Ruminant rumen bypass protein feed and preparation method thereof

A protein feed, ruminant technology, applied in the direction of animal feed, animal feed, animal feed molding or processing, etc., can solve the problems of reduced digestibility, poor palatability, toxic chemical treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

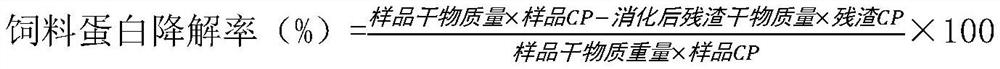

Method used

Image

Examples

Embodiment 1

[0036] The feed pellets are cylindrical in shape of 0.8mm*1.2mm.

[0037] The specific feed formula includes the following components in parts by weight: 98 parts of cottonseed meal, 1 part of feed binder and water, based on the total mass of vegetable protein and feed binder, wherein 32% of water. The feed binder is starch.

[0038] The preparation method is as follows:

[0039] (1) Mix the vegetable protein raw material, starch and water evenly, and the water content is 32%;

[0040] (2) be prepared into cylindrical granules with a granulator;

[0041] (3) Dry the feed granules with hot air at 160° C. after drying, the water content is 12%, and Maillard reaction occurs on the surface, and the surface color of the feed granules is light yellow.

Embodiment 2

[0043] The feed pellets are cylindrical with a diameter of 1.2mm*0.8, or the pellets are cylindrical with a diameter of 0.9mm*1.1mm.

[0044] The specific feed formula includes the following components in parts by weight: 90 parts of rapeseed meal, 4 parts of feed binder and water, based on the total mass of vegetable protein and feed binder, wherein 18% of water. The feed binder is carboxymethyl cellulose.

[0045] The preparation method is as follows:

[0046] (1) Mix the vegetable protein raw material, carboxymethyl cellulose and water evenly, and the water content is 18%;

[0047] (2) be prepared into cylindrical shape with granulator;

[0048] (3) Dry the feed granules with hot air at 120° C. after drying, the water content is 8%, and Maillard reaction occurs on the surface, and the surface color of the feed granules is light yellow.

Embodiment 3

[0050] Feed pellets are 1mm spherical pellets.

[0051] The specific feed formula includes the following components in parts by weight: 95 parts of soybean meal, gluten and water, based on the total mass of vegetable protein and feed binder, wherein 30% of water. Based on the total mass of the feed, 2% gluten powder.

[0052] The percentage content of dry matter of soybean meal is 86-90%, and the percentage content of crude protein is 40-44%.

[0053] The preparation method is as follows:

[0054] (1) Mix the vegetable protein raw material, gluten powder and water evenly, and the water content is 30%;

[0055] (2) Prepare spherical particles with a granulator-spheronizer;

[0056] (3) Dry the feed granules with hot air at 140° C. after drying, the water content is 10%, and Maillard reaction occurs on the surface, and the surface color of the feed granules is pale yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com