keep the temperature at 95 Stir continuously at ℃ for 6 hours, the color of rice bran wax changes from brown to light, cool naturally, let stand for 1.5 hours to separate the wax and chromium slurry solution, the chromium slurry in th...

Embodiment 3

[0034] The invention provides a method for preparing light-colored rice bran wax acid wax, comprising the following steps:

[0035] Deoiling: Put the deoiled and unbleached rice bran wax into a stainless steel reactor and soak it in ethyl acetate with a concentration of 99.7% for 4 hours, then open the valve under the stainless steel reactor to pump the ethyl acetate into the storage tank for distillation and recovery , the deoiled rice bran wax is heated to 100°C and melted, then cooled and sliced for later use;

[0036] Oxidation: Put 550kg of sliced rice bran wax and 1800ml of 50% dilute sulfuric acid into the enamel reaction kettle, heat to 100°C to melt the rice bran wax, then add 1800ml of 50% red alum sodium solution for oxidation, and keep the temperature at 100 Stir continuously at ℃ for 6 hours, the color of rice bran wax changes from brown to light, cool naturally, let stand for 2 hours to separate the wax and chromium slurry solution, the chromium slurry in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com