Patents

Literature

174 results about "Krill oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Krill oil is an extract prepared from a species of Antarctic krill, Euphausia superba. Two of the most important components in krill oil are omega-3 fatty acids similar to those in fish oil, and phospholipid-derived fatty acids (PLFA), mainly phosphatidylcholine (alternatively referred to as marine lecithin).

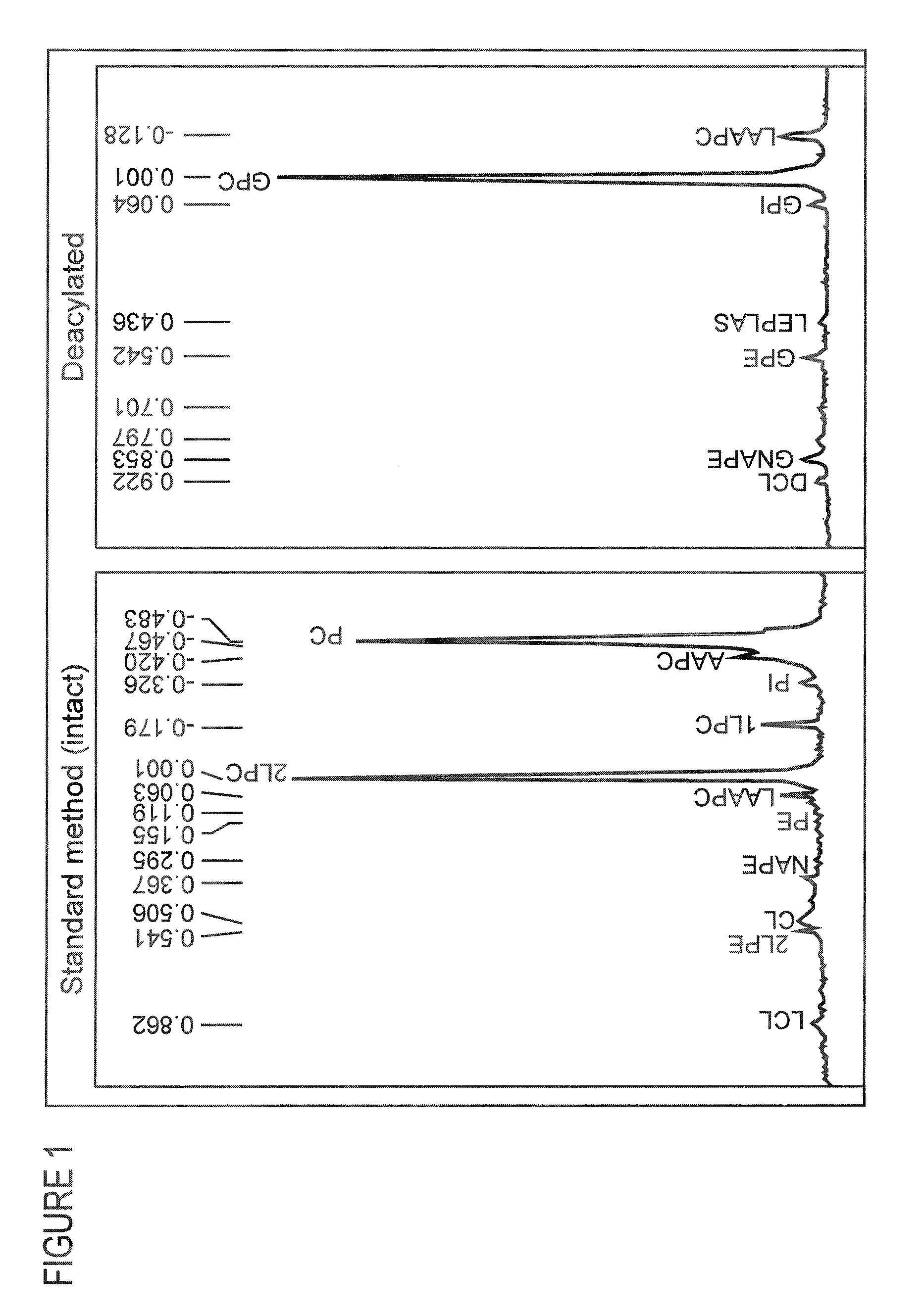

Bioeffective krill oil compositions

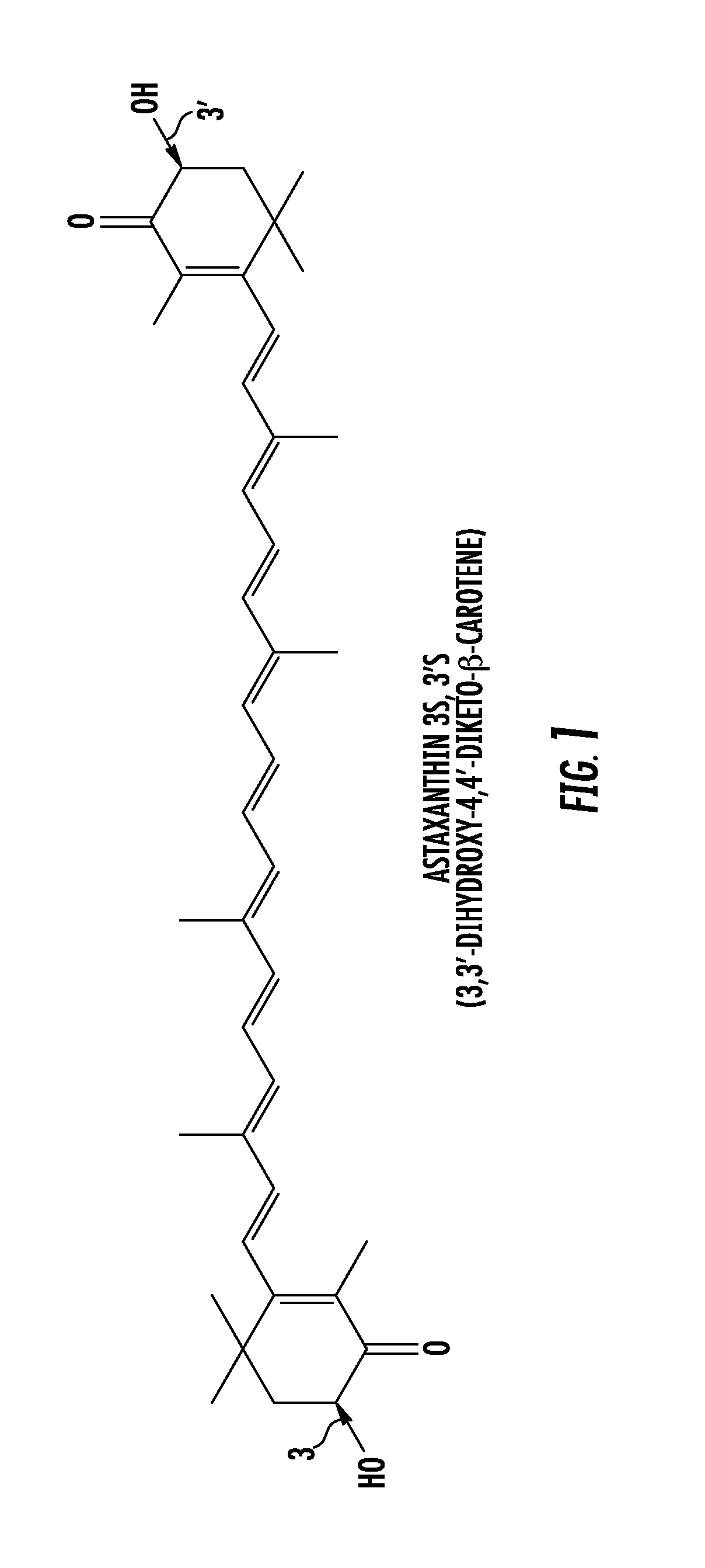

InactiveUS20080274203A1Increasing flesh colorationPromote growthBiocideMetabolism disorderInsulin resistanceAnti oxidant

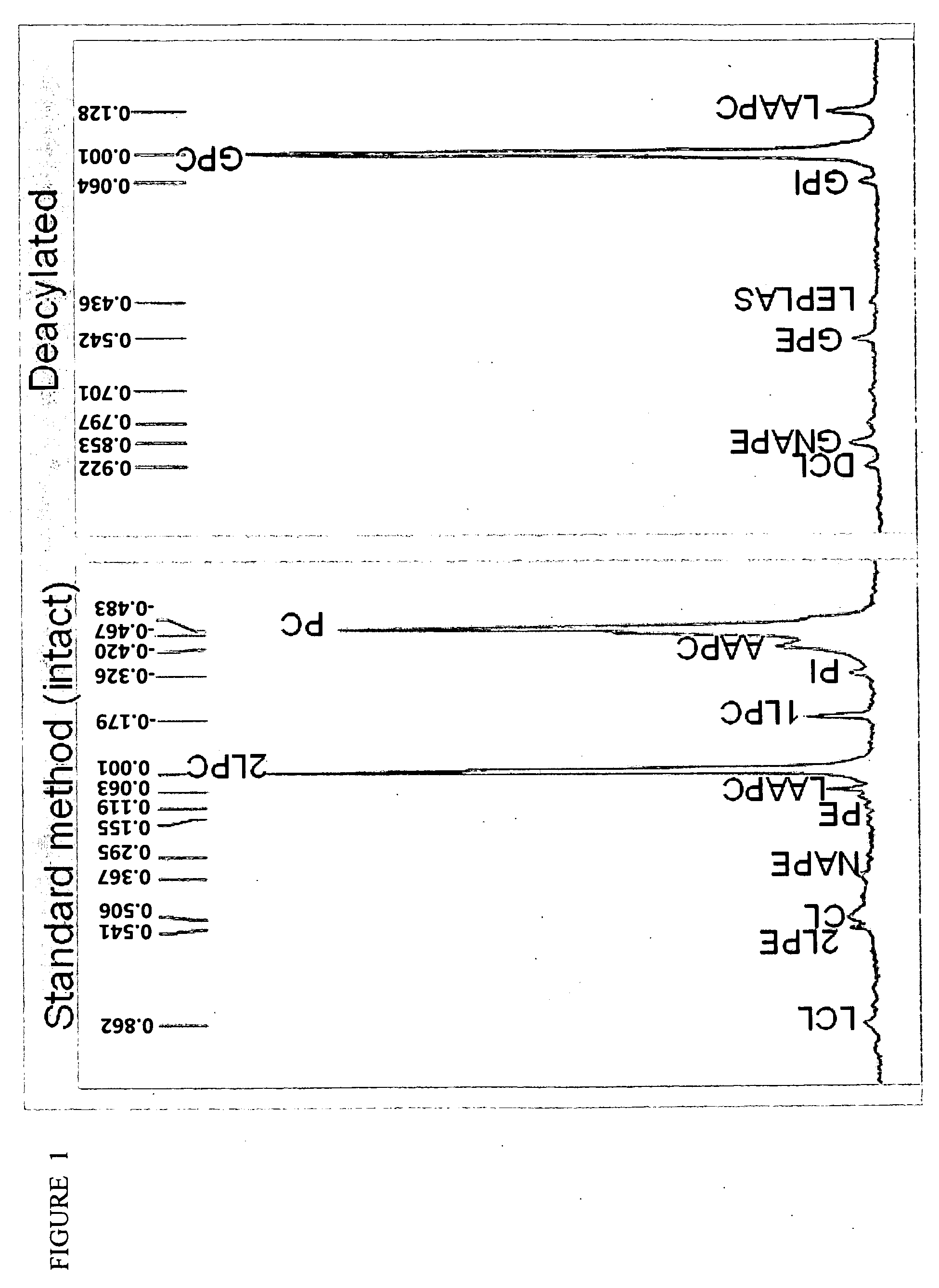

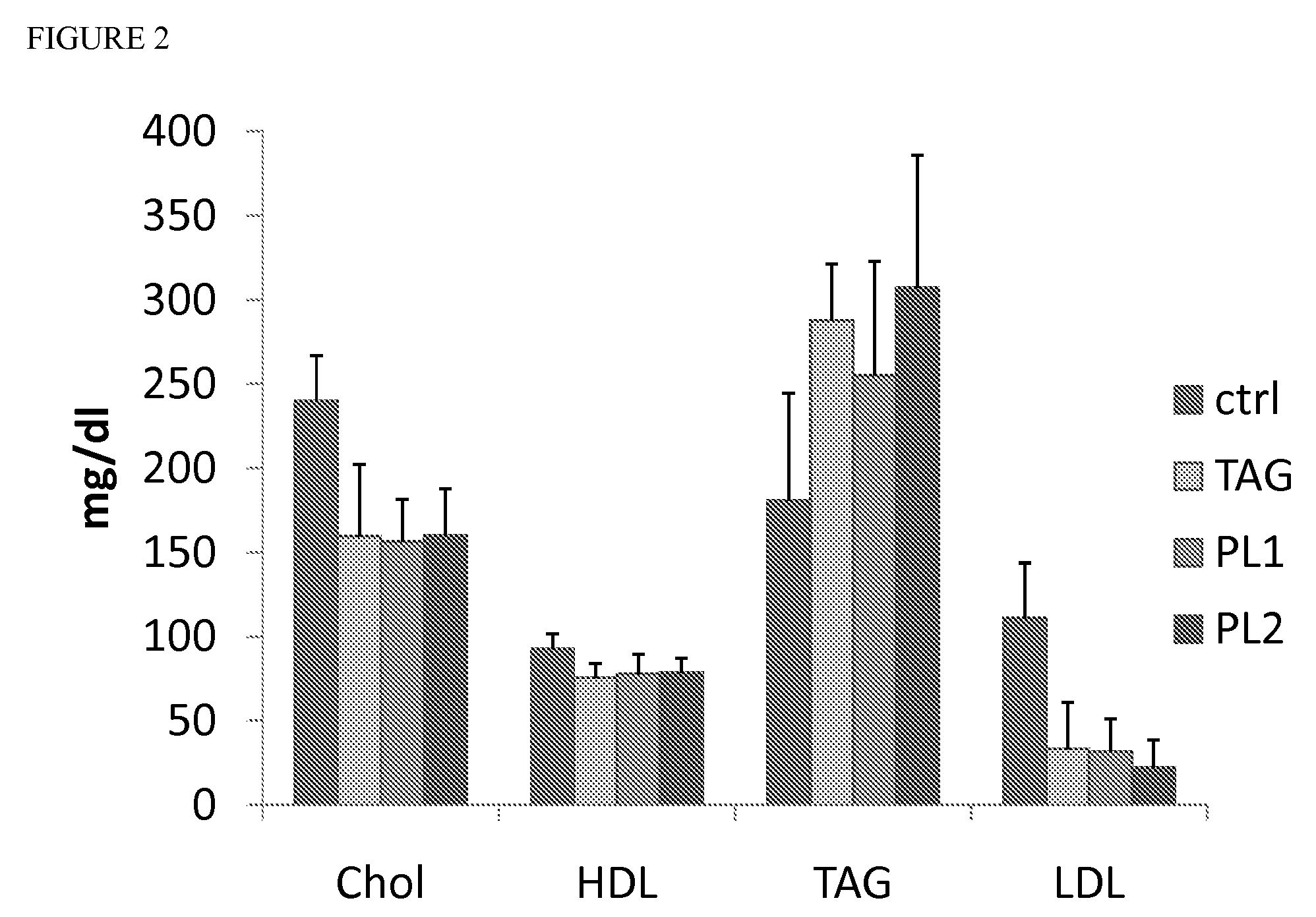

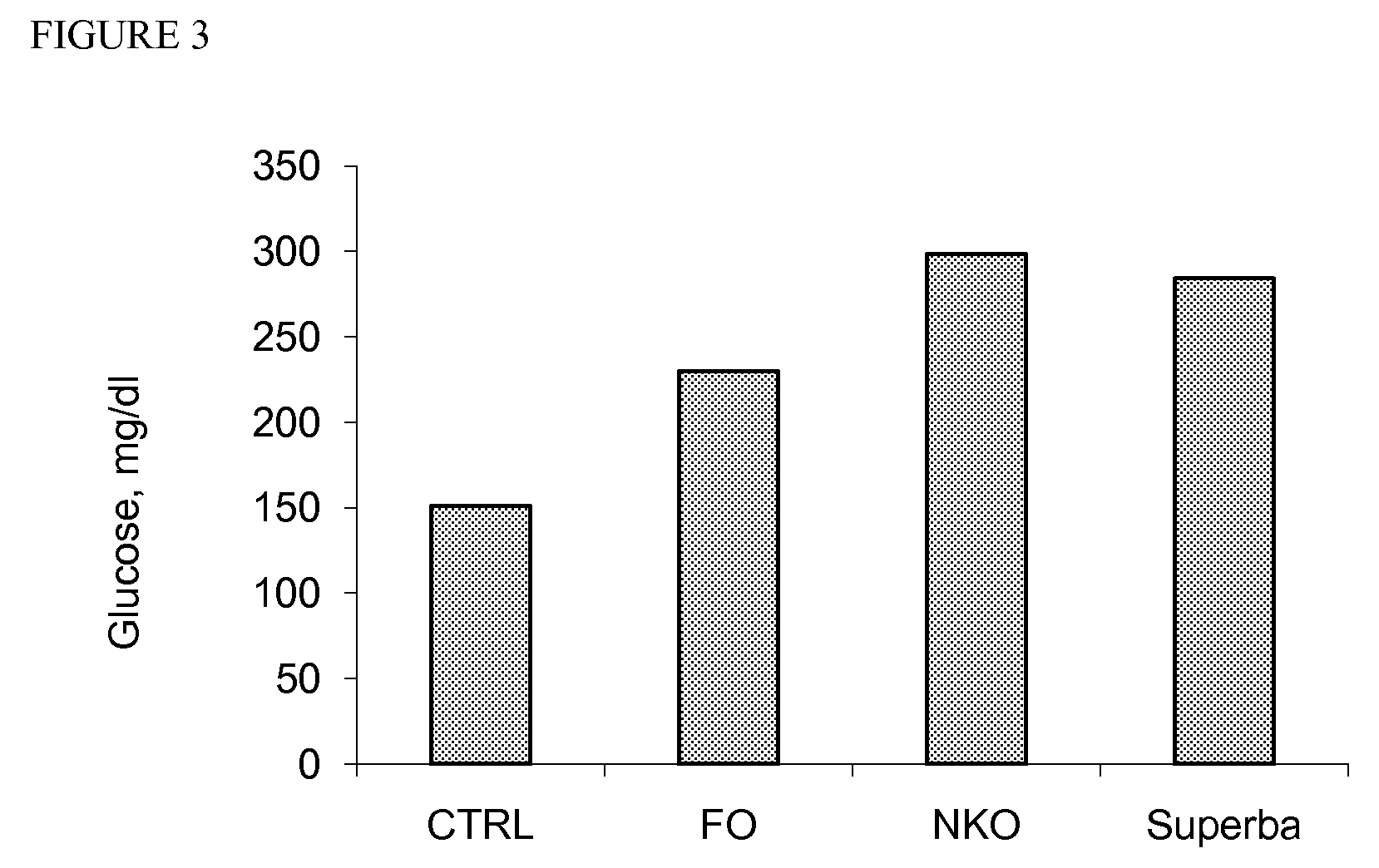

This invention discloses new krill oil compositions characterized by having high amounts of phospholipids, astaxanthin esters and / or omega-3 contents. The krill oils are obtained from krill meal using supercritical fluid extraction in a two stage process. Stage 1 removes the neutral lipid by extracting with neat supercritical CO2 or CO2 plus approximately 5% of a co-solvent. Stage 2 extracts the actual krill oils by using supercritical CO2 in combination with approximately 20% ethanol. The krill oil materials obtained are compared with commercially available krill oil and found to be more bioeffective in a number of areas such as anti-inflammation, anti-oxidant effects, improving insulin resistances and improving blood lipid profile.

Owner:AKER BIOMARINE ANTARCTIC

Method for extracting krill oil with high phosphatide content from Antarctic krills

InactiveCN102041166AImprove enrichment effectImprove extraction efficiencyFatty-oils/fats productionOrganic solventPrawn

The invention discloses a method for extracting krill oil with high phosphatide content from Antarctic krills. The method comprises the following steps: (1) drying fresh Antarctic krills to obtain dry Antarctic krills; (2) performing extraction to dry Antarctic krills for 3 times with organic solvent; (3) mixing the extracting solutions, evaporating the mixed extracting solution to obtain Antarctic krill oil with the phosphatide content of 30-35%; then introducing nitrogen or carbon dioxide to remove the residual organic solvent; and adding polar organic solvent in the Antarctic krill oil, mixing evenly, standing to ensure that the mixed solution performs natural layering; and evaporating the lower solution to obtain the Antarctic krill oil with high phosphatide content, and then introducing nitrogen or carbon dioxide to remove the residual polar organic solvent so as to obtain a product. The extraction technology is performed at a low temperature, thus the red color of krill oil can be maintained and the beneficial ingredients in the product can not be damaged. The invention has high extraction efficiency and good phosphatide accumulation effect. Therefore, the Antarctic krill oil with high phosphatide content can be obtained and other byproducts can also be obtained.

Owner:SHANDONG NORMAL UNIV +1

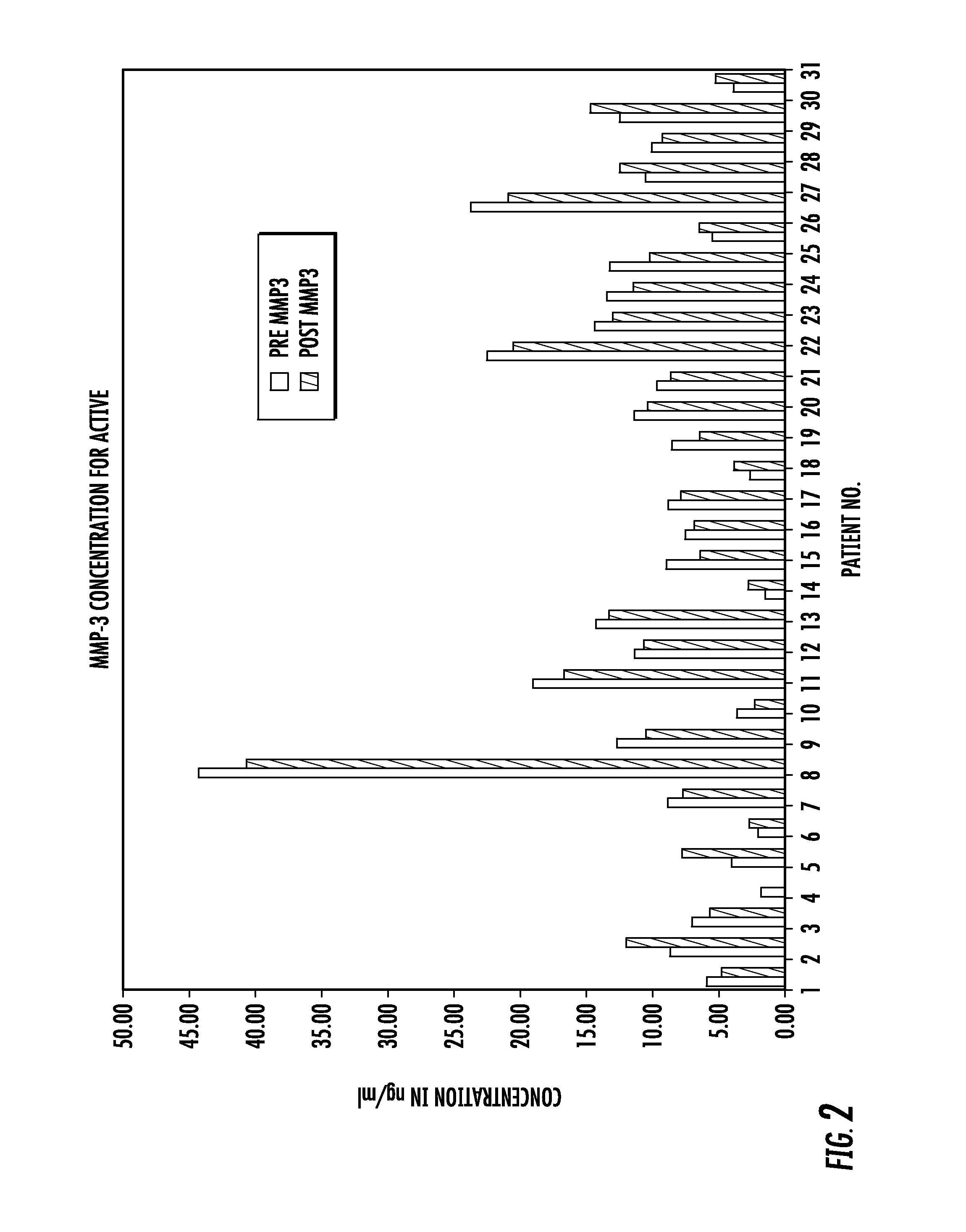

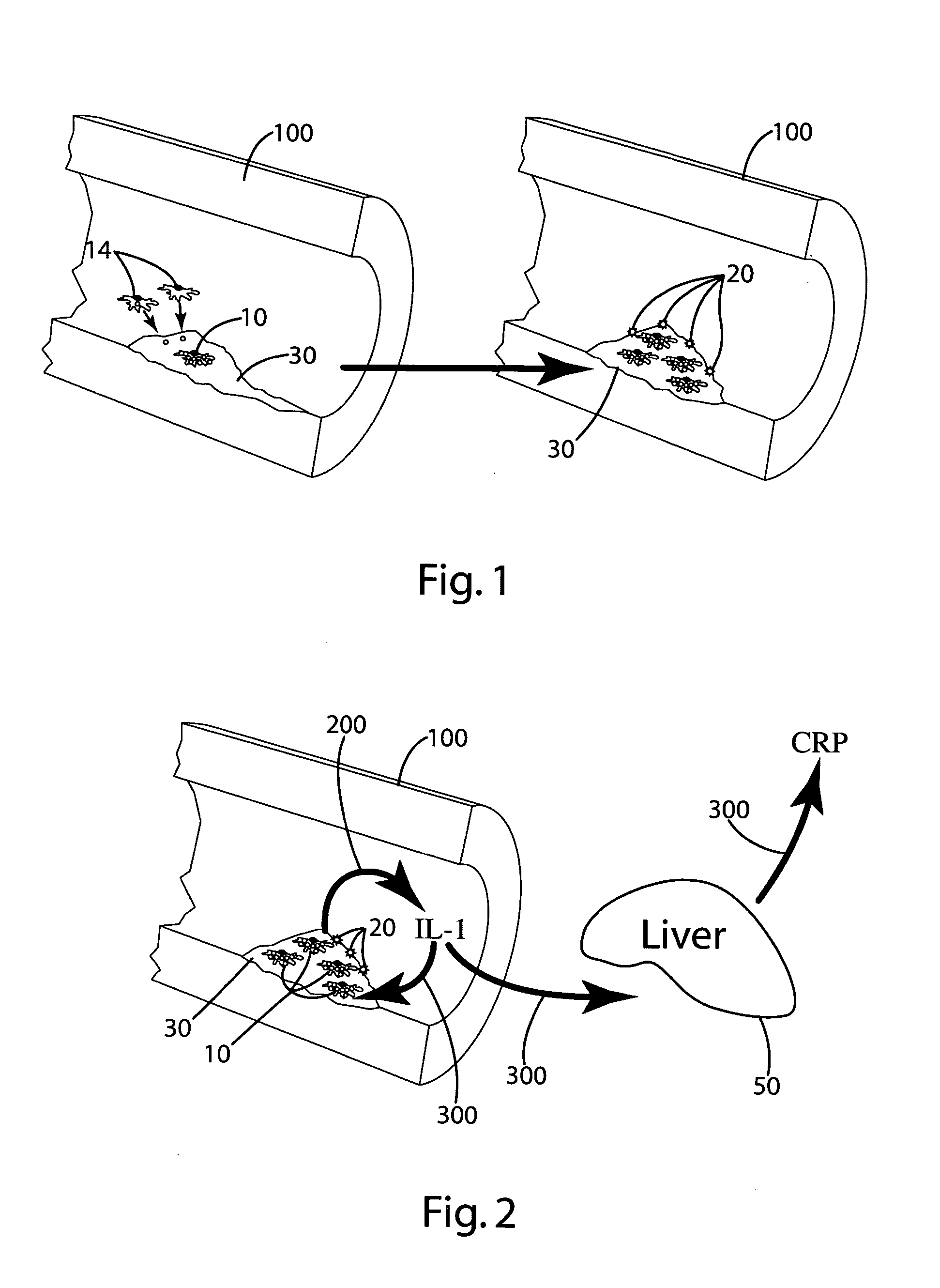

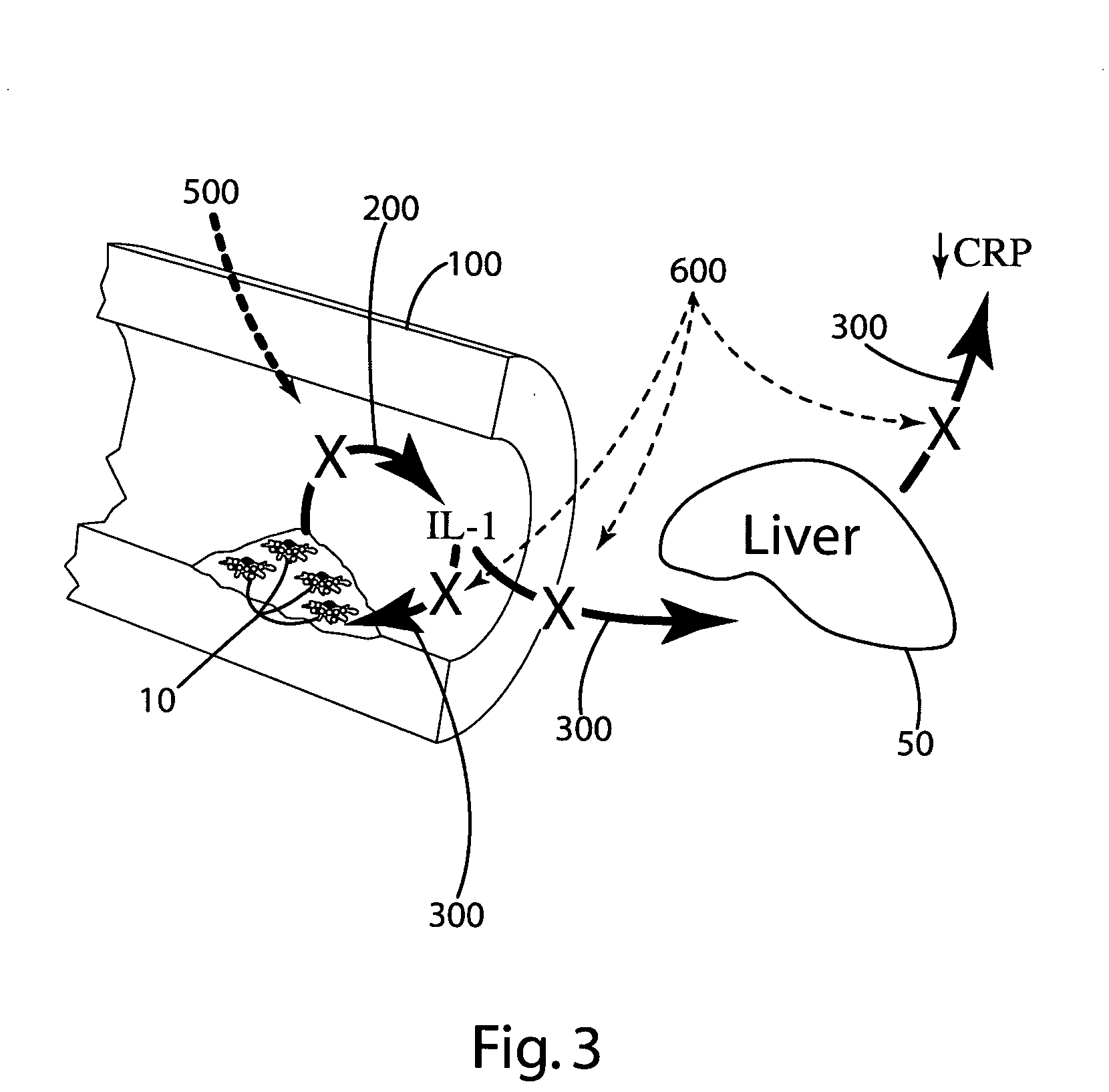

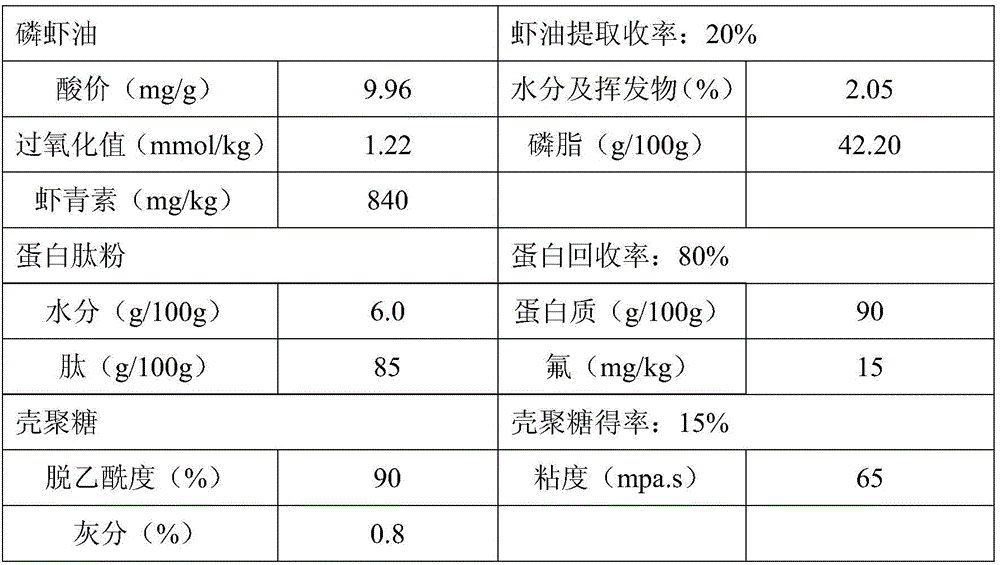

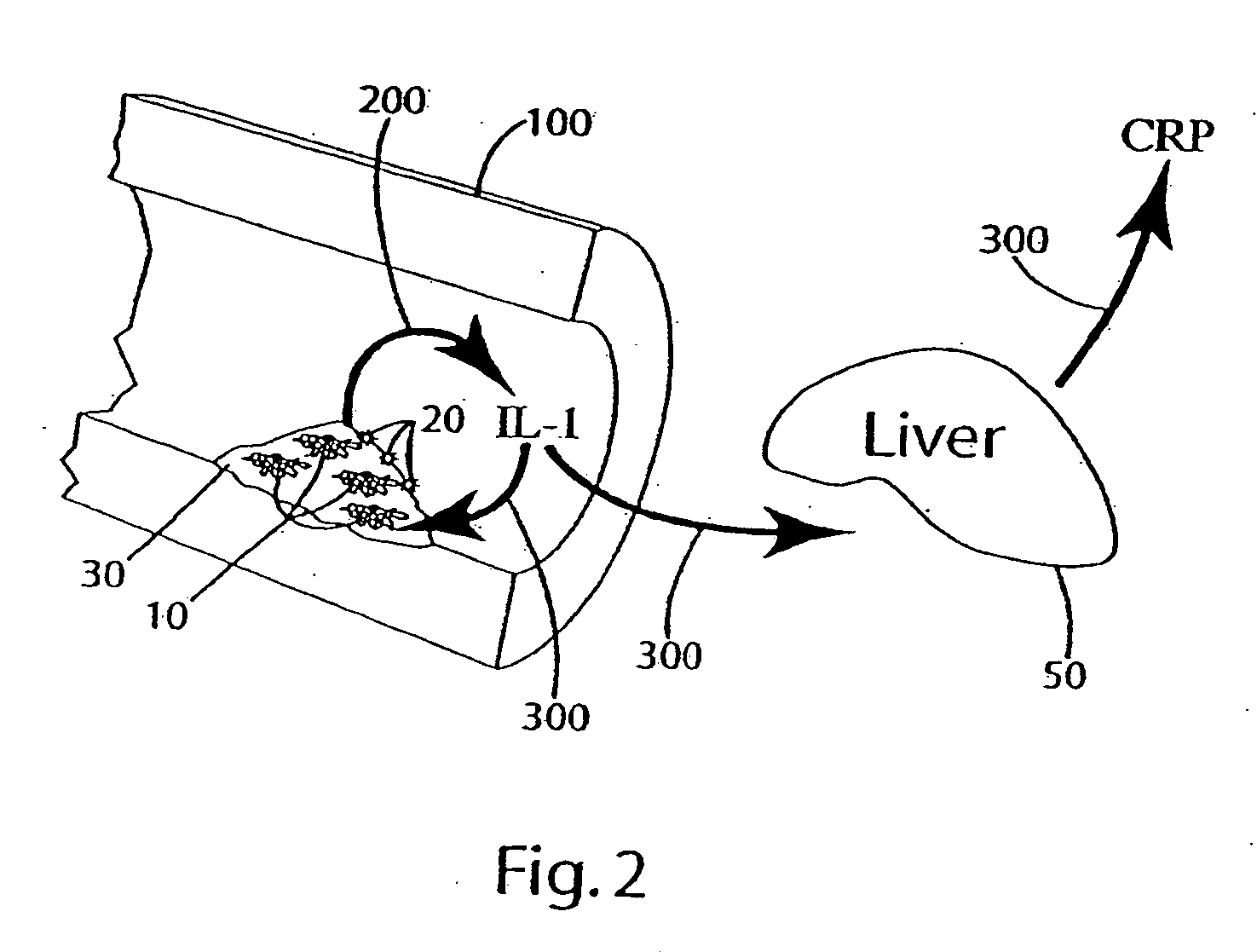

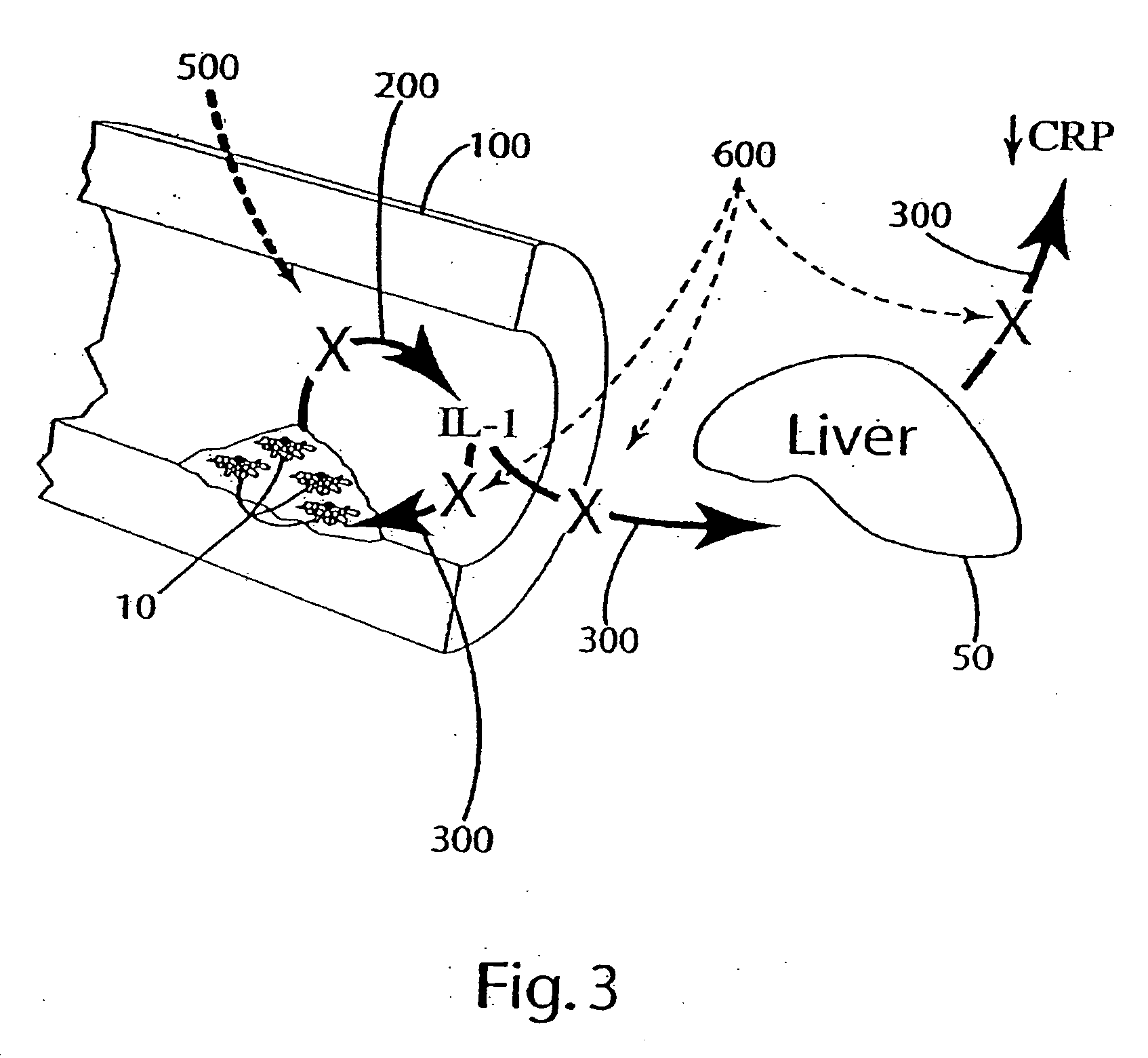

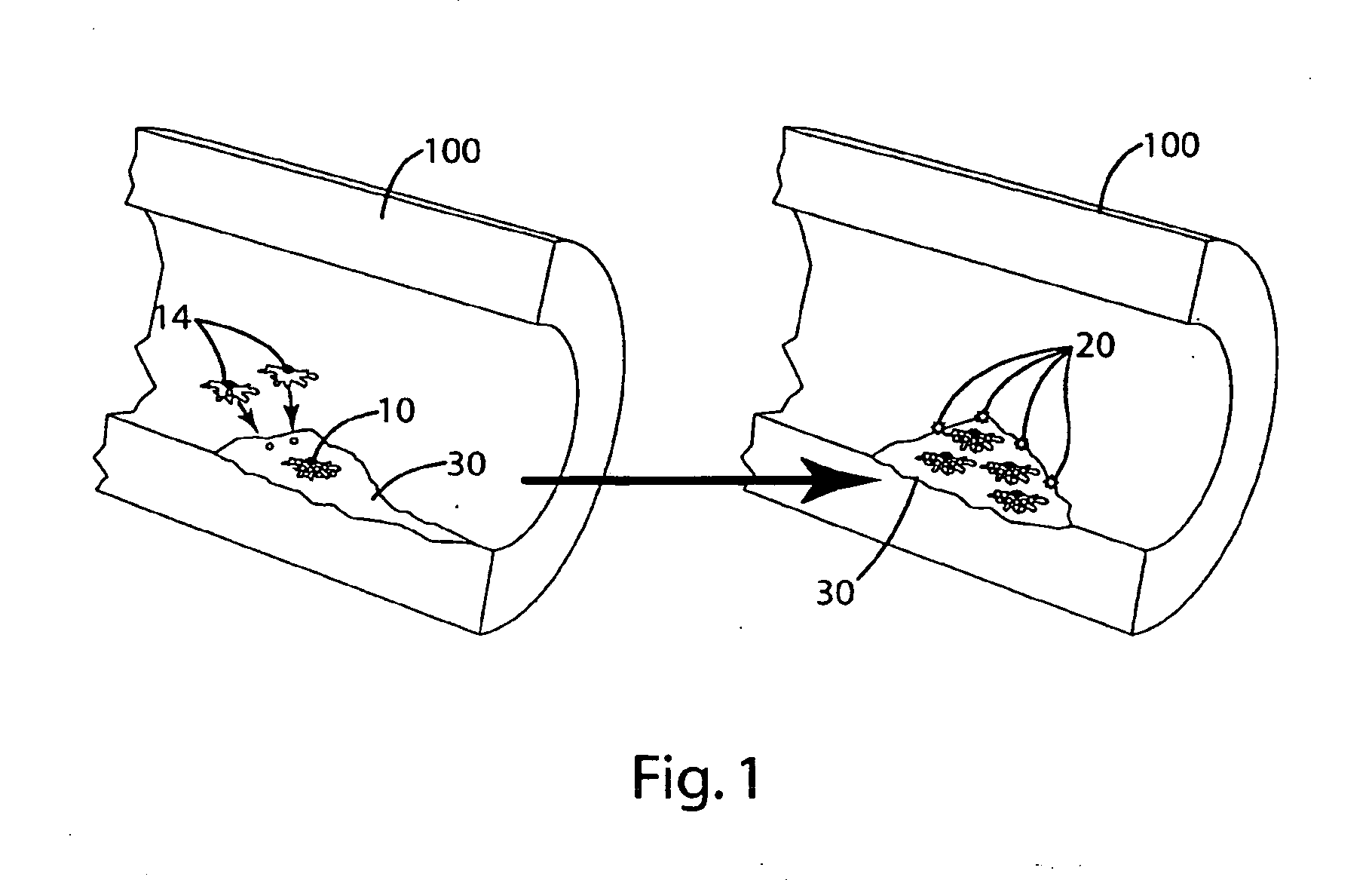

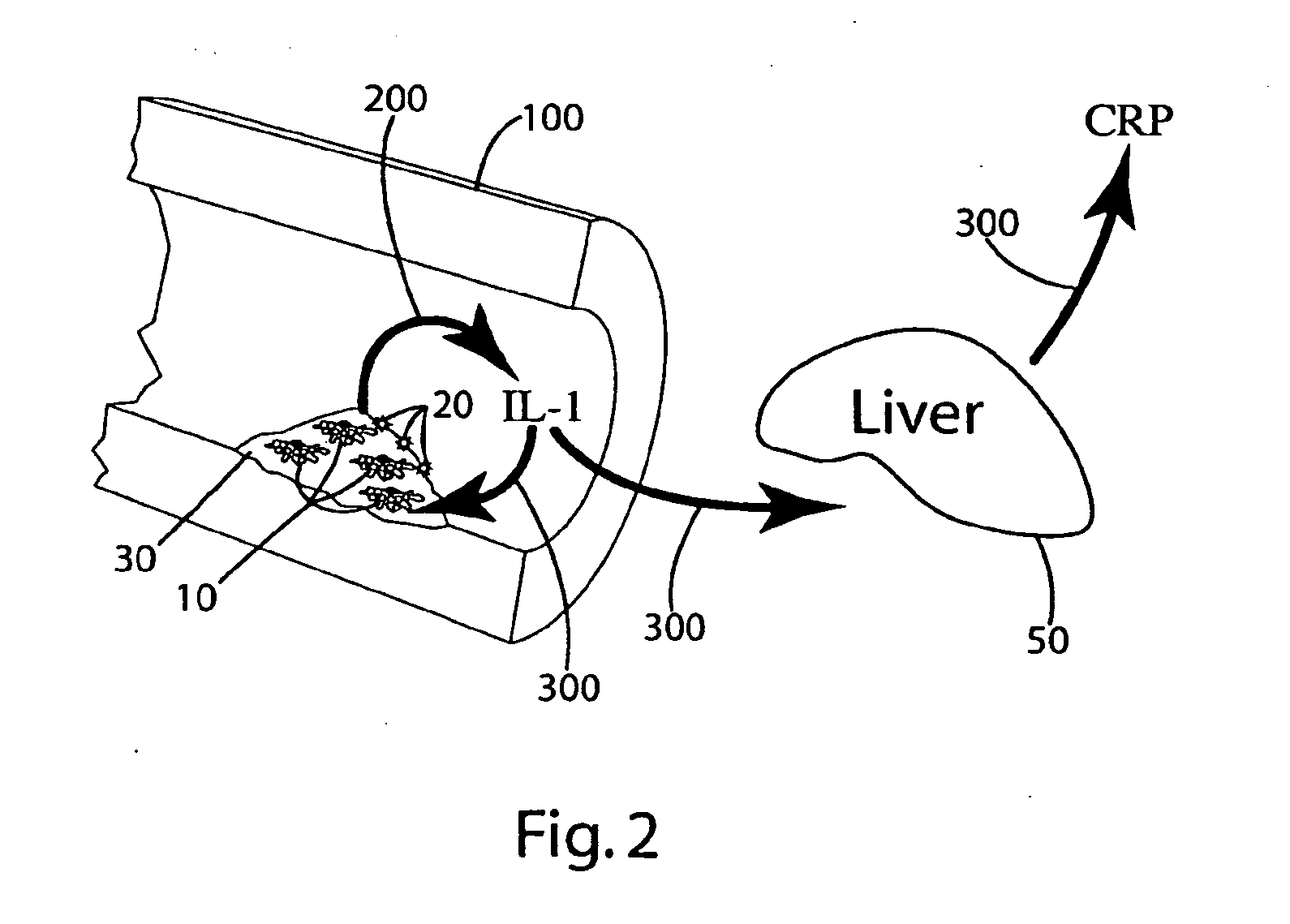

Anti-inflammatory compositions for treating multiple sclerosis

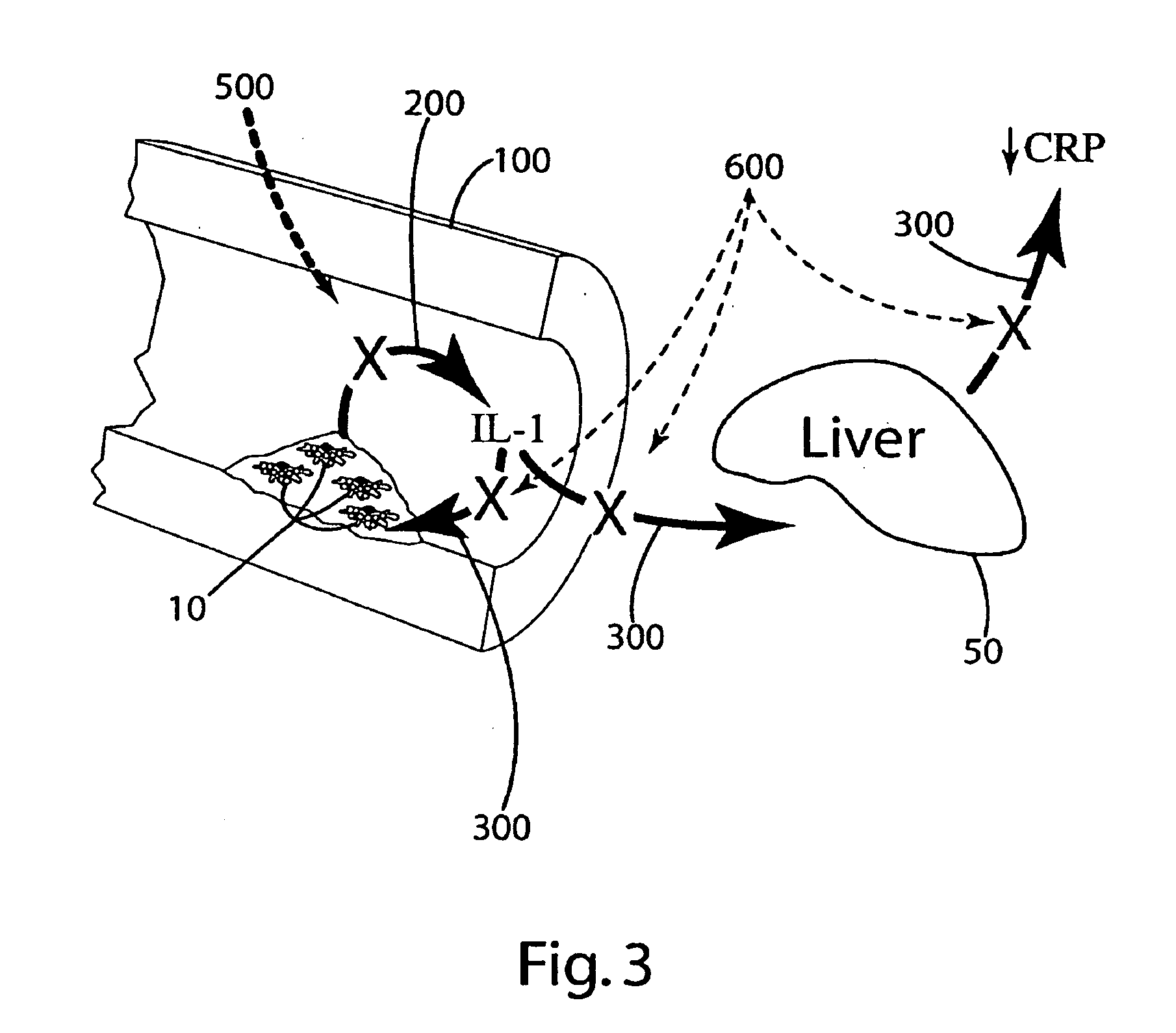

Compositions with synergistic anti-inflammatory effects in inflammatory diseases resulting from activation and consequent degranulation of mast cells and followed by secretion of inflammatory biochemicals from the activated mast cells, the compositions containg one or more of a flavone or flavonoid glycoside a heavily sulfated, non-bovine proteoglycan, an unrefined olive kernel extract that increases absorption of these compositions in various routes of administration, a hexosamine sulfate such as D-glucosamine sulfate, S-adenosylmethionine, a histamine-1 receptor antagonist, a histamine-3 receptor agonist, an antagonist of the actions of CRH, a long-chain unsaturated fatty acid, a phospholipid, Krill oil, a polyamine, glutiramer acetate and interferon. Certain of the present compositions are useful in protecting against the neuropathological components of multiple sclerosis and similar inflammatory neurological diseases.

Owner:THETA BIOMEDICAL CONSULTING & DEVMENT

Composition and method to alleviate joint pain

Beneficial and synergistic effects for alleviating joint pain and symptoms of osteoarthritis and / or rheumatoid arthritis have been found with krill oil and / or marine oil in combination with other active constituents, including astaxanthin and polymeric hyaluronic acid or sodium hyaluronate (hyaluronan) in an oral dosage form.

Owner:US NUTRACEUTICALS LLC

Method for extracting phospholipid-enriched krill oil from Antarctic krill

InactiveCN102071101ARich sourcesSafe storageFatty-oils/fats productionDocosahexaenoic acidPhospholipid

The invention discloses a method for extracting phospholipid-enriched krill oil from Antarctic krill. The method comprises the following steps: using Antarctic krill as the raw material and using the autologous protease to decompose the Antarctic krill and release lipids, quickly heating to inactivate the enzymes in the krill, drying at low temperature, and extracting krill oil with rich eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) phospholipids at low temperature by using low carbon alcohol as the solvent. The method disclosed by the invention is simple to operate, has the advantages of clear process and high input-output ratio; and compared with other organic solvents, ethanol or isopropanol is safer for storage, transportation and use, has abundant sources, and has obvious advantages of being used as the solvent for extracting oil of krill type crustacean.

Owner:SHANDONG KERUIER BIOLOGICAL PRODS

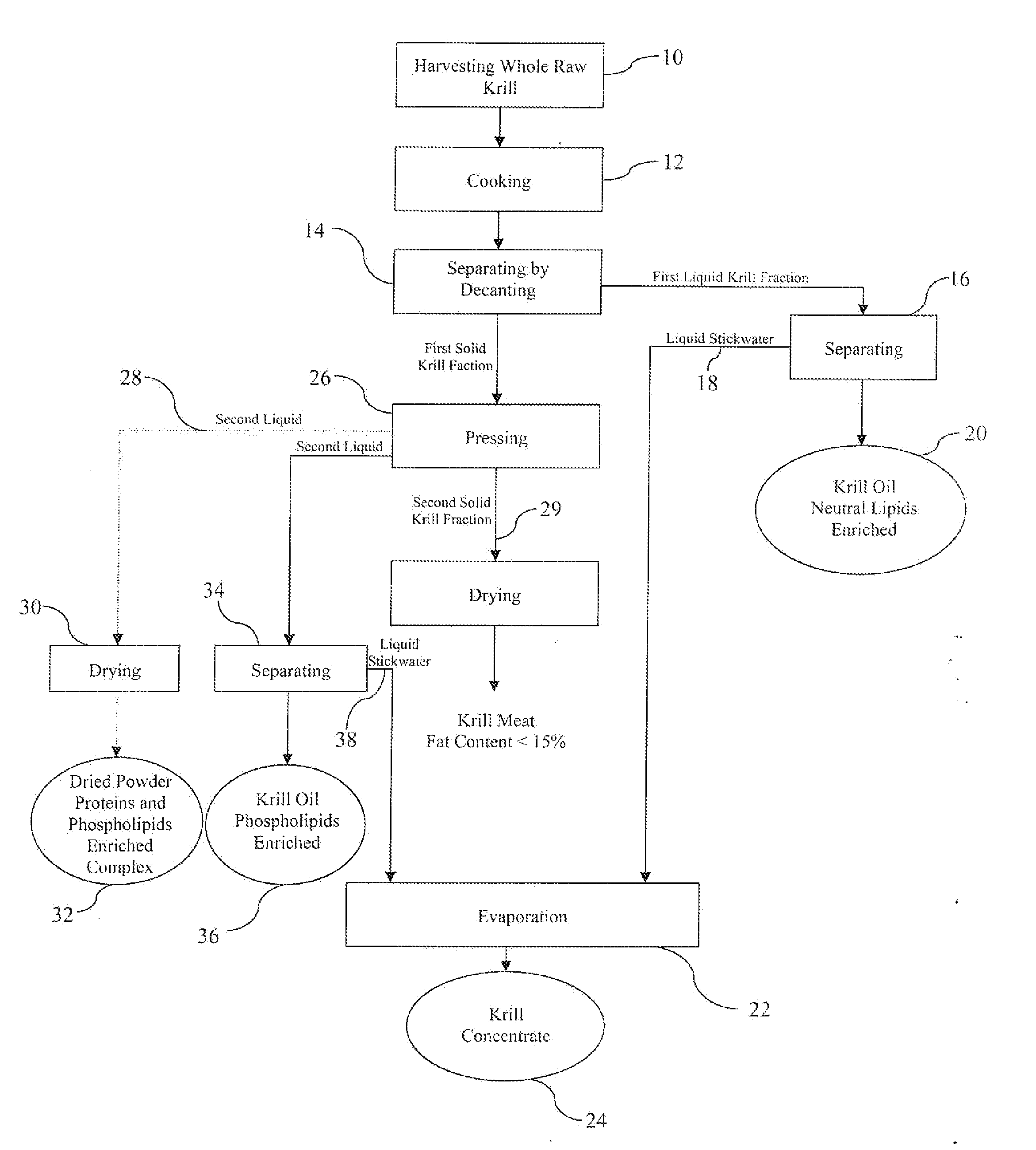

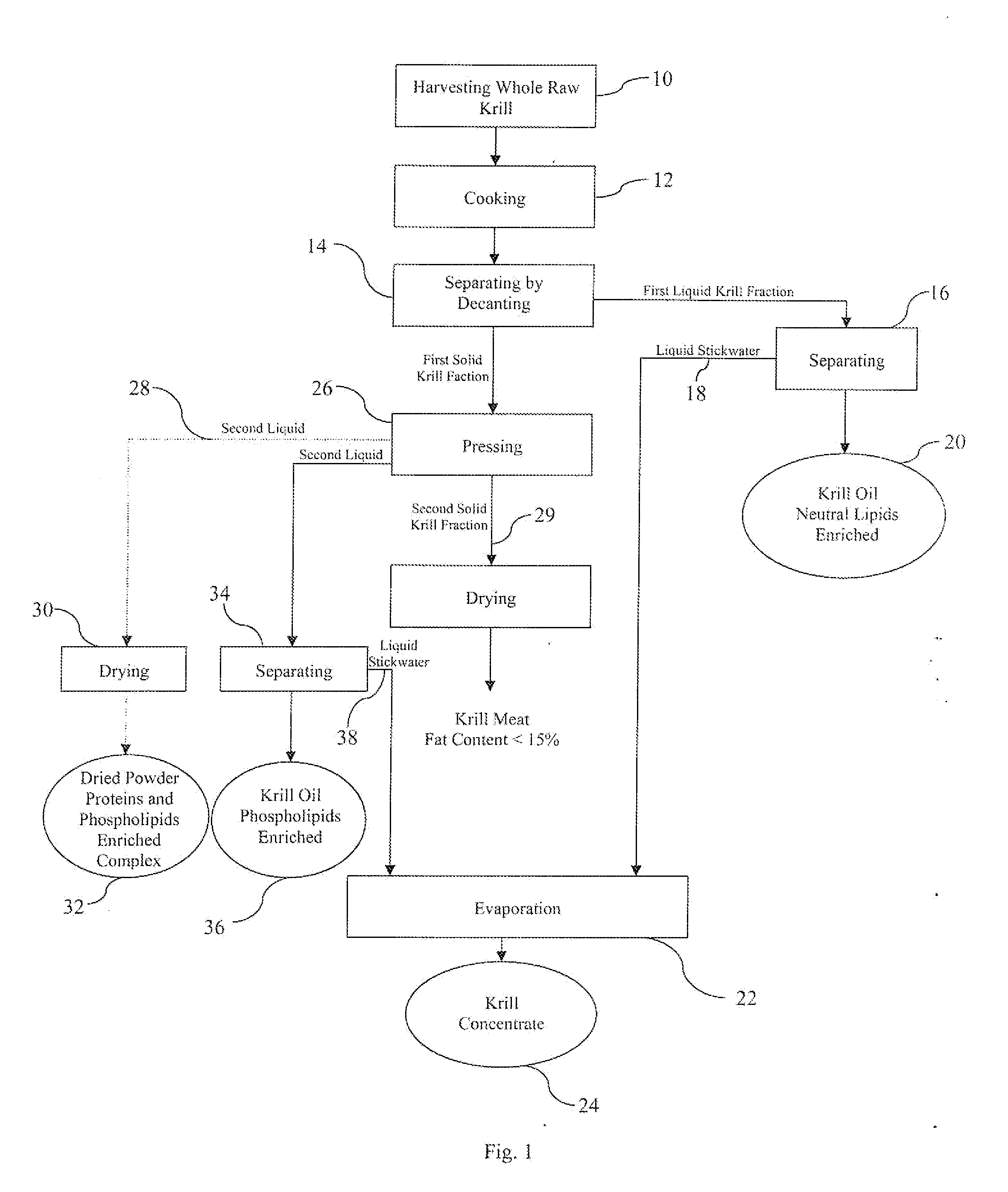

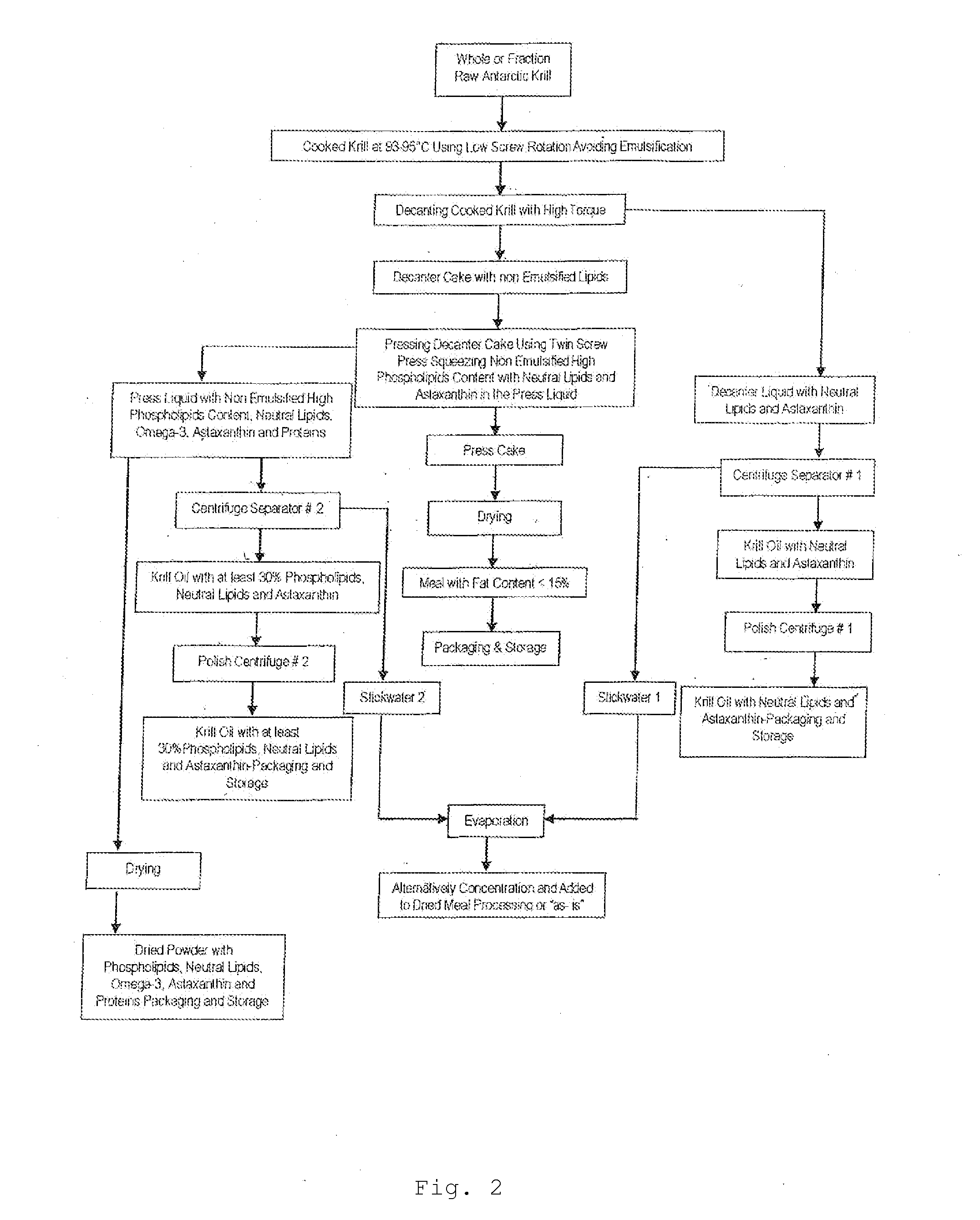

Solvent-free process for obtaining phospholipids and neutral enriched krill oils

ActiveUS20110224450A1Prevent freezingCost for structure can be reducedFatty oils/acids recovery from wasteCosmetic preparationsOrganic solventSolvent free

Organic solvent-free processes for obtaining krill oil compositions are disclosed. The processes include a) cooking krill in a cooker vessel for a time and at a temperature sufficient to denature the protein content of the krill and cause a first solid krill fraction and a first liquid krill fraction to be formed while substantially avoiding emulsification of the first solid and first liquid hill fractions; b) removing the first solid and first liquid krill fractions from the cooker vessel at a temperature of at least about 90° C.; c) separating the first solid fraction and the first liquid fraction; and d) obtaining krill oil with neutral enriched from the first liquid fraction, and e) by pressing of first solid fraction to obtain press liquid or a second liquid krill fraction for obtaining hill oil with phospholipids enriched krill oil, the separating and the obtaining steps being carried out without the use of organic solvents. Krill oil compositions made by the process are also disclosed.

Owner:THAROS +1

Krill Oil Compositions

InactiveUS20080166420A1Low densityHigh densityCrustacean material medical ingredientsEster active ingredientsSignificant riskNiacin

The present disclosure provides for novel krill oil-based compositions, method of administration and method of manufacture which provide for the treatment and prevention of cardiovascular disease, including the reduction of one or more significant risk factors involved with cardiovascular disease. The active ingredients of the composition include krill oil, combined in one embodiment with niacin, and combined in an alternate embodiment with polymethoxylated flavones (PMFs), and combined in yet another embodiment with Cissus quadrangularis, and combined in a further embodiment with Gynostemma pentaphyllum.

Owner:SONES SCOTT F

Krill oil microcapsule powder and preparation method thereof

The invention discloses a krill oil microcapsule powder and a preparation method thereof. The method comprises the following steps of: preparing an oil phase solution and an aqueous phase solution, mixing, emulsifying, homogenizing and drying the two solutions. The krill oil microcapsule powder is prepared from the following raw materials in percentage by weight: 0.001-90 percent of krill oil, 0.001-10 percent of oil-phase antioxidant, 0.5-90 percent of wall material, 0.001-5 percent of aqueous phase antioxidant, 0.001-5 percent of aqueous phase stabilizer, 0.001-5 percent of antitackiness agent, 0-5 percent of edible essence and 0.01-99 percent of filling agent. The krill oil coated by the krill oil microcapsule powder is high in content, high in stability and high in liquidity; in addition, the krill oil can be completely dispersed in water in an nm microparticle form after rehydration and is stably preserved for a long time, and the phenomena of floating oil, precipitation and bottle adhesion are avoided. The application range of the krill oil is widened, and the krill oil can be applied to the fields of dry-blending, beverages, dairy products, baking, tablets and the like. No waste residue, waste gas and waste water are generated in the production process, the production process is environmentally-friendly and simple, and the industrialization is easy and feasible.

Owner:辽渔集团有限公司

Resveratrol-containing compositions for general health and vitality

InactiveUS20080254135A1High ORAC valueImprove general healthBiocideMetabolism disorderAdditive ingredientMammal

The present invention is directed towards an orally administered composition comprising multiple plant extracts, which are characterized as having high ORAC values, and promote an increase in a mammal's dietary intake of antioxidant and polyphenols to a therapeutically effective amount. The ingredients of the present compositions represent a broad spectrum of polyphenols providing antioxidant activity for the purpose of improving general health and vitality by enhancing cardioprotection and immune system functions. The composition of the present invention comprises an extract of Polygonum cuspidatum and an extract of grape skin. In additional aspects of the present invention, one or more of Red wine extract, piceantannol, krill oil, pomegranate, mangosteen, apple, goji (wolfberry), and acai berry, cranberry, mulberry, bilberry, noni, and blueberry are added to the composition to further broaden the polyphenol spectrum. Both a composition and method are provided by the present invention.

Owner:IOMEDIX DEV INT

Krill oil compositions

InactiveUS20080166419A1Low densityHigh densityEster active ingredientsCrustacean material medical ingredientsSignificant riskNiacin

The present disclosure provides for novel krill oil-based compositions, method of administration and method of manufacture which provide for the treatment and prevention of cardiovascular disease, including the reduction of one or more significant risk factors involved with cardiovascular disease. The active ingredients of the composition include krill oil, combined in one embodiment with niacin, and combined in an alternate embodiment with polymethoxylated flavones (PMFs), and combined in yet another embodiment with Cissus quadrangularis.

Owner:SONES SCOTT F

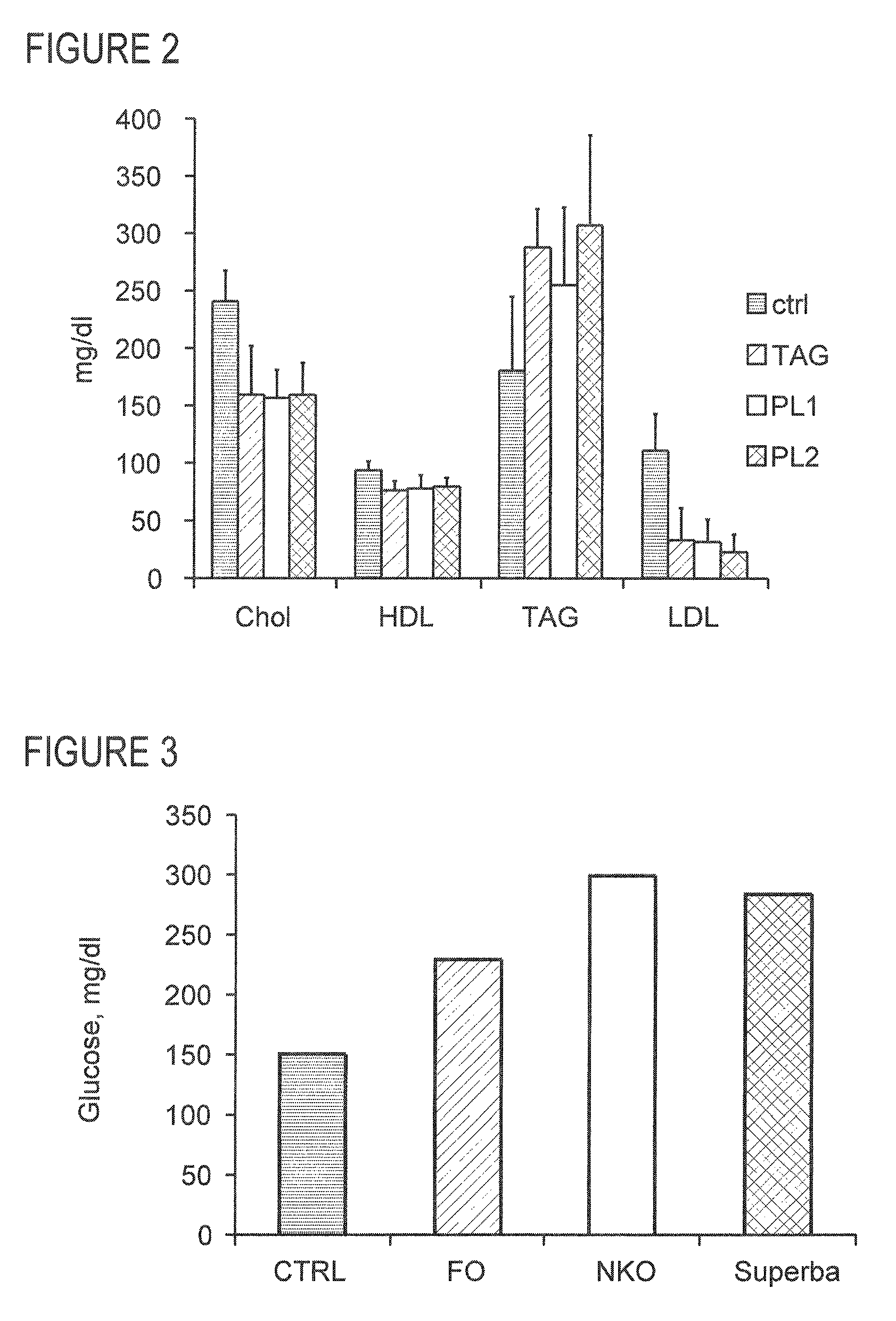

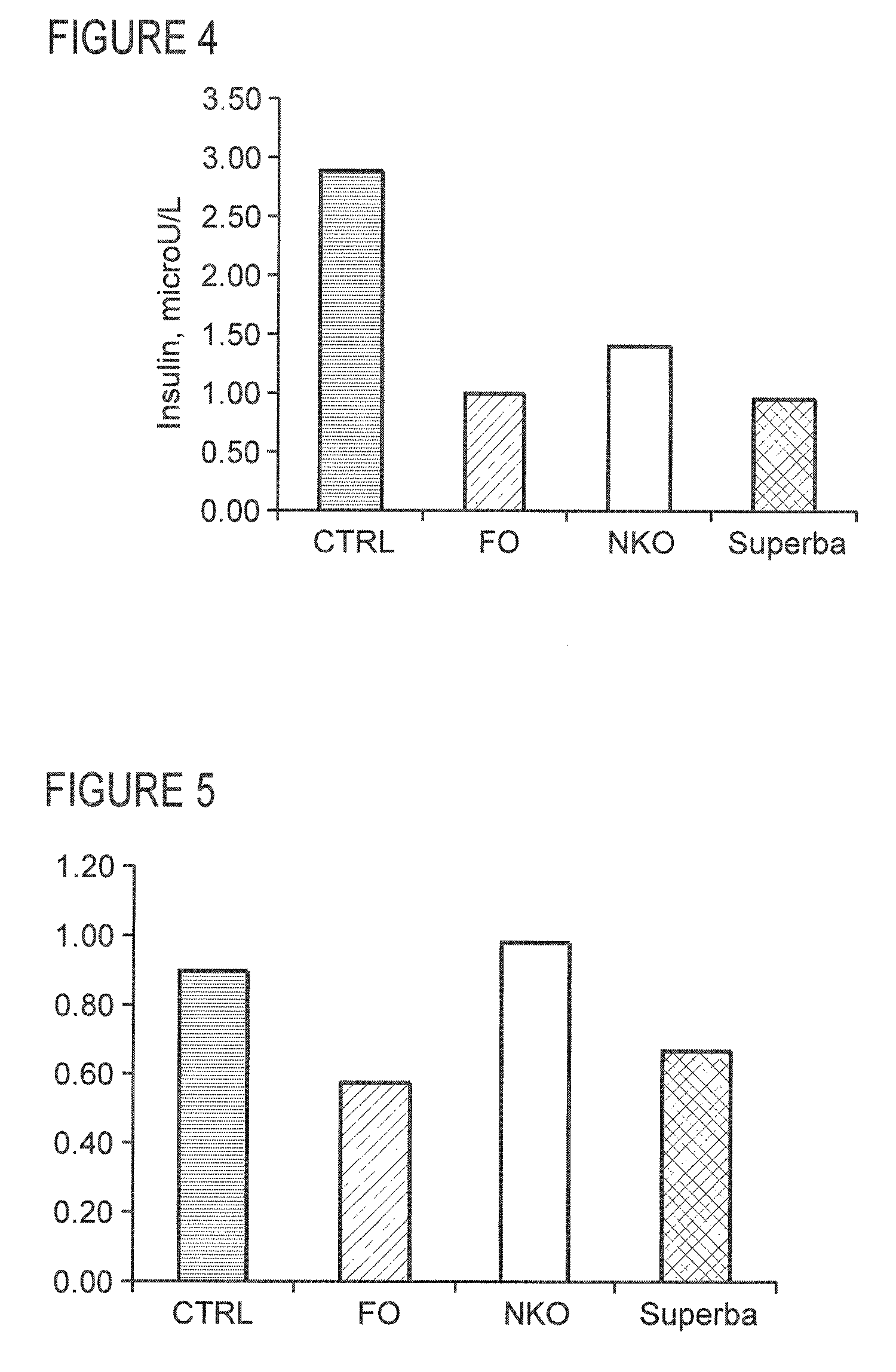

Methods of using krill oil to treat risk factors for cardiovascular, metabolic, and inflammatory disorders

ActiveUS8697138B2Lower Level RequirementsReduced activityOrganic active ingredientsAnthropod material medical ingredientsCvd riskCholesterol biosynthesis

This invention discloses methods of using krill oil and compositions comprising krill oil to treat risk factors for metabolic, cardiovascular, and inflammatory disorders. The present invention also relates to methods of using compositions comprising krill oil to modulate biological processes selected from the group consisting of glucose metabolism, lipid biosynthesis, fatty acid metabolism, cholesterol biosynthesis, and the mitochondrial respiratory chain. The present invention further includes pharmaceutical and / or nutraceutical formulations made from krill oil, methods of making such formulations, and methods of administering them to treat risk factors for metabolic, cardiovascular, and inflammatory disorders.

Owner:AKER BIOMARINE ANTARCTIC

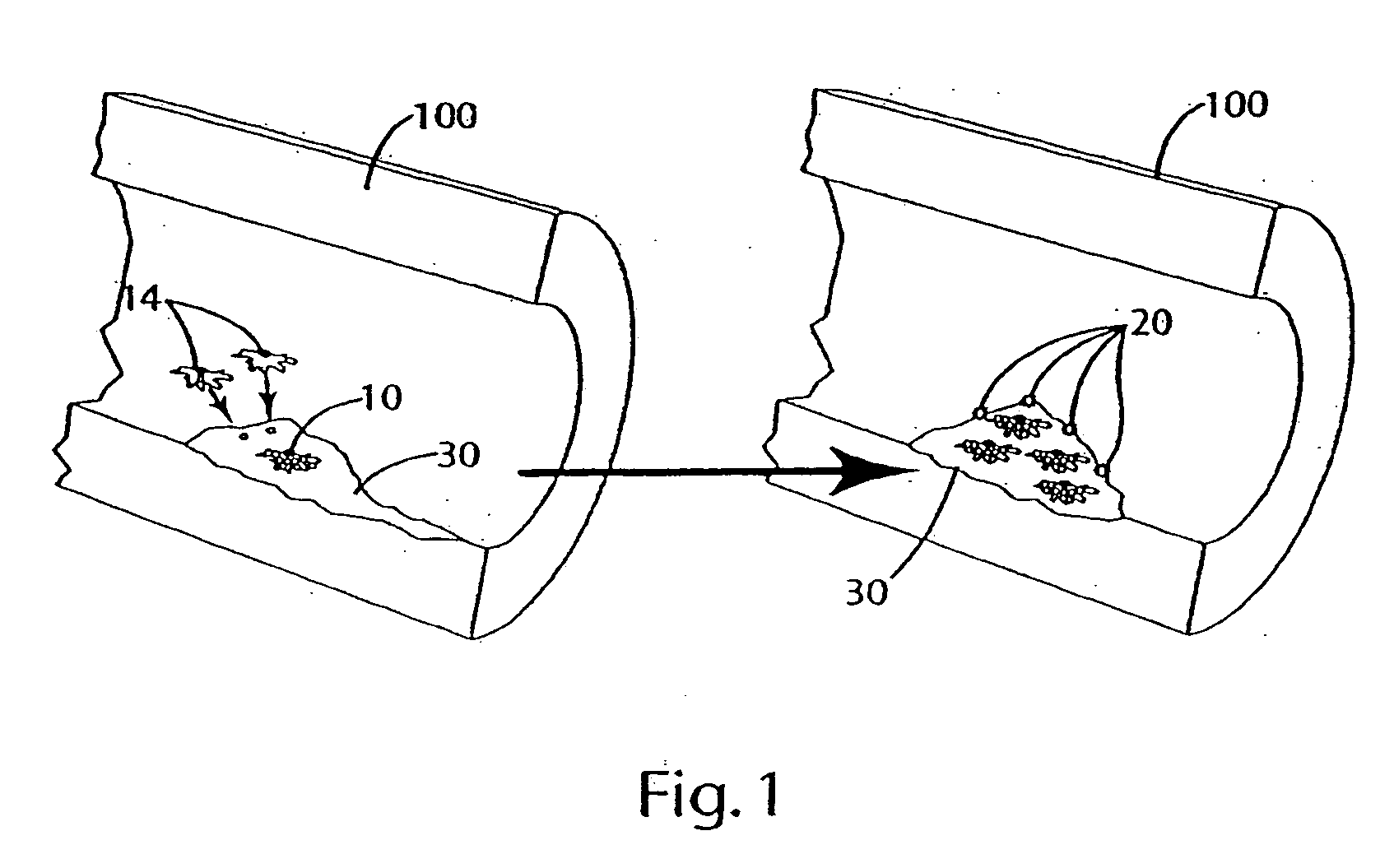

Cytokine modulators and related method of use

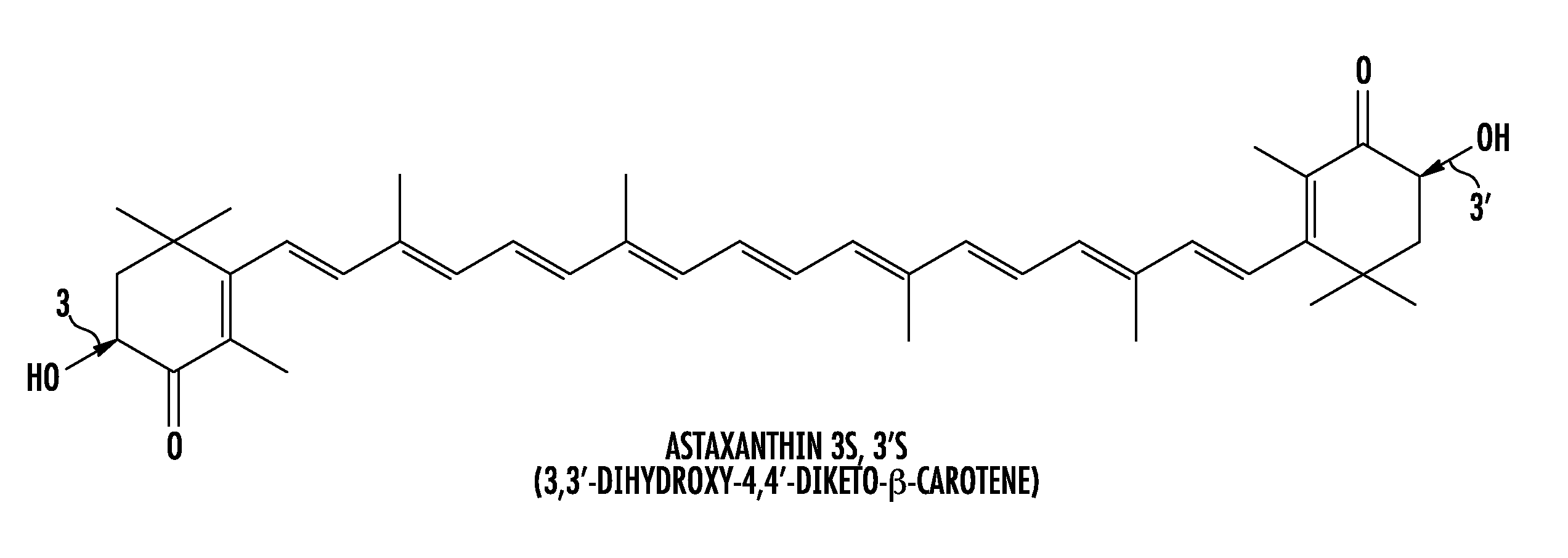

ActiveUS20050058728A1Relieve and eliminate painRelieve and eliminate and tendernessBiocideNervous disorderDiseaseAstaxanthin

A composition for modulating cytokines to regulate an inflammatory or immunomodulatory response. The composition can include at least one of rosehips, blueberry, blackberry, elderberry, cranberry, rosemary, clove, feverfew, nettle root, artichoke, reishi mushroom, olive extract, green tea extract, grape seed extract, resveratrol, Aframomum melegueta, boswellia serrata extract, boswellia forte, ipriflavone, tocotrienols, evening primrose oil, INM-176, borage oil, krill oil, at least one type of xanthophyll (e.g., astaxanthin), green coffee extract and ferulic acid. Specifically, a composition of the invention can include: rosehips and at least one of blackberry, blueberry, elderberry, and optionally krill oil; or rosehips, resveratrol and at least one of Aframomum melegueta and astaxanthin. Based on the cytokine modulation and cytokine response inhibition of the composition, it can be used to regulate an immunomodulatory and / or inflammatory response, and subsequently treat diseases and / or abnormal conditions associated with inflammatory response, for example, cardiovascular conditions, arthritis, osteoporosis and Alzheimer's disease.

Owner:ACCESS BUSINESS GRP INT LLC

Method for simultaneously extracting high-phospholipid krill oil and high-astaxanthin krill oil

The invention relates to a method for simultaneously extracting high-phospholipid-content krill oil and high-astaxanthin-content krill oil. The method comprises the following steps: carrying out countercurrent ultrasonic extraction on Antarctic krill meal by adopting a mixed solvent; finally, carrying out three-grade filtering and filtering krill residues to obtain filtrate, namely an extracting solution; decompressing and evaporating the extracting solution; removing an organic solvent in the extracting solution to obtain crude oil; adding an ethanol solution with the volume which is equal to that of the crude oil and has the mass concentration of 45 percent to 75 percent into the crude oil; standing and layering for 2h to 4h; collecting supernatant and subnatant respectively; decompressing and evaporating respectively to obtain the high-phospholipid-content krill oil and the high-astaxanthin-content krill oil respectively. According to the method provided by the invention, the krill oil is extracted by adopting a mixed solvent of n-hexane and ethanol, so that the dissolution rate and dissolution efficiency of the krill oil are greatly improved; the three-grade filtering and precipitation of the 45 percent to 75 percent ethanol solution are combined and the obtained krill oil has high purity; two products including the high-phospholipid-content krill oil and the high-astaxanthin-content krill oil can be obtained in one step; an extraction process is simple and the production cost is low.

Owner:徐霞 +1

Method for extracting krill oil with high phospholipid content from krill

ActiveCN102405988AIncrease contentPrevent corruption and denaturationEdible oils/fatsOrganic solventEvaporation

The invention discloses a method for extracting krill oil with high phospholipid content from krill. In the method, Antarctic krill is taken as a raw material, the dried Antarctic krill raw material is ground into krill powder, the krill powder is extracted by using an organic solvent, shear extraction is adopted in the extraction process, extracting solutions are mixed and residual organic solvent is removed from the mixed extracting solution through evaporation, and the Antarctic krill oil with 40 to 45 percent of phospholipid is obtained. The process is easy to operate, a final product has high phospholipid content, and the method can serve as the most simple and feasible method for extracting oil, particularly oil with rich phospholipid.

Owner:辽渔南极磷虾科技发展有限公司

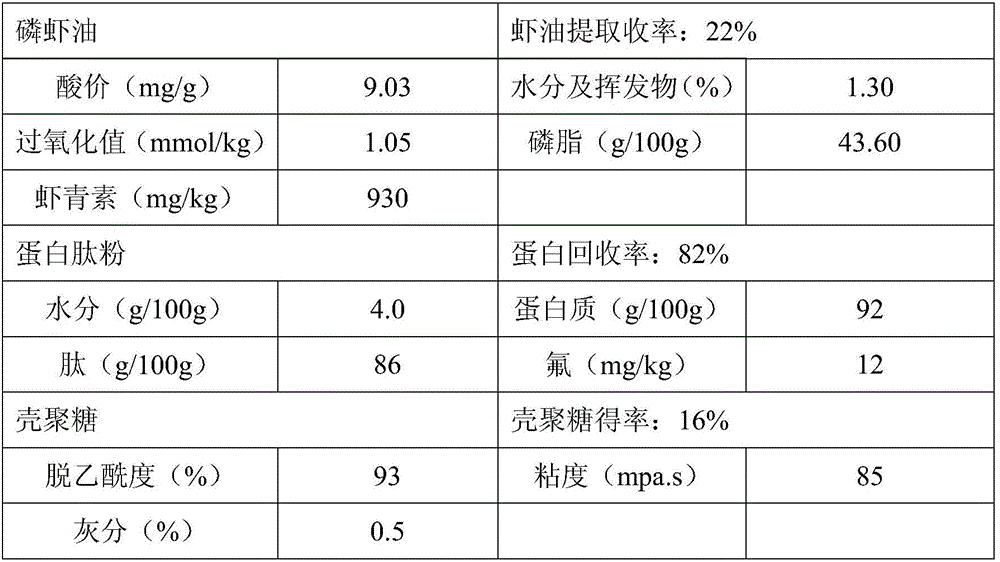

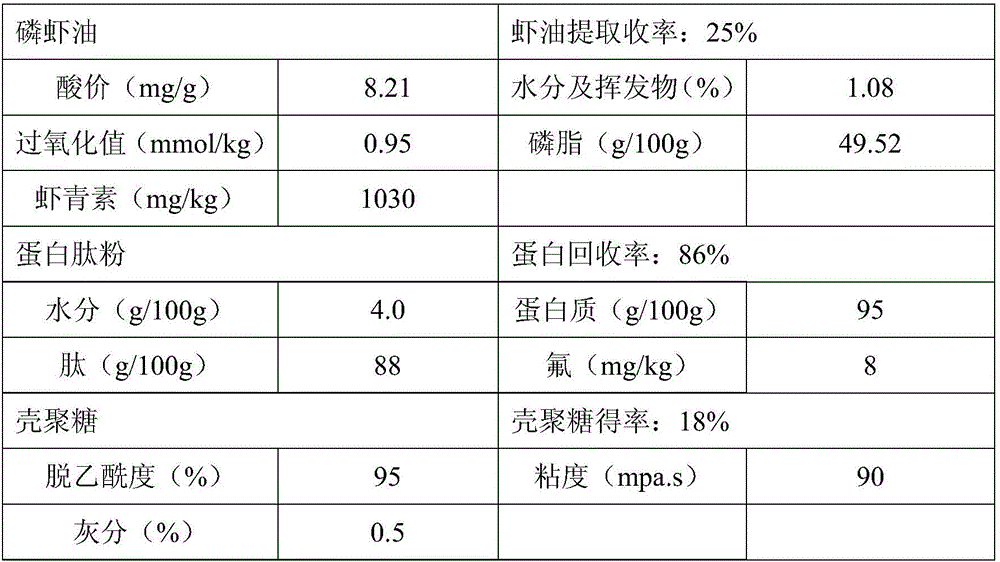

Method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder

InactiveCN106010783ARealize high-value comprehensive utilizationRealize full utilization of high valueCultivating equipmentsFatty-oils/fats productionResource utilizationAdditive ingredient

The invention discloses a method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder. The method comprises the following steps: 1. extraction of krill oil: extracting the Antarctic krill powder by adopting an organic solvent, and carrying out low-temperature decompression desolvation, extraction and concentration on the extracting solution, wherein the contents of obtained krill oil phospholipid and astaxanthin are high; 2. preparation of protein peptide powder: carrying out compound enzymolysis on degreased shrimp meal to obtain an enzymolysis solution, and refining and then spray-drying the enzymolysis solution to obtain the protein peptide powder, wherein the peptide content of the obtained protein peptide powder is greater than or equal to 85%; and 3. preparation of chitosan: decalcifying the shrimp shell meal which is degreased by the organic solvent and is subjected to deproteinization by enzymolysis by adopting microorganism fermentation, further carrying out deproteinization, carrying out oxidative decoloration, and carrying out deacetylation to obtain chitosan and byproduct organic calcium. The method really realizes high-valued full utilization of the Antarctic krill powder, can be used for extracting nutritional ingredients in the Antarctic krill powder to the maximum extent so as to improve the resource utilization ratio, can avoid generation of waste residues, and can ensure the benefit maximization of an enterprise.

Owner:青岛南极维康生物科技有限公司 +1

Method for extracting krill oil rich in phospholipid from euphausia superba

InactiveCN103320217AHigh in phospholipidsImprove qualityFatty-oils/fats productionOrganic solventAstaxanthin

The invention discloses a method for extracting krill oil rich in phospholipid from euphausia superba. The method comprises the following steps of: A, drying; B, extracting; C, volatilizing a solvent; and D, concentrating phospholipid. Through the four steps, the phospholipid content of the obtained krill oil is high and more than 50 percent, the quality is good, and the obtained krill oil also contains multiple elements which are beneficial to the human body such as astaxanthin, unsaturated fatty acid, vitamin and trace elements; the concentrating step of the phospholipid adopts polarity organic solvent as a solvent, so that the residual extracting solvent in the krill oil can be further removed from the euphausia superba; not only can the euphausia superba krill oil with high phospholipid content be obtained, the euphausia superba krill oil on the upper solution in the concentration step also can be recycled, and the extracted euphausia superba powder also can be used for producing other products; and the extracting method is simple, the obtained product is stable in quality, and the used solvent is relatively safe and practical.

Owner:日照海大博远海洋生物科技有限公司

High-content krill oil microcapsules and preparation technology thereof

ActiveCN104824651AGood moisture absorptionGood moisturizing effectFood ingredient as encapsulating agentEdible oils/fatsAntioxidantEngineering

The invention relates to high-content krill oil microcapsules and a preparation technology thereof. The technology comprises the following steps: by taking krill oil and microporous starch as core materials, adding a small amount of xanthan gum into oil phase; and by taking chitosan oligosaccharide and oxidized starch as wall materials, mixing an oil-phase antioxidant, a water-phase antioxidant, an emulsifier, a dispersant and the like in proportion to prepare micro-emulsion, and performing spray drying to prepare krill oil microcapsule powder. The obtained krill oil microcapsule product contains 10-30 percent of phosphatide and keeps biological activity, improves the light-heat stability, acid-alkali stability and the like of krill oil, has good solubility in cold water, and is relatively easy to process, transport and store, safety, fluidity and water solubility are greatly improved, the application range of krill oil is enlarged, and the krill oil is an excellent health-food raw material, and is widely applied to dairy products, beverages, health-care products, baking, tablets and the like. The yield of the krill oil microcapsule powder prepared according to the technology is high, the phosphatide content of the product is high, and the technology is suitable for mass preparation of krill oil microcapsule powder and realizes continuous large-scale production.

Owner:武汉志邦化学技术有限公司

Method for extracting krill oil from antarctic krill

ActiveCN102492537AResidues in line with national standardsPrevent strong odorFatty-oils/fats productionOrganic solventLiquid ratio

The invention relates to a method for extracting krill oil from antarctic krill. The method comprises: heating the captured antarctic krill for 3-20 minutes at a temperature of 60-100 DEG C; drying the antarctic krill, wherein the drying temperature is 60-89 DEG C; crushing the dried antarctic krill into the krill powder with the particle size of 30-100 meshes; adopting an ethanol solution with the concentration more than 95% to soak the krill powder at the temperature of 4-30 DEG C, wherein a solid / liquid ratio is 1:2-1:10, and the time is 0.5-2 hours; carrying out shear extraction on the soaked suspension liquid by using a shearing emulsifying machine, and carrying out standing or stirring extraction on the resulting suspension liquid after the shear extraction; separating the extracting solution, and carrying out extracting separation on the extracting solution 2-4 times; and evaporating the resulting extracted solution at the temperature of 30-60 DEG C and under the vacuum degree of from -0.05 to -0.1 MPa to remove the organic solvent in the extracted solution to obtain the antarctic krill oil with the phospholipid content of 40-45%. According to the present invention, the operation of the method of the present invention is simple, the phospholipid content of the final product is high, and the method can be used as the most simple and feasible method for extracting the greases, and especially the phospholipid-rich greases.

Owner:辽渔南极磷虾科技发展有限公司

Method for extracting Antarctic krill oil with high phosphatide content from Antarctic krill

ActiveCN102492538AKeep it fresh and strongAvoid enzymatic digestionFatty-oils/fats productionOrganic solventPhospholipid

The invention relates to a method for extracting Antarctic krill oil with high phosphatide content from Antarctic krill, which takes fresh Antarctic krill as a raw material, the method comprises the following steps: heating, killing enzyme, disinfecting, removing moisture, drying and crushing, extracting Antarctic krill powder by an organic solvent, cutting and extracting in the extraction process, evaporating the separated extract, removing the residual organic solvent to obtain the Antarctic krill oil with the phosphatide content of 40%-45%. The invention has the advantages of simple operation and high phosphatide content of the final product, and can be the most available method for extracting grease, especially phosphatide-rich grease.

Owner:辽渔南极磷虾科技发展有限公司

Cytokine modulators and related methods of use

ActiveUS20070031518A1Relieve and eliminate painRelieve and eliminate and tendernessBiocideHydroxy compound active ingredientsDiseaseAstaxanthin

A composition for modulating cytokines to regulate an inflammatory or immunomodulatory response. The composition can include at least one of rosehips, blueberry, blackberry, elderberry, cranberry, rosemary, clove, feverfew, nettle root, artichoke, reishi mushroom, olive extract, green tea extract, grape seed extract, resveratrol, viniferin, Aframomum melegueta, boswellia serrata extract, boswellia forte, ipriflavone, tocotrienols, evening primrose oil, INM-176, borage oil, krill oil, at least one type of xanthophyll (e.g., astaxanthin), green coffee extract and ferulic acid. Specifically, a composition of the invention can include: rosehips and at least one of blackberry, blueberry, elderberry, and optionally krill oil; or rosehips, resveratrol and at least one of Aframomum melegueta and astaxanthin. Based on the cytokine modulation and cytokine response inhibition of the composition, it can be used to regulate an immunomodulatory and / or inflammatory response, and subsequently treat diseases and / or abnormal conditions associated with inflammatory response, for example, cardiovascular conditions, arthritis, osteoporosis and Alzheimer's disease.

Owner:ACCESS BUSINESS GRP INT LLC

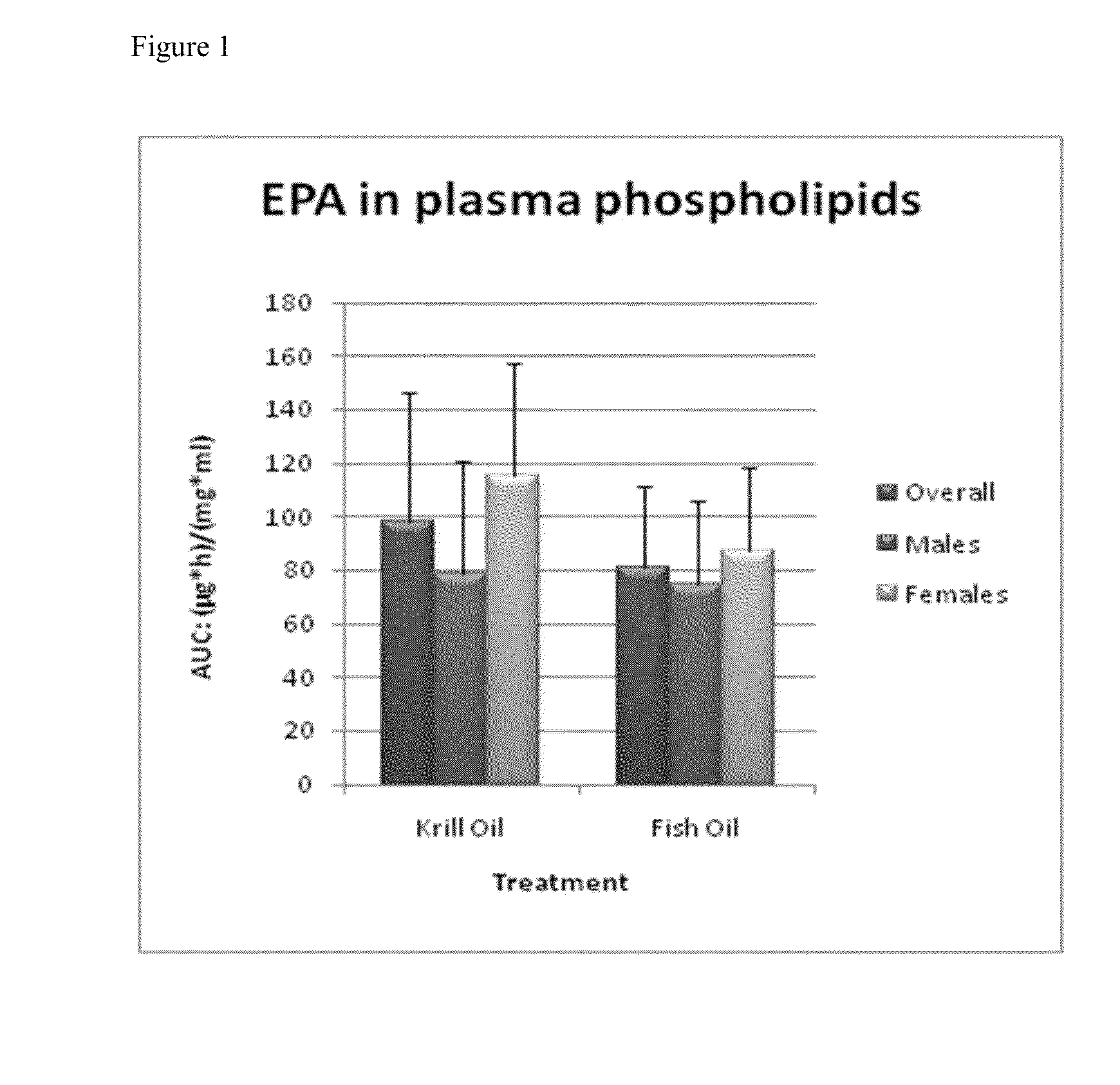

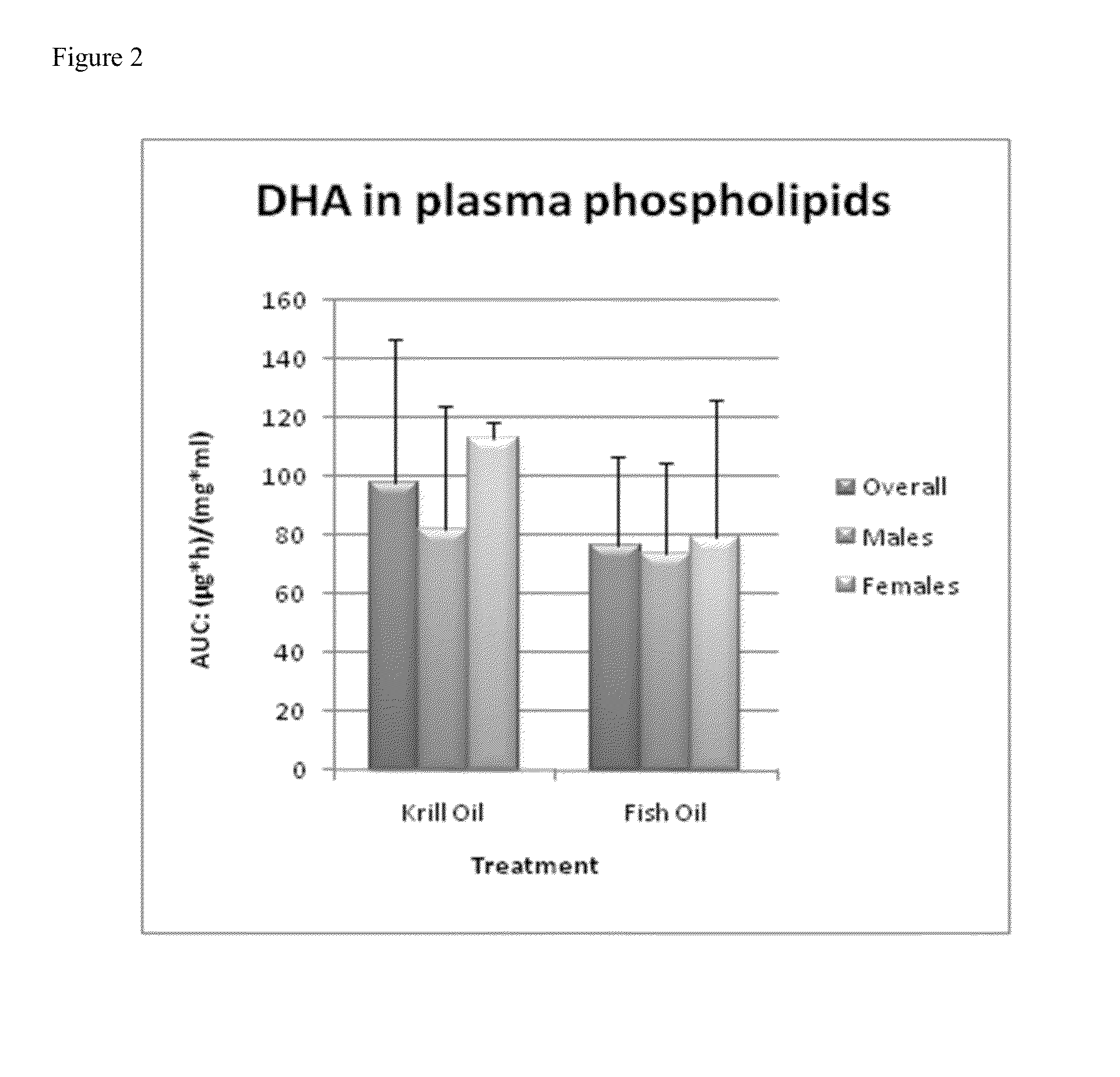

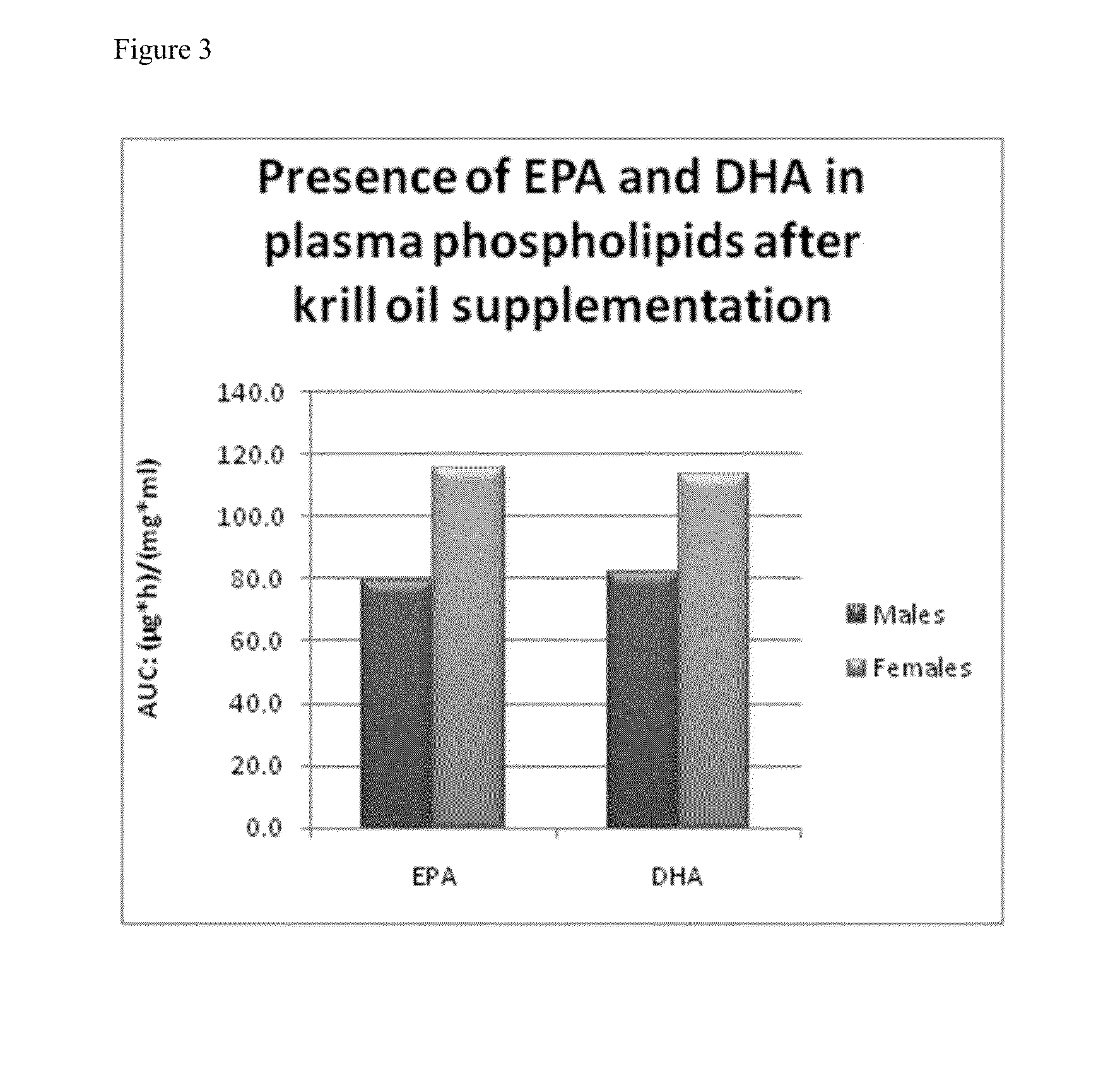

Omega-3 phospholipid supplements for females

InactiveUS20140080791A1High indexIncreasing DHABiocidePhosphorous compound active ingredientsOmega 3 indexOmega-3 phospholipids

The invention relates to omega-3 phospholipid supplements for females, and in particular to omega-3 phospholipid supplements with increased bioavailability as evidenced by increased EPA and DHA in plasma phospholipids and an increase in omega-3 index as compared to males. In preferred embodiments, the omega-3 phospholipid is krill oil.

Owner:AKER BIOMARINE ANTARCTIC

Method for refining krill oil from Antarctic krill powder

InactiveCN103981021AImprove liquidityHigh transparencyFatty-oils/fats refiningFatty-oils/fats productionDistillationAstaxanthin

The invention relates to a method for refining krill oil from Antarctic krill powder, belonging to the technical field of deep processing of Antarctic krill. Acccording to the invention, the solvent ethanol and a small part of water in the extracting solution are removed not directly by one-step reduced pressure distillation, but are removed by the following steps: removing part of the solvent, adding deionized water, concentrating phospholipid, unsaturated fatty acids, krill astaxanthin and other effective substances by utilizing the characteristics of phospholipid, adding anhydrous ethanol to remove most of polysaccharides, proteins and salts, and finally, distilling under reduced pressure to remove the solvent and water. By using the refinement technique, the contents of the phospholipid DHA, EPA and other unsaturated fatty acids, astaxanthin and other effective components in the obtained krill oil are obviously enhanced, and the quality (flowability and transparency) of the obtained krill oil is obviously improved.

Owner:SHANDONG QIANQINGXIANGTAI BIOLOGICAL PROD CO LTD

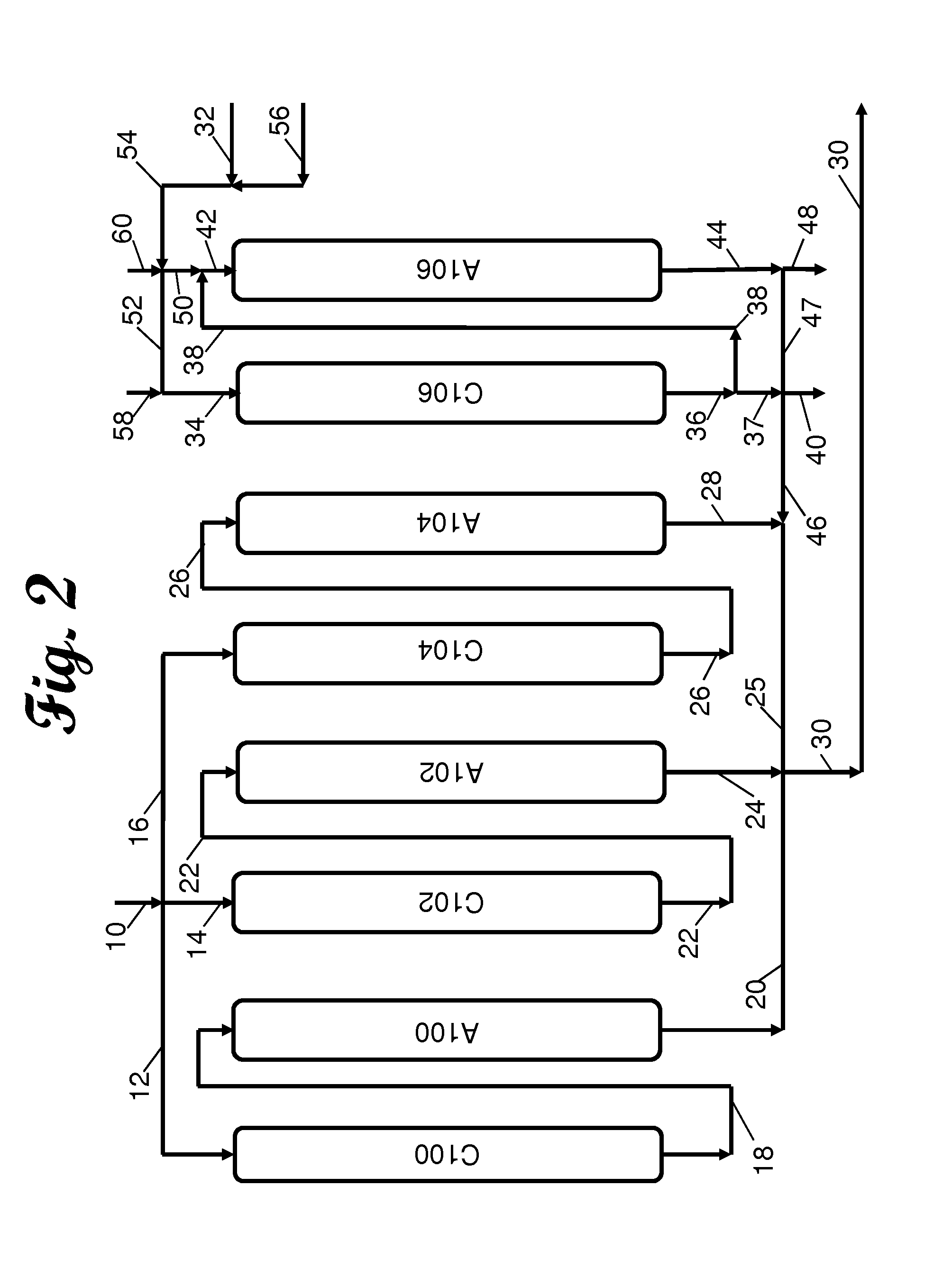

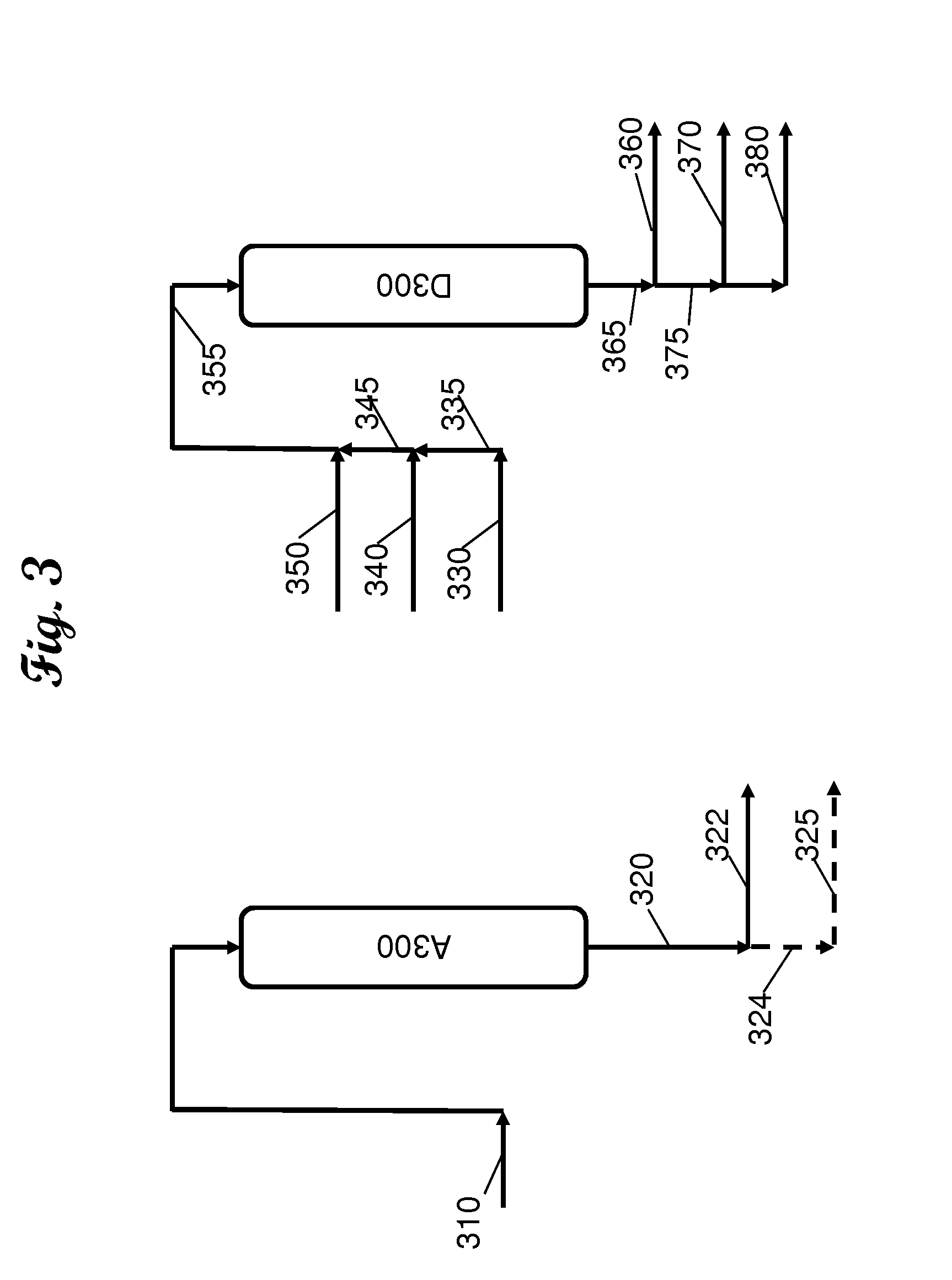

Krill oil refinery for purification of krill oil extract

InactiveUS20160229781A1Increase valueFatty-oils/fats refiningCarbonyl compound separation/purificationBiodieselDietary supplement

Disclosed is a chromatographic process complex for the refining of krill oil extract including desalting, removal of impurities such as trimethylamine oxide (TMAO), and the production of krill oil products including desalted krill oil extract, polar lipid products having polar lipid contents greater than 50 wt-% on a dry or solvent free basis, neutral lipid streams for biodiesel production and astaxanthin. The refinery includes a continuous desalting zone, a fixed bed polar lipid extraction zone to adsorb neutral lipids and astaxanthin to provide a polar lipid extract stream comprising solvent and polar lipids and being essentially free of neutral lipids and astaxanthin, and an astaxanthin separation zone to recover essentially pure astaxanthin and provide a neutral lipid stream. The enriched products of the krill oil refinery are essentially free of TMAO and salt and provide products which can be used as dietary supplements and as medicinal additives.

Owner:AKER BIOMARINE ANTARCTIC

Method for preventing the oxidation of lipids in animal and vegetable oils and compositions produced by the method thereof

InactiveUS20050192634A1Reduce oxidationLower Level RequirementsHeart defibrillatorsFatty substance preservation using additivesBiotechnologyPeroxide

A composition comprising an oil selected from the group consisting of vegetable oils, animal oils, and krill oil in an amount sufficient to lower the peroxide index of the composition. The composition may preferably comprise a fish oil also having astaxanthin added thereto.

Owner:BEAUDOIN ADRIEN

Method for preventing the oxidation of lipids in animal and vegetable oils and compositions produced by the method thereof

InactiveUS20100239715A1Reduce oxidationLower Level RequirementsFatty oils/acids recovery from wasteOrganic compound preparationBiotechnologyPeroxide

A composition comprising an oil selected from the group consisting of vegetable oils, animal oils, and krill oil in an amount sufficient to lower the peroxide index of the composition. The composition may preferably comprise a fish oil also having astaxanthin added thereto.

Owner:BIOCEAN CANADA

Preparation method of antarctic krill oil

ActiveCN102559369AEasy to operateReduce dosageFatty-oils/fats productionAlkaline proteaseMaximum level

The invention discloses a preparation method of antarctic krill oil, which comprises the following steps: directly homogenizing harvested fresh live antarctic krill, and allowing low-temperature autolysis of the homogenate after ultraviolet irradiation; adding water, sodium chloride and ethanol to the low-temperature autolyzed homogenate, heating the homogenate after ultraviolet irradiation treatment to 30-65 DEG C in a gradient manner, and allowing high-temperature autolysis; performing ultrasonic treatment of the high-temperature autolyzed homogenate, adjusting pH, adding alkali protease for extraneous enzyme enzymolysis; and adding n-hexane to the enzymatic hydrolysate to extract krill oil. The method of the invention is especially suitable for operation immediately in a fishing boat after the fresh live antarctic krill are harvested. The method is simple in operation and has high efficiency. Especially, the use amount of the extraneous enzyme is reduced by using the strong autolysis capacity of the fresh live antarctic krill, so as to reduce production cost. The extraction method has mild conditions, so that some original physiologically active substances in the krill oil can be stored at a maximum level, and the product is both nutritional and functional.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for extracting krill oil with high phosphatide content from Antarctic krills

InactiveCN102041166BImprove enrichment effectImprove extraction efficiencyFatty-oils/fats productionOrganic solventPrawn

The invention discloses a method for extracting krill oil with high phosphatide content from Antarctic krills. The method comprises the following steps: (1) drying fresh Antarctic krills to obtain dry Antarctic krills; (2) performing extraction to dry Antarctic krills for 3 times with organic solvent; (3) mixing the extracting solutions, evaporating the mixed extracting solution to obtain Antarctic krill oil with the phosphatide content of 30-35%; then introducing nitrogen or carbon dioxide to remove the residual organic solvent; and adding polar organic solvent in the Antarctic krill oil, mixing evenly, standing to ensure that the mixed solution performs natural layering; and evaporating the lower solution to obtain the Antarctic krill oil with high phosphatide content, and then introducing nitrogen or carbon dioxide to remove the residual polar organic solvent so as to obtain a product. The extraction technology is performed at a low temperature, thus the red color of krill oil can be maintained and the beneficial ingredients in the product can not be damaged. The invention has high extraction efficiency and good phosphatide accumulation effect. Therefore, the Antarctic krill oil with high phosphatide content can be obtained and other byproducts can also be obtained.

Owner:SHANDONG NORMAL UNIV +1

Method for extracting phospholipid-rich krill oil from antarctic krills

InactiveCN102816638AIncrease profitHigh comprehensive utilization rate and high practical application valueFatty-oils/fats productionOrganosolvPhospholipid

Disclosed is a method for extracting phospholipid-rich krill oil from antarctic krills. The method includes utilizing antarctic krills as raw materials, performing pretreatment process of raw materials such as heating to deactivate enzyme and sterilize and soaking in alkali solution, extracting krill powder with organic solvent after removing moisture, drying and smashing, separating solid and liquid, depressurizing and distilling extracting solution separated, and removing residual organic solvent to obtain antarctic krill oil containing more than 45% of phospholipid. The method for extracting phospholipid-rich krill oil from the antarctic krills is simple to operate, finished products are high in phospholipid content, low in acid value and fine in liquidity, stability of the phospholipid oil is improved, fat quality is improved, and comprehensive utilization rate of the antarctic krills is greatly increased. Besides, the method is low in cost, safe and environment-friendly and can be used as the simplest and most feasible method for extracting oil fat, especially oil fat rich in phospholipid in the antarctic krills.

Owner:辽渔集团有限公司

Process for extracting krill oil, co-produced protein and chellotosan from antarctic krill powder

ActiveCN103589507ASolve the disadvantages that only a single product can be extractedRich sourcesPeptide preparation methodsFatty-oils/fats productionAstaxanthinOrganosolv

The invention discloses a process for extracting krill krill oil, co-produced protein and chellotosan from antarctic krill powder. The process comprises the following steps: 1, krill oil is extracted, wherein the phospholipid content of the krill oil is 38-45%, and the astaxanthin content of the krill oil is 240-350 mg / kg; 2, protein is extracted, and the yield of the protein extracted through the alkali-solution and acid-isolation method is 30-36%; 3, chellotosan is prepared, alkali deproteinization and acid decalcification are performed on shrimp shells, and the deproteinization and decalcification operations are repeatedly performed for two times to prepare high purify chellotosan, and the yield of the chellotosan is 13-21%. According to the invention, three types of high purify products, namely the krill oil, the protein and the chellotosan, are extracted in sequence, so that the comprehensive utilization ratio of a raw material and the added value of products are greatly improved; the antarctic krill is replaced by the antarctic krill powder, so that the rich raw material source is realized, the severe conditions are avoided during storage and transformation of the antarctic krill, and the process is suitable for large scale industrial production; during the production process, the cyclic utilization of organic solvents, waste liquor and waste residue, and high value and efficient comprehensive utilization of sources are realized.

Owner:青岛福创环境科技有限公司

Cytokine modulators and related methods of use

ActiveUS20060029686A1Relieve and eliminate painRelieve and eliminate and tendernessBiocideHydroxy compound active ingredientsAstaxanthinArthritis

A composition for modulating cytokines to regulate an inflammatory or immunomodulatory response. The composition can include at least one of rosehips, blueberry, blackberry, elderberry, cranberry, rosemary, clove, feverfew, nettle root, artichoke, reishi mushroom, olive extract, green tea extract, grape seed extract, resveratrol, Aframomum melegueta, boswellia serrata extract, boswellia forte, ipriflavone, tocotrienols, evening primrose oil, INM-176, borage oil, krill oil, at least one type of xanthophyll (e.g., astaxanthin), green coffee extract and ferulic acid. Specifically, a composition of the invention can include: rosehips and at least one of blackberry, blueberry, elderberry, and optionally krill oil; or rosehips, resveratrol and at least one of Aframomum melegueta and astaxanthin. Based on the cytokine modulation and cytokine response inhibition of the composition, it can be used to regulate an immunomodulatory and / or inflammatory response, and subsequently treat diseases and / or abnormal conditions associated with inflammatory response, for example, cardiovascular conditions, arthritis, osteoporosis and Alzheimer's disease.

Owner:ACCESS BUSINESS GRP INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com