Thermal transfer ribbon for printing golden and silver bar codes and preparation method thereof

A barcode printing, gold and silver color technology, applied to chemical instruments and methods, printing, ink ribbons, etc., can solve the problems of serious pollution, cumbersome plate making, waste, etc., and achieve the effect of simple preparation method, easy popularization and application, and strong covering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

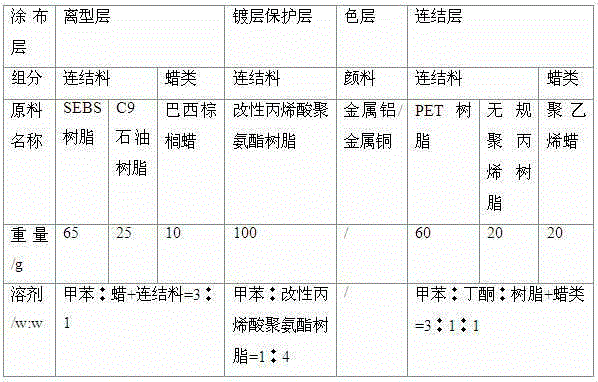

Embodiment 1

[0040]

[0041] The preparation method of the above-mentioned gold and silver barcode printing ribbon comprises the following steps:

[0042] a. In terms of weight ratio, gasoline: linking material = 9: 1, dilute and mix the linking material silicone resin (85g) of the back coat with gasoline, and then add the additive methyl in proportion within 30 minutes before use Hydrogen siloxane (15g) is mixed evenly, coated on the surface of the tape base with a thickness of 4.5 μm, dried at 80°C to form a back coating with a thickness of 0.2 μm, and enters the next process;

[0043] b. By weight, toluene: wax + resin = 3: 1, heat and dissolve the wax, SEBS resin and C9 petroleum resin with toluene, apply it on the other side of the tape base, and dry it at 75°C to form a thickness of 0.4 μm Release layer, enter the next process;

[0044] c. By weight, toluene: modified acrylic polyurethane resin = 1:4, heat and dissolve the modified acrylic polyurethane resin with toluene, apply i...

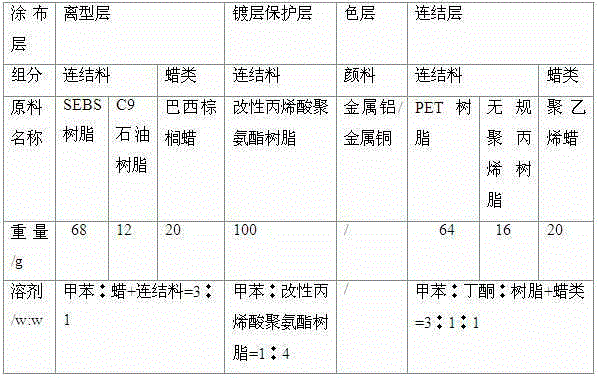

Embodiment 2

[0048]

[0049] Preparation:

[0050] The thickness of the tape base is 4.5 μm, the drying temperature is 80°C, and the thickness of the back coating is 0.2 μm; the drying temperature in step b is 75°C, and the thickness of the release layer is 0.5 μm; the drying temperature in step c is 90°C, and the coating protective layer The thickness is 1 μm; the thickness of the color layer in step d is 1.3 μm, the drying temperature in step e is 80°C, and the thickness of the connecting layer is 0.8 μm; the total thickness of the gold and silver barcode printing ribbon is 8.3 μm; the printing hiding power: 1.1; the printing gloss 25. Others are the same as in Example 1.

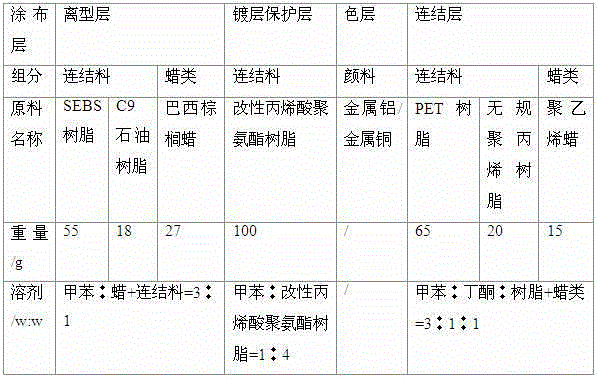

Embodiment 3

[0052]

[0053] Preparation:

[0054] The thickness of the tape base is 4.5 μm, the drying temperature is 80°C, and the thickness of the back coating is 0.2 μm; the drying temperature in step b is 75°C, and the thickness of the release layer is 0.4 μm; the drying temperature in step c is 90°C, and the coating protective layer Thickness: 0.7 μm; color layer thickness in step d: 1.5 μm; drying temperature in step e: 80°C, connecting layer thickness: 0.8 μm; total thickness of gold and silver barcode printing ribbon: 8.1 μm; blot hiding power: 1.4; blot gloss Degree 27, other are all with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com