Process for rare-earth smelting resource reclamation and cyclic production

A process method and resource-based technology, applied in the field of rare earth smelting resource recovery and recycling production, can solve the problems of no major breakthrough, waste, and no solution, and achieve the effect of breaking through the technical bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

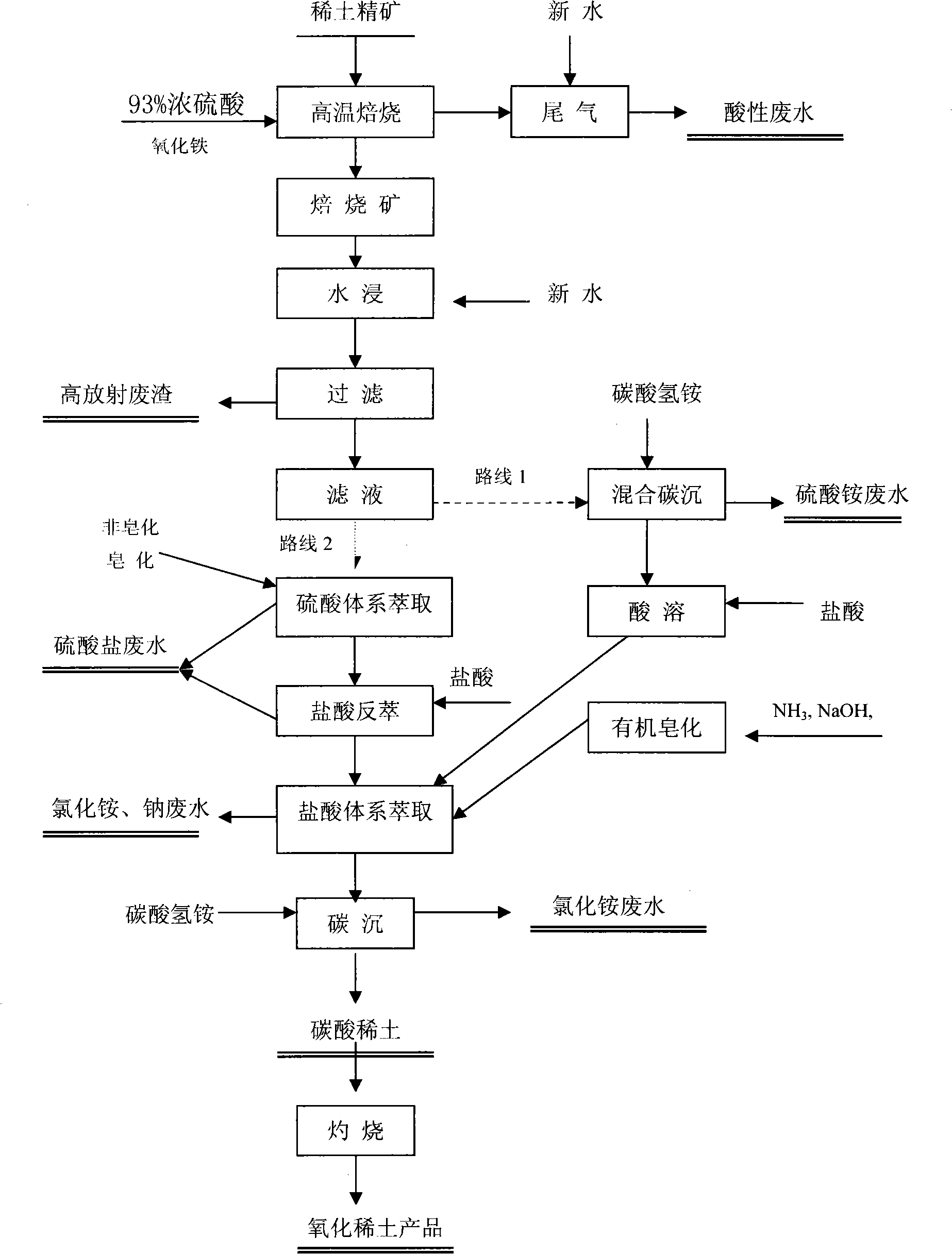

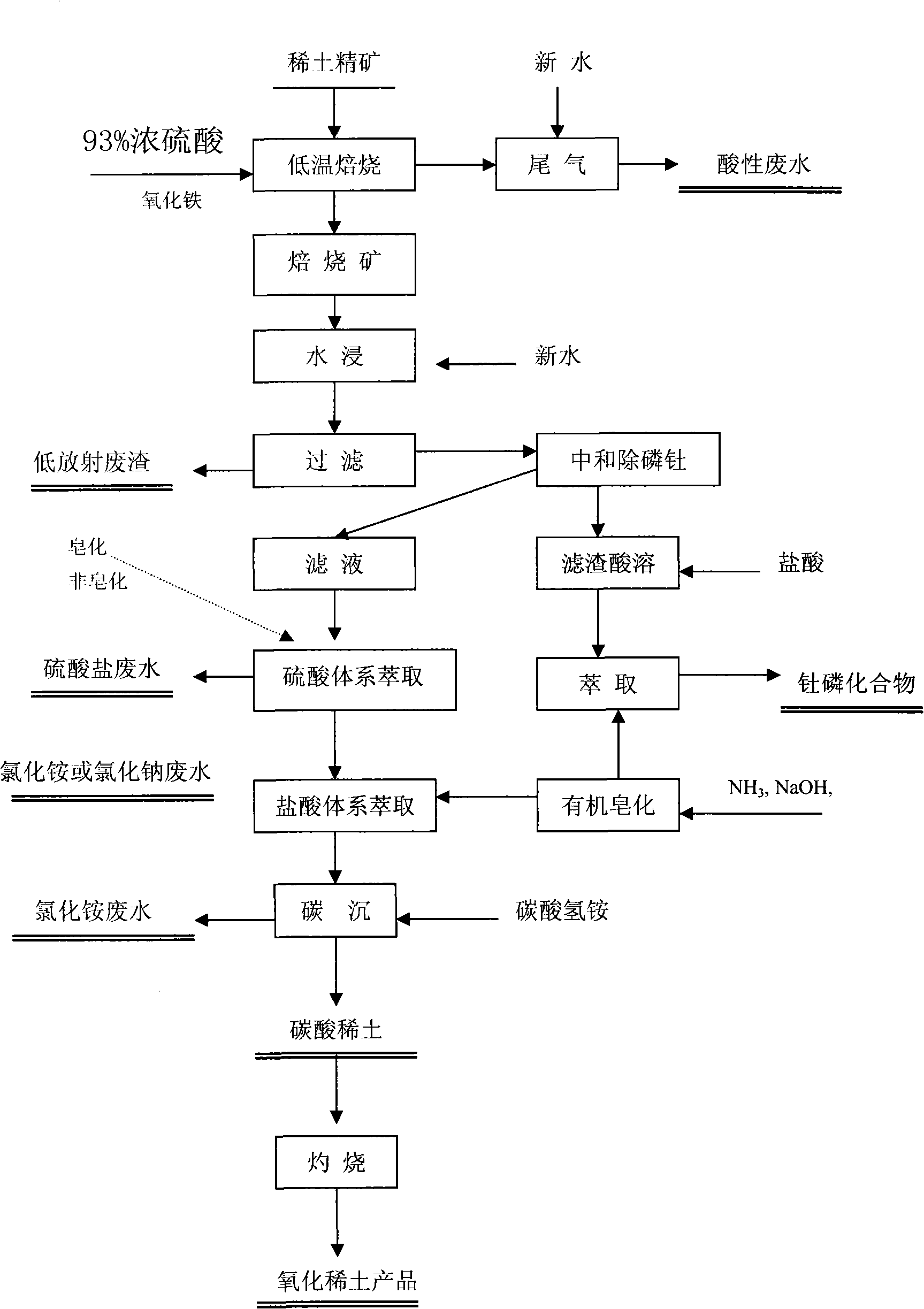

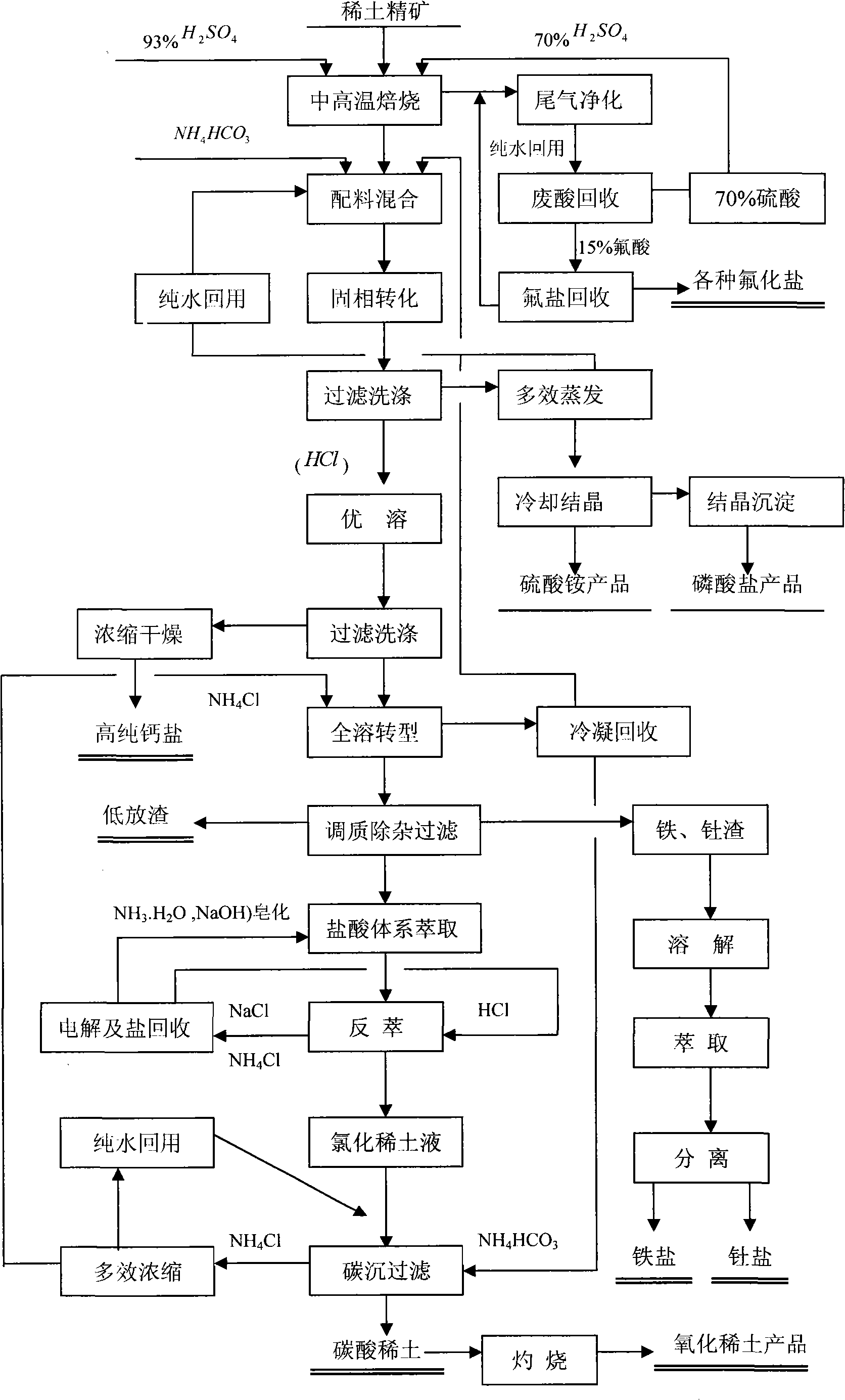

Method used

Image

Examples

Embodiment 1

[0194] 1. Mix the rare earth concentrate containing 20-70wt% REO into sulfuric acid with a concentration of 70wt% and sulfuric acid with a concentration of 93wt%. The mineral-acid ratio (weight ratio) is 1.1-2.1. , keep the kiln head at a temperature of 500-600°C, and the kiln tail at about 150-200°C. The material stays in the kiln for 1 to 1.5 hours to obtain the rare earth sulfate roasted ore.

[0195] 2. The 150-200°C high-temperature acid tail gas generated during the roasting process enters the tail gas deep purification and waste acid recovery system for deep purification and recovery. The recovered concentration is more than 70wt%. The sulfuric acid is returned to the concentrate for roasting and reused. Enter the fluoride salt preparation system to produce various fluoride salts.

[0196] 3. Mix the roasted ore with the recovered and supplemented ammonium bicarbonate to form a high-concentration phase slurry, and then enter the closed continuous reactor, control the t...

Embodiment 2

[0207] 1000g Baotou mixed rare earth concentrate (REO: 50.5wt%, FeO: 3.1wt%, P 2 o 5 : 2.6wt%, ThO 2 : 0.21wt%, CaO: 8.4wt%) and sulfuric acid (70wt% concentration: 93wt% concentration = 1: 3.5) are mixed by acid ore ratio 1: 1.8 at material temperature 350~400 ℃ of roasting 1.5~2 hours, draw Roasted ore 1390.2g, analysis wherein the main components REO: 34.5wt%, CaO: 5.9wt%.

[0208] Weigh 1000g of roasted ore, add 4000ml of tap water, 530g of ammonium bicarbonate, and stir evenly. Then pour it into a closed reactor, control the temperature at 70-90°C and react for 0.5-1.0 hours, the reaction pressure is gradually reduced from 0.2MPa to -0.09MPa, the gas in the reactor is cooled and absorbed by the coil cooler and absorber, and the slurry is vacuum pumped After the filtered carbide ore was dried at 105° C. for 2 hours, the dry filter cake weighed 657.2 g, of which REO: 52.5 wt %, CaO: 8.9 wt %. Obtain mother liquor and adopt after stepwise concentrated crystallization to ...

Embodiment 3

[0210] Get 500g carbonized rare earth ore with 5-8wt%NH 4 Cl solution 2000ml water stirring reaction and maintaining the reaction temperature 40 ~ 65 ℃, adding a small amount of 2wt% hydrochloric acid during the control process to maintain PH = 3 ~ 5 reaction for 15 ~ 60 minutes, then filtered, separated, dried to obtain 470g of dry weight filter cake; to obtain the mother liquor 1850ml, composition CaO2.25%, repeated test phenomenon and results are basically the same, the dissolution rate of total calcium is more than 80%.

[0211] Take 1000g of finely dissolved carbide ore, add 4000ml of water and 650g of ammonium chloride and mix, then pour into a closed reactor at a temperature of 115-150°C, stir and react for 2-3.5 hours, and the reaction pressure is gradually reduced from 0.5MPa to - 0.09MPa, the gas in the reactor is absorbed into ammonium bicarbonate liquid through the coil cooler and absorber for reuse, the air is finally evacuated through the vacuum pump, the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com