Method for preparing pine tree bark extract using barrier separation integrated process engineering

A technology of pine bark extract and process technology, applied in the field of preparing pine bark extract, can solve the problems of difficult operation control, high production cost and high energy consumption, achieve the effects of protecting health care and pharmacological functions, and ensuring purity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

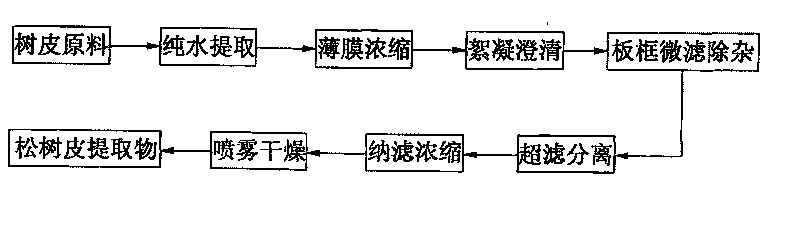

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0018] see figure 1 , a method for preparing pine bark extract using membrane separation and integration technology. The raw material is fresh and pollution-free pine bark after crushing, and the particle size is 16-40 mesh pine bark raw material; the pine bark raw material is purified by hot boiling deoxygenation The process parameters for water extraction and pure water extraction are: the ratio of the weight of the pine bark raw material to the volume of the liquid is 1:2 to 1:15, the temperature is between 60 and 100°C, and the time is 30 to 200min / time. Extract 2 to 3 times; Concentrate the filtered extract after pure water extraction, the process parameters used for film concentration are: vacuum degree is -0.08 ~ 0Mpa, temperature is 30 ~ 100°C, and the concentration of the concentrated solution is 1.01~1.50; then add flocculant and then flocculate and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com