Halogen-free flame-retardant PP-GF20 composite material and preparation method thereof

A technology of PP-GF20 and composite materials, which is applied in the field of halogen-free flame-retardant PP-GF20 composite materials and its preparation, can solve the problems of high shrinkage rate of polypropylene molding, low thermal deformation temperature, and insufficient wear resistance, etc., and achieve Uniform properties, simple preparation method, and the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention also discloses a preparation method of a halogen-free flame-retardant PP-GF20 composite material, which specifically includes the following steps:

[0047] (1) Weigh each raw material of a halogen-free flame-retardant PP-GF20 composite material described in any one of claims 1-8, and set aside;

[0048] (2) Add the wood powder, flame retardant polyether, impact modifier, black masterbatch and odor absorber, and photocatalyst in the step (1) into a high-speed mixer and stir for 3-5 minutes to obtain a uniform mixture;

[0049] (3) Add the PP-GF20, plasticizer, toughening agent and auxiliary agent weighed in the step (1) to the homogeneous mixture prepared in the step (2) in sequence and continue stirring at high speed for 10 -15min, obtain the mixed material;

[0050] (4) Extrude the mixed material obtained in step (3) in a twin-screw extruder to obtain PP-GF20 composite material particles.

[0051] In order to further realize the technical effect of the...

Embodiment 1

[0054] Oxidation treatment of wood flour:

[0055] After the wood flour is baked at 260-300°C for 10-15 minutes, it is added to a saturated solution of sodium silicate at a solid-to-liquid ratio of 1.5-2:0.8-1.5, soaked for 30-40 hours, and then dried and pulverized in a nitrogen environment. Obtain oxidized wood flour.

Embodiment 2

[0057] Preparation of flame retardant polyether:

[0058] Add inorganic fluoride, polyether, catalyst, and polytetrafluoroethylene with a mass ratio of 1-2:0.5-0.8:1.4-2.3:1.5-3 in a closed reactor. In non-oxygen conditions, the temperature is 700-800 Under the reaction conditions of ℃, pressure 70-90Mpa, and voltage 1.5-23,000 volts, mixing and stirring for 1-3 hours, the flame-retardant polyether is obtained.

PUM

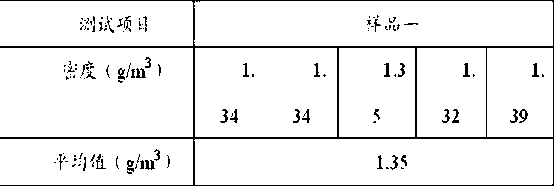

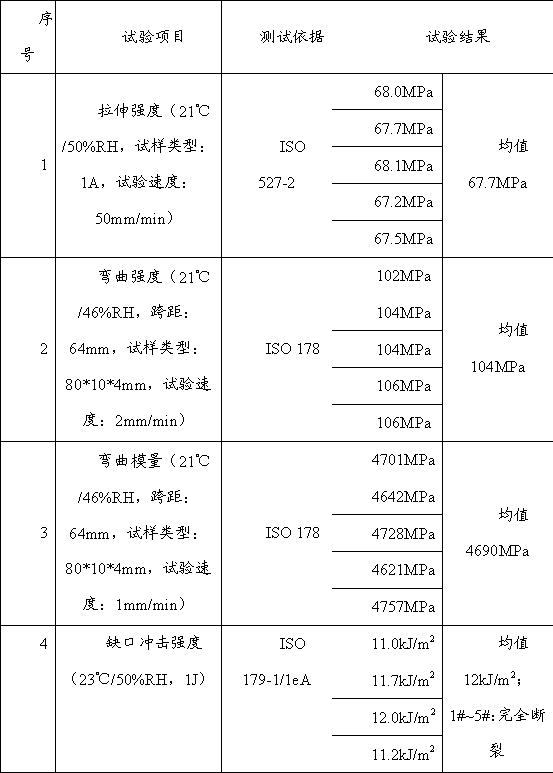

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com