By-pass rumen choline chloride microcapsules and preparation method thereof

A choline chloride and microcapsule technology, applied in the field of feed additives, can solve the problems of moisture absorption, low effective components, and difficulty in long-term storage, so as to promote the improvement of rumen passing rate and release rate, reduce hygroscopicity, The effect of preventing moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

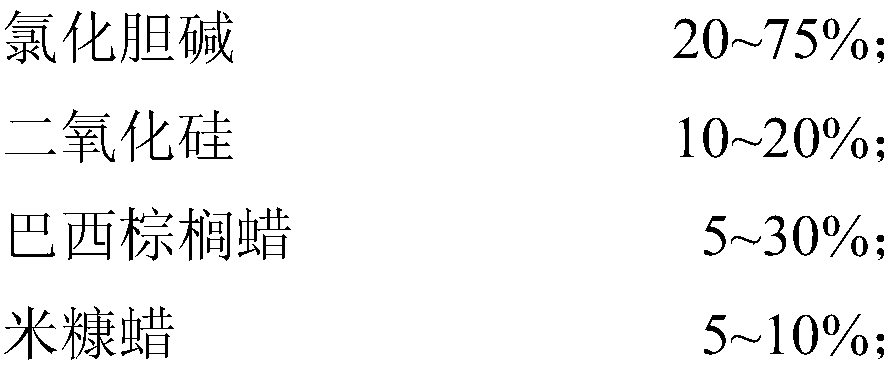

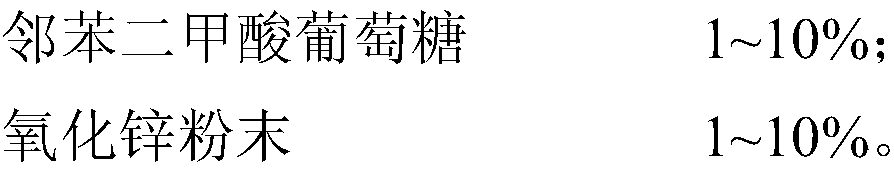

[0048] A rumen-passed choline chloride microcapsule, the raw material composition is as follows: 25% choline chloride; 25% silicon dioxide; 30% carnauba wax; 10% rice bran wax; 5% glucose phthalate; zinc oxide powder 5%.

[0049] Concrete preparation process is as follows:

[0050] (1) Get 250kg choline chloride, after pulverizing, mix homogeneously with 250kg silicon dioxide, obtain mixture I;

[0051] (2) Take 300kg of carnauba wax and put it in the reactor to melt, and keep it warm at a temperature of 20°C higher than its melting point; then mix the melted carnauba wax with mixture I, stir well, and spray into the frozen Freeze-drying at low temperature (8°C) in a chamber to obtain primary coated particles;

[0052] (3) 100kg rice bran wax, 50kg phthalate glucose are dissolved in 500L of 75% (volume fraction) ethanol solution, then add 50kg zinc oxide powder, obtain mixed solution II; In the fluidized bed, spray mixed solution II at the same time, and after the product o...

Embodiment 2

[0066] A rumen-passed choline chloride microcapsule, the raw material composition is as follows: 50% choline chloride; 25% silicon dioxide; 15% carnauba wax; 5% rice bran wax; 2.5% glucose phthalate; zinc oxide powder 2.5%.

[0067] Concrete preparation process is as follows:

[0068] (1) Get 500kg choline chloride, after pulverizing, mix homogeneously with 250kg silicon dioxide, obtain mixture I;

[0069] (2) Take 150kg of carnauba wax and put it in the reactor to melt, and keep it warm at a temperature of 20°C higher than its melting point; then mix the melted carnauba wax with mixture I, stir well, and spray into the frozen Freeze-drying at low temperature (8°C) in a chamber to obtain primary coated particles;

[0070] (3) 50kg of rice bran wax and 25kg of glucose phthalate are dissolved in 500L of 75% (volume fraction) ethanol solution, and then 25kg of zinc oxide powder is added to obtain mixed solution II; In the fluidized bed, spray the mixed solution II simultaneous...

Embodiment 3

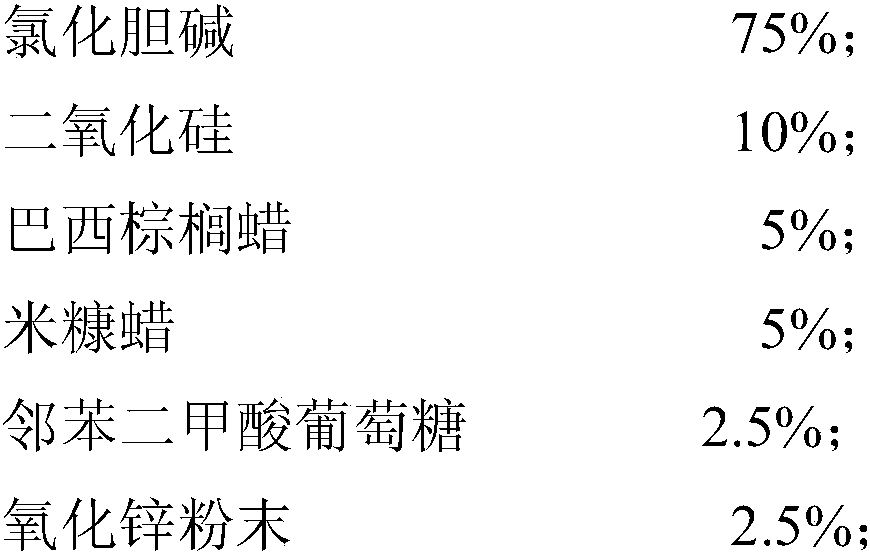

[0073] A rumen-passed choline chloride microcapsule, the raw material composition is as follows: 75% choline chloride; 10% silicon dioxide; 5% carnauba wax; 5% rice bran wax; 2.5% glucose phthalate; zinc oxide powder 2.5%.

[0074] Concrete preparation process is as follows:

[0075] (1) Get 750kg choline chloride, after pulverizing, mix homogeneously with 100kg silicon dioxide, obtain mixture I;

[0076] (2) Take 50kg of carnauba wax and put it in the reactor to melt, and keep it warm at a temperature of 20°C higher than its melting point; then mix the melted carnauba wax with mixture I, stir well, and spray into the frozen Freeze-drying at low temperature (8°C) in a chamber to obtain primary coated particles;

[0077] (3) 50kg of rice bran wax and 25kg of glucose phthalate are dissolved in 500L of 75% (volume fraction) ethanol solution, and then 25kg of zinc oxide powder is added to obtain mixed solution II; In the fluidized bed, spray mixed solution II at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com