A kind of preparation method of high-quality Antarctic krill oil

An Antarctic krill oil, high-quality technology, applied in fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of technology lag, high moisture content, loss of active function, etc., to ensure production safety, reduce Moisture content, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

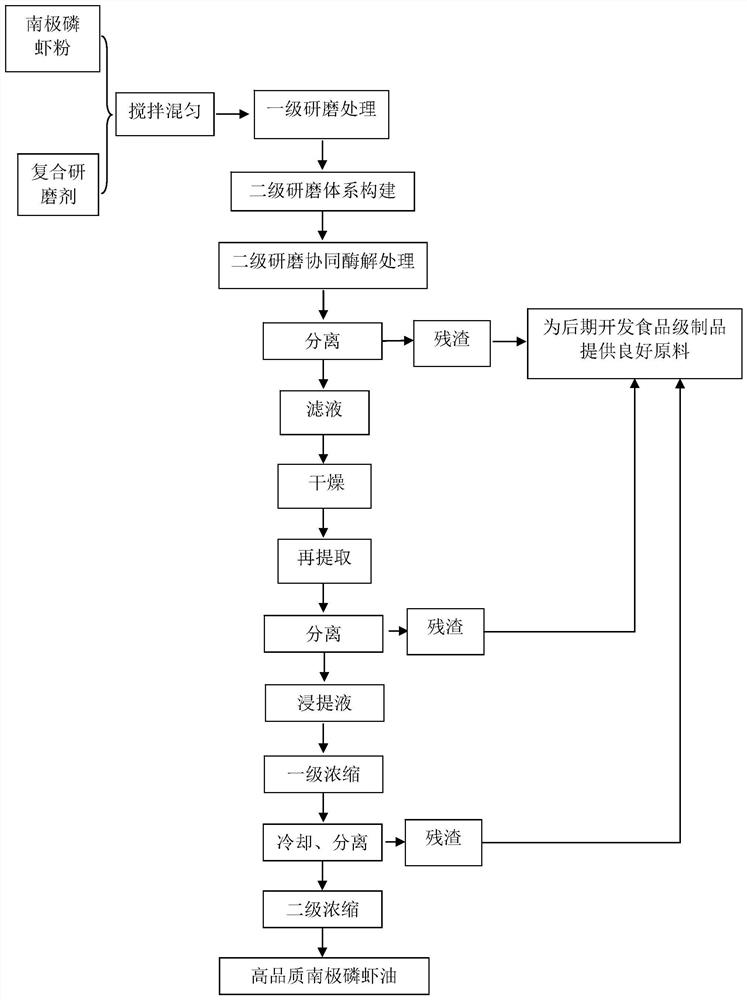

Method used

Image

Examples

Embodiment 1

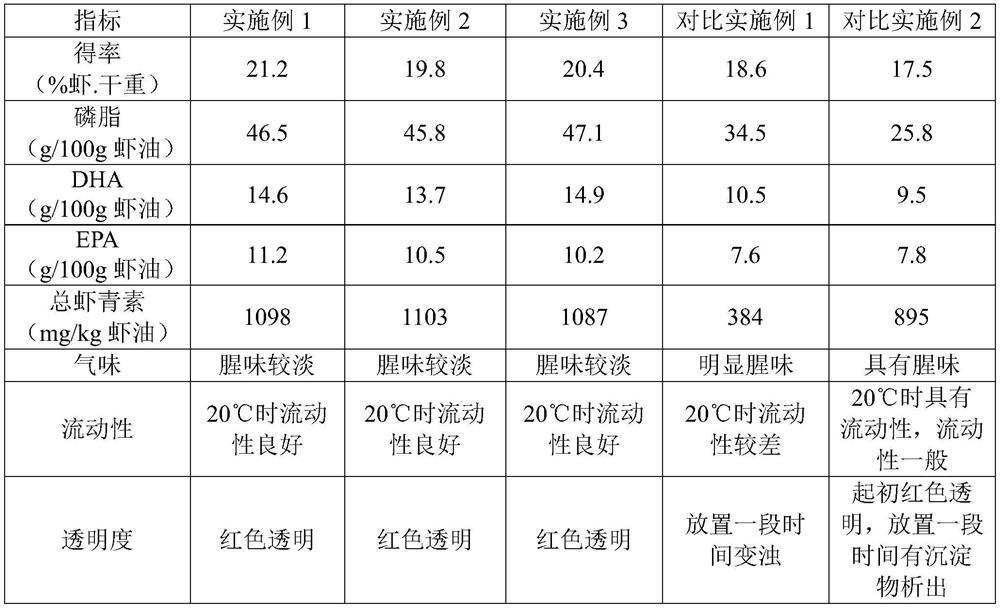

[0042]Take 100kg of Antarctic krill powder, add 100L of composite grinding agent (the mass ratio of ethanol: Tween 80: sodium ascorbate is 1:2:0.05), stir well, and then grind at 60°C to make it Homogeneous system, to obtain a primary grinding system. Add 200 L of enzyme-containing aqueous solution (containing 3000 U / g of neutral protease and 1000 U / g of Candida esterase) at a temperature of 60° C. to the primary grinding system. The pH of the system was adjusted to 7.0 with 0.1 mol / L hydrochloric acid solution and 0.1 mol / L sodium hydroxide solution, and then ground at 60° C. for 1 hour to obtain a secondary grinding system. The secondary grinding system is filtered with 60-mesh silk cloth, and after filtration, the filtrate is spray-dried to make the water content therein 8% to obtain crude extraction. Add 3 times the mass volume of extractant (20% ethyl acetate in ethanol) to the crude extract, and extract at room temperature for 1 hour to obtain an extract. Concentrate t...

Embodiment 2

[0046] Take 200g of Antarctic krill powder, add 200mL of composite grinding agent (wherein the mass ratio of glycerin: Tween 85: tea polyphenols is 1:1.5:0.02), fully stir and mix, and then grind at 50°C to make It is a homogeneous system, resulting in a primary grinding system. Add 300 mL of an enzyme-containing aqueous solution (containing 4000 U / g of papain and 800 U / g of Aspergillus esterase) at a temperature of 50° C. to the primary grinding system. The pH of the system was adjusted to 7.0 with 0.1 mol / L citric acid solution and 0.1 mol / L potassium hydroxide solution, and then ground at 45° C. for 1.5 h to obtain a secondary grinding system. Then centrifuge under the condition of 2000r / min for 15min, take the supernatant, spray dry it, make the water content therein be 10%, and obtain the rough extraction. Add 5 times the mass volume of extractant (10% ethyl acetate ethanol solution, which contains 0.001% gallate by mass volume fraction) to the crude extract, and extract...

Embodiment 3

[0050] Take 250g of Antarctic krill powder, add 500mL of compound grinding agent (the mass ratio of ethanol: sucrose stearate: coenzyme Q10: 1:2:0.01), stir well, and then grind at 55°C , so that it is a homogeneous system, and a primary grinding system is obtained. Add 1500 mL of an enzyme-containing aqueous solution (containing 3500 U / g of bromelain and 1200 U / g of Pseudomonas esterase) at a temperature of 45° C. to the primary grinding system. The pH of the system was adjusted to 6.5 with 0.1 mol / L acetic acid solution and 0.1 mol / L sodium hydroxide solution, and then ground at 40°C for 2 hours to obtain a secondary grinding system. Then filter with 70-mesh silk cloth, spray dry the filtrate to make the water content therein 70%, and obtain rough extraction. Add 4 times the mass volume of extractant (5% ethyl acetate ethanol solution, which contains carnosic acid with a mass volume fraction of 0.002%) to the crude extract, and extract at room temperature for 0.5 h to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com