Method for reducing strong alkalinity of red mud

A strong alkaline and red mud technology, applied in the field of red mud resource utilization, can solve the problems of great harm, loss of red mud components, strong corrosion of acidic solution, etc., and achieve increased organic nutrients, large specific surface area, and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

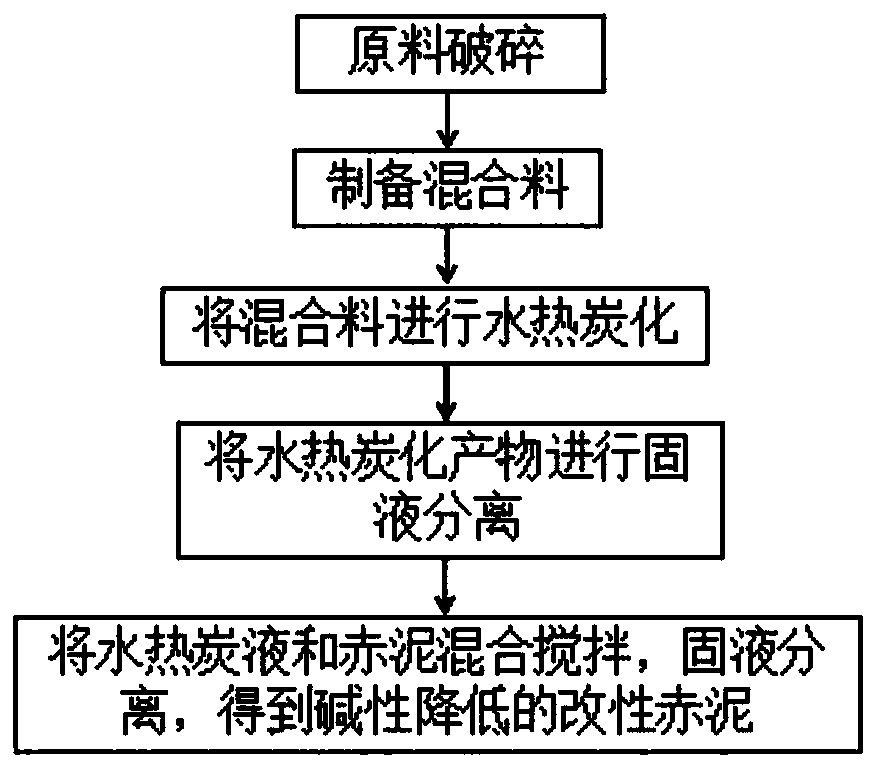

[0097] The method for reducing the strong alkalinity of red mud of the present embodiment may further comprise the steps:

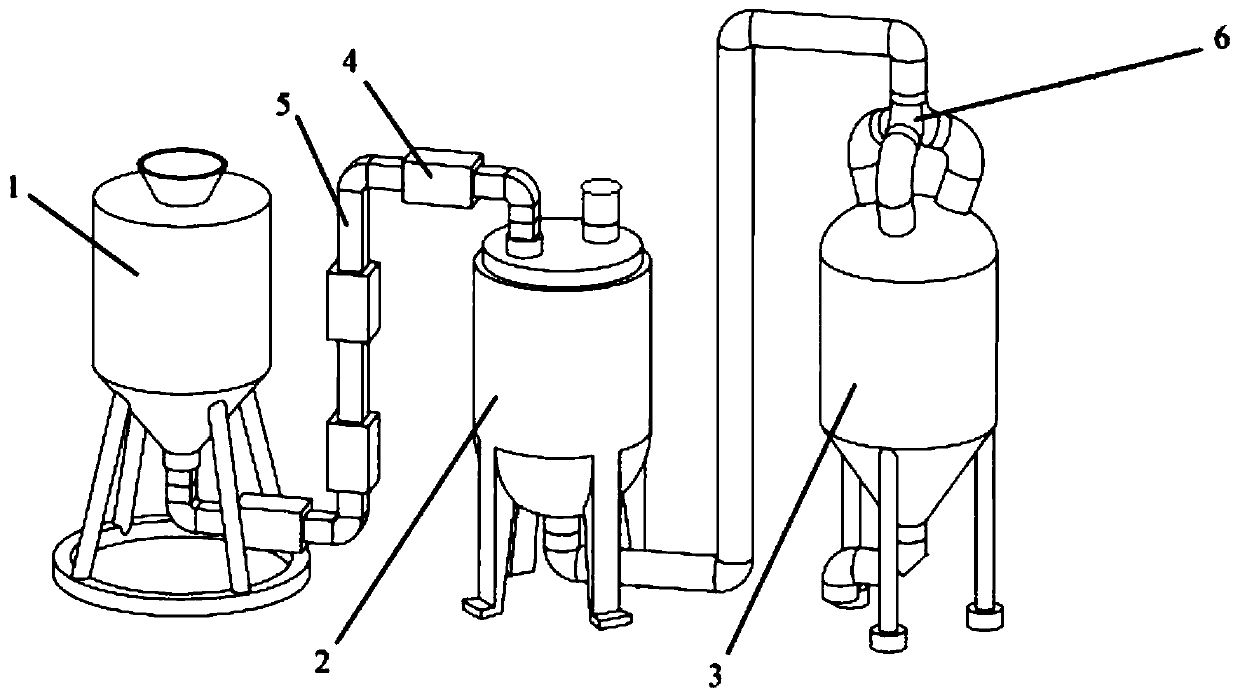

[0098] Step S1, adding the biomass raw material (in this embodiment, straw) into the crusher 1, and the crusher 1 crushes the straw into a powder with a particle size of 1 mm;

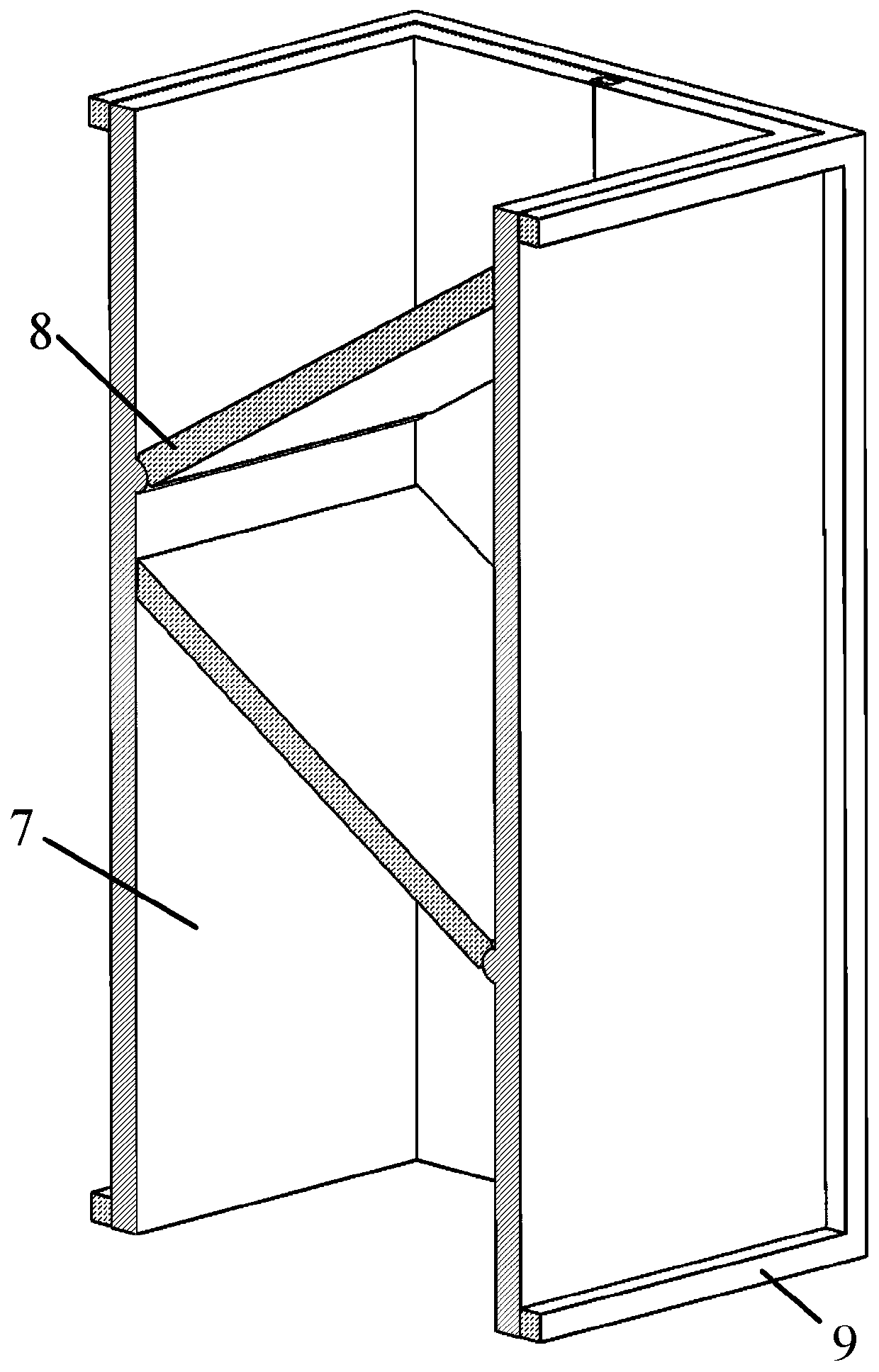

[0099] Step S2, use the material lifting mechanism 4 to transport the powder into the mixing tank 2 from the first feeding port, and then add water and catalyst (the catalyst is red mud in this embodiment) into the mixing tank 2 through the second feeding port , stirring to obtain a mixture, the stirring speed is 700rpm, the stirring time is 20min, and the mass ratio of powder, water and catalyst is: 0.3:1:0.0025;

[0100] Step S3, adding the mixed material to the autoclave 3, heating the autoclave 3 at 30°C / min, heating to 180°C, and keeping it warm for 20 minutes; then cooling to room temperature to obtain a hydrothermal carbonization product;

[0101] Step S4, performing solid...

Embodiment 2

[0104] The method for reducing the strong alkalinity of red mud in this embodiment adopts the same overall steps as in Embodiment 1, wherein different parameters are as follows:

[0105] Step S1, the biomass raw material is fallen leaves, and the fallen leaves are crushed into powders with a particle size of 1.5 mm;

[0106] Step S2, the catalyst is calcined red mud powder, the stirring speed is 300rpm, the stirring time is 120min, and the mass ratio of powder, water and catalyst is: 0.6:1:0.01;

[0107] Step S3, heat up the autoclave 3 at 50°C / min, heat up to 120°C, and keep it warm for 120min;

[0108] Step S4, the specific surface area of the hydrothermal charcoal is 60m 2 / g, the yield of hydrothermal charcoal is 85%; The mass percentage of humic acid in hydrothermal charcoal is 5%;

[0109] Step S5, the mass percentage of red mud in the mixture of hydrothermal charcoal liquid and red mud is 60%, stirring at a speed of 300rpm for 10h, wherein the pH value of red mud is...

Embodiment 3

[0111] In this example, the modified red mud of Example 1 or 2 is used as a red mud soil matrix. Specifically, straw powder and livestock manure are added to the modified red mud and stirred evenly to obtain a red mud soil matrix. Among them, the mass ratio of modified red mud, straw powder and livestock manure is: 3-7:2-5:1-2.

[0112] The red mud soil matrix is used for planting ryegrass, and the growth is good. It can be seen that the red mud soil matrix of the present application can be better suitable for plant growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com