Microcapsule gel breaker and preparation method thereof

A technology of microcapsules and gel breakers, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that have not entered the field application and industrial production, the process operation is complicated and difficult to control, and the particle sphericity is low. Achieve good sphericity, reduce production cost, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The microcapsule gel breaker described in this embodiment is mainly composed of ammonium persulfate as the core material, ethyl cellulose as the clothing material, and an aqueous plant glue solution as the protective agent. In terms of mass percentage, the mass ratio of the core material to the clothing material is 2 :1~1:4. Wherein, the vegetable gum aqueous solution is a gelatin aqueous solution with a concentration of 1% to 2% by mass.

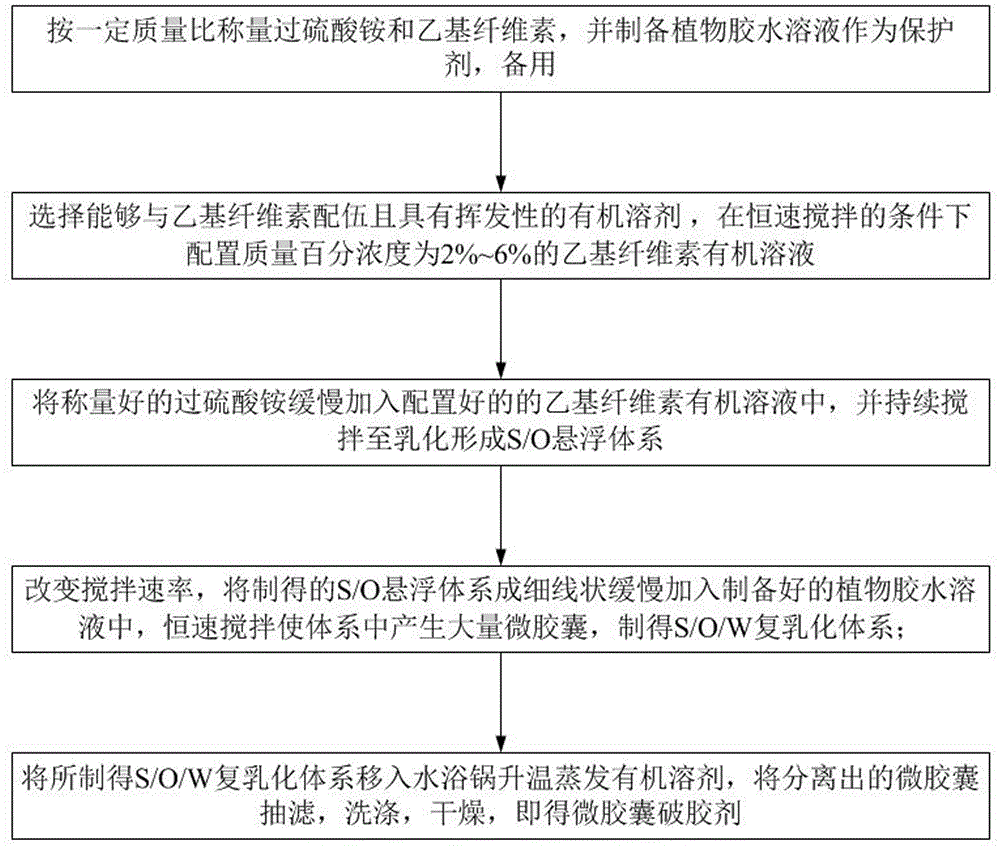

[0039] The preparation method of this microcapsule breaker, such as figure 1 Shown, and in conjunction with the following specific examples the present invention will be further described.

[0040] (1) Weigh 2g of ethyl cellulose and 4g of ammonium persulfate solid powder, and control the volume ratio of dichloromethane to distilled water to be 1:5; take a 500ml beaker and prepare the mass fraction with distilled water in a warm water bath at 40°C 2% gelatin solution, and keep it warm for later use;

[0041] (2) Measure an appropr...

Embodiment 2

[0047] The present embodiment carries out corresponding performance index test to the prepared ammonium persulfate capsule gel breaker, and concrete test item is as follows:

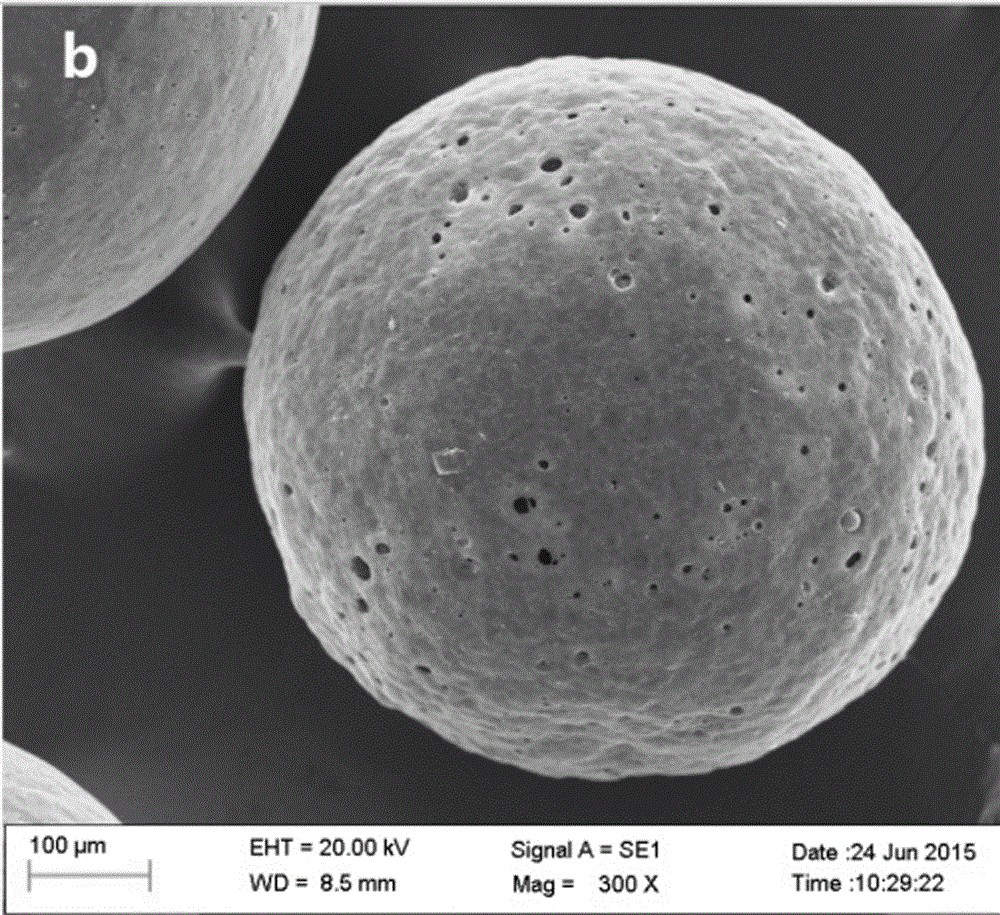

[0048] (1) Determination of appearance and morphology: the surface of the microcapsules was scanned by spraying gold at room temperature with a scanning electron microscope to obtain a morphology map.

[0049] The appearance of the sample ammonium persulfate capsule gel breaker is shown in the scanning electron microscope image, such as figure 2 shown. Depend on figure 2 It can be clearly seen that the surface of ammonium persulfate microcapsules is round and smooth, and there are very few microporous channels on the surface that can be used for the release of core materials, which is more in line with industry requirements.

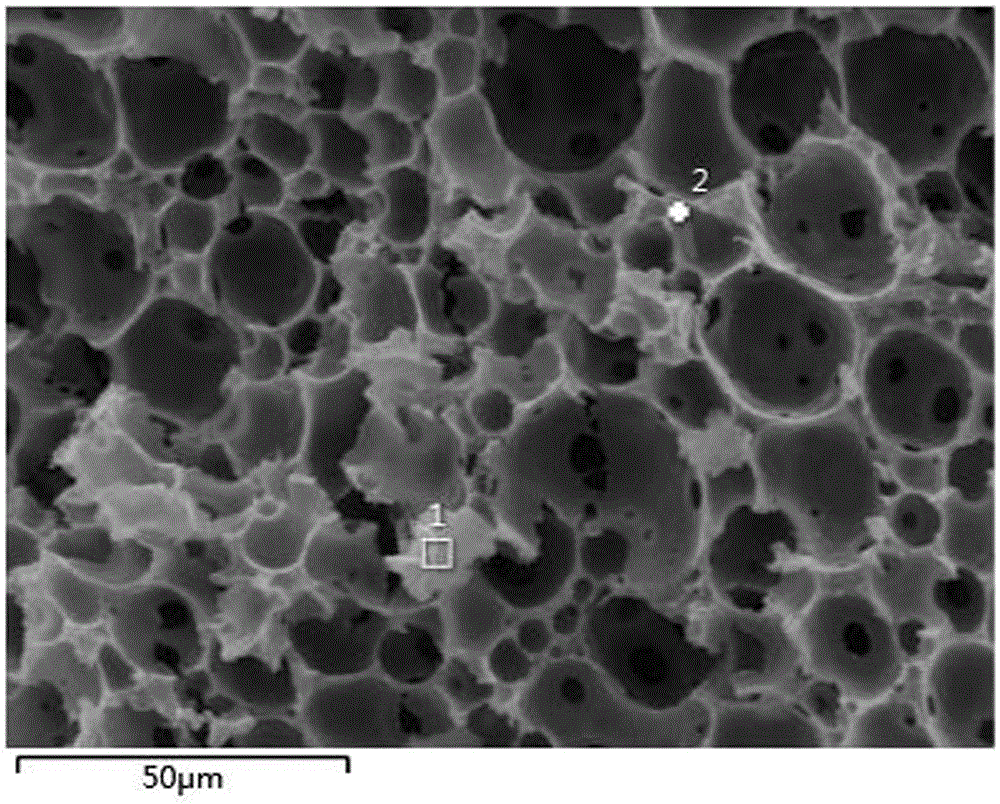

[0050] (2) At the same time, under room temperature conditions, the ammonium persulfate microcapsule sample of the embodiment is sliced, and the ammonium persulfate microcapsul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com