Patents

Literature

268results about How to "High effective content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-free fountain solution with high viscosity and low surface tension

InactiveCN103935150AHigh effective contentReduce pollutionPrinting pre-treatmentAlcohol freeAqueous alcohol

The invention discloses alcohol-free fountain solution with high viscosity and low surface tension. The alcohol free fountain solution with high viscosity and low surface tension comprises the following components by weight, 30-55 parts of alcohol solvents, 2-6 parts of buffer agents, 3-8 parts of wetting agents, 1-4 parts of surface active agents, 0.3-2.2 parts of antifoaming agents, 0.5-3 parts of thickening agents, 0.5-1.2 parts of anticorrosion and bactericidal agents, 1-3 parts of penetrating agents, 0-2 parts of electrolyte and 20-45 parts of viscosity modifier water. The fountain solution is free of volatile solvents containing alcohol and isopropyl alcohol and pollution to the environment, the surface tension ranges from 4*10-2N / m to 7*10-2N / m, pH ranges from 4.8 to 5.5, the heat conduction rate ranges from 800mus / cm to 1200mus / cm, and therefore, quality requirements of the fountain solution can be met better.

Owner:苏州禾川化学技术服务有限公司

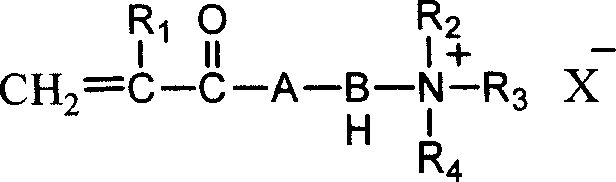

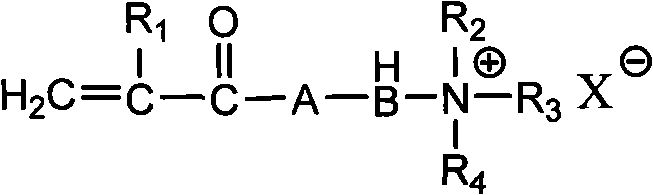

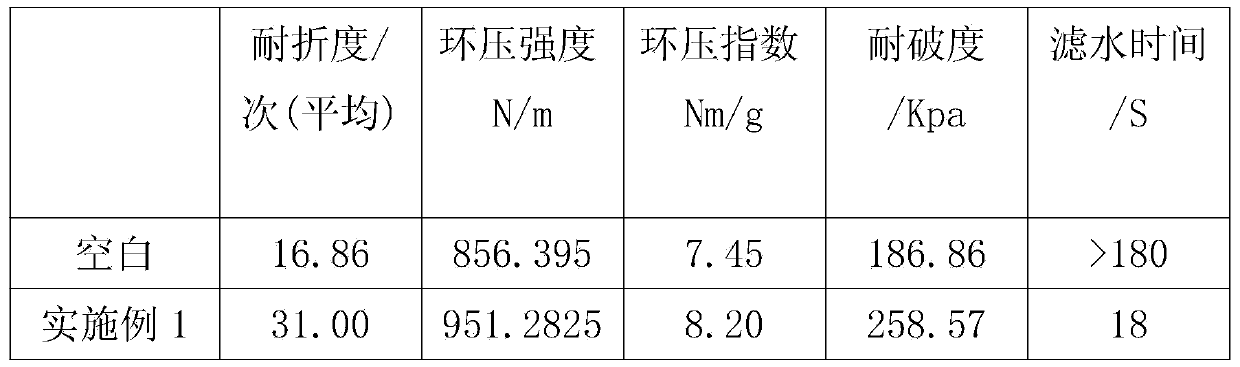

Method of synthesizing cation polyacrylamide water-in-water emulsion

The invention discloses a synthesizing method of cationic polyacrylamide 'water-in-water' emulsion, which is characterized by the following: adopting inorganic solution as dielectric with specific viscosity number is 30-90ml / g low-molecular cationic polymer solution as stabilizer; copolymerizing free radical of cationic monomer with double bond and non-ion monomer to form the product with grain size less than 1um; fitting for disposing urban effluent, oil-field effluent and paper-making domain.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

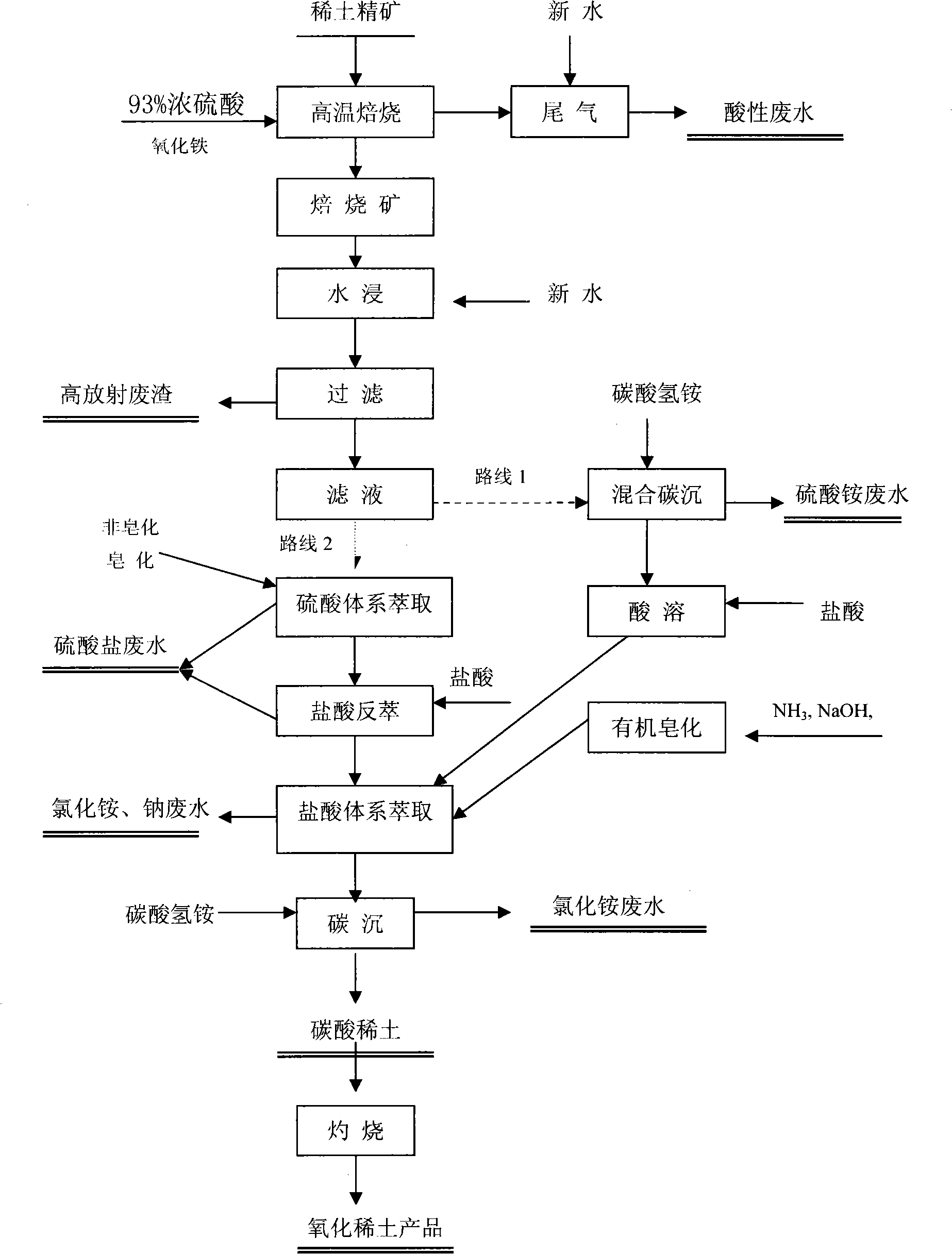

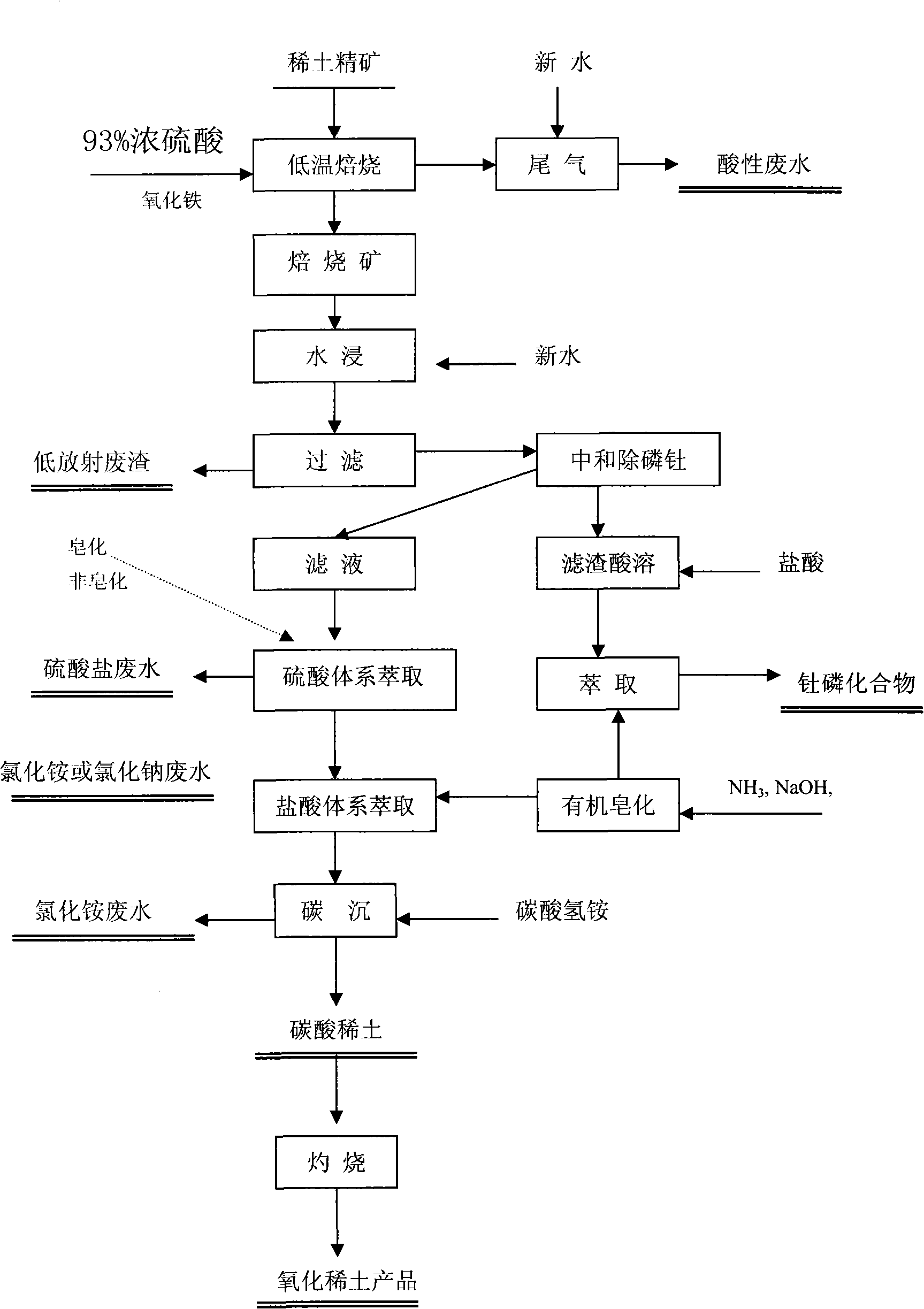

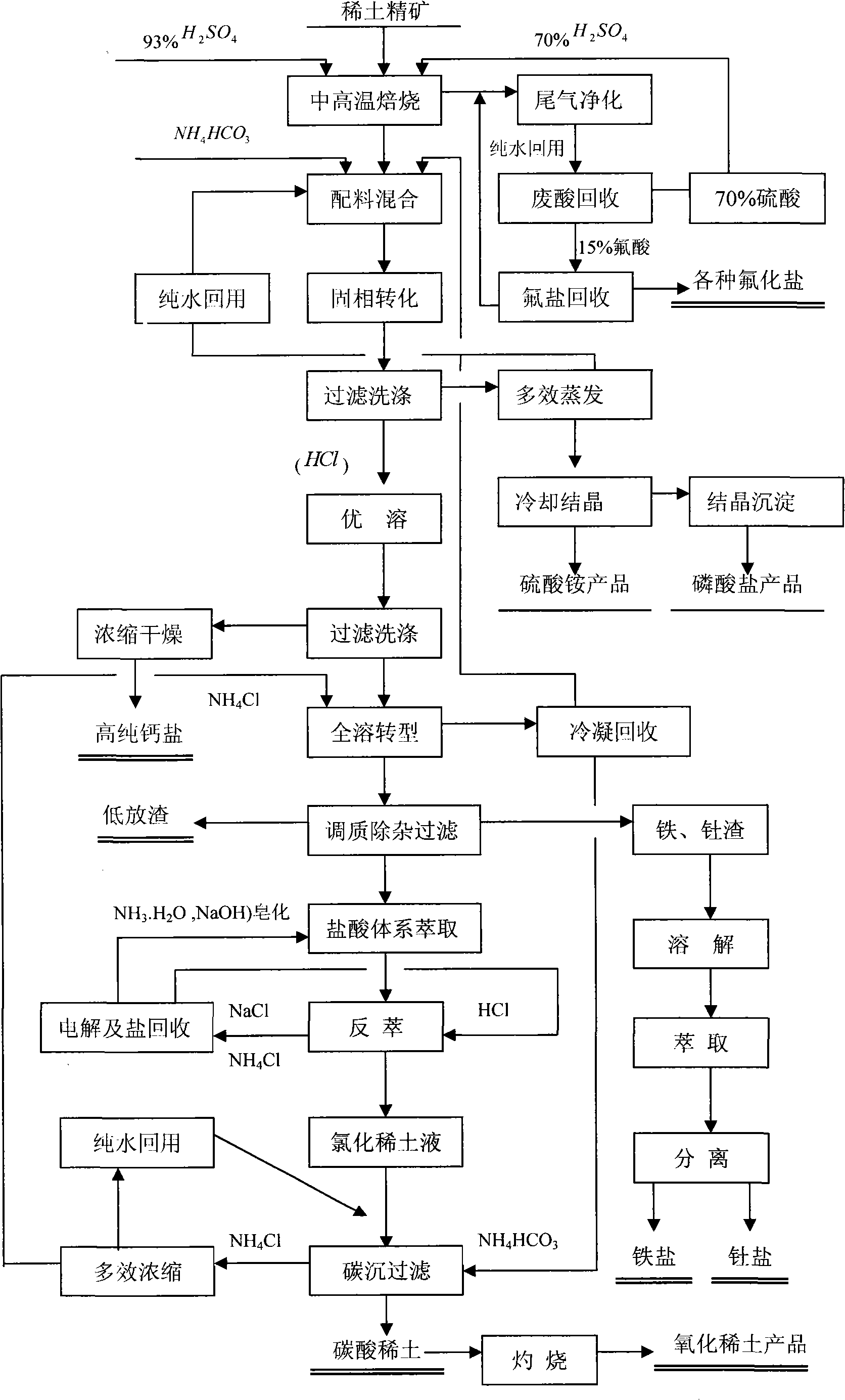

Process for rare-earth smelting resource reclamation and cyclic production

InactiveCN101880782AAchieve governanceAchieve recyclingProcess efficiency improvementIndustrial waste waterSmelting process

The invention relates to a process for rare-earth smelting resource reclamation and cyclic production. The process has the main characteristic of comprehensively and systematically solving the problems of environmental protection and industrial promotion of the whole rare-earth industrial chain by adopting innovative integrated technical means. The process mainly comprises administration and comprehensive utilization of waste gas, waste water and waste slag, revolution of a rare-earth smelting process, and reclamation and repeated utilization of various important resources such as sulfur, fluorine, ammonium, thorium, phosphorus, calcium and the like so as to achieve smokeless and harmless treatment of the waste gas, full utilization of the resources and zero discharge of industrial waste water and fulfill the final goal of cyclic production. The process radically solves the maximum environment-friendly bottleneck problem in a sustainable development process of the Baotou rare-earth industry from resource advantage to industrial advantage, in particular the historical key environment-friendly technical problem, reduces energy consumption of a large amount of resources and pollutiondischarge, greatly reduces the production cost, upgrades the rare-earth industry, and extends the larger industrial chain at the same time.

Owner:马克印 +1

Preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

Chinese medicinal preparation for treating breast diseases and uterine fibroid and preparation method thereof

InactiveCN102727832AGood treatment effectHigh cure rateAntineoplastic agentsSexual disorderDiseaseMyrrh

The invention discloses a Chinese medicinal preparation for treating breast diseases and uterine fibroid and a preparation method thereof. The Chinese medicinal preparation is prepared by extracting and mixing the following raw materials in percentage by weight: 8 to 15 percent of Chinese thorowax root, 4 to 6 percent of turmeric root-tuber, 3 to 6 percent of pangolin, 4 to 6 percent of nutgrass galingale rhizome, 3 to 5 percent of thunbery fritillary bulb, 3 to 5 percent of snake gourd fruit, 3 to 4 percent of hemlock parsley, 3 to 5 percent of suberect spatholobus stem, 2 to 4 percent of red-rooted salvia root, 2 to 3 percent of common burreed rhizome, 2 to 3 percent of curcuma zedoary, 2 to 3 percent of frankincense, 2 to 3 percent of myrrh, 3 to 5 percent of rhizoma corydalis, 3 to 5 percent of turtle shell, 2 to 4 percent of spina gleditsiae, 2 to 3 percent of semen litchi, 5 to 6 percent of selfheal, 3 to 6 percent of Astragalus root, 2 to 4 percent of angelica, 2 to 3 percent of Atractylis ovate, 2 to 3 percent of white peony root, 2 to 3 percent of poria, and 2 to 3 percent liquorice. The Chinese medicinal preparation can be used for treating patients with hyperplasia of mammary glands, mamstitis or hysteromyoma, and has high clinical cure rate and good healing effect.

Owner:王焕江

Additive for strengthening wet flue gas desulfurization technology

InactiveCN102580514AImprove qualityAchieve reuseCalcium/strontium/barium sulfatesDispersed particle separationOrganic acidAdipic acid

The invention belongs to the technical field of a limestone / gypsum wet flue gas desulfurization technology, and particularly relates to an additive for strengthening a wet flue gas desulfurization technology, which comprises the following components in percentage by mass: 35-45% of mixed organic acid, 5-10% of organic acid salt, 6-9% of surfactant, 1-6% of heavy metal salt and 35-45% of dirt dispersion agent; and the mixed organic acid comprises adipic acid, wherein the percentage of mass of the adipic acid in the mixed organic acid is not less than 50%. The additive can be added and used for strengthening the wet flue gas desulfurization technology, improve the desulfurization efficiency of a system, reduce the energy consumption, strengthen oxidization, improve the limestone quality and restrain system scaling, and accordingly, the purposes of energy conservation, consumption reduction and waste recycling are realized.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

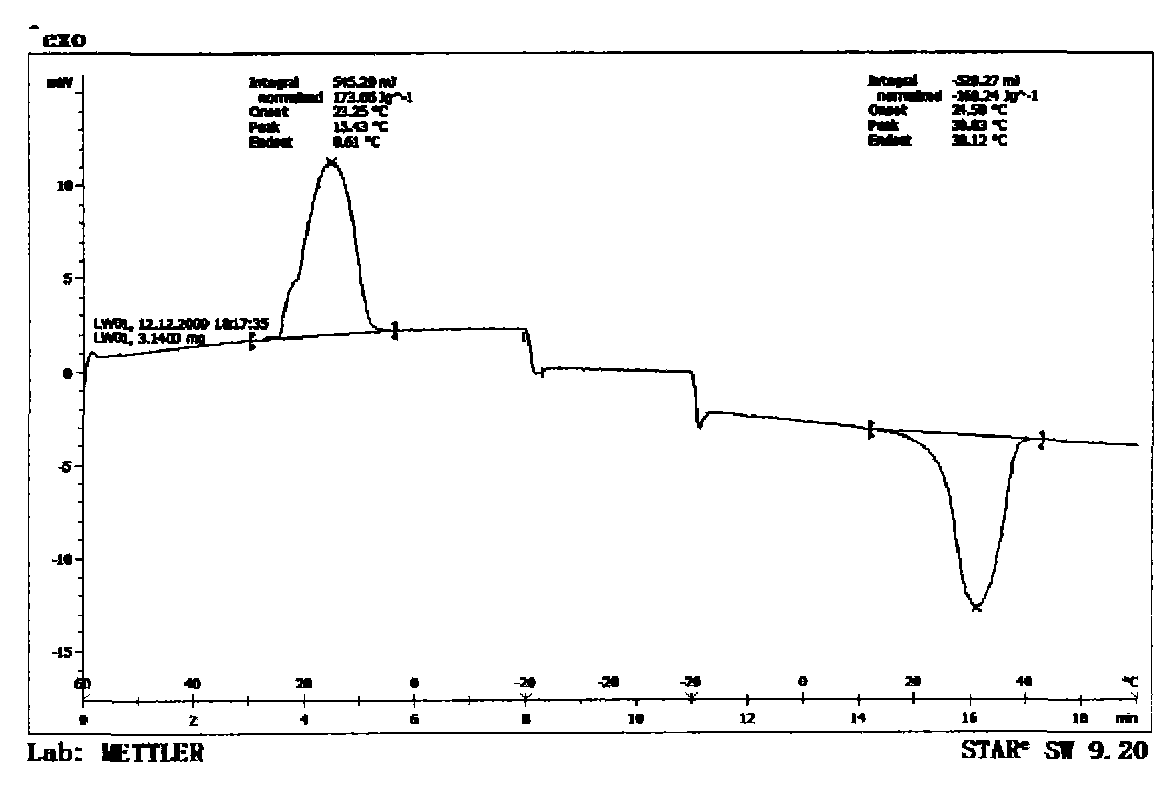

Preparation method of phase change fibers

ActiveCN103710964AHigh effective contentSimple processFibre treatmentHeat-exchange elementsFiberTemperature control

The invention provides a preparation method of phase change fibers. The preparation method comprises the following steps: putting hollow fibers in a liquid storage tank, adding phase change materials to the liquid storage tank, and pressing by using a pressing plate; putting the liquid storage tank in a vacuum bin, sealing the vacuum bin, and vacuumizing the vacuum bin; heating the vacuum bin so as to ensure that the temperature in the vacuum bin is higher than the melting point of the phase change materials so as to melt the phase change materials; stopping vacuumizing, and opening a valve of the vacuum bin so as to ensure that the phase change materials enter inner parts of the hollow fibers under the effect of external atmospheric pressure and are fixed under the capillarity action of inner holes of the hollow fibers; and taking out the hollow fibers filled with the phase change materials, and removing the phase change materials adhered to the surfaces of the hollow fibers, thus obtaining the phase change fibers with a temperature control effect. The preparation method has the advantages that the phase change materials are directly poured into the inner parts of the hollow fibers and are fixed through the capillarity action of the hollow fibers, compared with a microcapsule method, the preparation method is simple in process and low in cost, the effective content of the phase change materials is high, and the temperature adjusting effect can be substantially improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

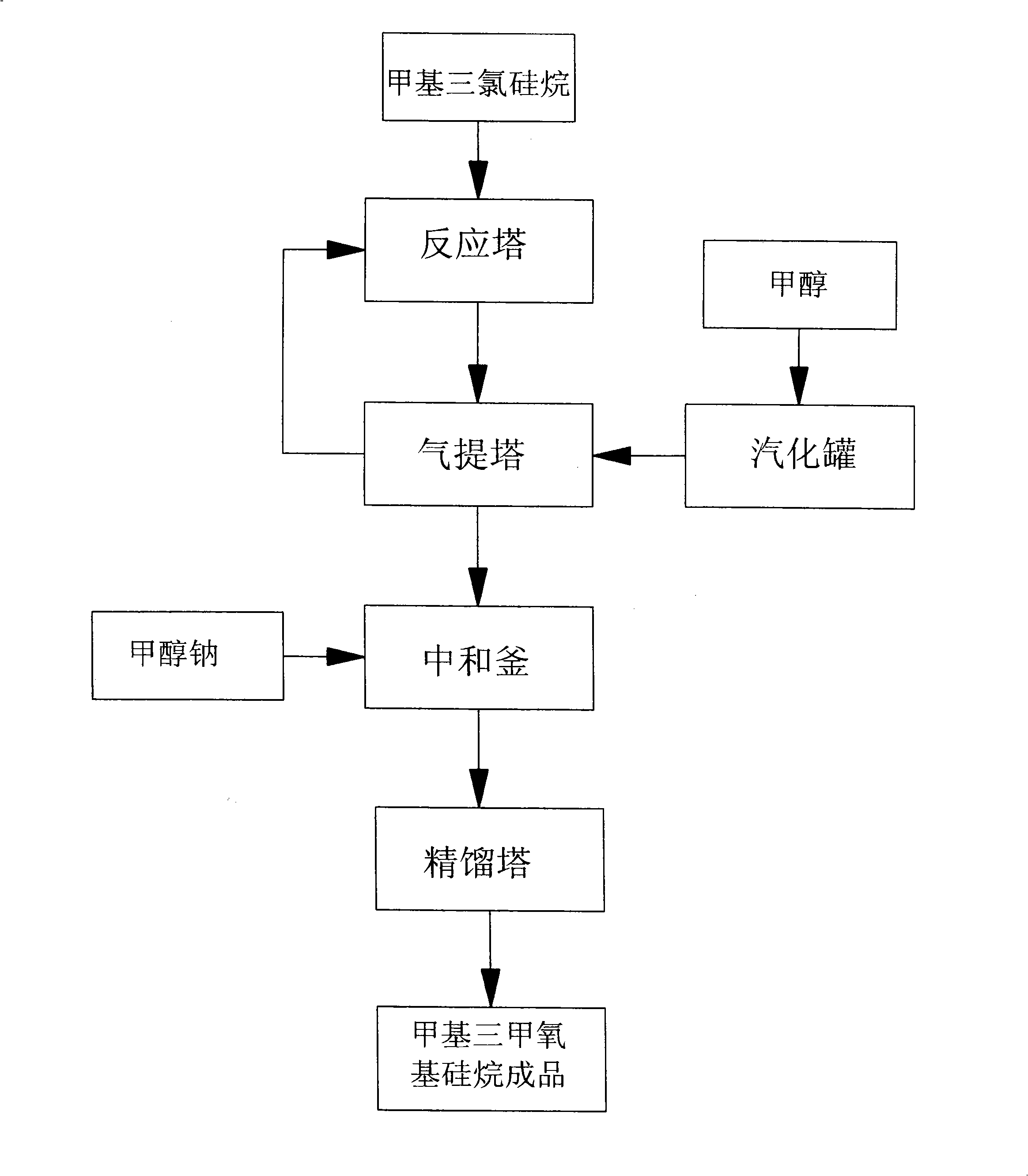

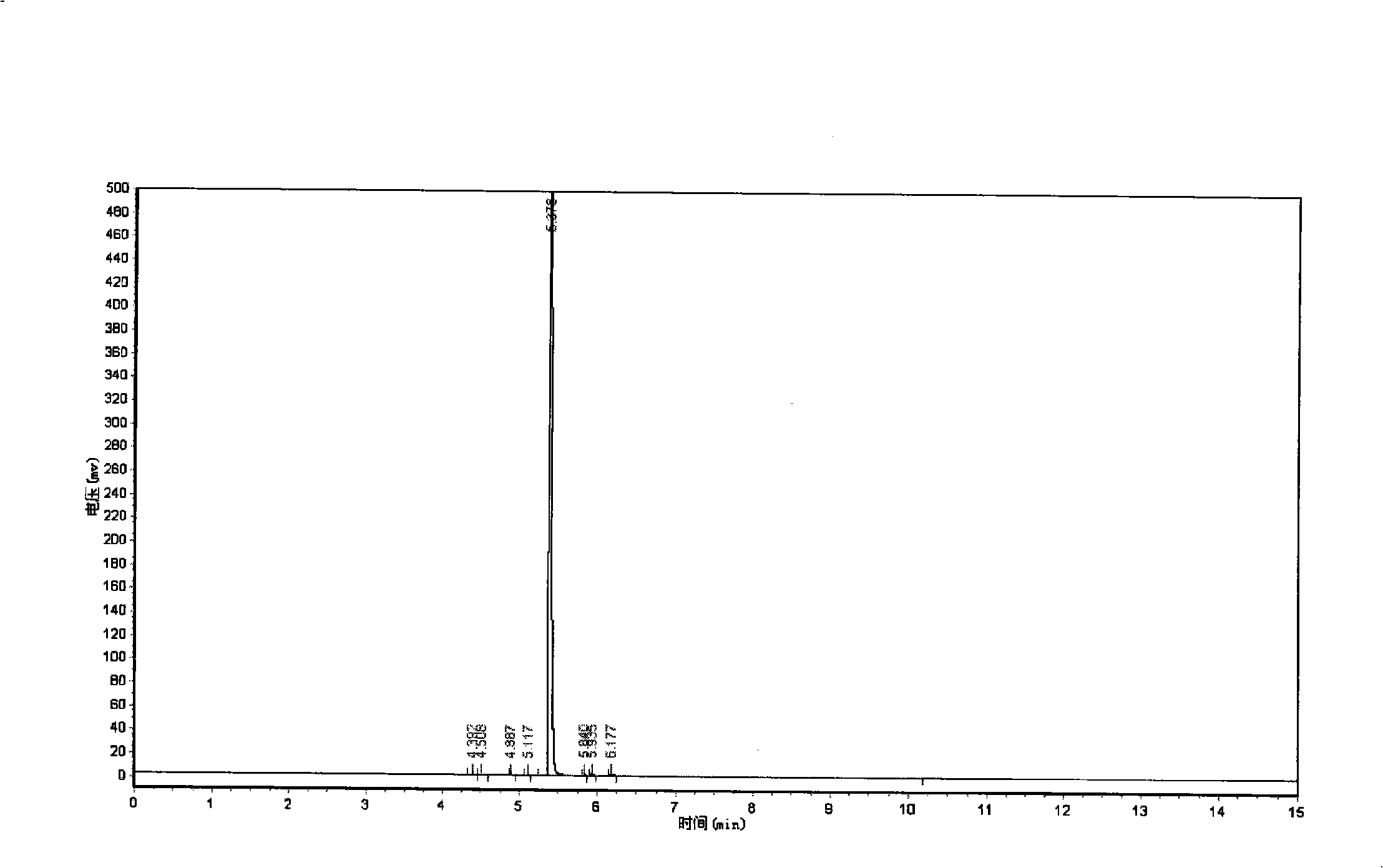

Preparation technique of methyl trimethoxysilane

ActiveCN101348497AEfficient removalAvoid it happening againGroup 4/14 element organic compoundsMethyltrichlorosilaneSilanes

The invention provides a process for preparing methyltrimethoxy silane. The process comprises the following steps that: a. methanol is subjected to vaporization by a vaporizing cylinder and passes through a stripping tower, and enters the bottom part of a reaction tower, methyl trichlorosilane enters the reaction tower from the top and is sprayed downward, and methanol reacts with methyl trichlorosilane by counter current contact; b. a primary product is pumped in the top part of the stripping tower and subjected to steam stripping by methanol gases passing by the stripping tower, after falling onto the bottom part of the stripping tower, the primary product is pumped in a neutralization kettle, and the saturated sodium methylate solution is added in the neutralization kettle for neutralization; c. the coarse product of methyltrimethoxy silane is pumped in a rectification tower for rectification. The process has the characteristics of high working efficiency, stable process and big output, etc. Because the process of the invention is continuously carried out, the process has the advantages of having few operators, ensuring safe production and being capable of easily realizing the control of DCS computers; moreover, the product yield is 90 percent, the effective content of the product is high, and the content of methyltrimethoxy silane is more than 99 percent.

Owner:湖北新蓝天新材料股份有限公司

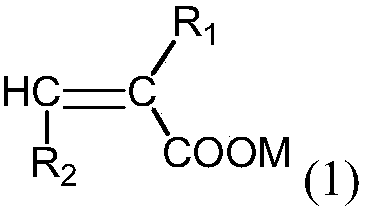

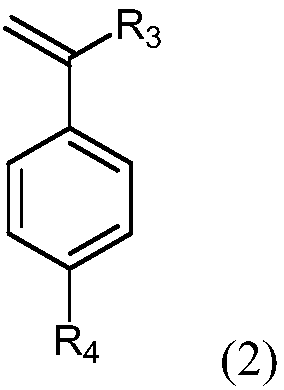

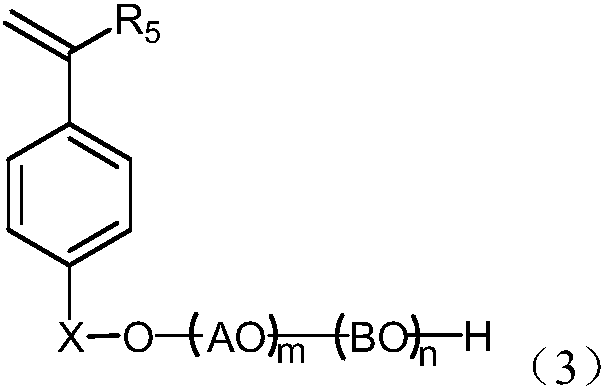

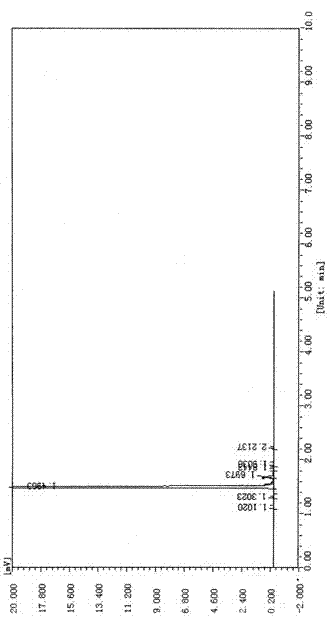

Synthesis method of methyl allyl alcohol polyethenoxy ether

ActiveCN102898639AHigh effective contentNarrow molecular weight distributionPtru catalystPolyethylene glycol

The invention discloses a synthesis method of methyl allyl alcohol polyethenoxy ether, which comprises the following steps: 1) reacting 5-20 wt% of prescribed methyl allyl alcohol and a catalyst, adding the reaction product into residual prescribed methyl allyl alcohol, and introducing epoxyethane to react, thereby obtaining methyl allyl alcohol polyethenoxy ether low polymer; and 2) reacting 5-20 wt% of prescribed methyl allyl alcohol polyethenoxy ether low polymer obtained in the step 1) and a catalyst, adding the reaction product into residual prescribed methyl allyl alcohol polyethenoxy ether low polymer, and introducing epoxyethane to react, thereby obtaining the methyl allyl alcohol polyethenoxy ether. The methyl allyl alcohol polyethenoxy ether product prepared by the method disclosed by the invention has the advantages of low content of byproducts (polyethyleneglycol and the like), narrow molecular weight distribution, high double-bond protective rate and the like, and is suitable for synthesizing polycarboxylic-acid high-performance water reducing agents.

Owner:ZHEJIANG HUANGMA TECH

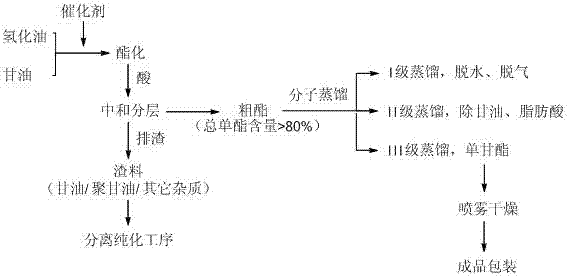

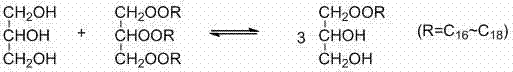

Process for preparing high-purity molecular distillation monoacylglycerol

InactiveCN102876464AImprove economic efficiencyEmission reductionFatty acid esterificationFatty-oils/fats refiningPhosphoric acidGlycerol

The invention relates to a process for synthesizing high-purity molecular distillation monoacylglycerol. The process comprises the following steps of: (1) mixing glycerol and a catalyst A, vacuumizing, stirring for heating, adding hydrogenated oil added with a catalyst B into a reaction system in batches to perform ester exchange reaction, after the ester exchange reaction is finished, keeping temperature, adding phosphoric acid for neutralizing, cooling and standing a reactant for demixing, wherein an upper layer is a crude glyceride layer, a lower layer is materials which are not reacted completely and impurities generated in the reaction process; (2) dehydrating and degassing the crude glyceride layer by primary distillation; (3) performing secondary distillation on the product, and removing free fatty acid and excessive glycerol; and (4) performing third-level distillation on the product to obtain a distillment and a distillation remnant, wherein the distillment is the high-purity molecular distillation monoacylglycerol, and the distillation remnant is diglyceride and triglyceride. By the process, the content of total monoester in crude ester can be improved obviously, the abrasion of equipment in subsequent molecular distillation process is reduced, the energy consumption of distillation is reduced, and the economic benefit is improved obviously.

Owner:NANCHANG UNIV

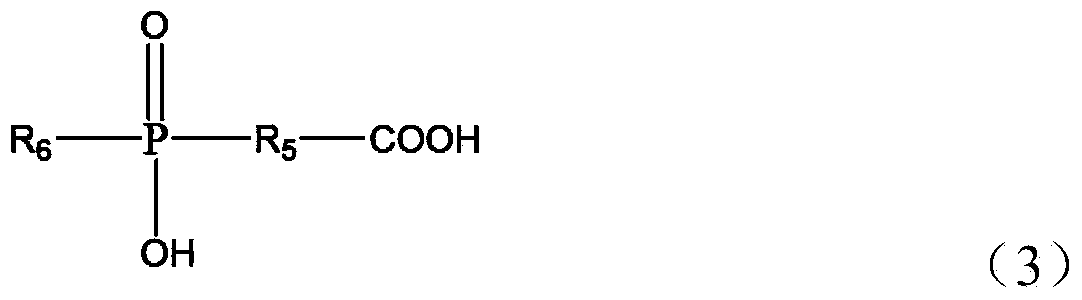

Preparation method of mud-resistant type polycarboxylate superplasticizer

The invention relates to a preparation method of a mud-resistant type polycarboxylate superplasticizer. First, polyethylene glycol monomethyl ether and acrylic acid are used as raw materials and synthetized into polyethylene glycol monomethyl ether methyl acrylate. Then, the prepared polyethylene glycol monomethyl ether methyl acrylate is copolymerized with mixed liquid which is made from the acrylic acid and diacrylamide sodium dimethallyl sulphonate and mixed liquid which is made from ammonium persulfate and mercaptoethanol, alkaline compounds are added to regulate a pH value to 7-8 after reaction, and the mud-resistant type polycarboxylate superplasticizer is obtained. In the preparation method, technical parameters and conditions, such as raw material ratio, the used amount of chain transfer agents and initiators, copolymerization temperature, time and the like are determined. The reaction conditions are mild, the adopted equipment is simple, the equipment investment is small, the technology is reasonable, and the operation is simple and favorable for industrial production.

Owner:江苏汇迪建材有限公司

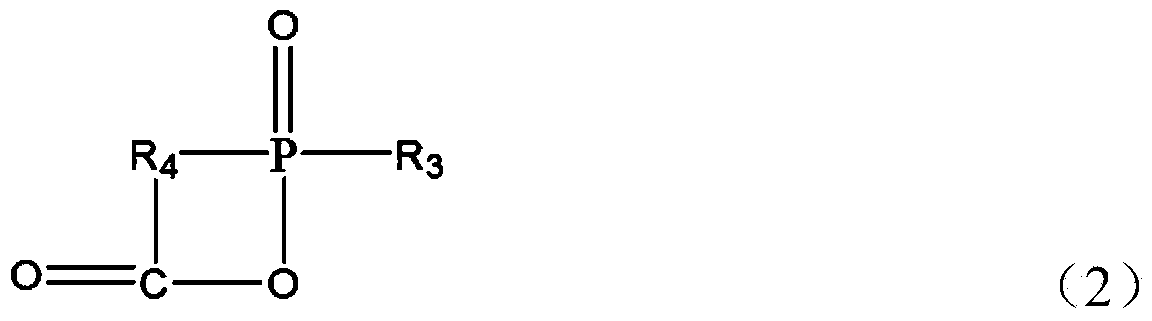

Preparation method of cationic dyeable flame-retardant polyester resin

The invention discloses a preparation method of cationic dyeable flame-retardant polyester resin. The manufacturing method is characterized by comprising the following steps: performing an esterification reaction on a halogen-free copolymerized phosphorus-based flame retardant, ethylene glycol and a composite catalyst to prepare an esterification solution of the halogen-free copolymerized flame retardant; performing ester exchange reaction on sulfoisophthalic acid dimethyl ester and the ethylene glycol to prepare a sulfonate-based bis(hydroxyethyl) isophthalate solution; performing an esterification reaction on terephthalic acid (or dimethyl terephthalate), the ethylene glycol and auxiliaries, then adding a catalyst, a stabilizer, the auxiliaries, the esterification solution of the phosphorus-based flame retardant (or a prepolymer solution of the phosphorus-based flame retardant) and the sulfonate-based bis(hydroxyethyl) isophthalate solution, performing condensation polymerization reaction, and cooling and dicing after the end of reaction to prepare the cationic dyeable flame-retardant polyester resin. The cationic dyeable flame-retardant polyester resin prepared by the method disclosed by the invention has the characteristics of good spinnability, polyester fiber cationic dye boiling dyeing under normal pressure conditions, complete chromatogram and strong dye adhesion.

Preparation method and application of powdery polycarboxylic acid water-reducing agent

The invention discloses a preparation method and application of a powdery polycarboxylic acid water-reducing agent. The preparation method comprises the following steps: preparing from a carboxylic acid monomer a, a benzene ring-containing small monomer b and a benzene ring-containing polyether monomer c in an aqueous medium through free radical copolymerization to obtain polycarboxylic acid water-reducing agent mother liquor; and directly forming the polycarboxylic acid water-reducing agent mother liquor into fog drops through a centrifugal atomizer for a sprayer without adding an isolation agent, controlling the average particle size of powder to be 50-150 [mu]m, drying into powder after the fog drops enter a drying room, leading a material to a discharge port through an induced draft fan, and packaging and discharging by adopting a bagged packaging machine to obtain the powdery polycarboxylic acid water-reducing agent. The preparation method disclosed by the invention has the benefits that not only is the effective content of polymers in the powder improved, but also the production technical process is reduced, and the production cost is reduced; and the prepared powdery polycarboxylic acid water-reducing agent is optimal in fluidity, incapable of caking, high in storage stability, low in long-distance transportation cost, excellent in water-reducing property and suitable for various dry mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

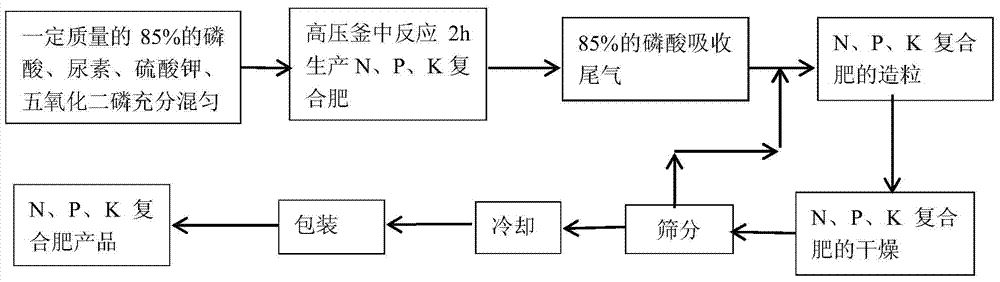

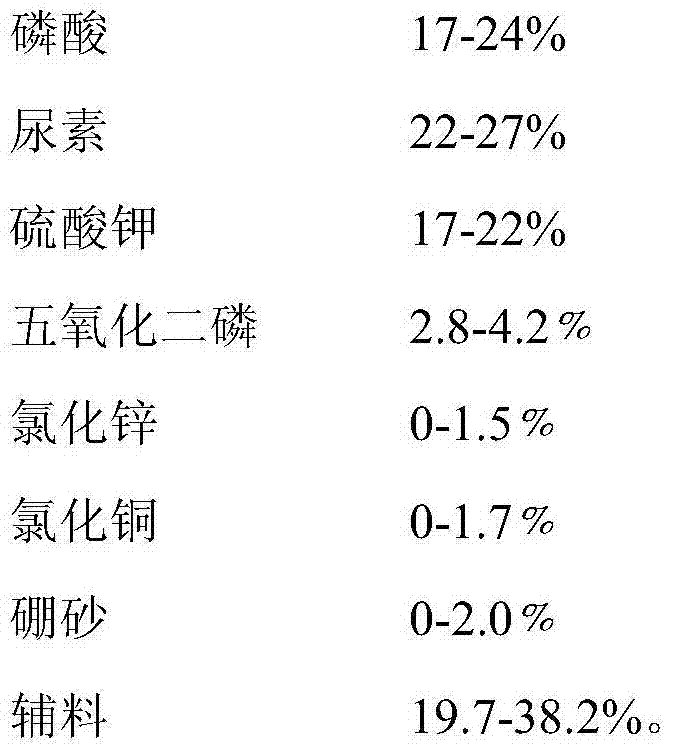

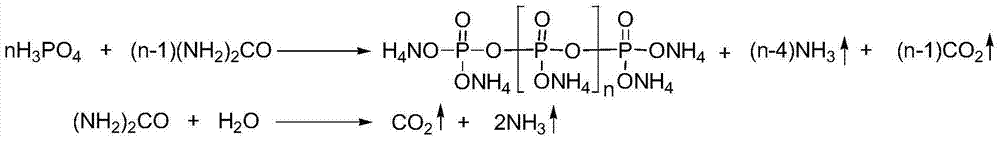

Ammonium polyphosphate water soluble fertilizer and preparation method thereof

ActiveCN103787726AGood water solubilityLow impurity contentPhosphatesFertilizer mixturesSolubilityPhosphoric acid

The invention belongs to the field of fertilizers and particularly relates to an ammonium polyphosphate water soluble fertilizer and a preparation method thereof. The preparation method comprises the following steps: adding phosphoric acid, urea, potassium sulphate, zinc chloride, copper chloride, borax and auxiliaries into a reaction kettle, mixing and dissolving in the kettle, then adding phosphorus pentoxide and uniformly stirring; heating the reaction kettle to 180-185 DEG C while stirring, reacting for 30-45 minutes, and then heating to 200-205 DEG C to react for 1.5-2 hours; and after the reaction is finished, reducing the temperature in the reaction kettle to room temperature, and simultaneously absorbing ammonia gas generated by reaction by using a diluted phosphoric acid solution to obtain the ammonium polyphosphate water soluble fertilizer. The ammonium polyphosphate-potassium sulfate water soluble fertilizer prepared by the preparation method has the characteristics of good water solubility, low impurity content and high effective contents of nitrogen, phosphorus and potassium. The preparation method disclosed by the invention has the advantages of simplicity, practicality, low production cost and the like.

Owner:广西泰宝生物科技有限公司

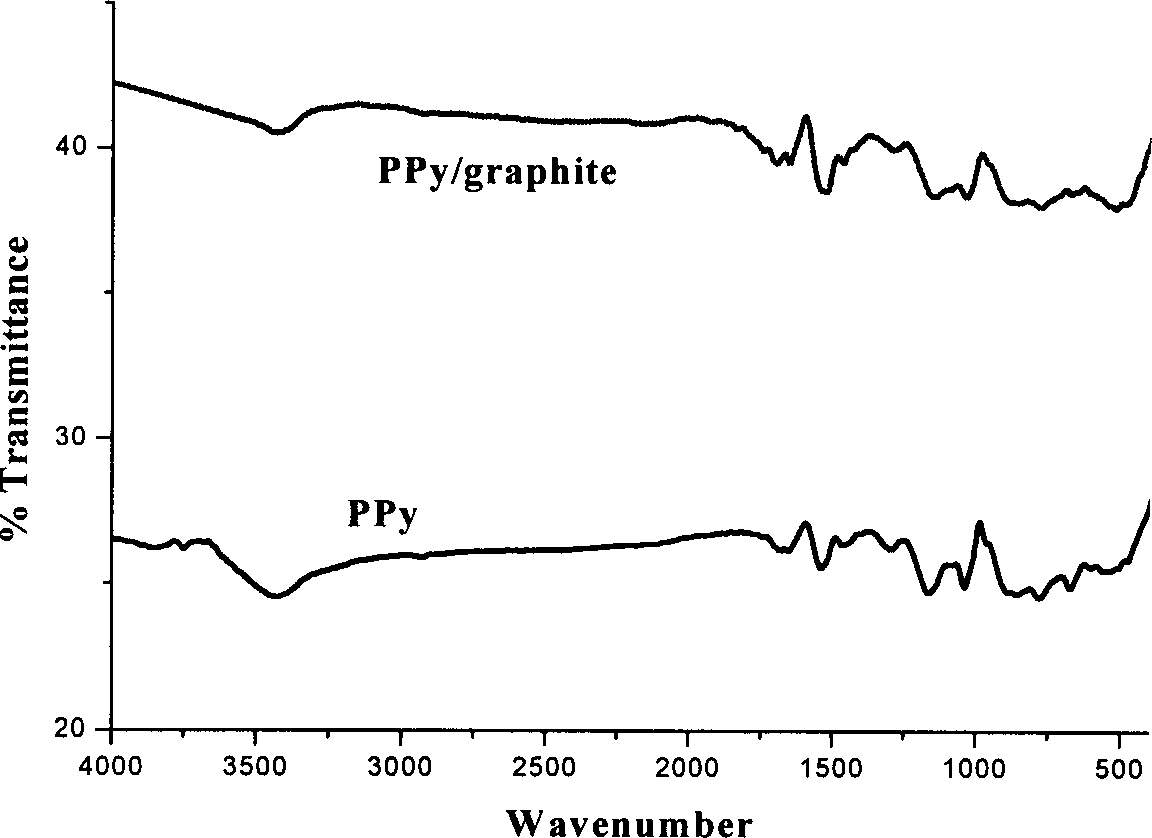

Method for preparing polymer/graphite nanometer composite material by utilizing ultrasonic dispersion technology

InactiveCN1803927AHigh effective contentImprove the interface binding forceIn situ polymerizationNanoscopic scale

The provided preparation method for polymer / graphite composite material comprises: using supersonic crushing technique to break the interlayer bonding of expanded graphite as material and prepare the nano dispersive flake graphite; than, in-situ polymerizing the flake with polymer monomer to obtain the target with super conductivity and heat endurance and mechanical processing property. This invention has high production efficiency with low cost.

Owner:NORTHWEST NORMAL UNIVERSITY

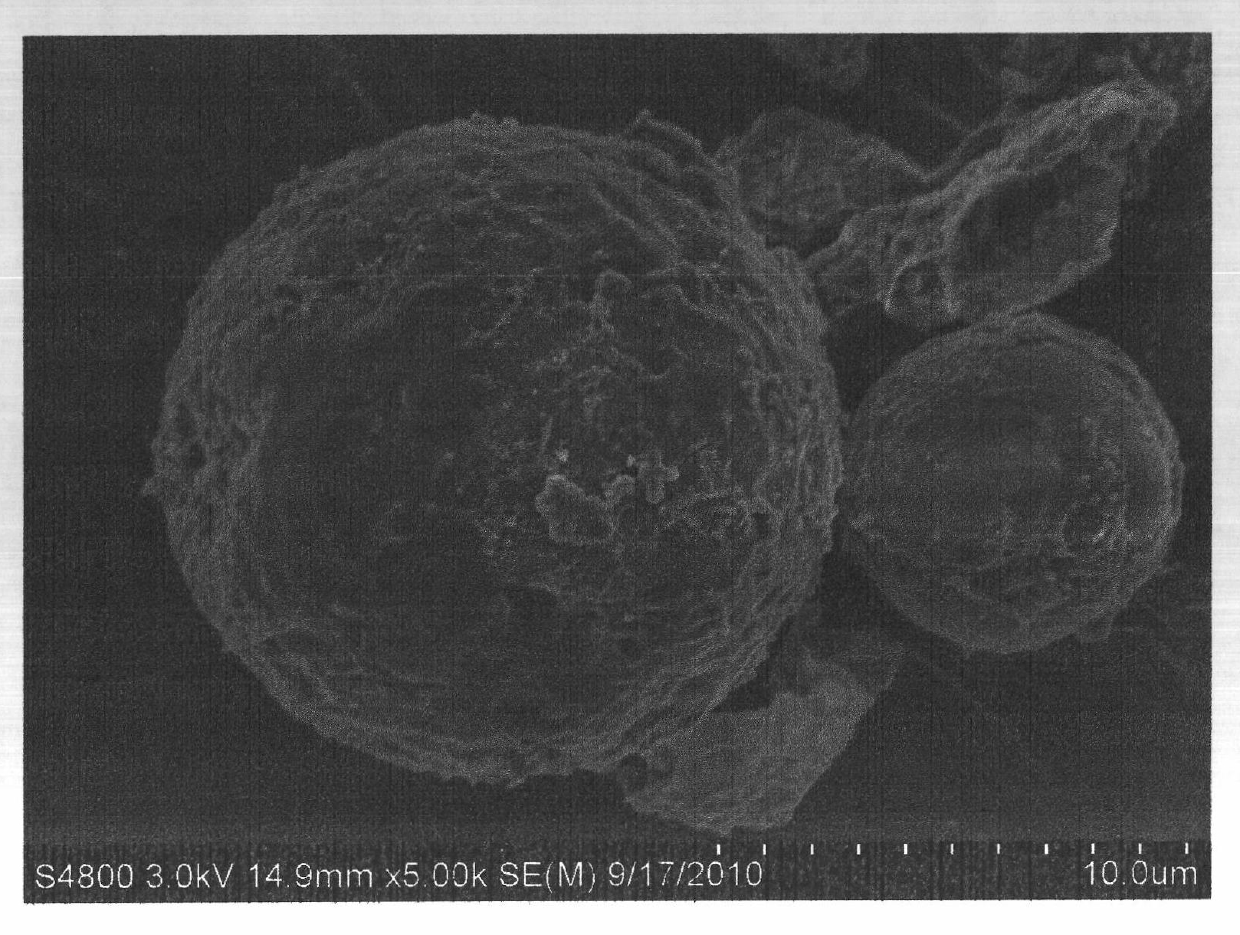

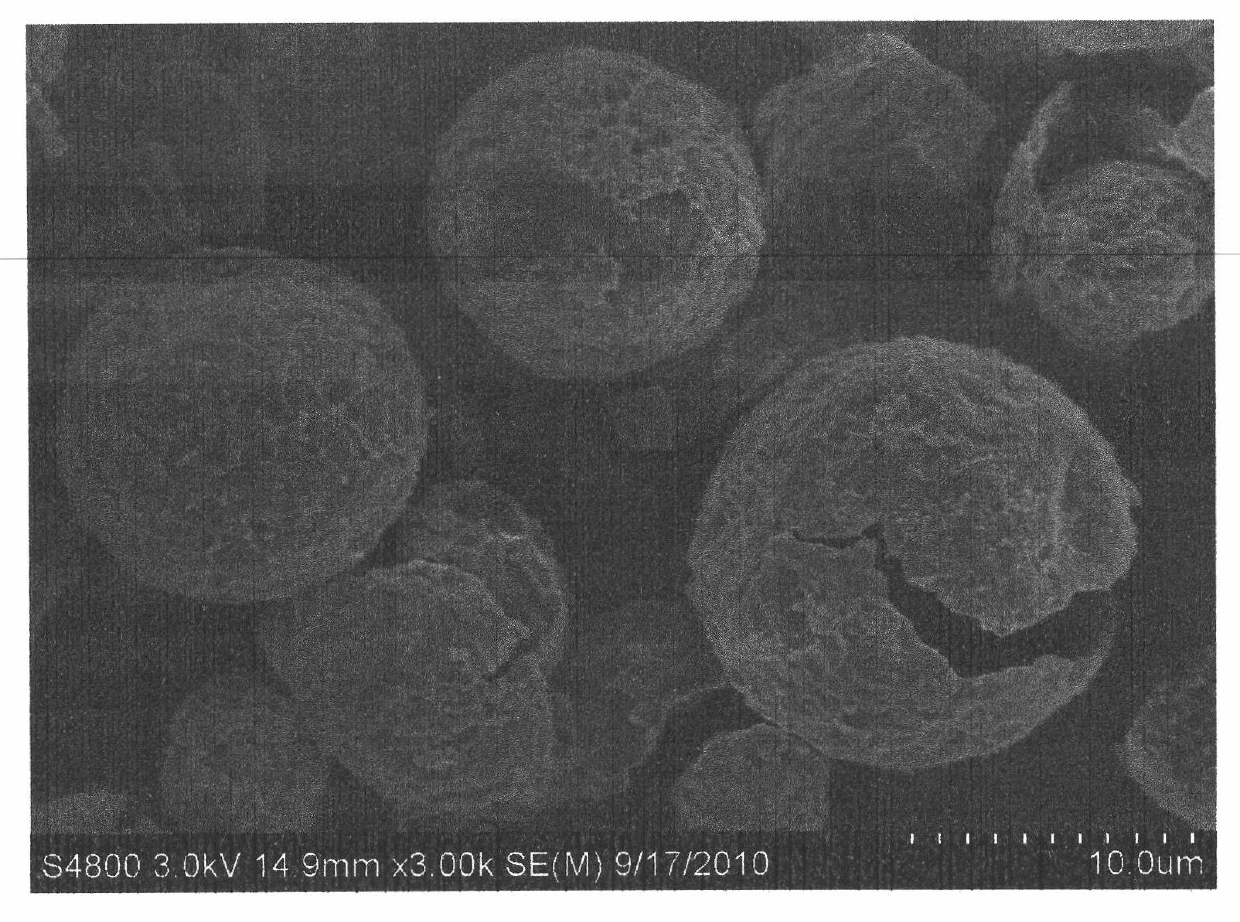

Polyurea capsule with composite wall and high core content and preparation method thereof

InactiveCN102000536AHigh effective contentAvoid harmMicroballoon preparationMicrocapsule preparationBenzoyl peroxideDivinylbenzene

A preparation method of a polyurea capsule with composite wall and high core content comprises the following steps: (1) uniformly mixing 100 parts of oily substances, 10-30 parts of polyisocyanates, 8-25 parts of styrene, 3-5 parts of divinylbenzene and 0.1-0.3 parts of initiator azodiisobutyronitrile or benzoyl peroxide to prepare oil phase; dropwise adding the oil phase to 500-1200 parts by weight of emulsifier aqueous solution with concentration of 1-10wt% and stirring the mixture at high speed to fully emulsify the oil phase to prepare O / W emulsion; (2) stirring the emulsion at 100-1000rpm and simultaneously dropwise adding 500-1100 parts by weight of polyamine aqueous solution with concentration of 2-5wt% to the emulsion; and (3) after dropwise adding the polyamine aqueous solution, raising the temperature to 30-60 DEG C and maintaining the temperature for 1-3hr; then raising the temperature to 75-95 DEG C and curing the mixture for 1-3hr and obtaining the capsule powder through pumping filtration, washing and drying. The capsule has the following advantages: the capsule adopts the reactive monomer as the cosolvent or adds the substance with the same functions as the core to serve as the cosolvent to replace the traditional organic cosolvent with low boiling point, has core content as high as 60-90wt% and avoids harms to human and the environment caused by using the organic solvent.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

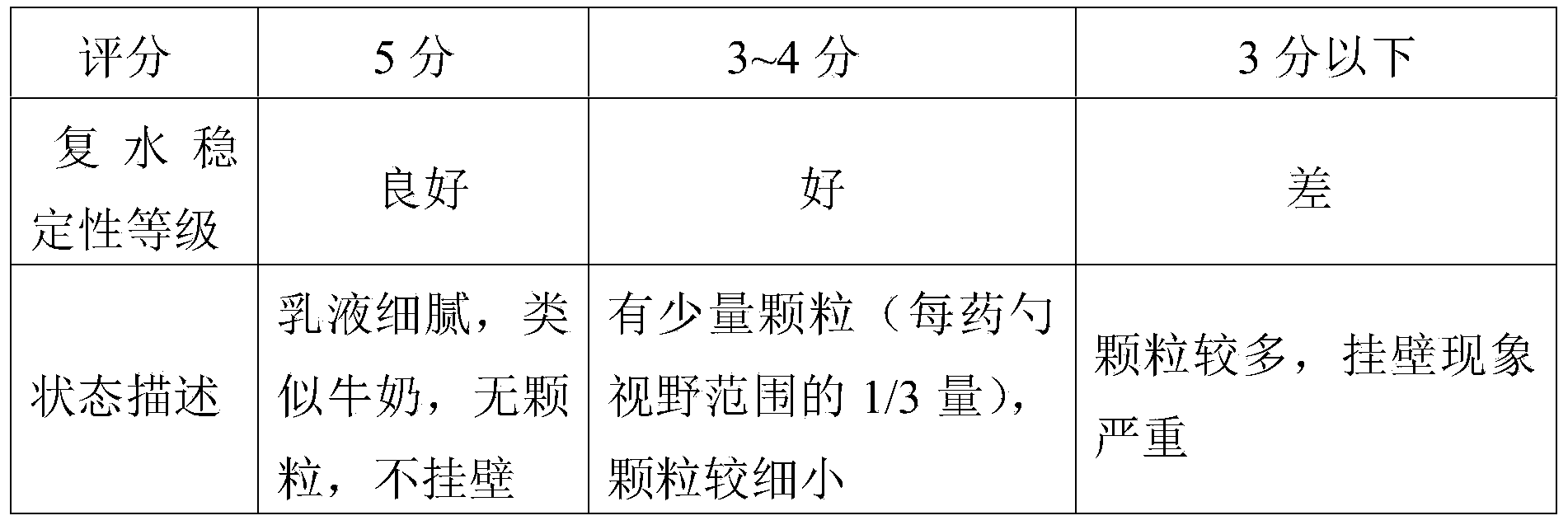

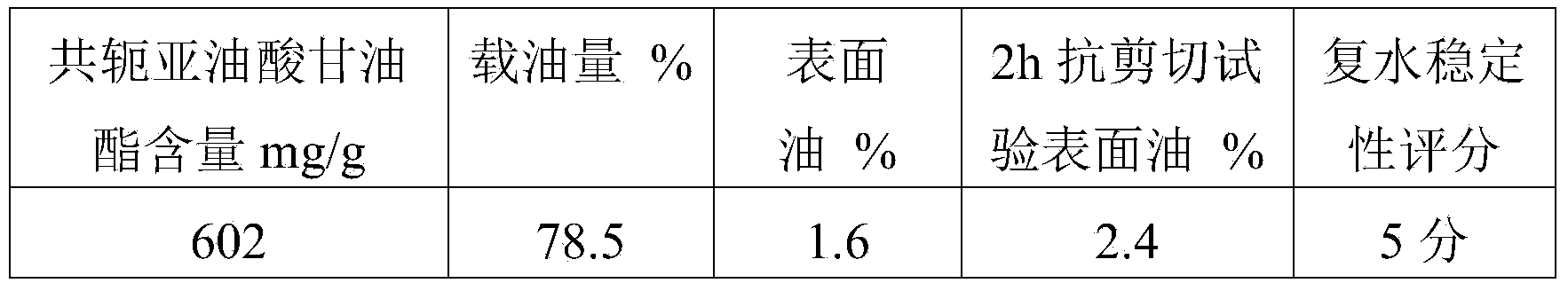

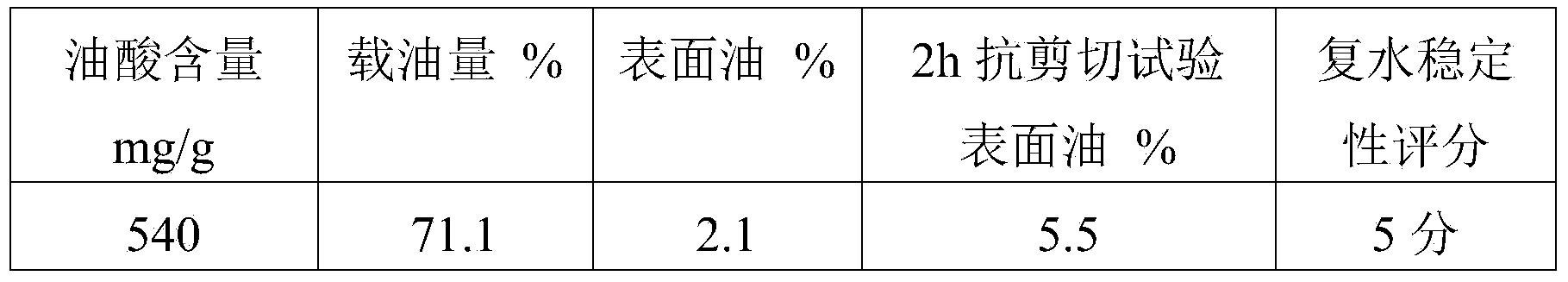

Preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring

InactiveCN104304838ASolve the fragile problemReduce dosageSugar food ingredientsVitamin food ingredientsBiotechnologyDairy foods

The invention provides a preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring. The preparation method comprises the following steps: adding protein type wall materials into water, stirring for dissolving the materials at 40-70 DEG C, adjusting the pH of an obtained solution to 7.0-12.0, reacting under the condition of 40-70 DEG C for 0.5-4 hours, adding sugar type wall materials and a stabilizing agent into an obtained reaction solution, and stirring for dissolving, thereby obtaining a water phase solution; adding an antioxidant and an emulsifier into nutrition lipid type core materials, and stirring for dissolving at 40-70 DEG C, thereby obtaining an oil phase solution; and mixing the water phase solution with the oil phase solution, emulsifying and homogenizing, and spray-drying, thereby obtaining the micro-capsule powder. The content of total fat in the micro-capsule powder reaches up to 60%-85%, and the content of surface oil in the micro-capsule powder is lower than 5%. The micro-capsule powder has tolerance to mechanical force, is good in self-emulsifying capability, can be dissolved to form uniform and stable fine emulsion without floating particles and sediments, can be applied to the field of food, and can be added to food such as bread, cookies, nutrition bars and milk products and also be taken as solid granules.

Owner:INNOBIO CORP LTD

Method for preparing low-amine rubber anti-aging agent TMQ

The invention provides a method for preparing a low-amine rubber anti-aging agent TMQ. The method comprises the following steps: adding aniline and hydrochloric acid into a reactor, stirring, heating to 130 DEG C and stirring for 30min, wherein the using amount of the hydrochloric acid is 6-10% of the weight of the aniline; putting 2, 2, 4-trimethyl-1, 2-dihydroquinoline monomers into the reactor, wherein the adding quantity is 70-80% of the mass of the aniline; controlling the temperature at 120-125 DEG C, continuously dropping acetone, keeping the mass ratio of the aniline to the acetone at 1:(1-4), controlling the adding time to be 5-9 hours, controlling the adding temperature at 115-150 DEG C, keeping the temperature at 140 DEG C after the end of dropping, and maintaining the temperature for 4 hours; stopping heating, adding a sodium hydroxide water solution, stirring for 30 minutes, neutralizing, then controlling the pH value at 11, and then standing for 60 minutes; separating to remove a water phase and further obtaining an organic phase; and removing the monomers by distillation in a vacuum state, thus obtaining an anti-aging agent TMQ product. According to the method provided by the invention, the operation is simple, and the content of a primary amine compound is less than 2%.

Owner:KEMAI CHEM

Covering method for orchard sod culture

The invention discloses a covering method for orchard sod culture. The covering method comprises steps as follows: soil preparation and fertilization: fine soil preparation is performed before sowing, 50 kilograms of calcium magnesium phosphate fertilizer and 2,000-3,000 kilograms of organic fertilizer are applied for each mu; seed selection: grass seeds meeting requirements that the heights are smaller than 50 cm after the seeds grow up, the seeds grow in a creep manner and the main roots are shallow are selected; sowing in strip: the seeds are sowen when the soil is in a moisture status after rainfall in spring, the row spacing is 20-30 cm, the depth for seed sowing is 1-2 cm, the seeds are sowed in the middle of space between fruit tree rows, 1-2 meters of a clean cultivation zone is reserved between plants, and 0.5-1 kilogram of seeds are used for each mu; and cutting of green crops: green crops are cut twice every year, and 10 kilograms of calcium superphosphate is applied for each mu after cutting of the green crops each time. The method is reasonable, the content of organic matters in the oil can be improved, pests are prevented, the pesticide dosage is reduced, and rain-waterlogging danger is reduced.

Owner:王秀芬

Prepn process of medicine for treating cerebral apoplexy and its sequela

ActiveCN101020034AReduce adhesion rateReduce resistancePowder deliveryHeavy metal active ingredientsSequelaTraditional medicine

The present invention provides preparation process of medicine for treating cerebral apoplexy and its sequela. The reasonable preparation process has classified extraction of Chinese medicine components in different properties, and the medicine has greatly raised effective component content and obviously reduced dosage.

Owner:李宏良

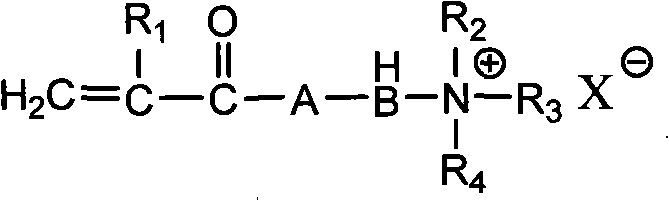

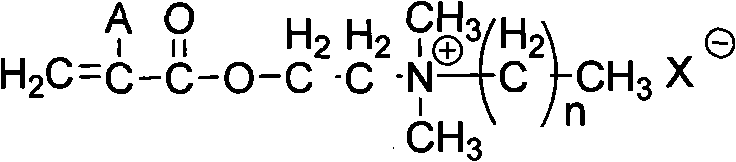

A Cationic Hydrophobic Association Polyacrylamide "Water-in-Water" Emulsion

InactiveCN102286128ASolve the problems of high cost, unsafe and environmental protectionReduce apparent viscositySaline waterInorganic salts

The invention relates to the synthesis of a hydrophobic association polyacrylamide "water-in-water" emulsion. Stable " "Water-in-water" emulsion has a small particle size and can be quickly dissolved in water, which solves the problem that the current hydrophobic association polyacrylamide dry powder is difficult to dissolve.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

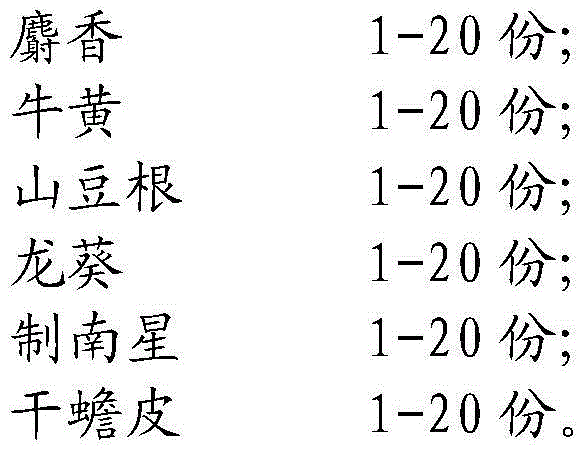

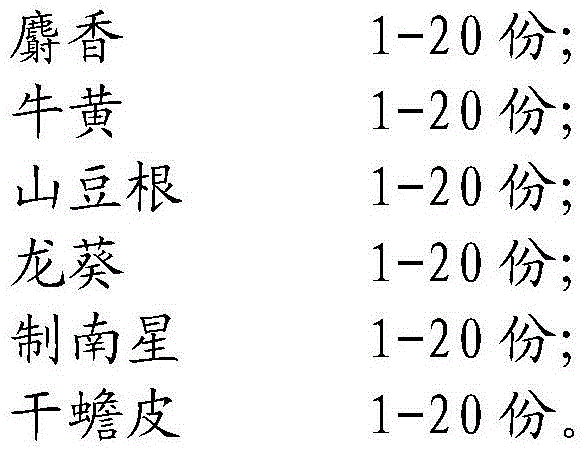

Anti-cancer Chinese patent medicine preparation and extraction and compatibility process thereof

InactiveCN104069294AIncrease concentrationEffective treatmentHeavy metal active ingredientsAnthropod material medical ingredientsModern medicineGlucocorticoid

The invention relates to an anti-cancer Chinese patent medicine preparation which is characterized in that every 100 parts of Chinese medicine formula comprises the following substances in parts by mass: 1-20 parts of musk, 1-20 parts of bezoar, 1-20 parts of subprostrate sophora, 1-20 parts of nightshade and 1-20 parts of dried bufonidae skin. The invention further provides an extraction and compatibility process of the Chinese patent medicine preparation. Long-term clinical observation and application of the preparation shows that by adopting a treatment mode that cancer toxicity is eliminated, the body protein immunity is enhanced, the glucocorticoid of a body is activated, and a three-dimensional grouping and comprehensive system based on time and main and collateral channels through viscera is adopted, detailed and specific analysis and deep study on clinical cancer are achieved by taking the theory of YIN and YANG and five elements of traditional Chinese medicine and the cause, restriction, multiplying and insulation theory as the guidance and the enzymology and the pPhysiology theory of the modern medicine as the basis.

Owner:SHANGHAI YUANDONG TRADITIONAL CHINESE MEDICINE INST

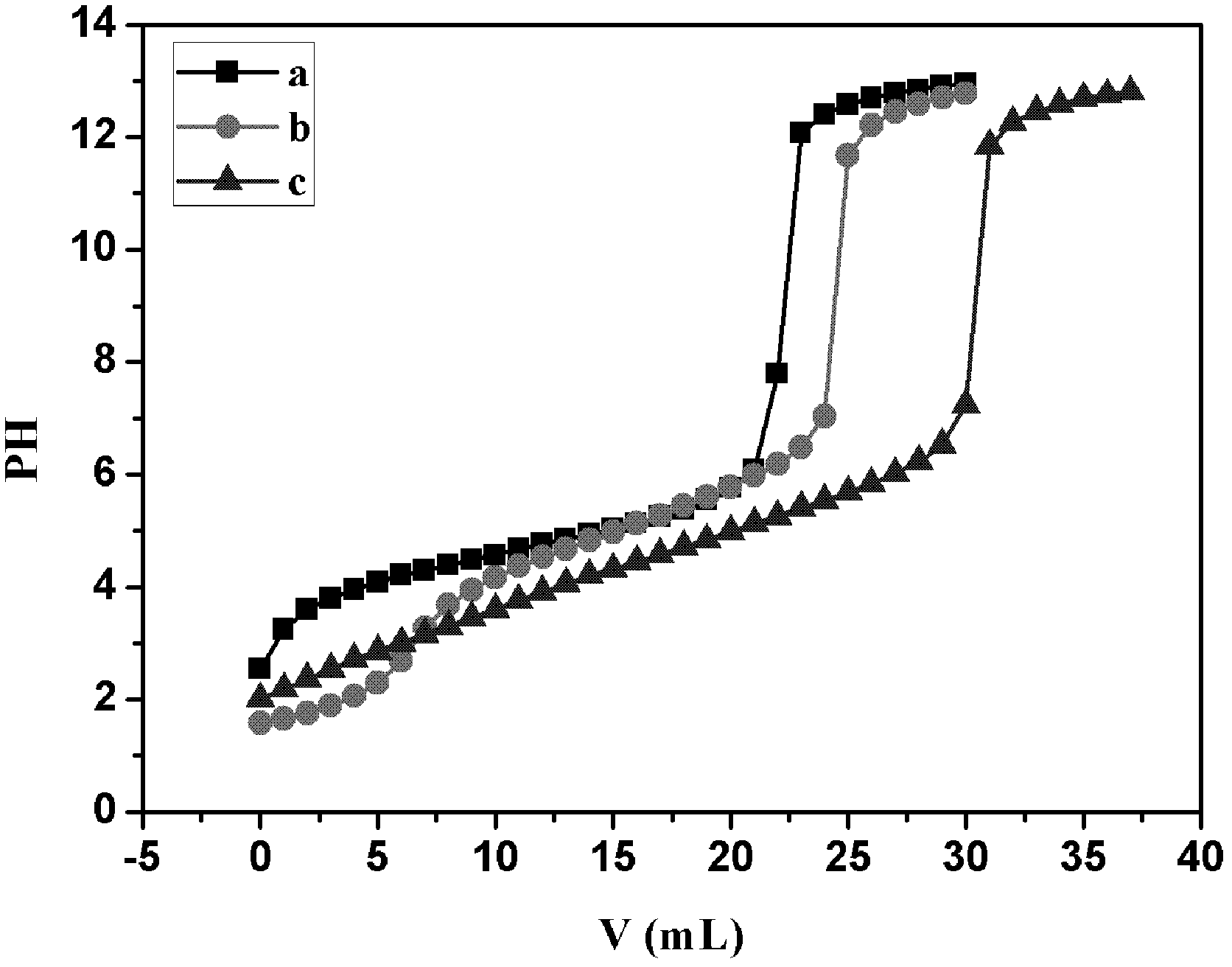

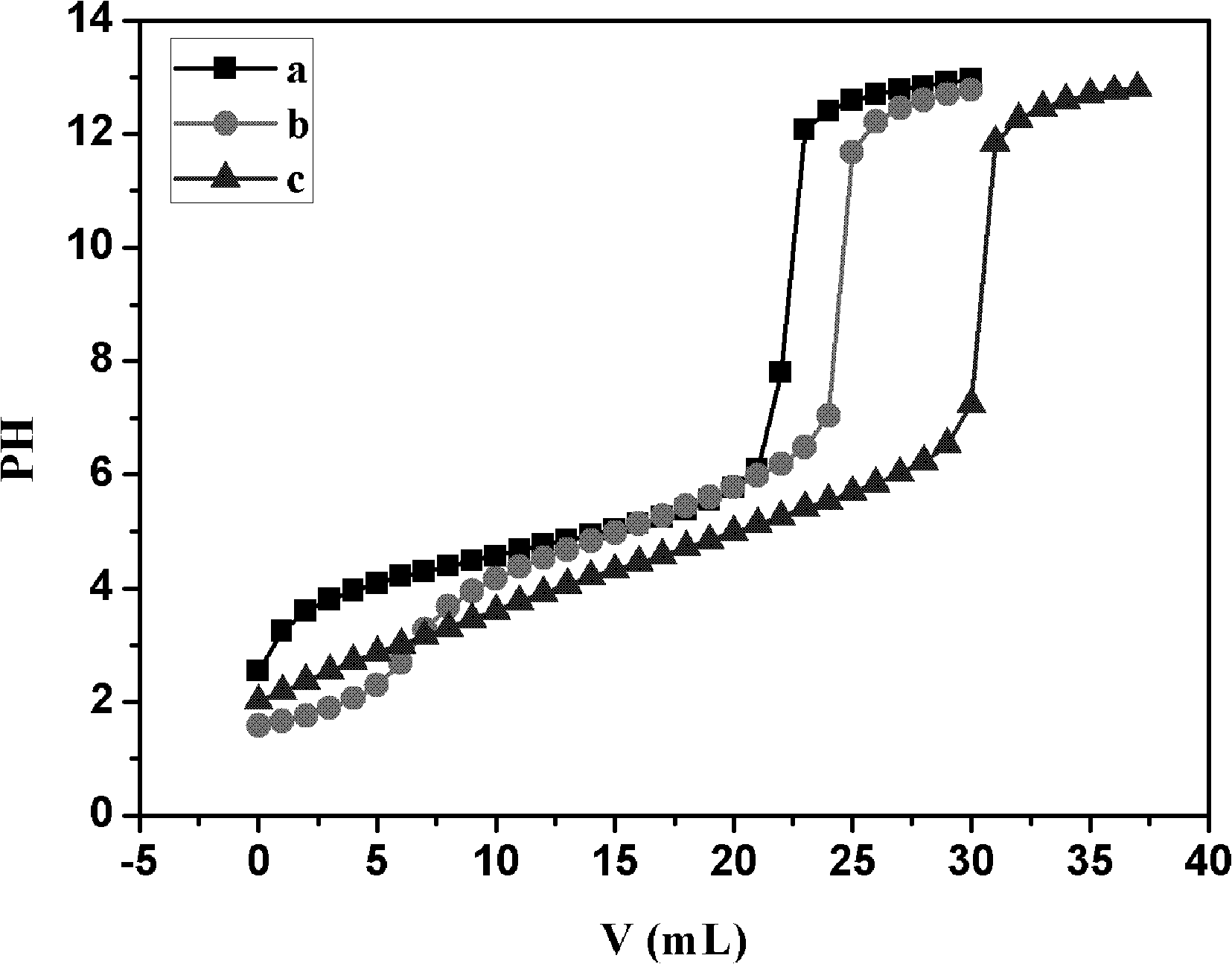

Preparation method for amphoteric water-in-oil inverse emulsion

The invention discloses a preparation method for amphoteric water-in-oil inverse emulsion. The preparation method comprises the following steps: respectively adding a non-ion monomer, an anion monomer, a cation monomer, a water quality stabilizer and a molecular weight modifier into water; adjusting PH (Potential of Hydrogen) to obtain a water phase A and a water phase B with different ratios; adding a non-ion emulsifying agent into a hydrocarbons solvent to prepare an oil phase; dividing the oil phase into two parts; respectively dropwise adding the water phase A and the water phase B into the two parts of the oil phase; carrying out one-step emulsification or multi-step emulsification to obtain emulsion A and emulsion B; displacing the emulsion A and the emulsion B by using insert gas to remove oxygen; adjusting the temperature of the emulsion B to an initiation temperature; adding an initiator and after polymerization is carried out for 30-120 minutes, dropwise adding the emulsion A; continually reacting to convert all the monomers into polymers; and finishing the reaction to obtain an amphoteric water-in-oil inverse emulsion product. Amphoteric polyacrylamide prepared by the preparation method has different molecular structures, also has the advantages of high effective content, high molecular weight, low viscosity and can be dissolved quickly.

Owner:JIANGSU FEYMER TECH

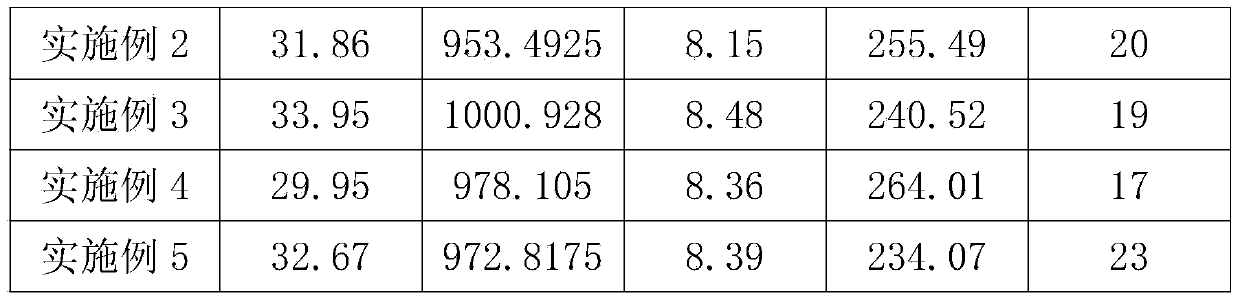

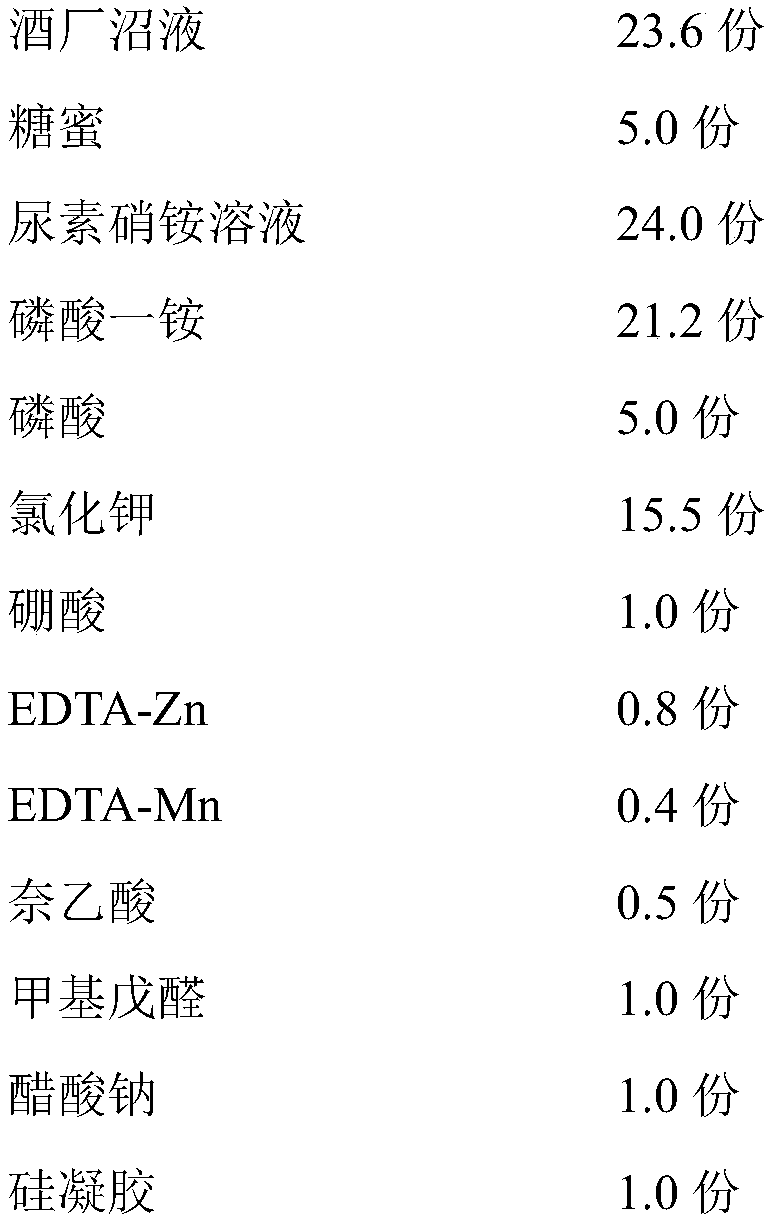

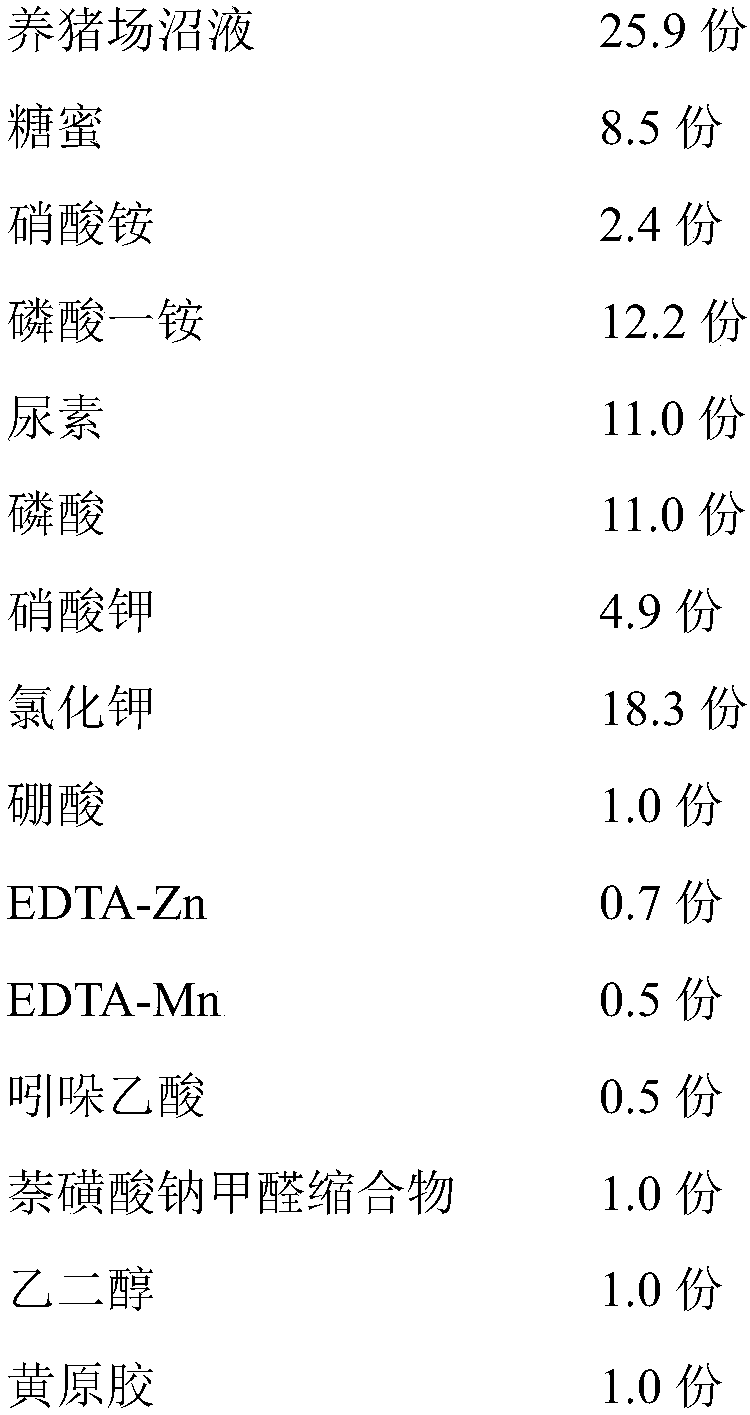

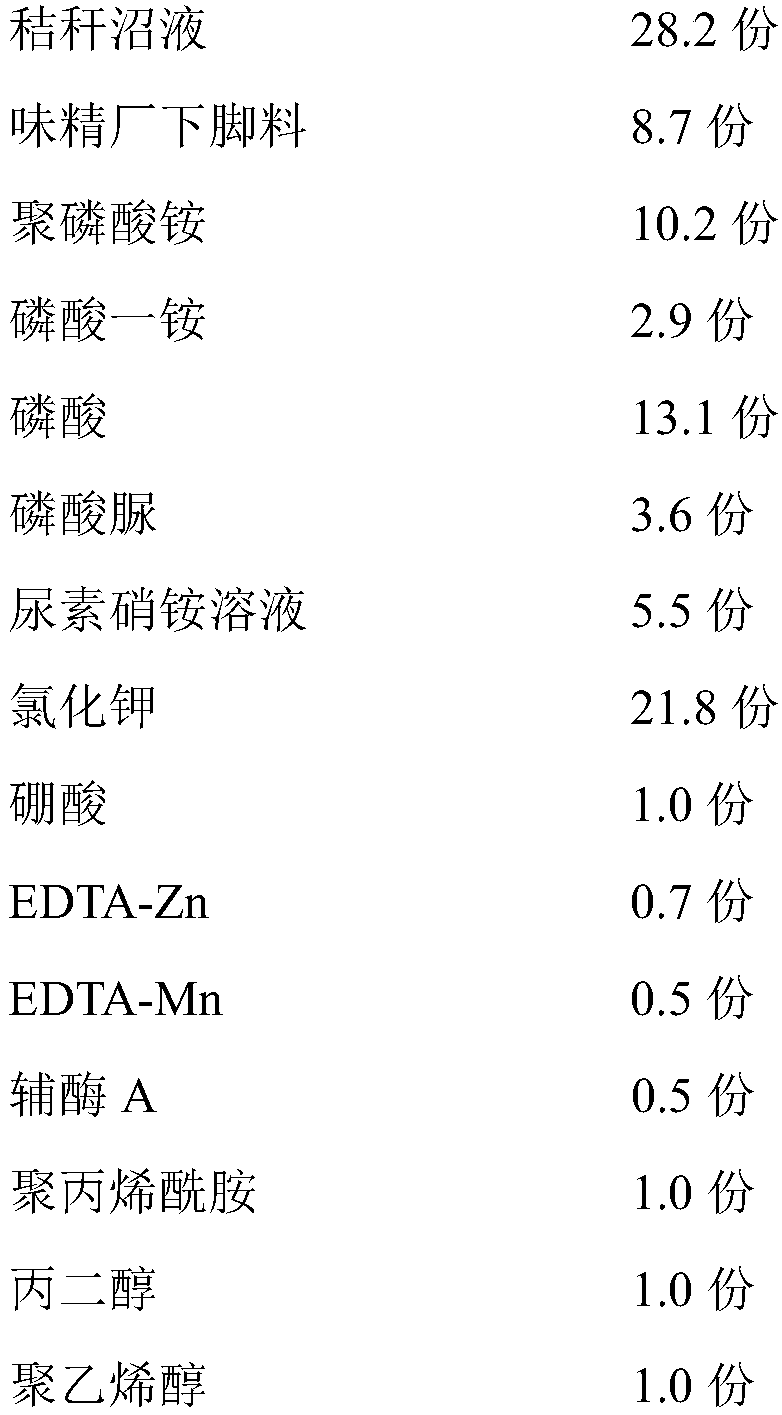

High-efficiency biogas slurry organic suspension liquid fertilizer and preparation method thereof

InactiveCN108546177AHigh nutrient contentPhysical stabilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumSlurry

The invention discloses a high-efficiency biogas slurry organic suspension liquid fertilizer and a preparation method thereof. The high-efficiency biogas slurry organic suspension liquid fertilizer comprises, by weight, 21.0-42.0 parts of a biogas slurry, 6.0-9.0 parts of organic matters, 4.0-25.0 parts of a nitrogen fertilizer, 9.0-20.0 parts of a potassium fertilizer, 0.5-1.0 part of a boron fertilizer, 0.5-0.8 part of EDTA-Zn, 0.4-0.6 part of EDTA-Mn, 0.1-2.0 parts of a wetting dispersant, 0.1-2.0 parts of a thickener, 0.1-2.0 parts of an antifreeze agent and 0.1-1.0 part of a root promoter. The high-efficiency biogas slurry organic suspension liquid fertilizer is an organic-inorganic suspension liquid fertilizer, and the high-efficiency biogas slurry fertilizer is prepared by fermenting a substrate biogas slurry, so the problem of the pollution of discharge of the biogas slurry to the environment is effectively solved, the biogas slurry is transformed into valuables from wastes andis fully used, and the production cost of the liquid fertilizer is reduced. The fermented biogas slurry is used to prepare the liquid fertilizer, so the liquid fertilizer can be more rapidly dissolved in water than general products, and has the advantages of high total nutrient content, stable physical and chemical properties, and no crystallization, precipitation and stratification phenomena under high temperature, low temperature and normal temperature conditions.

Owner:DONGGUAN YIXIANG LIQUID FERTILIZER +1

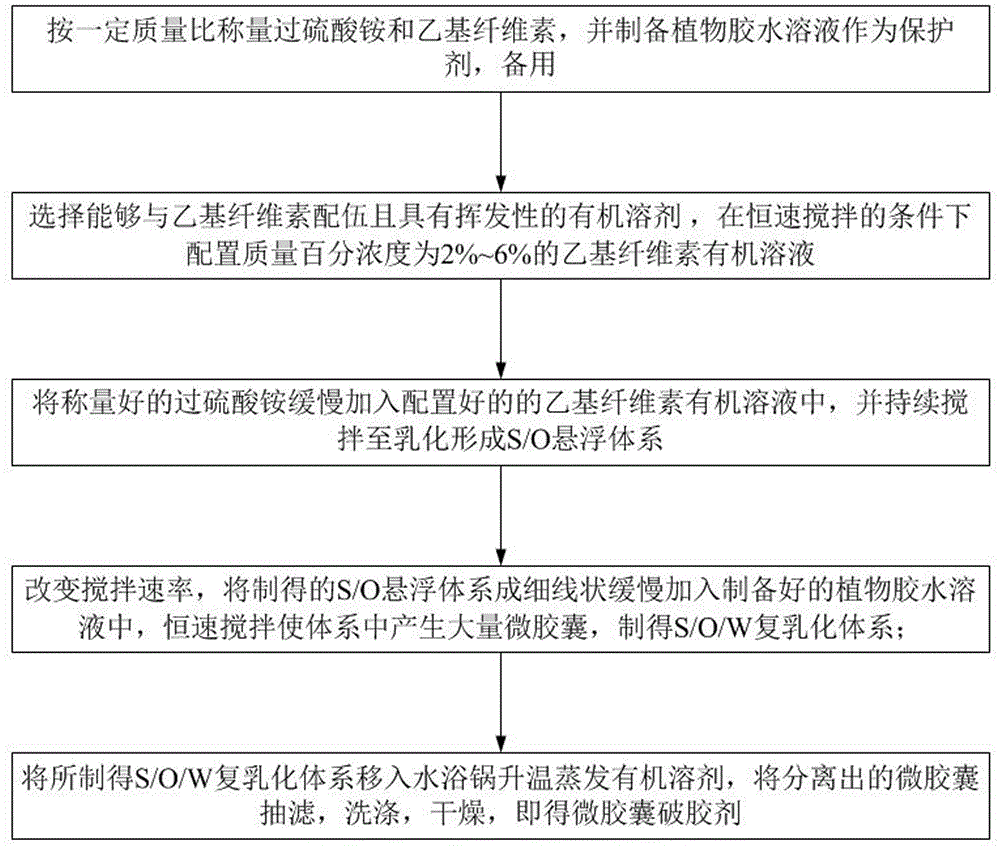

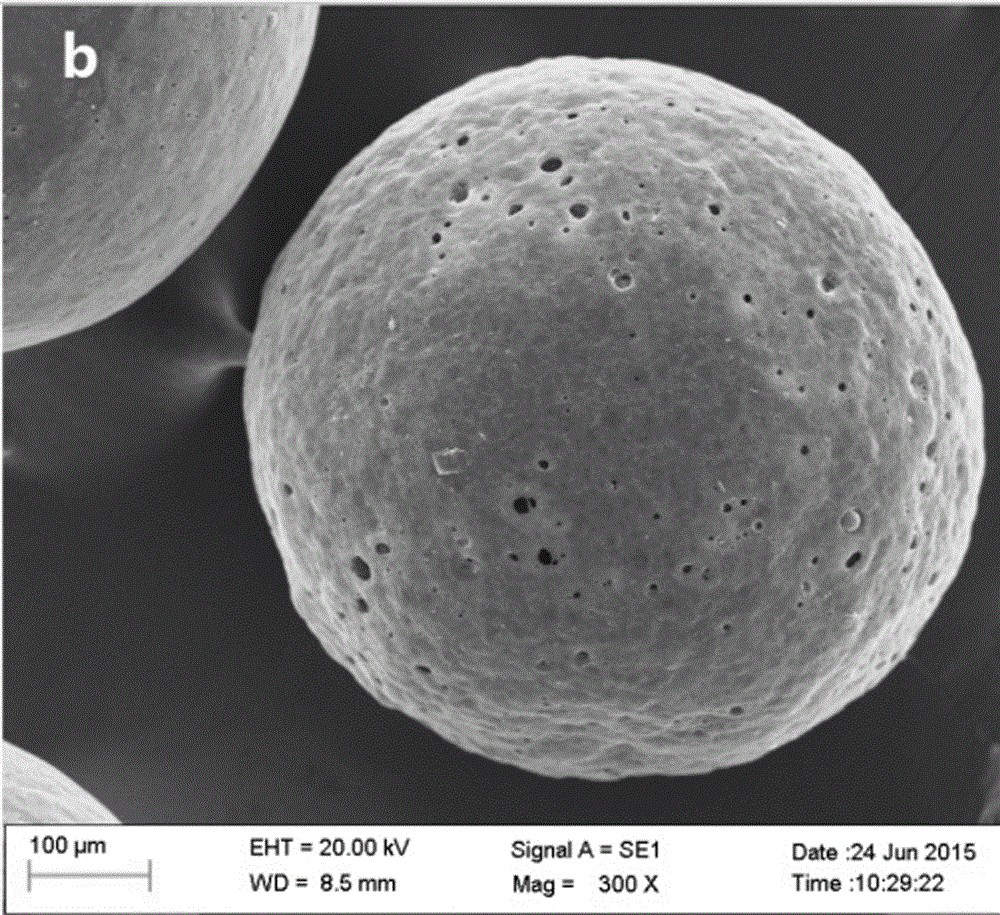

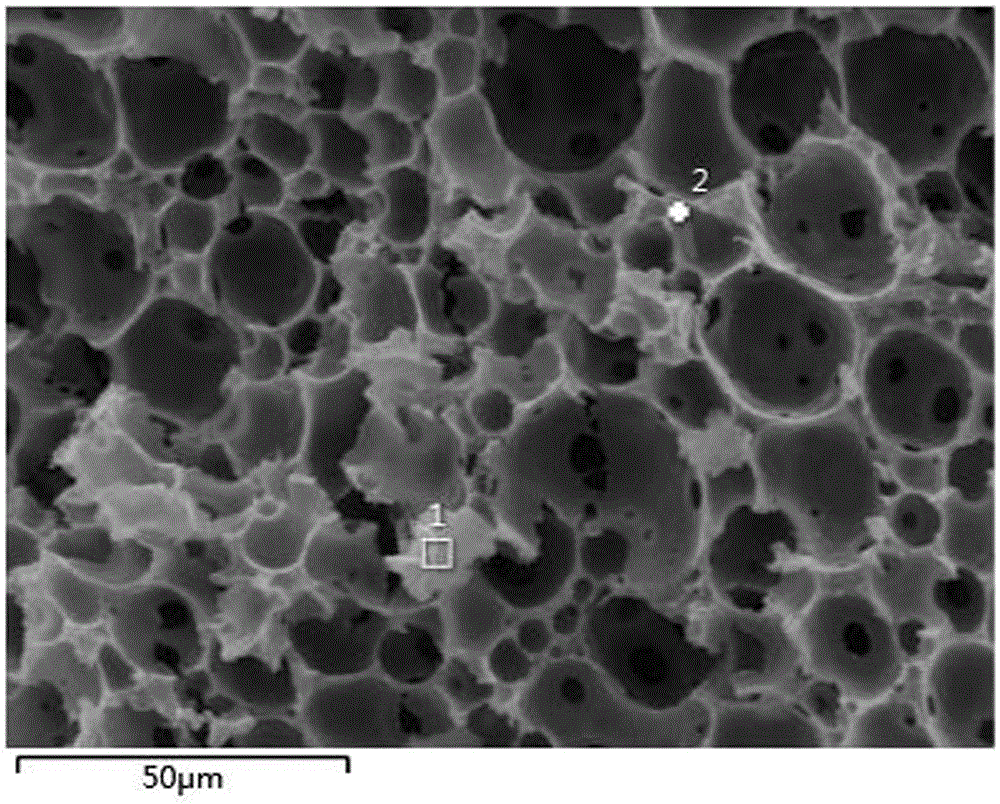

Microcapsule gel breaker and preparation method thereof

InactiveCN105647504AGood sphericityUniform particle size distributionDrilling compositionWater basedGranularity

The invention discloses a microcapsule gel breaker. The microcapsule gel breaker is mainly prepared from ammonium persulfate as the core material and ethyecellulose as the wrapper material according to the mass ratio of 2:1 to 1:4 by mass percentage in a gelatine water solution as the protective agent. The preparation method specifically includes the steps of firstly, weighing and preparing raw materials; secondly, preparing a wrapper material solution; thirdly, adding the core material to prepare an S / O suspension system; fourthly, adding the protective agent in the suspension system to prepare an S / O / W composite emulsification system; fifthly, separating a microcapsule, and conducting suction filtration, washing and drying. The microcapsule gel breaker has the advantages of high sphericity, uniform granularity, high effective content, slow-release gel breaking property and the like; gelatine (guanidine gum) fracturing fluid can be effectively broken under ideal conditions during fracture construction; few devices are used in the preparation method, device and investment cost is reduced, and operation is easy; the required raw materials are wide in source and easy to obtain, and a foundation is laid for application and popularization of the microcapsule gel breaker in water base fracture work.

Owner:SOUTHWEST PETROLEUM UNIV

Method for synchronizing anode polyacrylamide latex

The invention relates to a method for synchronizing anode polyacrylamide latex. Raw materials are as follows: 52 to 268 portions of non-ionic monomer, 61 to 345 portions of anode monomer, 116 to 398 portions of deionized water, 2.0 to 2.5 portions of emulsifying agent, 0.3 to 0.8 portions of evocating agent, 0.5 to 0.8 portions of sodium bisulfite, 50 to 60 portions of organic solvent and 10 to 20 portions of phase inversion agent; the method for synchronizing anode polyacrylamide latex is as follows: the non-ionic monomer, the anode monomer and the deionized water are mixed and dissolved uniformly to obtain aqueous phase solution; the emulsifying agent is dissolved in part of the organic solvent to obtain oil phase solution, and the aqueous phase solution, the oil phase solution, the evocating agent and the rest organic solvent are led into a reaction kettle and are protected by nitrogen to be stirred and reacted for 3 hours at the temperature of 20 to 40 DEG C; sodium bisulfite is added for eliminating the residual monomer, and phase inversion agent is added at normal temperature for rubber latex property regulation so that the anode polyacrylamide latex can be obtained. The effective latex of the invention is prepared from green synchronized technical materials, and the process overcomes the disadvantages of slow dissolution and decentralization and high energy consumption and cost.

Owner:东营市诺尔化工有限责任公司

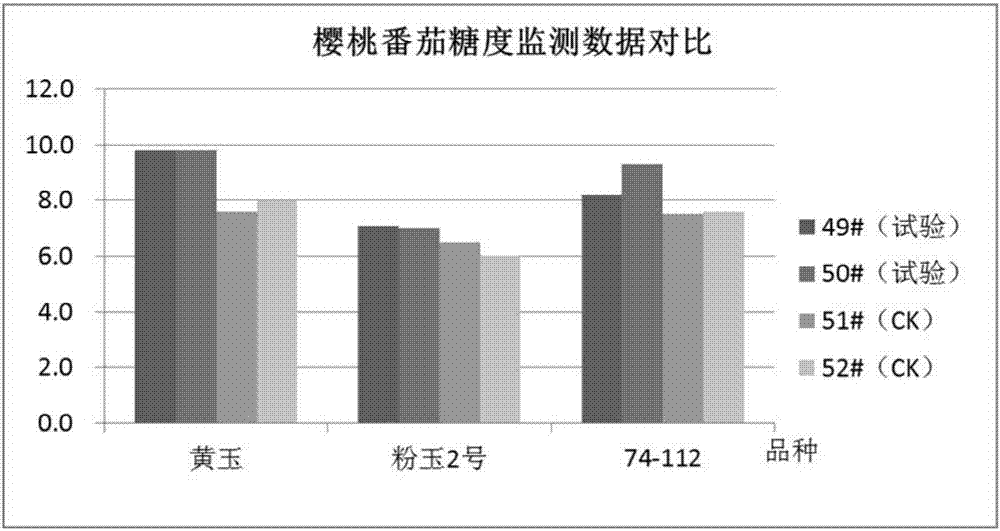

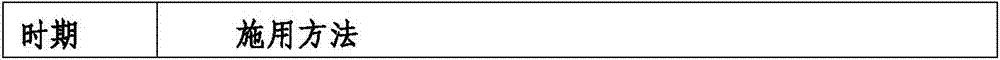

Ferment fertilizer product with sweetening effect and preparation method of ferment fertilizer product

InactiveCN107344888ARealize comprehensive utilizationNutritional supplementsMagnesium fertilisersAlkali orthophosphate fertiliserDrug biological activityFermentation

The invention belongs to the field of microbial fermentation and provides a preparation method of a ferment fertilizer product with the sweetening effect. The preparation method comprises the following steps of by taking wastes, including inferior fruits, fallen fruits, fruit residues, vegetable straw and the like in agricultural production as raw materials, utilizing a mode of multiple fermentation to finally obtain the liquid ferment fertilizer with the sweetening effect. The obtained bacterial fertilizer has very good ecological benefits, and plants can absorb and convert the bacterial fertilizer to reach the effects of rapidly supplementing plant nutrients, accumulating sugar, and thus increasing the sweetness of fruits and promoting conversion absorption of components, including vitamins, bioactive enzyme and selenium in a product, thereby reaching the purposes of reducing acid, sweetening, removing acerbity and enhancing fresh from the source.

Owner:SHANDONG BOHUA HIGHLY EFFICIENT ECOLOGICAL & AGRI TECH CO LTD

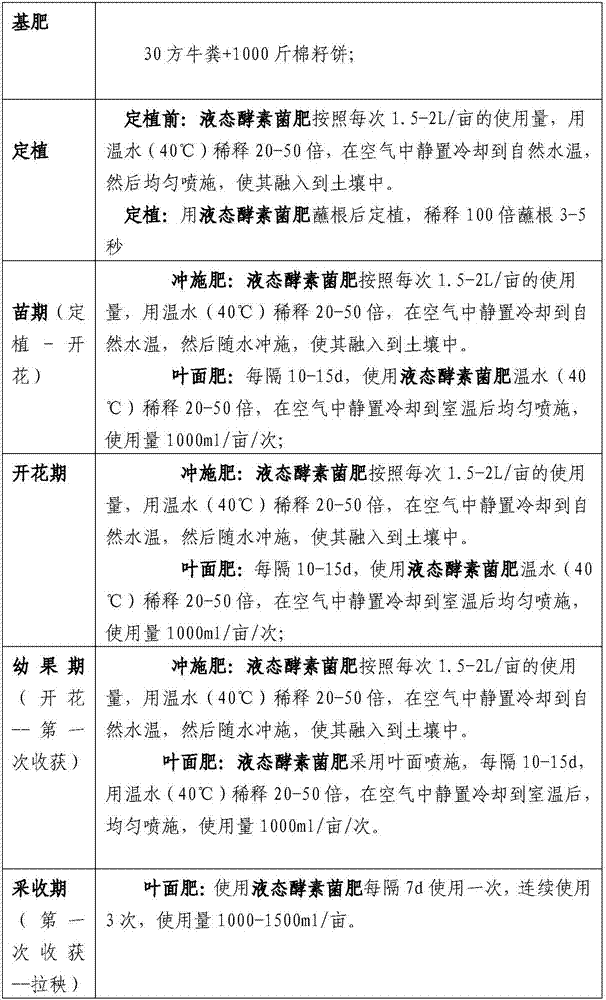

Preparation method of propyl trimethoxy silane

InactiveCN102924504AEfficient removalAvoid it happening againGroup 4/14 element organic compoundsSodium methoxideSilanes

The invention discloses a preparation method of propyl trimethoxy silane. The method comprises the steps that propyl trichlorosilane and methanol are respectively measured through a flowmeter according to the mass ratio being 1.5 : 1; the methanol passes through a heating tank after being vaporized through a vaporizing tank, and then enters the bottom of an esterification column; the propyl trichlorosilane enters the esterification column from the top and is sprayed down; principal products at the bottom of an esterifying kettle is pumped into the top of the esterification column through a centrifugal pump; methanol gas flowing through the esterification column performs gas stripping to residual HCl in the principal products so as to take away HCl while the principal products drop down; after the principal products drop down to the bottom of the esterifying kettle, the principal products are pumped into a neutralizing kettle through a delivery pump; saturated sodium methoxide solution is dropwise added into the neutralizing kettle to be conducted to neutralizing; and propyl trimethoxy silane crude products are obtained after filtering; the propyl trimethoxy silane crude products are pumped into a rectifying tower to be rectified; and after impurities are separated, propyl trimethoxy silane finished products are obtained. The method solves the problems of the comprehensive utilization of side products in the industrial product of gamma-chloropropyl trichlorosilane, has the characteristics of high production efficiency, stable process and high quantity of production, and improves the product yield and purity, thereby realizing the continuity of the process.

Owner:江西晨光新材料股份有限公司

Synthesis method of 4-hydroxybutyl vinyl ether polyoxyethylene ether

The invention relates to a synthesis method of 4- hydroxybutyl vinyl ether polyoxyethylene ether, and belongs to the technical field of polyether compound synthesis in organic chemistry. The synthesis method comprises two phases, namely a primary synthesis phase and a final synthesis phase, and specifically comprises the following steps: subjecting a part of 4-hydroxybutyl vinyl ether to a pre-reaction with a primary synthesis catalyst, adding the pre-reaction product into the rest part of 4-hydroxybutyl vinyl ether, introducing ethylene oxide to carry out primary synthesis so as to obtain a primary product, adding a final synthesis catalyst into a part of the primary product to carry out a secondary pre-reaction, and subjecting the secondary pre-reaction product to final synthesis reactions with the rest part of the primary product and ethylene oxide so as to obtain the final product. The product obtained by the technical scheme provided by the invention has the advantages of low by-product content, narrow molecular weight distribution, and high double-bond protection rate.

Owner:ZHEJIANG LYUKEAN CHEM

Chlorpyrifos containing powder coating agent

InactiveCN1593146AOvercome the problem of storage decompositionHigh effective contentBiocideAnimal repellantsSurface-active agentsDisease cure

The invention relates to a powdery seed coating agent for the prevention and cure of underground pests of sprout period corns and soybeans containing chlorpyrifos, wherein the agent comprises 1-50 wt% of chlorpyrifos, 1-50 wt% of bactericidal agent, 1-20% of surface active agent, 1-20% of binding agent and film former, 0.1-2% of aposematic coloration and right amount of extender.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com