Polyurea capsule with composite wall and high core content and preparation method thereof

A technology of capsule core and polyurea, which is applied in the field of preparation of phase change energy storage capsules, can solve the problems of low content of microcapsule capsule core and residual organic co-solvent, etc., and achieve the effect of increasing effective content and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

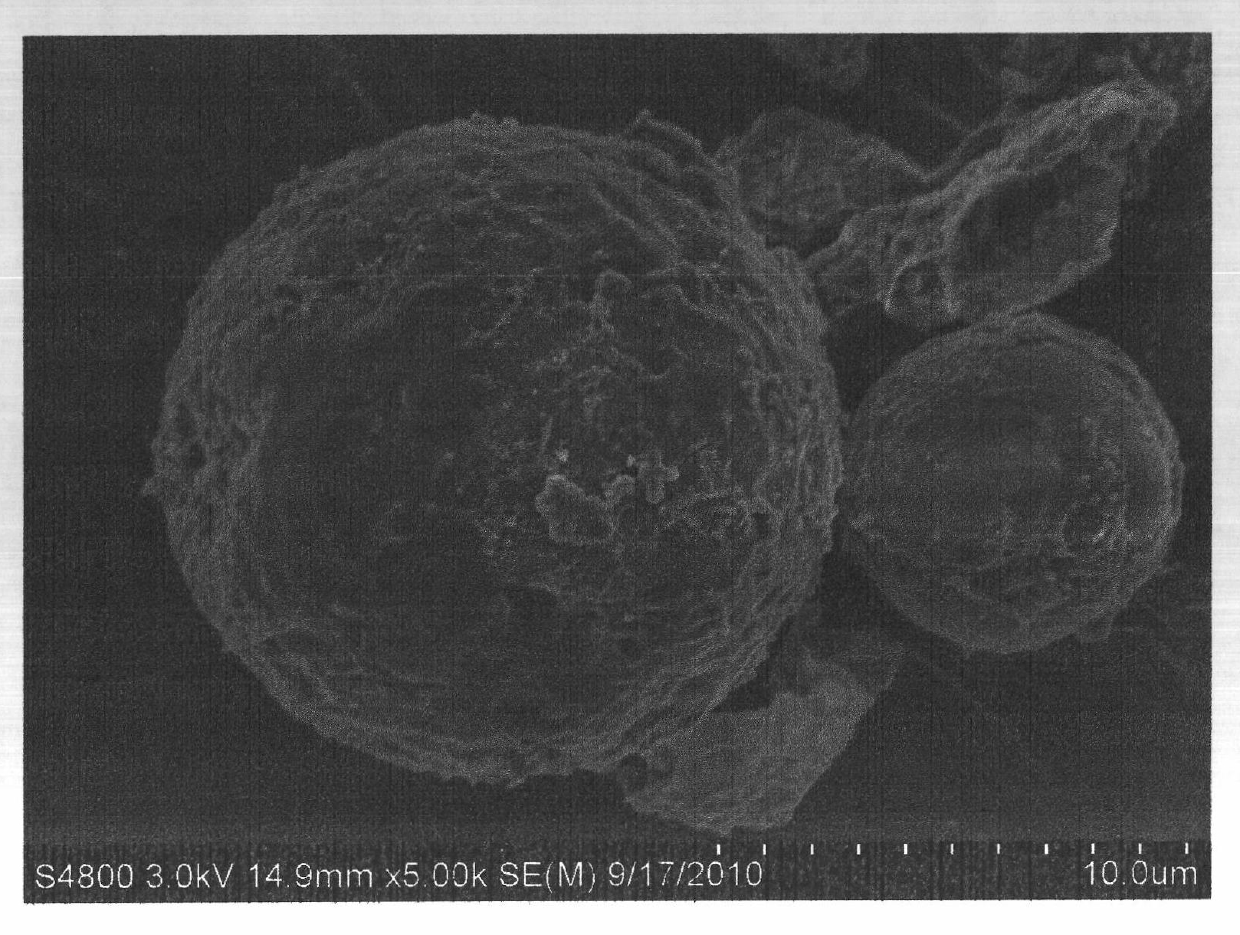

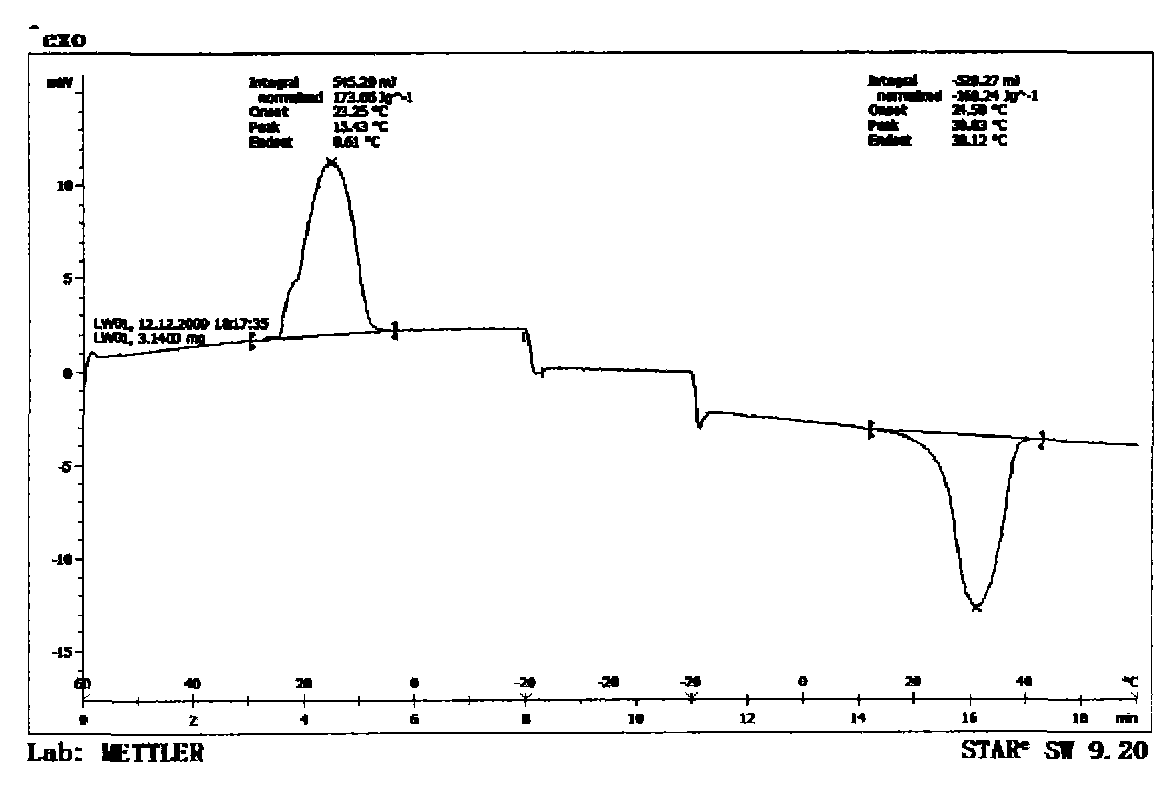

Embodiment 1

[0034] 1. Preparation of oil phase, water phase A and water phase B

[0035] Mix 3.0 g of toluene diisocyanate, 2.5 g of styrene, 0.5 g of divinylbenzene, 0.05 g of azobisisobutyronitrile and 10.0 g of n-octadecane to obtain an oil phase.

[0036] 4.0 g of a styrene-maleic anhydride copolymer was dissolved in 100.0 g of distilled water to prepare an aqueous phase A (that is, an aqueous emulsifier solution).

[0037] Aqueous phase B was prepared by dissolving 3.0 g of diethylenetriamine in 100.0 g of distilled water.

[0038] 2. Add dropwise or pour the oil phase solution into the water phase A solution, stir and emulsify at a high speed at 35°C and 4000 rpm for 10 minutes to prepare an O / W emulsion.

[0039] 3. Stir the O / W emulsion at a speed of 400 rpm, and at the same time add the aqueous phase B solution to the O / W emulsion dropwise.

[0040] 4. After the dropwise addition, the temperature was raised to 50° C., and the reaction was continued for 3.0 hr.

[0041] 5. Raise ...

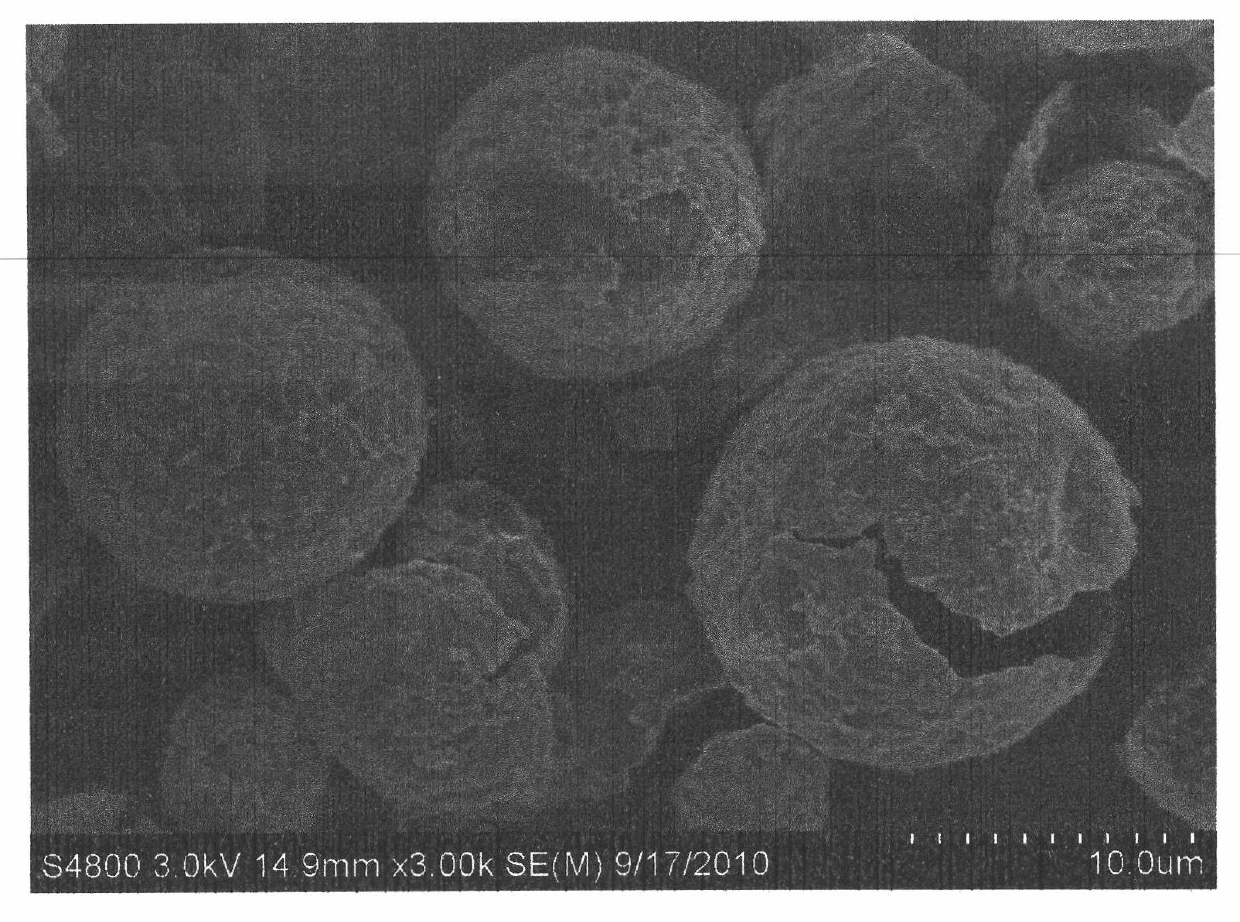

Embodiment 2

[0047] 1. Preparation of oil phase, water phase A and water phase B

[0048] 20.0 g of toluene diisocyanate, 70.0 g of n-octadecane, and 10.0 g of butyl octadecanoate were uniformly mixed to obtain an oil phase.

[0049] 30.0 g of a styrene-maleic anhydride copolymer was dissolved in 700.0 g of distilled water to prepare an aqueous phase A.

[0050] 15.0 g of tetraethylenepentamine was dissolved in 300.0 g of distilled water to prepare an aqueous phase B.

[0051] 2. Add dropwise or pour the oil phase solution into the water phase A solution, stir and emulsify at a high speed at 35°C and 4000 rpm for 10 minutes to prepare an O / W emulsion.

[0052] 3. Stir the O / W emulsion at a speed of 600rpm, and at the same time add the aqueous phase B solution to the O / W emulsion dropwise.

[0053] 4. After the dropwise addition, the temperature was raised to 50° C., and the reaction was continued for 3.0 hr.

[0054] 5. Suction filtration, washing and drying the prepared capsules, the p...

Embodiment 3

[0057] 1. Preparation of oil phase, water phase A and water phase B

[0058] Mix 5.0 g of toluene diisocyanate, 3.5 g of styrene, 1.5 g of divinylbenzene, 0.08 g of benzoyl peroxide and 40.0 g of rose essence to obtain an oil phase.

[0059] 10.0 g of a styrene-maleic anhydride copolymer was dissolved in 200.0 g of distilled water to prepare an aqueous phase A.

[0060] Aqueous phase B was prepared by dissolving 5.0 g of hexamethylenediamine in 100.0 g of distilled water.

[0061] 2. Pour the oil phase solution into the water phase A solution, stir and emulsify at a high speed at 8000 rpm for 10 minutes at room temperature to prepare an O / W emulsion.

[0062] 3. Stir the O / W emulsion at a speed of 400 rpm, and at the same time add the aqueous phase B solution to the O / W emulsion dropwise.

[0063] 4. After the dropwise addition, the temperature was raised to 50° C., and the reaction was continued for 3.0 hr.

[0064] 5. Then raise the temperature to 85°C, react and mature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com