Preparation method for amphoteric water-in-oil inverse emulsion

A technology of inverse emulsion and water-in-oil, which is applied in the field of preparation of amphoteric water-in-oil inverse emulsion, can solve the problems of affecting the normal production of paper, reducing the dewatering speed of paper machines, increasing energy consumption, etc. Transport, high molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

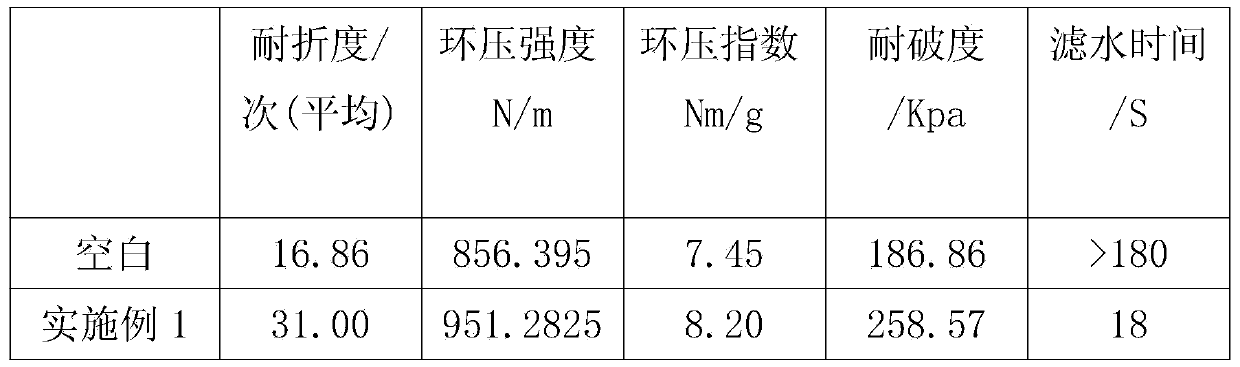

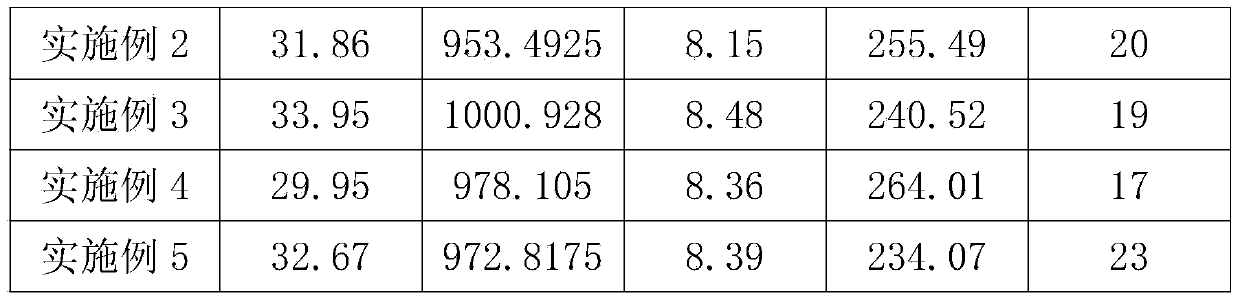

Examples

Embodiment 1

[0030] (1) Add acrylamide, maleic acid, acryloyloxyethyltrimethylammonium chloride, ethylenediaminetetraacetic acid sodium salt, and mercaptan into water, adjust the pH to 5.0, and prepare the aqueous phase A, in which acryloyl The mass ratio of oxyethyltrimethylammonium chloride and maleic acid is 9:1;

[0031] Add acrylamide, maleic acid, acryloyloxyethyltrimethylammonium chloride, ethylenediaminetetraacetic acid sodium salt, and mercaptan into water, adjust the pH to 10.0, and prepare the aqueous phase B, in which acryloyloxyethyl The mass ratio of trimethylammonium chloride and maleic acid is 1:9, and the mass ratio of aqueous phase A and aqueous phase B is 4:6;

[0032] (2) Add fatty acid polyoxyethylene ester into cyclohexane solvent to form an oil phase; divide the oil phase into two parts, drop water phase A and B into the oil phase respectively, and obtain two emulsions A and emulsion through one-step emulsification B;

[0033] (3) Replace emulsion A and emulsion B ...

Embodiment 2

[0036](1) Add methacrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacrylamidopropyltrimethylammonium chloride, diethylenetriaminepentaacetic acid sodium salt, sodium formate into water, Adjust PH=6.0, configure to obtain aqueous phase A, wherein the mass ratio of methacrylamidopropyltrimethylammonium chloride to 2-acrylamido-2-methylpropanesulfonic acid is 4:1;

[0037] Add methacrylamide, 2-acrylamido-2-methylpropanesulfonic acid, methacrylamidopropyltrimethylammonium chloride, diethylenetriaminepentaacetic acid sodium salt, and sodium formate into water to adjust the pH= 8.0, configured to obtain water phase B, wherein the mass ratio of methacrylamidopropyltrimethylammonium chloride to 2-acrylamido-2-methylpropanesulfonic acid is 1:6; water phase A and water phase The mass ratio of B is 3:7

[0038] (2) Add sorbitan fatty acid ester and polyoxyethylene sorbitan fatty acid ester (8:1 by weight) to 7# white oil to form an oil phase; divide the oil phase into two par...

Embodiment 3

[0042] (1) Add hydroxyethyl acrylate, acrylic acid, methacryloyloxyethyltrimethylammonium chloride, diethylenetriaminepentaacetic acid pentasodium salt, and sodium formate into water, adjust the pH to 7.0, and prepare the water phase, press The mass ratio of cationic monomers and anionic monomers in water is 5:1 to obtain aqueous phase A; the mass ratio of cationic monomers to anionic monomers is 1:4 to obtain aqueous phase B; the mass of aqueous phase A and aqueous phase B The ratio is 7:3

[0043] (2) Add alkylphenol polyoxyethylene ether to toluene to form an oil phase; divide the oil phase into two parts, drop water phase A and B into the oil phase respectively, and obtain two kinds of emulsion A and emulsion through one-step emulsification B;

[0044] (3) Replace emulsion A and emulsion B with an inert gas to remove oxygen, adjust the temperature of emulsion B to the initiation temperature, add azobisisobutyronitrile, and after 45 minutes of polymerization, start to add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com