Patents

Literature

43results about How to "Realize high-value comprehensive utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

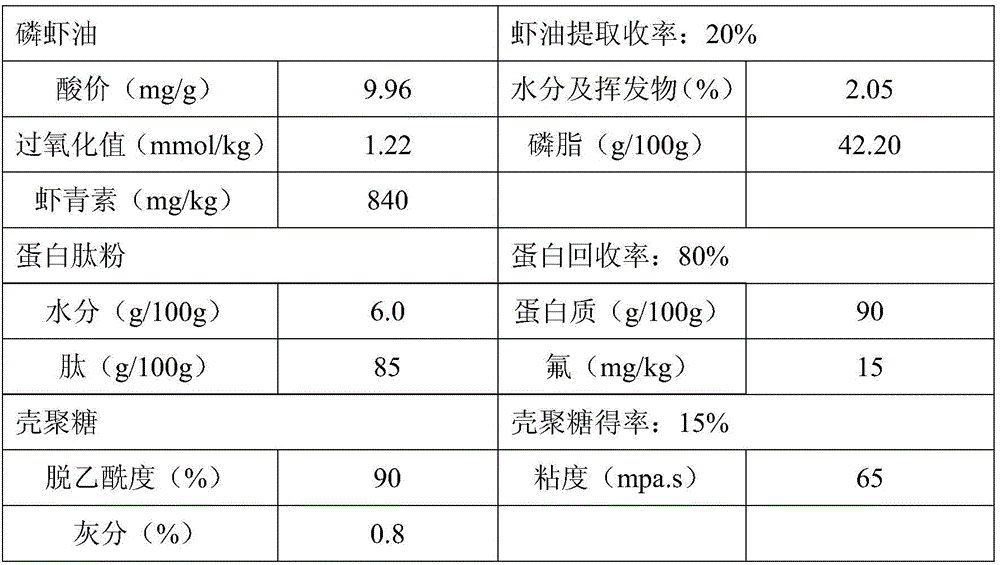

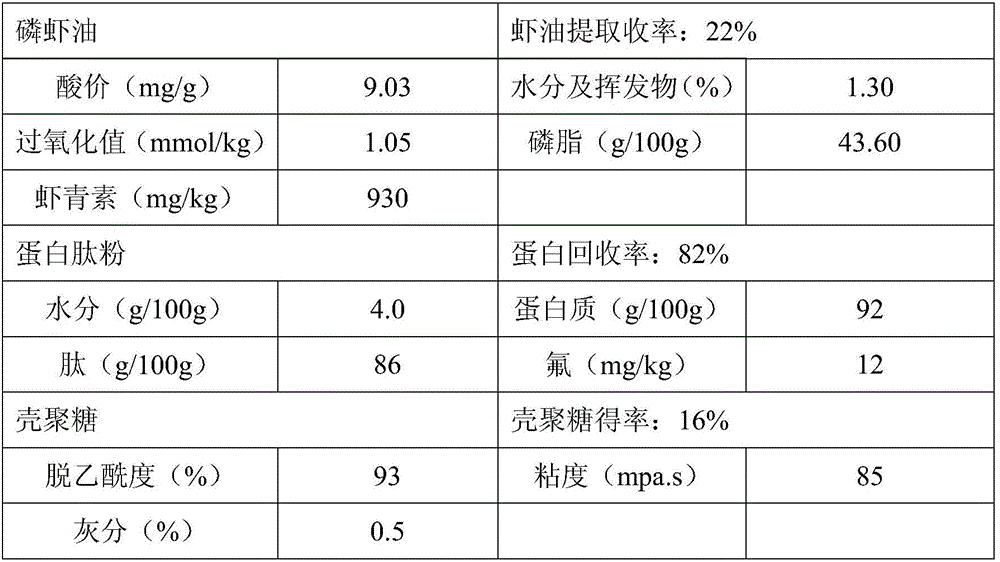

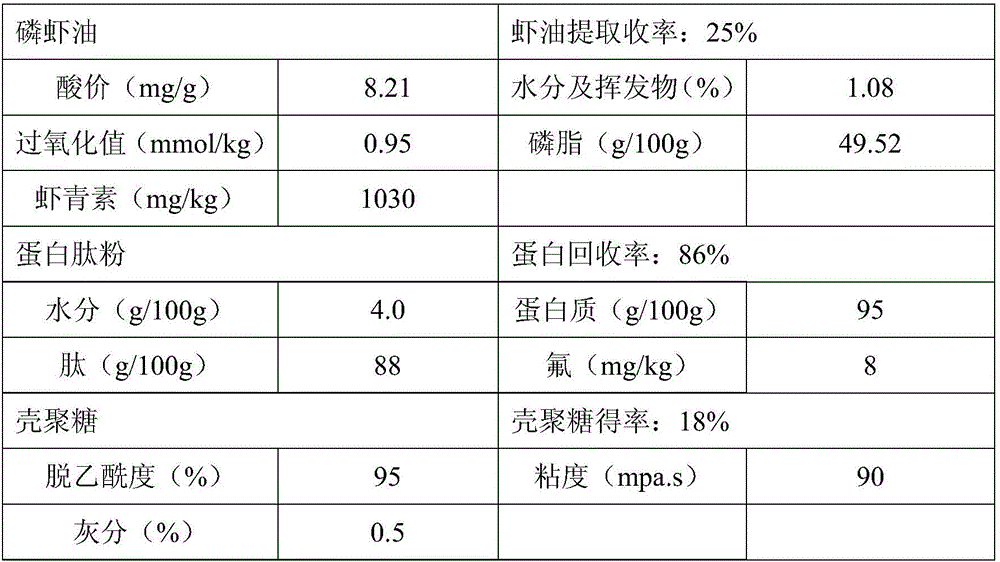

Method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder

InactiveCN106010783ARealize high-value comprehensive utilizationRealize full utilization of high valueCultivating equipmentsFatty-oils/fats productionResource utilizationAdditive ingredient

The invention discloses a method for producing krill oil, protein peptide powder and chitosan by full utilization of Antarctic krill powder. The method comprises the following steps: 1. extraction of krill oil: extracting the Antarctic krill powder by adopting an organic solvent, and carrying out low-temperature decompression desolvation, extraction and concentration on the extracting solution, wherein the contents of obtained krill oil phospholipid and astaxanthin are high; 2. preparation of protein peptide powder: carrying out compound enzymolysis on degreased shrimp meal to obtain an enzymolysis solution, and refining and then spray-drying the enzymolysis solution to obtain the protein peptide powder, wherein the peptide content of the obtained protein peptide powder is greater than or equal to 85%; and 3. preparation of chitosan: decalcifying the shrimp shell meal which is degreased by the organic solvent and is subjected to deproteinization by enzymolysis by adopting microorganism fermentation, further carrying out deproteinization, carrying out oxidative decoloration, and carrying out deacetylation to obtain chitosan and byproduct organic calcium. The method really realizes high-valued full utilization of the Antarctic krill powder, can be used for extracting nutritional ingredients in the Antarctic krill powder to the maximum extent so as to improve the resource utilization ratio, can avoid generation of waste residues, and can ensure the benefit maximization of an enterprise.

Owner:青岛南极维康生物科技有限公司 +1

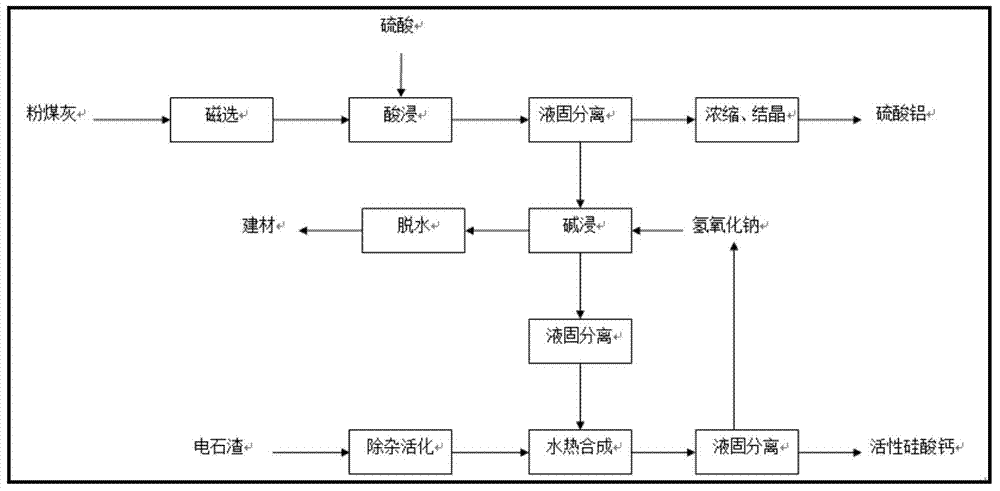

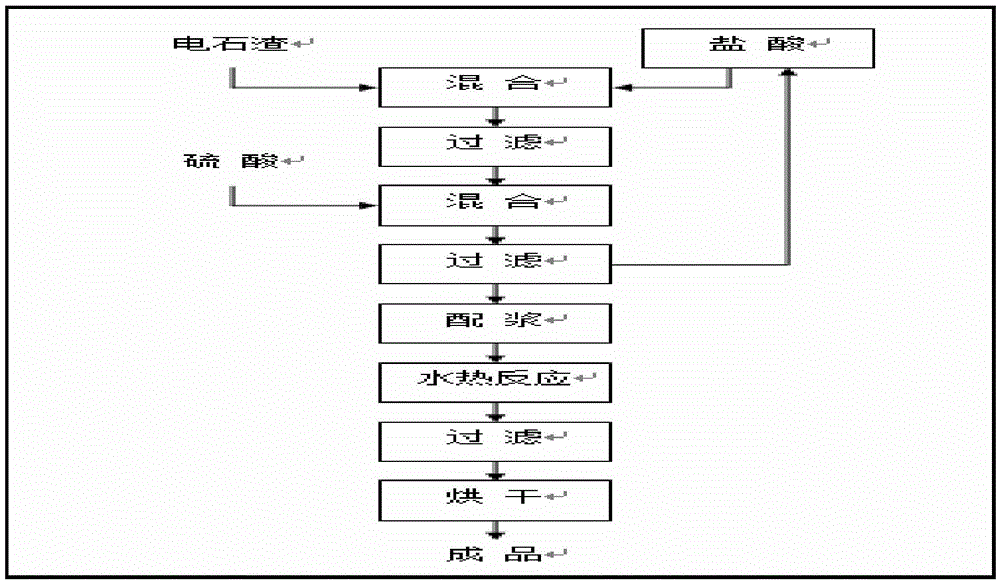

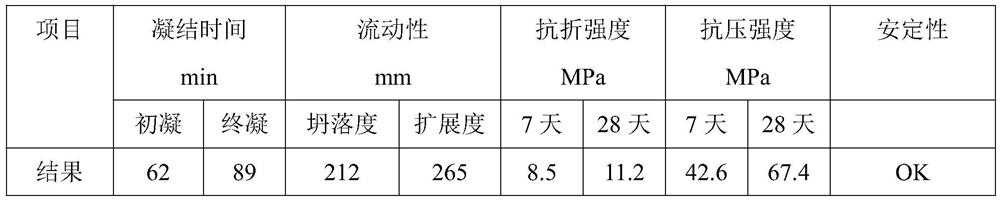

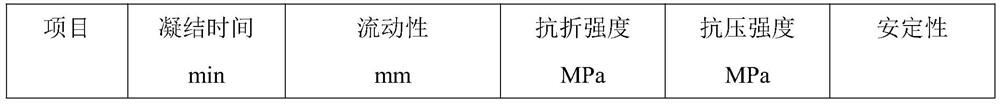

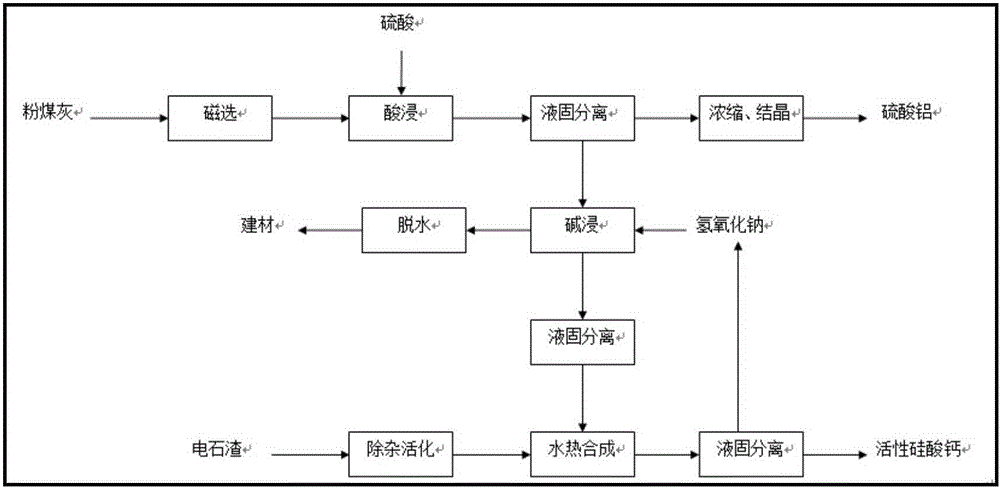

Method for synergic resource utilization of acetylene sludge and coal ash

ActiveCN104495899AShort processZero emissionAlkaline-earth metal silicatesCement productionCalcium silicateResource utilization

The invention provides a method for synergic resource utilization of acetylene sludge and coal ash. The method comprises the following steps: carrying out magnetic separation, acid leaching and filtering on coal ash to obtain an aluminum sulfate solution and acidic leaching residues, carrying out evaporative concentration and cooling crystallization on filtrate to obtain an aluminum sulfate crystal; carrying out alkaline leaching and filtering on the acidic leaching residues to obtain a sodium silicate solution and alkaline leaching residues, and carrying out cleaning and activation on the acetylene sludge to prepare lime milk which is subjected to hydro-thermal synthesis with the sodium silicate solution, and drying and dehydrating to prepare active calcium silicate powder, wherein the alkaline leaching residues can be directly used for preparing building materials after being dehydrated. According to the invention, by adopting the method for producing aluminum sulfate co-production active calcium silicate through synergic resource utilization of the acetylene sludge and coal ash, high-value utilization of large quantity of industrial solid wastes can be realized, and the production added value is high; all byproducts can be recycled, zero discharge is realized, energy consumption is low, and economical efficiency and environmental protection are achieved.

Owner:陕西龙湘科创节能环保科技有限公司

Method for producing sodium alginate and co-producing ethanol and seaweed organic fertilizer

InactiveCN103232554ARealize high-value comprehensive utilizationHigh extraction rateFermentationOrganic fertilisersIon exchangeDigestion

The invention discloses a method for producing sodium alginate and co-producing ethanol and a seaweed organic fertilizer. The method comprises the following steps of: with brown algae kelp serving as a raw material, pre-processing through cellulase and compound protease in an enzymolysis manner; decomposing cellulose in the kelp into microbially available monosaccharide and oligosaccharide in order to ferment to produce ethanol; preparing the seaweed organic fertilizer through the rest fermentation broth with little kelp residue; extracting and separating sodium alginate from the pre-processed kelp; and then performing a dilute alkali digestion technology and a calcium coagulating-ion exchange method to obtain high-quality sodium alginate. According to the method, the preprocessing is performed through bio-enzyme, and the main components, namely, cellulose, protein and the like in the kelp, are separated in advance through the cellulose and protease, thus high extraction rate of the sodium alginate is grained; simultaneously, wastes generated in processing are utilized to prepare a fuel, namely, ethanol; and the waste liquid and waste residues remained in ethanol preparation are utilized to prepare the seaweed organic fertilizer, therefore, high-valued utilization of the kelp is realized, and marine biomass energy is developed.

Owner:QINGDAO BETTER BIO TECH

Method for preparing sodium alginate and organic fertilizer from gulfweed

ActiveCN104341534AHigh extraction rateRealize high-value comprehensive utilizationFertilizer mixturesPectinaseIon exchange

The invention discloses a method for preparing sodium alginate and an organic fertilizer from gulfweed, and is characterized in that the method comprises the following steps: (1) raw material pretreatment, (2) cellulose enzymolysis, (3) proteolysis, (4) brine digestion, (5) dilution and filtration, (6) decoloring, (7) CaCl2 solution treatment, (8) ion exchange, (9) preparation of sodium alginate, and (10) preparation of the gulfweed organic fertilizer. A composite enzyme is prepared from protease, pectinase and cellulase by a scientific ratio, and raw material is pretreated, so as to help to improve the extraction rate of sodium alginate; and Chinese humic acid resources are fully developed and utilized, the organic fertilizer rich in humic acid and macronutrients is produced with water as a solvent, and the high-valued comprehensive utilization of undaria pinnatifida sporophylls is achieved.

Owner:万物生(深圳)生物科技控股有限公司

Co-generation method for preparing methane, fulvic acid and organic fertilizer by taking peat as raw material

InactiveCN103352056ARealize high-value comprehensive utilizationSolve the problem of single use methodBio-organic fraction processingOrganic chemistrySoil sciencePeat

The invention discloses a co-generation method for preparing methane, fulvic acid and an organic fertilizer by taking peat as a raw material. The method comprises the following basic steps: preparing methane from peat though anerobic fermentation, extracting fulvic acid from methane fermentation residues, and further compounding, decomposing and fermenting the residues after the fulvic acid is extracted to produce the organic fertilizer rich in humic acid. The method realizes poly-generation of preparing methane, fulvic acid and the organic fertilizer from peat, solves the key problems that at present only single component of peat is utilized and the product added value of peat mainly serving as an organic fertilizer and horticultural substrate is low, and realizes high-value comprehensive utilization of peat resources.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

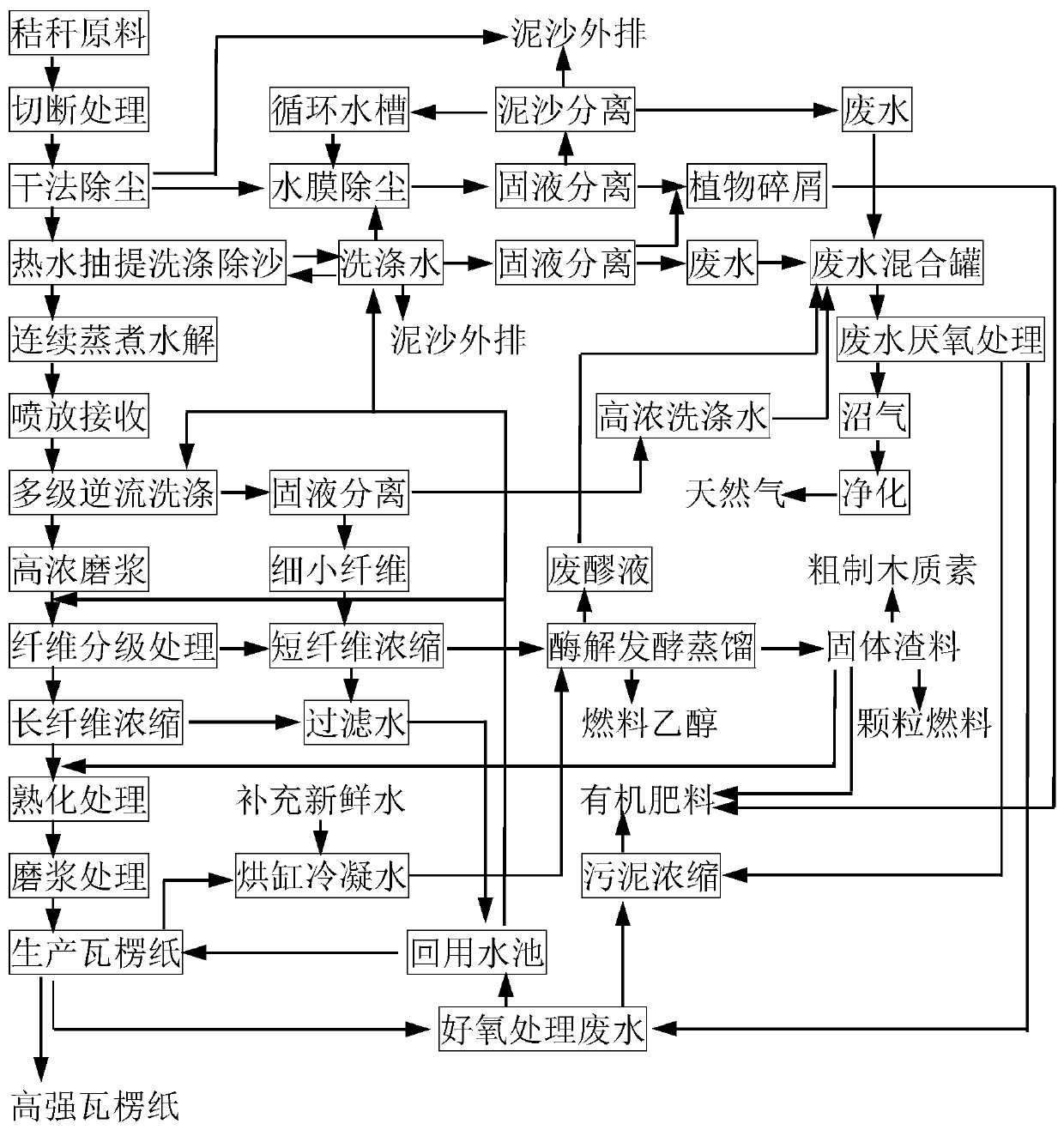

Method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer

InactiveCN110129380AImprove water filtration performancePromote degradationPretreatment with water/steamSludge treatment by de-watering/drying/thickeningDistillationHigh concentration

The invention relates to a method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer. The method includes: cutting the straw, dusting through a dry process and a waterfilm, washing through hot water extraction for desanding, continuously boiling for hydrolysis, blowing and receiving, performing multistage countercurrent washing, jordaning at high concentration, treating fiber in a staged manner, concentrating long fiber, curing the long fiber, jordaning the long fiber, and using the long fiber to produce the corrugated paper; concentrating the short fiber, subjecting fine and broken fiber to enzymolysis, fermentation and distillation to produce cellulose alcohol, and separating waste mash for utilization. By the method, high-value comprehensive utilizationof each component of the straw is realized, wastewater COD biochemical degradability is high, inorganic salt accumulation is avoided, biogas is produced by high-concentration wastewater in the process and purified as natural gas, and low-concentration wastewater is recycled after being treated, so that a water system is a closed cycle, and there is no wastewater emission; a fine and broken fibercomponent is large in specific surface area and high in enzymolysis efficiency; the corrugated paper produced by a long fiber component is high in strength and quality, and cost of the cellulose alcohol can be lowered; biological natural gas and biomass particle fuel can reduce consumption of mineral fuel.

Owner:吴学军 +5

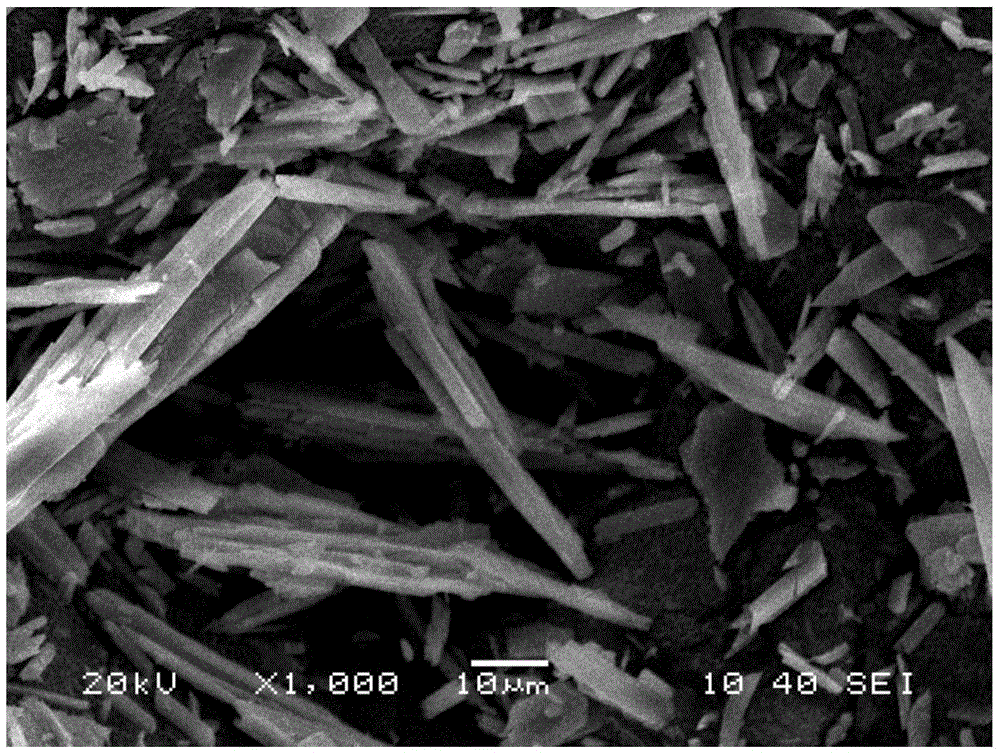

Method for preparing calcium sulfate whiskers from acetylene sludge and waste sulfuric acid

InactiveCN105483816AShort processZero emissionPolycrystalline material growthFrom normal temperature solutionsSludgeSlurry

The invention discloses a method for preparing calcium sulfate whiskers from acetylene sludge and waste sulfuric acid. The method includes the steps of grinding and screening the acetylene sludge, conducting an acid leaching hybrid reaction, removing impurities and decoloring the waste sulfuric acid, preparing and filtering calcium sulfate slurry, mixing the calcium sulfate slurry, synthesizing the calcium sulfate whiskers and the like. With the acetylene sludge and the waste sulfuric acid as main raw materials, the calcium sulfate whiskers are produced through a normal pressure and temperature acidizing method, the problems of environmental pollution and potential safety hazards caused by stacking and storing the acetylene sludge and the waste sulfuric acid for a long time are effectively solved, the process is simple, the requirement for equipment is low, and technological content and additional value of the calcium sulfate whiskers are high; the method is easy to industrialize, meets the requirement of the circular economy industrial policy in developing countries and has wide market prospects.

Owner:HUNAN UNIV OF SCI & TECH

Method for effectively extracting nutrient substances in seaweed

InactiveCN106496351ARealize high-value comprehensive utilizationHigh extraction rateClimate change adaptationOrganic fertilisersWater bathsLiquid waste

The invention discloses a method for effectively extracting nutrient substances in seaweed. The method is characterized by including the steps of 1), pretreatment of raw materials; 2), water bath soaking; 3), fiber enzymolysis; 4), proteolysis; 5), salt water digestion; 6), diafiltration; 7), decoloration; 8), CaCl2 solution treatment; 9), ion exchange; 10), preparation of sodium alginate; 12), preparation of seaweed fertilizer. Compound enzyme is prepared through scientific matching of protease, pectinase and cellulose, the raw materials are pretreated, and extraction ratio of sodium alginate is favorably increased; meanwhile, fuel ethanol is prepared by the aid of kelp processing waste rich in cellulose; residual liquid waste and residual waste during processing are manufactured into seaweed organic fertilizer through concentration, spray-drying and granulation, high-valued comprehensive utilization of the seaweed is realized, and marine biological energy is developed.

Owner:威海红印食品有限公司

Enteromorpha prolifera high-valued extraction method

The invention discloses an enteromorpha prolifera high-valued extraction method, and is characterized in that the method comprises the following steps: (1) raw material pretreatment, (2) cellulose enzymolysis, (3) proteolysis, (4) brine digestion, (5) dilution and filtration, (6) decoloring, (7) CaCl2 solution treatment, (8) ion exchange, (9) preparation of sodium alginate, (10) preparation of ethanol, and (11) preparation of an enteromorpha prolifera organic fertilizer. A composite enzyme is prepared from protease, pectinase and cellulase by a scientific ratio, and raw material is pretreated, so as to help to improve the extraction rate of sodium alginate; at the same time, fuel ethanol is prepared by using cellulose-rich enteromorpha prolifera processing waste; the enteromorpha prolifera organic fertilizer is prepared through concentration, spray drying and granulation, so as to realize the high-valued comprehensive utilization of enteromorpha prolifera, and develop marine biological energy.

Owner:邳州德好科技有限公司

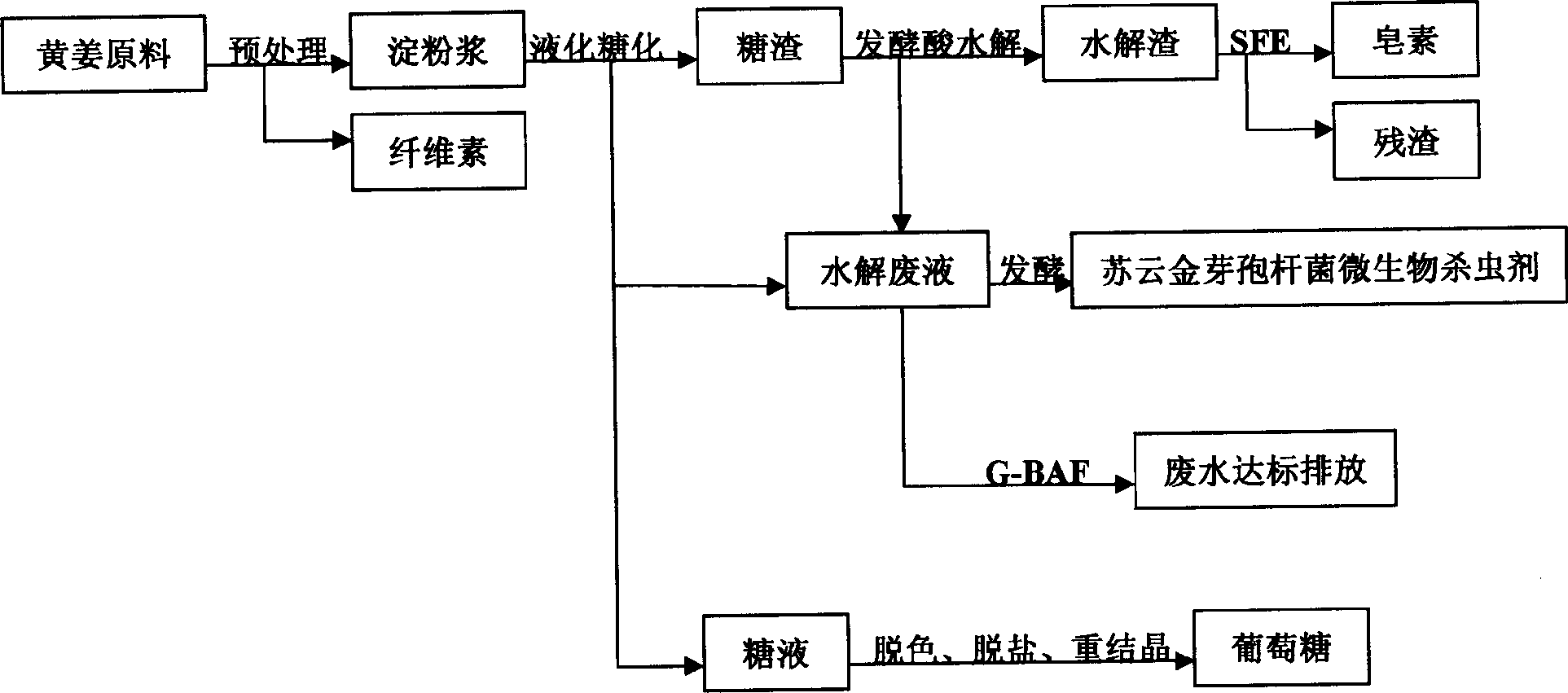

Integreted tech., or treating yellow ginger processing and waste water

InactiveCN1792862ASolve pollutionSolve resource problemsBiocideChemical industryCelluloseAureobasidium sp.

An integrated process for preparing the products from yam and treating its sewage includes such steps as physical separation to obtain cellulose and starch paste, liquefying and saccharifying the starch paste to obtain sugar dreg, fermenting and acidolyzing to obtain saponin, transferring sugar liquid to obtain glocose, using the hydrolyzed sewage to prepare Bacillus thuringienis insecticide, and treating sewage.

Owner:PEKING UNIV

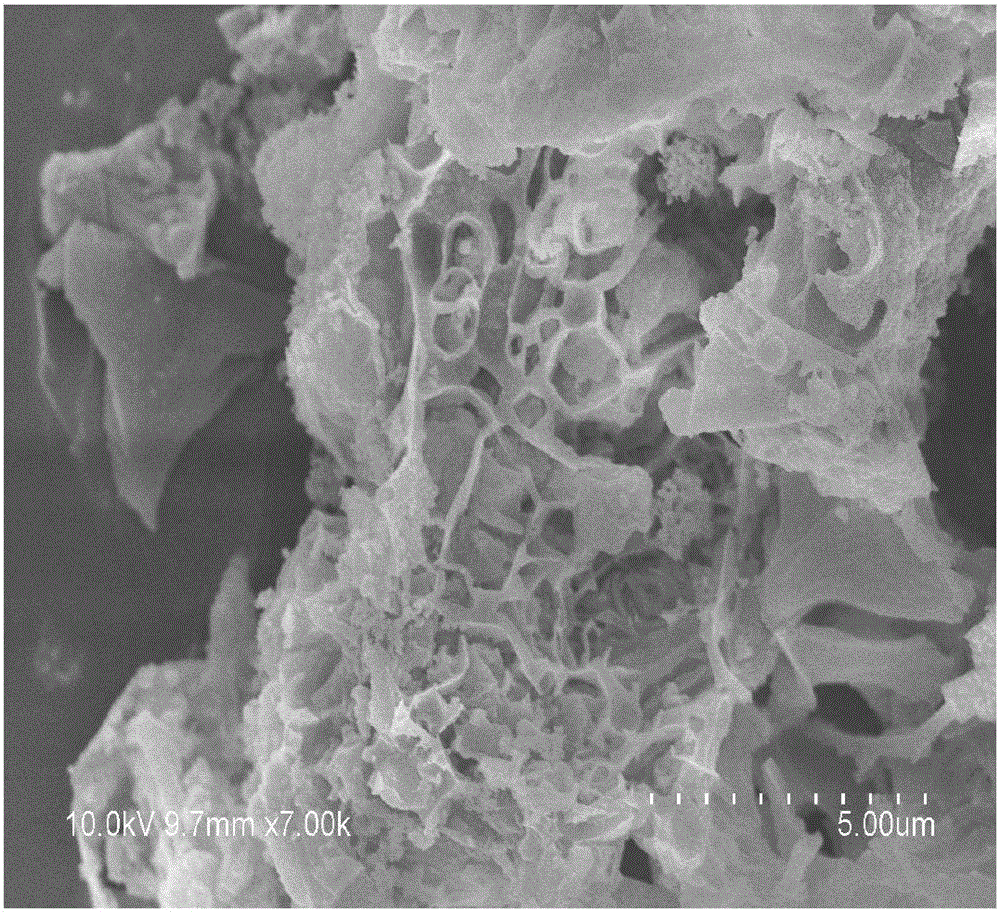

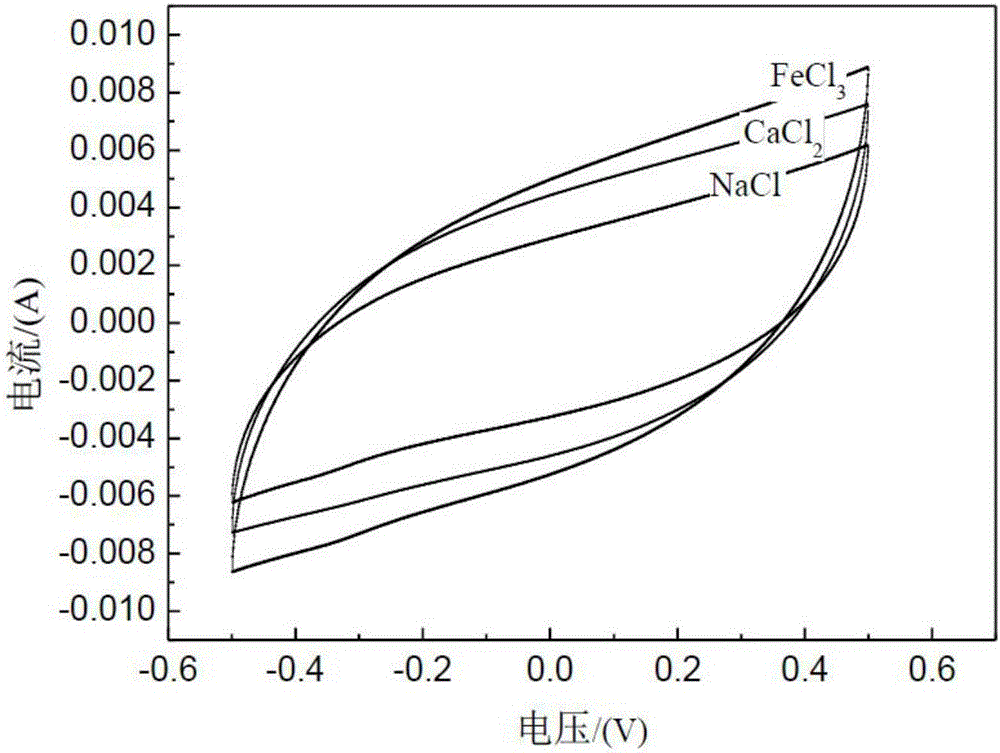

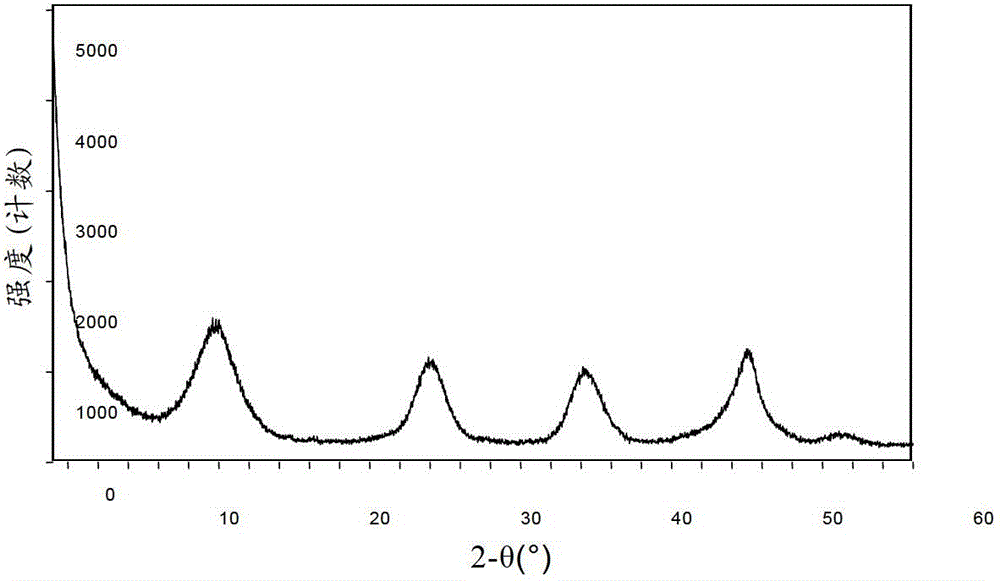

Suaeda-salsa-base porous carbon and application thereof

InactiveCN106629707ARich pore structureEvenly distributedCarbon compoundsDispersed particle separationChemistryMoisture

The invention discloses a Suaeda-salsa-base porous carbon and application thereof. The preparation method of the Suaeda-salsa-base porous carbon comprises the following steps: collecting mature-stage Suaeda salsa, cleaning with clear water, naturally airing until the moisture content is lower than 12-15%, and pulverizing to 150-200 meshes; in an inert gas protective atmosphere, heating activation temperature, and keeping the temperature constant for 120-240 minutes; and after cooling, sufficiently removing impurities by using hot mixed acid, cleaning with deionized water until the pH value is 7.0, and drying to obtain the Suaeda-salsa-base porous carbon. The salt impurities are removed from the carbonized high-salt-content plant to leave abundant pores, thereby implementing regulation on the pore size and distribution. The prepared Suaeda-salsa-base porous carbon material with abundant pore structures and uniform distribution has excellent properties when being used as an electrode active material in capacitor deionization. The Suaeda-salsa-base porous carbon has abundant raw material sources, and has important social meanings, economic value and environmental protection benefits.

Owner:YANCHENG INST OF TECH

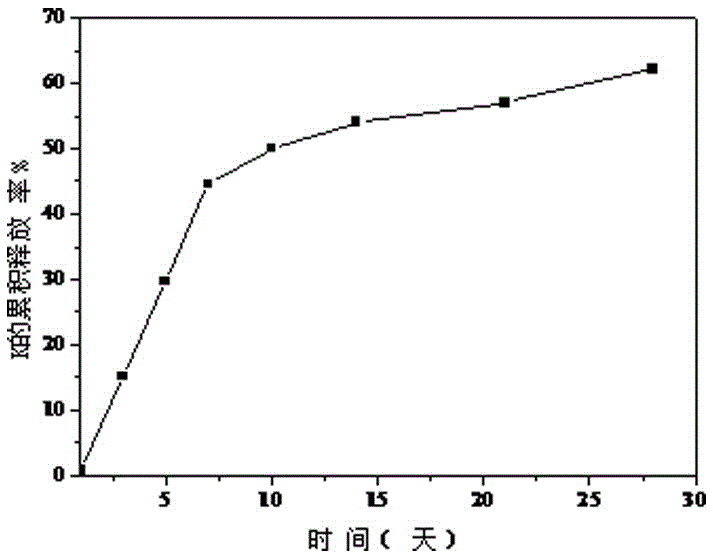

Slow release compound fertilizer via phosphoric acid passivation of magnesium slag

InactiveCN105461431ALow priceReduce energy consumptionFertilizer mixturesCalcium biphosphateMagnesium phosphate

The invention relates to the field of preparation of slow release compound fertilizers, in particular to a method for preparing a slow release compound fertilizer via phosphoric acid passivation of magnesium slag. The method, which is simple in production technology, low in cost, environmentally friendly, and high in slow release effect, comprises the following steps: a, preparation of a raw material: grinding magnesium slag, urea and industrial potassium sulfate respectively into powder, and preparing a phosphoric acid solution; b, mixing the prepared phosphoric acid solution with powder of magnesium slag, and stirring, so as to generate a calcium phosphate magnesium salt cementitious inorganic binding agent, and passivate the powder of magnesium slag; c, respectively adding powder of urea and that of industrial potassium sulfate into magnesium phosphate slag reactant obtained after a passivation reaction, and carrying out mixing granulation. The method is mainly applied to resource utilization of magnesium slag.

Owner:SHANXI UNIV

Method for high-efficiency extraction of nutrient substances in undaria pinnatifida sporophyll

InactiveCN104341233ARealize high-value comprehensive utilizationHigh extraction rateBiofuelsFermentationPectinaseIon exchange

The invention discloses a method for high-efficiency extraction of nutrient substances in undaria pinnatifida sporophyll, and is characterized in that the method comprises the following steps: (1) raw material pretreatment, (2) ultrasonic treatment, (3) cellulose enzymolysis, (4) proteolysis, (5) brine digestion, (6) dilution and filtration, (7) decoloring, (8) CaCl2 solution treatment, (9) ion exchange, (10) preparation of sodium alginate, (11) preparation of ethanol, and (12) preparation of an undaria pinnatifida sporophyll organic fertilizer. A composite enzyme is prepared from protease, pectinase and cellulase by a scientific ratio, and raw material is pretreated, so as to improve the extraction rate of sodium alginate; at the same time, fuel ethanol is prepared by using cellulose-rich undaria pinnatifida sporophyll processing waste; Chinese humic acid resources are fully developed and utilized in the processing process, the organic fertilizer rich in humic acid and macronutrients is produced with water as a solvent, and the high-valued comprehensive utilization of the undaria pinnatifida sporophyll is realized.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

Method for preparing crab seasoning using meat residue of crab processing

InactiveCN100426987CRealize high-value comprehensive utilizationAchieve separationAnimal proteins working-upFood preparationCooling downChemistry

The invention provides a process for preparing crab essence flavoring, which comprises steaming leftover bits and pieces of crab meat processing, cooling down and disintegrating, charging water, adjusting pH to 4.5-6.0, charging proteinase, stirring for enzymolysis, adjusting pH to 5.0-6.5, charging proteinase, stirring for enzymolysis, heating, filtering the residue, and allocating the filter liquor.

Owner:SOUTH CHINA UNIV OF TECH

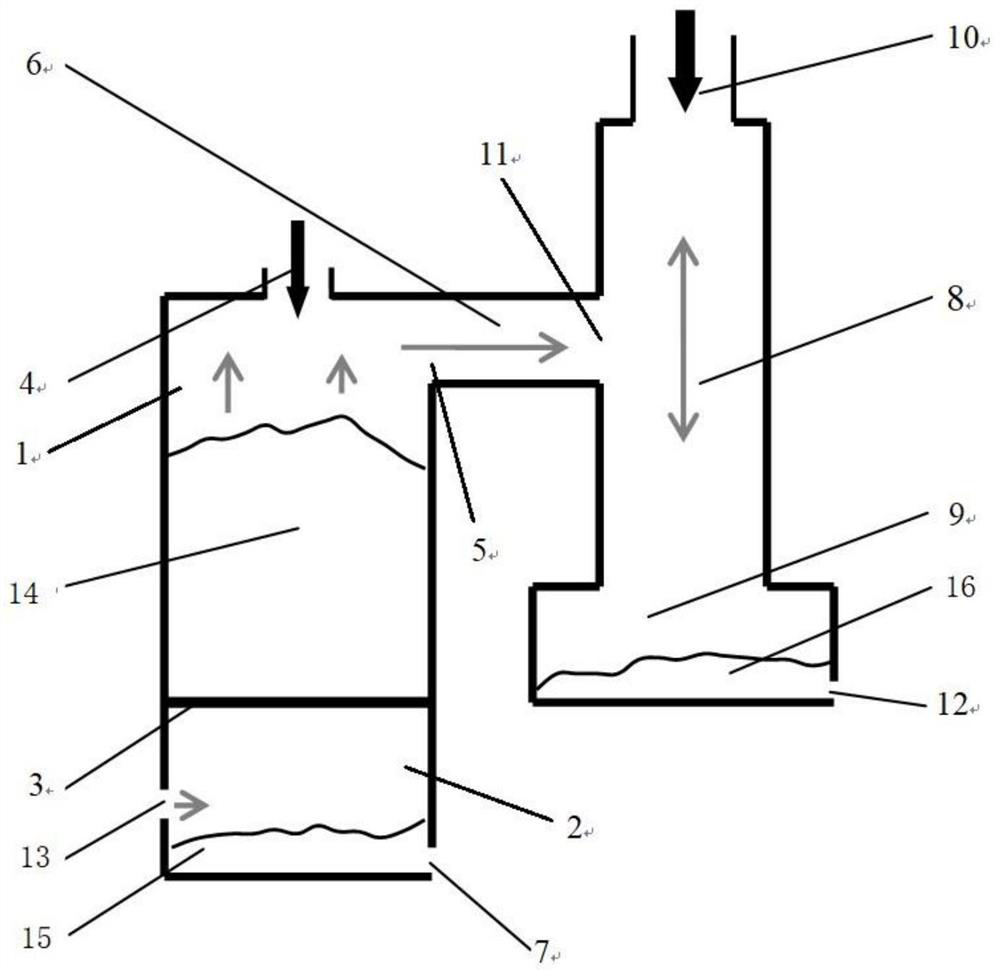

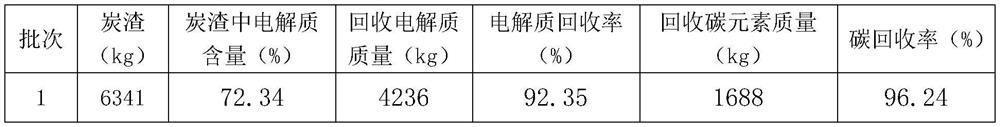

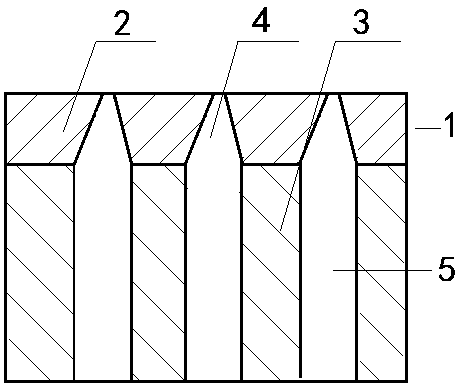

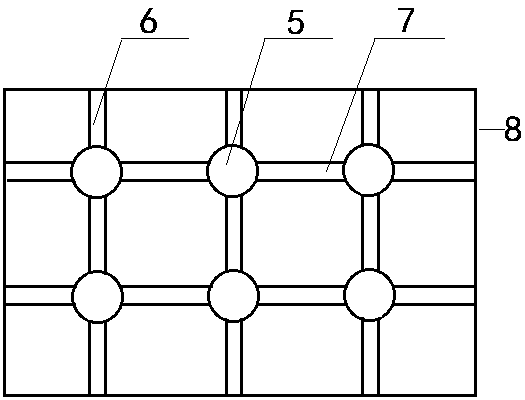

System and method for separating carbon and electrolyte in aluminum electrolysis carbon slag

ActiveCN111646454ARealize high-value comprehensive utilizationTake advantage ofCarbon preparation/purificationAluminium electrolysisFlue gas

The invention discloses a system for separating carbon and electrolyte in aluminum electrolysis carbon slag. The system comprises a carbon slag heating volatilization system, a high-temperature flue gas channel and a gaseous electrolyte collecting system; the carbon slag heating volatilization system comprises a volatilization bin and a low-fluorine carbon slag bin which are arranged from top to bottom, a latticed carbon electrode is arranged between the volatilization bin and the low-fluorine carbon slag bin, a carbon slag feeding port is formed in the top of the volatilization bin, and a flue gas outlet is formed in the side upper part of the volatilization bin and communicated with the high-temperature flue gas channel; the side part of the low-fluorine carbon slag bin is provided withan inert gas inlet, and the side lower part is provided with a low-fluorine carbon slag discharge port; the gaseous electrolyte collecting system comprises a collecting bin and an aluminum electrolysis material bin which are arranged from top to bottom, the top of the collecting bin is provided with an aluminum electrolysis material inlet, the side part of the collecting bin is provided with a flue gas inlet, and the other end of the high-temperature flue gas channel is communicated with the flue gas inlet; and an aluminum electrolysis material discharge port is formed in the side lower part of the aluminum electrolysis material bin. The system and method can realize high-efficiency separation of carbon and electrolyte in the aluminum electrolysis carbon slag, is convenient to operate, andcan easily realize continuous and large-scale operation.

Owner:中铝郑州有色金属研究院有限公司

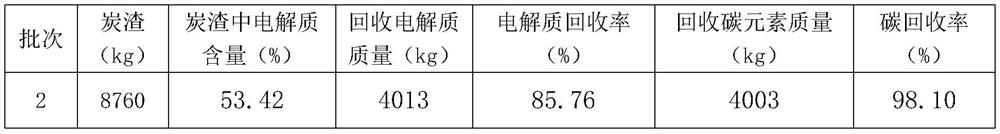

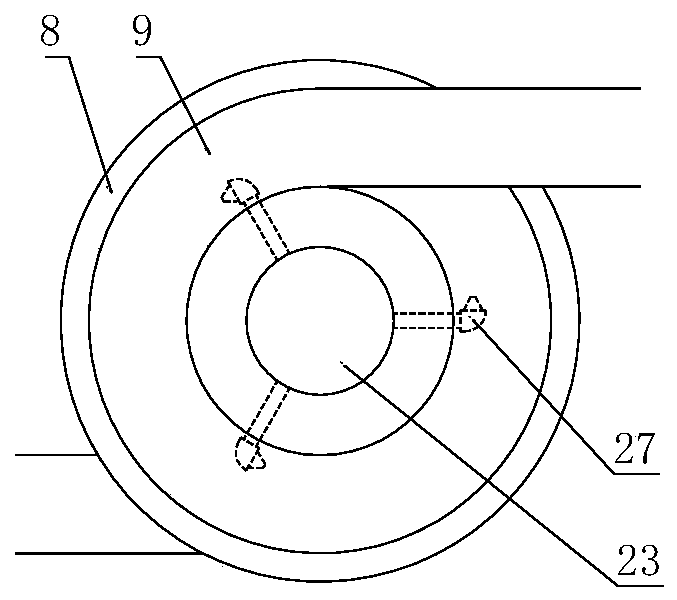

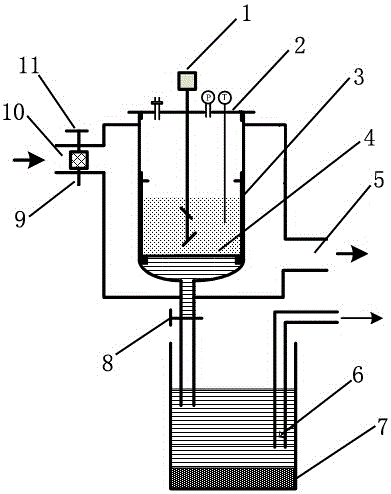

a co 2 Biomass continuous hydrothermal furfural preparation system and method under atmosphere

ActiveCN109621880BEfficient preparationImprove efficiencyOrganic chemistryChemical/physical/physico-chemical stationary reactorsSlurryFurfural

The invention discloses a system for preparing furfural from biomass through a continuous hydrothermal reaction in the atmosphere of CO2. The system comprises a raw material conveyor (6), a coil typereaction kettle (10) and a centrifugal machine (17); the raw material conveyor (6) comprises a feeding valve (4), a storage tank (5), a discharging valve (1) and a slurry conveyor (26); the coil typereaction kettle (10) is provided with a coil type reactor (9), a heating sleeve (8) sleeves the coil type reactor (9), and a CO2 pipeline (23) is arranged in the center of the coil type reactor (9); an exhaust port (16), a liquid outlet (21) and a solid phase outlet (20) are formed in the centrifugal machine (17), and the exhaust port (16) and the CO2 pipeline (23) are in butt joint. The continuous hydrothermal reaction is realized. The invention further discloses a method for preparing furfural from biomass through the continuous hydrothermal reaction in the atmosphere of CO2. The problems are solved that in an existing continuous reaction, operation is complex, and heating is not uniform, and product quality is improved effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

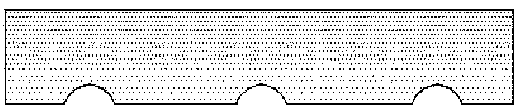

Carpet or automobile trim leftover material recycling technology and prepared lyophobic floor tile

The invention discloses a carpet or automobile trim leftover material recycling technology and a prepared lyophobic floor tile. The carpet or automobile trim leftover material recycling technology comprises the following steps that firstly, leftover materials are crushed; secondly, the leftover materials are heated to be partially melted, a plastomer is formed, and solid particles are prepared; thirdly, the small particles prepared in the second step are taken, preparing materials are added in the small particles, and mixing is uniform; and fourthly, products obtained after mixing in the thirdstep are poured into a die, pressurizing and hardening are conducted, and a finished product is obtained through demoulding. The technology input is low, benefits are high, and the application rangeis wide. The prepared lyophobic floor tile is good in water permeating effect, has elasticity, prevents skidding, and is environment-friendly, free of odor and suitable for outdoor footpaths.

Owner:褚乃博

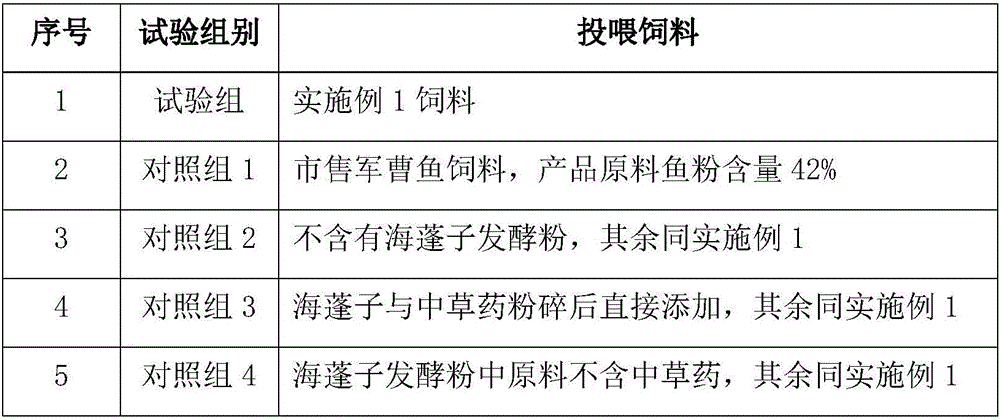

Biological method for preparing rachycentron canadum expanded compound feed by salicornia

PendingCN106721663APromote rapid growthRealize high-value comprehensive utilizationFood processingClimate change adaptationBetainePhytase

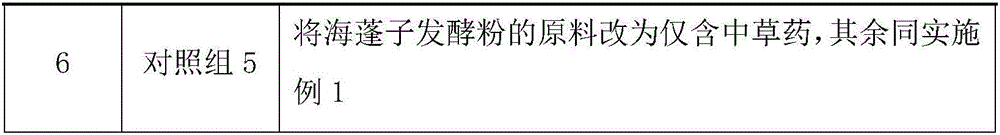

The invention discloses a biological method for preparing rachycentron canadum expanded compound feed by salicornia. The shortcoming of high fishmeal consumption of existing feed is overcome, waste materials are changed into wealth, and salicornia resources are developed and used in a high value manner. The feed mainly comprises salicornia fermentation powder, steam fish meal, fermented soybean meal, double-low rapeseed dregs, DDGS (distillers dried grains with soluble), flour, sodium alginate tech grade, sea fish oil, corn germ oil, soybean lecithin, squid ointment, choline chloride, glycine betaine, inositol, compound vitamins, compound microelements, allicin, bacillus licheniformis, bifidobacterium bifidum, phytase, non-starch polysaccharide enzyme and the like, and the salicornia fermentation powder comprises, by weight, 30 parts of yam flour, mongolian milkvetch roots, licorice roots, dried ginger, malt, bran, sugar stevia leaves and the like which prepare the salicornia fermentation powder by the aid of a two-step fermentation process. The feed has the advantages that rapid growth of rachycentron canadum is remarkably facilitated, aquaculture survival rate is increased, aquaculture cost is reduced, aquaculture digestion and absorption rate is increased, nitrogen and phosphorus discharge is reduced, aquaculture environments are improved, and the feed has high cost performance and popularization and application values.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Method for production of sodium alginate and co-production of ethanol and seaweed organic fertilizer

InactiveCN104945535ARealize high-value comprehensive utilizationHigh extraction rateFermentationOrganic fertilisersIon exchangeDigestion

The invention discloses a method for producing sodium alginate and co-producing ethanol and a seaweed organic fertilizer. The method comprises the following steps of: with brown algae kelp serving as a raw material, pre-processing through cellulase and compound protease in an enzymolysis manner; decomposing cellulose in the kelp into microbially available monosaccharide and oligosaccharide in order to ferment to produce ethanol; preparing the seaweed organic fertilizer through the rest fermentation broth with little kelp residue; extracting and separating sodium alginate from the pre-processed kelp; and then performing a dilute alkali digestion technology and a calcium coagulating-ion exchange method to obtain high-quality sodium alginate. According to the method, the preprocessing is performed through bio-enzyme, and the main components, namely, cellulose, protein and the like in the kelp, are separated in advance through the cellulose and protease, thus high extraction rate of the sodium alginate is grained; simultaneously, wastes generated in processing are utilized to prepare a fuel, namely, ethanol; and the waste liquid and waste residues remained in ethanol preparation are utilized to prepare the seaweed organic fertilizer, therefore, high-valued utilization of the kelp is realized, and marine biomass energy is developed.

Owner:QINGDAO BETTER BIO TECH

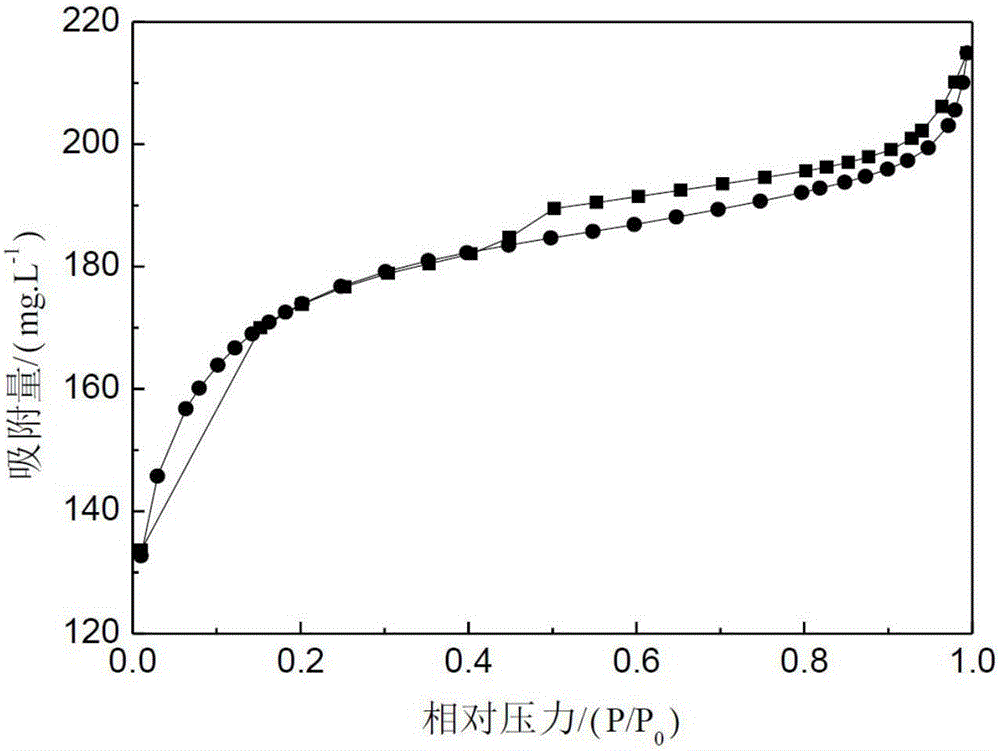

Method for preparing pseudo-boehmite co-preparation white carbon black by coal gangue

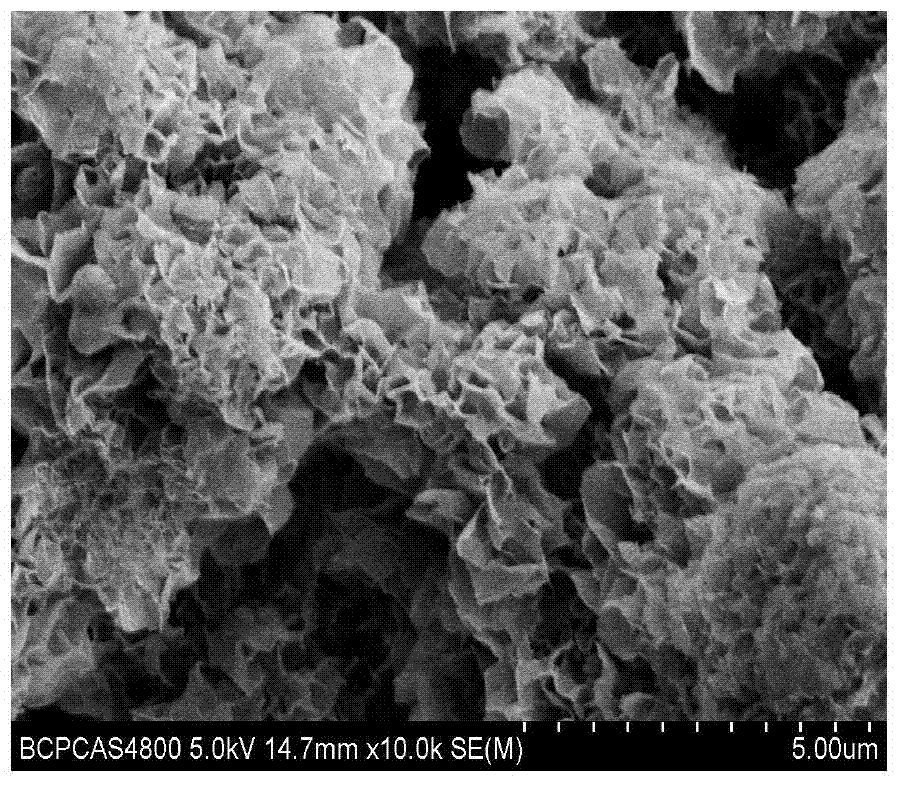

ActiveCN103145161BRealize high-value comprehensive utilizationIncrease added valueProductsSilicaGranularitySlurry

The invention provides a method for preparing pseudo-boehmite co-preparation white carbon black by coal gangue. The method comprises the steps: the coal gangue is ground, roasted, alkaline-leached and filtered so that sodium silicate solution and alkaline leaching dregs are obtained, a dispersing agent is added to the sodium silicate solution and after gas containing CO2 is fed into the solution, a white carbon black product is prepared; lime and sodium carbonate are added into the alkaline leaching dregs for sintering, clinker obtained by the sintering is water-quenched to obtain NaAlO2 solution, the gas containing CO2 is added to the NaAlO2 solution for carbonation to form glue, ageing treatment is performed to seriflux after glue forming and powder-shaped pseudo-boehmite is obtained after the aged seriflux is washed, filtered, dried and smashed. The coal gangue serves as a raw material for preparation of the pseudo-boehmite and the white carbon black so that high-valued comprehensive utilization of industry solid wastes is achieved and an additional value of a product is high; all by-products can be recovered and recycled so that zero release, low energy consumption, economy and environment protection are achieved; and a requirement for a device is low, the while coal black prepared and the pseudo-boehmite prepared are high in purity, fine and even in granularity and high in specific surface area.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

A kind of high-value extraction method of Enteromorpha

The invention discloses an enteromorpha prolifera high-valued extraction method, and is characterized in that the method comprises the following steps: (1) raw material pretreatment, (2) cellulose enzymolysis, (3) proteolysis, (4) brine digestion, (5) dilution and filtration, (6) decoloring, (7) CaCl2 solution treatment, (8) ion exchange, (9) preparation of sodium alginate, (10) preparation of ethanol, and (11) preparation of an enteromorpha prolifera organic fertilizer. A composite enzyme is prepared from protease, pectinase and cellulase by a scientific ratio, and raw material is pretreated, so as to help to improve the extraction rate of sodium alginate; at the same time, fuel ethanol is prepared by using cellulose-rich enteromorpha prolifera processing waste; the enteromorpha prolifera organic fertilizer is prepared through concentration, spray drying and granulation, so as to realize the high-valued comprehensive utilization of enteromorpha prolifera, and develop marine biological energy.

Owner:邳州德好科技有限公司

Method for co-producing organic fertilizer with peat as raw material for preparing biogas and fulvic acid

InactiveCN103352056BRealize high-value comprehensive utilizationSolve the problem of single use methodBio-organic fraction processingOrganic chemistryPeatOrganic manure

The invention discloses a co-generation method for preparing methane, fulvic acid and an organic fertilizer by taking peat as a raw material. The method comprises the following basic steps: preparing methane from peat though anerobic fermentation, extracting fulvic acid from methane fermentation residues, and further compounding, decomposing and fermenting the residues after the fulvic acid is extracted to produce the organic fertilizer rich in humic acid. The method realizes poly-generation of preparing methane, fulvic acid and the organic fertilizer from peat, solves the key problems that at present only single component of peat is utilized and the product added value of peat mainly serving as an organic fertilizer and horticultural substrate is low, and realizes high-value comprehensive utilization of peat resources.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

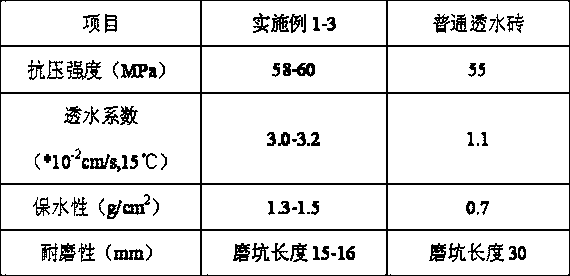

An ecological sponge brick made from waste rubber and plastic

ActiveCN107057151BRealize high-value comprehensive utilizationReduce the temperatureDomestic articlesCalcium silicatePorosity

The present invention relates to an ecological sponge brick prepared from waste rubbers and waste plastics. The ecological sponge brick comprises a surface layer and a bottom layer, wherein the surface layer is prepared from fine particle size waste rubber particles, fine particle size waste plastic particles, nanometer titanium dioxide, rare earth, calcium carbonate powder, bentonite, active alumina, polytetrafluoroethylene sintered powder, a block copolymer, calcium lignosulfonate, isomeric 13 alcohol polyether, polyoxyethylene sorbitan tristearate and a composite auxiliary agent, and the bottom layer is prepared from coarse particle size waste rubber particles, coarse particle size waste plastic particles, waste glass, bentonite, gravel, calcium silicate, a block copolymer, polyacrylamide, isomeric 13 alcohol polyether, polyoxyethylene sorbitan tristearate and a composite auxiliary agent. According to the present invention, the ecological sponge brick has characteristics of strong water permeation, high porosity, more through holes, good water retention, good skid resistance and good scale resistance, and achieves the high value comprehensive utilization of waste rubbers and waste plastics.

Owner:福建洁源循环经济研究院有限公司

A method for preparing sodium alginate and organic fertilizer from sargassum

ActiveCN104341534BHigh extraction rateRealize high-value comprehensive utilizationFertilizer mixturesPectinaseFiber

The invention discloses a method for preparing sodium alginate and organic fertilizer from Sargassum algae, which is characterized in that the method comprises the following steps: (1) raw material pretreatment (2) fiber enzymatic hydrolysis (3) protein enzymatic hydrolysis ( 4) Salt water digestion (5) dilution filtration (6) decolorization (7) CaCl2 solution treatment (8) ion exchange (9) preparation of sodium alginate (10) preparation of Sargassum organic fertilizer. The invention uses protease, pectinase and cellulase to make compound enzyme according to the scientific ratio, and pretreats the raw materials, which is beneficial to improve the extraction rate of sodium alginate; fully develops and utilizes the humic acid resources in my country, and produces Water is the solvent, organic fertilizer rich in humic acid and macronutrients. The high-value comprehensive utilization of wakame spore leaves has been realized.

Owner:万物生(深圳)生物科技控股有限公司

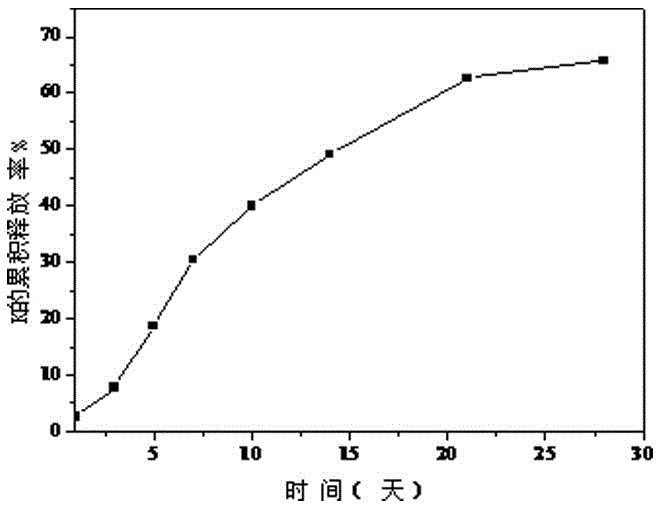

Method for preparing farmland chemical fertilizer sustained-release agent and potash fertilizer by using biomass incineration ash

ActiveCN105936512AEfficient extractionRealize high-value comprehensive utilizationAlkali metal nitrate preparationNitrate fertilisersStart upBinary compound

The invention discloses a method for preparing a farmland chemical fertilizer sustained-release agent and a potash fertilizer by using biomass incineration ash, wherein the method comprises the following steps: 1, taking a certain amount of biomass ash, placing on an ash frame, then smoothly putting into a reaction kettle, injecting a nitric acid solution with the mass ratio of 25-40%, closing with a cover of a reaction kettle, and checking sealing; 2, starting up a stirrer of the reaction kettle; heating the reaction kettle; keeping stirring for 10-12 min at the temperature of 180-220 DEG C and the pressure of 1.5-1.6 MPa; 3, opening a discharge valve at the bottom of the reaction kettle, and allowing a high-temperature solution to enter a cooling pond, wherein a cooling liquid is a KNO3 saturated solution at room temperature; and after the cooling liquid is cooled, collecting a precipitated KNO3 coarse crystal salt; 4, removing the ash frame of the reaction kettle, collecting a residual solid ash matter, and adding lime to adjust the pH to 6-8, to obtain the farmland sustained-release agent; and 5, extracting a supernatant of the cooling pond to prepare a nitric acid solution, restarting the step 1, and carrying out circulating production. The method can realize efficient rapid extraction of the potassium element in the biomass ash to prepare the binary compound fertilizer and preparation of the good chemical fertilizer sustained-release agent.

Owner:黑龙江炭和科技研发有限公司

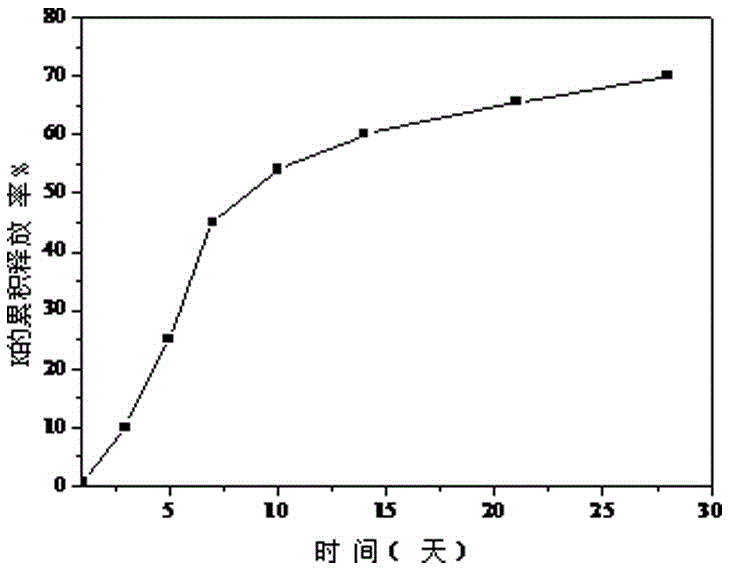

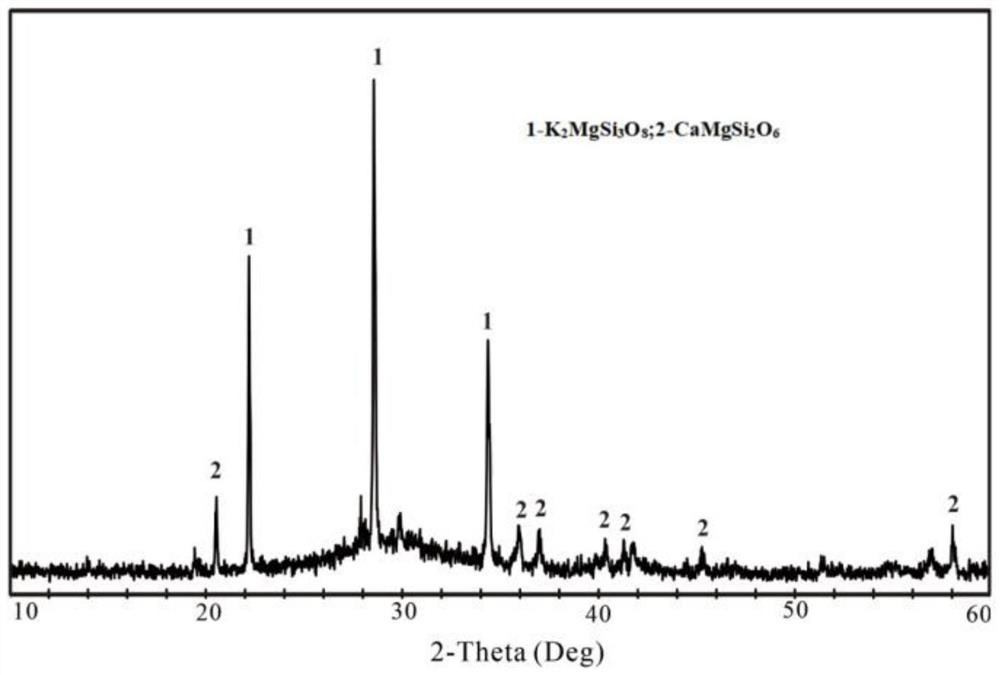

Method for preparing mineral type potassium-magnesium-silicon slow-release fertilizer from nephrite tailings

PendingCN114804963AAchieve long-term releaseIncrease profitSolid/semi-solid fertilisersPotassium fertilisersPotassiumEngineering

The invention discloses a method for preparing a mineral type potassium-magnesium-silicon slow-release fertilizer by using nephrite tailings, which comprises the following steps: S1, preparing raw materials, namely 3.30-5.00 parts of nephrite tailings, 0-3.04 parts of quartz sand and 3.77-5.72 parts of potassium carbonate, cleaning the prepared raw materials by using clear water, and after the raw materials are cleaned, drying the nephrite tailings, the quartz sand and the potassium carbonate by using a drying machine to obtain dried nephrite tailings, quartz sand and potassium carbonate; s2, putting the designed raw material components into a ball mill, mixing for 5-7 minutes, then taking out powder, carrying out sampling detection on the taken-out powder, and after sampling detection, screening the powder through a screening device to ensure that no large-particle raw material exists, S3 and S4. The potassium, magnesium, calcium and silicon compounds are prepared by mixing and sintering the raw materials, the potassium element can be properly limited in a silicate skeleton structure, and meanwhile, elements in the tailings are properly activated, so that the effect of releasing the potassium, magnesium, calcium and silicon elements for a long time is achieved, the utilization rate of the fertilizer is improved, and high-value comprehensive utilization of the nephrite tailings is realized.

Owner:河北地质大学

Microwave activation of coal gangue to prepare geopolymer material and method thereof

ActiveCN113429137BDoes not affect heat treatmentEfficient implementation of heat treatmentRecuperative heat exchangersCement productionPhysical chemistryGeopolymer

Owner:北京荣露材料科技有限公司

A special molten salt patch for adsorbing vocs solid waste regenerative boiling combustion furnace

ActiveCN107413304BLarge surface adhesionReduce pollutionGas treatmentOther chemical processesP-tert-ButylphenolSodium sulfate

The invention relates to the technical field of waste gas treatment of volatile organic compounds, in particular to a special molten salt patch for adsorbing VOCs solid waste heat storage boiling combustion furnace, which is characterized in that it includes the following components: circulating fluidized bed coal-fired boiler fly ash 100 parts, 10-15 parts of potassium sulfate, 15-20 parts of sodium sulfate, 3 parts of stainless steel fiber, 3 parts of p-tert-butylphenol formaldehyde resin, the components are calculated in parts by weight. Can effectively purify Cl in high temperature flue gas ‑ , SO 2 , particles and other pollutants, protect the metal components on the heating surface to avoid and reduce high-temperature corrosion and erosion wear, and prolong the life of the metal components on the heating surface.

Owner:山东信开源科技创新发展有限责任公司

A preparation method of special molten salt patch for absorbing vocs solid waste regenerative fluidized combustion furnace

ActiveCN106964325BLarge surface adhesionReduce pollutionGas treatmentOther chemical processesCombustionFlue gas

The invention relates to the technical field of volatile organic compound waste gas treatment, in particular to a preparation method of fused salt patch for adsorbing VOCs solid waste and special for a thermal-storage fluidized combustion furnace. The preparation method is characterized by comprising the steps of mixing based on a roller press, press forming, stationary ageing mixture, curing and drying, vacuum sintering and the like. Pollutants containing Cl-, SO2 and particulate matter in high temperature flue gas can be effectively purified, high-temperature corrosion and erosion abrasion to heated-surface metal components are avoided and decreased, and the service life of the heated-surface metal components is prolonged.

Owner:常州市富利环保科技有限公司 +1

A method for collaborative resource utilization of carbide slag and fly ash

ActiveCN104495899BShort processZero emissionAlkaline-earth metal silicatesCement productionCalcium silicateSludge

The invention provides a method for synergic resource utilization of acetylene sludge and coal ash. The method comprises the following steps: carrying out magnetic separation, acid leaching and filtering on coal ash to obtain an aluminum sulfate solution and acidic leaching residues, carrying out evaporative concentration and cooling crystallization on filtrate to obtain an aluminum sulfate crystal; carrying out alkaline leaching and filtering on the acidic leaching residues to obtain a sodium silicate solution and alkaline leaching residues, and carrying out cleaning and activation on the acetylene sludge to prepare lime milk which is subjected to hydro-thermal synthesis with the sodium silicate solution, and drying and dehydrating to prepare active calcium silicate powder, wherein the alkaline leaching residues can be directly used for preparing building materials after being dehydrated. According to the invention, by adopting the method for producing aluminum sulfate co-production active calcium silicate through synergic resource utilization of the acetylene sludge and coal ash, high-value utilization of large quantity of industrial solid wastes can be realized, and the production added value is high; all byproducts can be recycled, zero discharge is realized, energy consumption is low, and economical efficiency and environmental protection are achieved.

Owner:陕西龙湘科创节能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com