Patents

Literature

158 results about "P-tert-Butylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

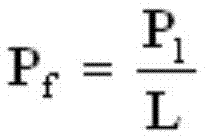

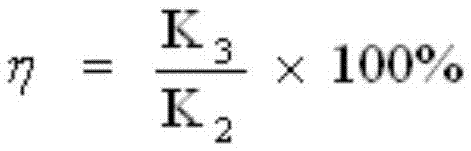

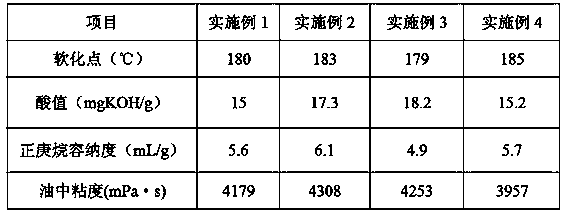

Oil-soluble hydraulic fracture temporary plugging reorientation agent and preparation method thereof

ActiveCN105441047AStrong temporary blocking abilityWide softening point rangeDrilling compositionSolubilityAdhesive

The invention provides an oil-soluble hydraulic fracture temporary plugging reorientation agent with the breakthrough pressure gradient higher than 50 MPa / m. The oil-soluble hydraulic fracture temporary plugging reorientation agent comprises a fluidity regulator, a toughener, a heat stabilizer, a colorant and the balance of an oil-soluble adhesive, wherein the oil-soluble adhesive has an adhesion function, can deform under the actions of the formation temperature and pressure and be adhered to crack and rock surfaces to realize plugging, particularly adopts one or two of rosin modified pentaerythritol resin, rosin modified phenolic resin, p-tert-butylphenol-formaldehyde resin and petroleum resin. The invention further provides a preparation method of the oil-soluble hydraulic fracture temporary plugging reorientation agent. The fracture temporary plugging reorientation agent has the characteristics of good oil solubility, adjustable softening point and applicability to deflection fracturing modification of a low-permeability reservoir oil well at different temperatures.

Owner:SHAANXI XINGYOU TECH DEV CO LTD

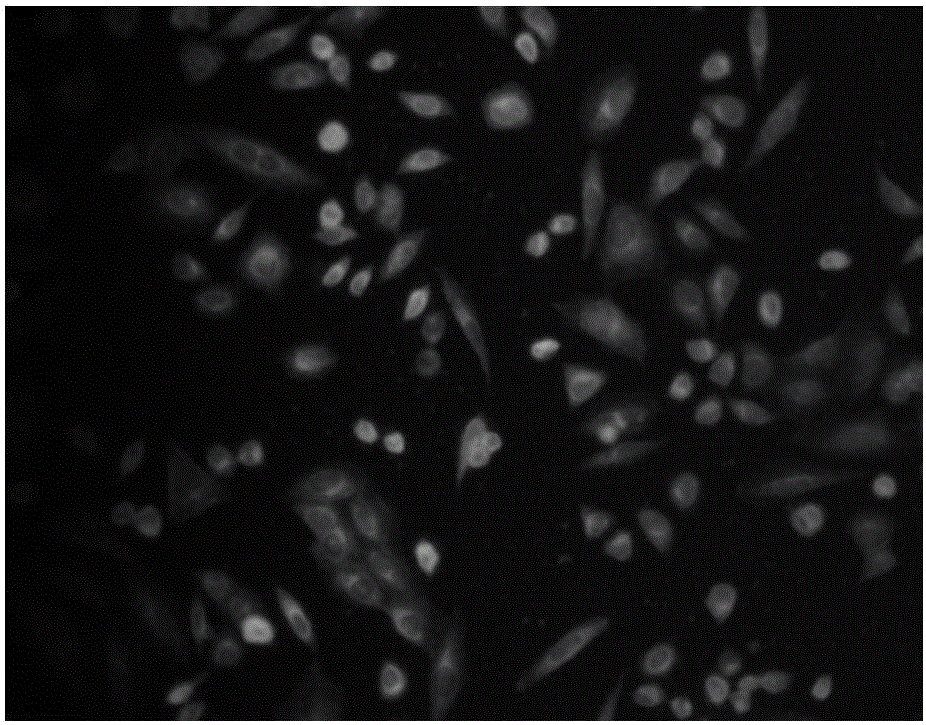

Preparation method and application of mercaptan fluorescence probe based on coumarin

The invention discloses a preparation method and application of a mercaptan fluorescence probe based on coumarin. The preparation method includes: coumarin and p-tert-butylphenol dialdehyde are used as raw materials to synthesize a bis-Schiff base coumarin derivative (compound I), the compound I has strong fluorescence, and the compound I is coordinated with copper ions to prepare coumarin-copper ion (II) complex, namely the mercaptan fluorescence probe I-Cu (II). Due to the influence of the paramagnetism of Cu2+ and photoinduction electron transfer effect, the fluorescence of the compound I is quenched; sulfur atoms in compounds such as mercapto-amino acid and derivatives such as glutathione thereof and Cu2+ have a strong coordination effect, the competitive coordination effect allows the copper ions in the coumarin-copper ion (II) complex to be taken away by the mercapto-amino acid and the derivatives thereof so as to regenerate the compound I, and the fluorescence of the compound I is restored. Accordingly, a method for fast and simply detecting mercaptan compounds is built.

Owner:XINXIANG MEDICAL UNIV

Preparation of rosen modified mixed alkyl phenolic resin

The present invention belongs to the field of resin preparation technology that is a kind of connecting material to printing ink. It is obtained with processed by the following steps: arbitrarily mixing p-methyl hydroxybenzene, p-tert-butylphenol, p-tex-octylphenol and p-nonylphenol, making them produce reaction with formaldehyde to synthesize A-stage mixed alkyl phenolic resin, then using rosin to make modification and using polyhydric alcohol to make esterification. Said invention is easy to operate, safe, and its resin oil-solubility and fatty hydrocarbon solubility are good. Its colour islight and softening point is high. The printing ink made up by using said invented product does not skin, and possesses good printing property.

Owner:山西省应用化学研究所

Toughening method of poly(3-hydrox butyrate) and poly(3-hydroxy butyrate-3-hydroxy pentanoate)

The present invention relates to a toughening method of poly(3-hydroxy butyrate) and poly(3-dydroxy butyrate-3-hydroxy pentanoate). The raw material includes the first component of poly(3-hydroxy butyrate) or poly(3-dydroxy butyrate-3-hydroxy pentanoate) with 3-hydroxy pentanoate monomer molar content less than 20%; the second copmonent of p-tert-butylphenol, bisphenol A, bisphenol S or 2,4,6-tri(2'-hydroxy-4'-butoxyphenyl)-1,3,5- triazine; and the optional component including plasticizer and stuffing. The weight ratio between the first component and the second component is 70-90 to 10-30 andthe optional component is 0-30 wt% of the first component. By means of solution blending or melting blending, modified material with excellent toughness may be obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

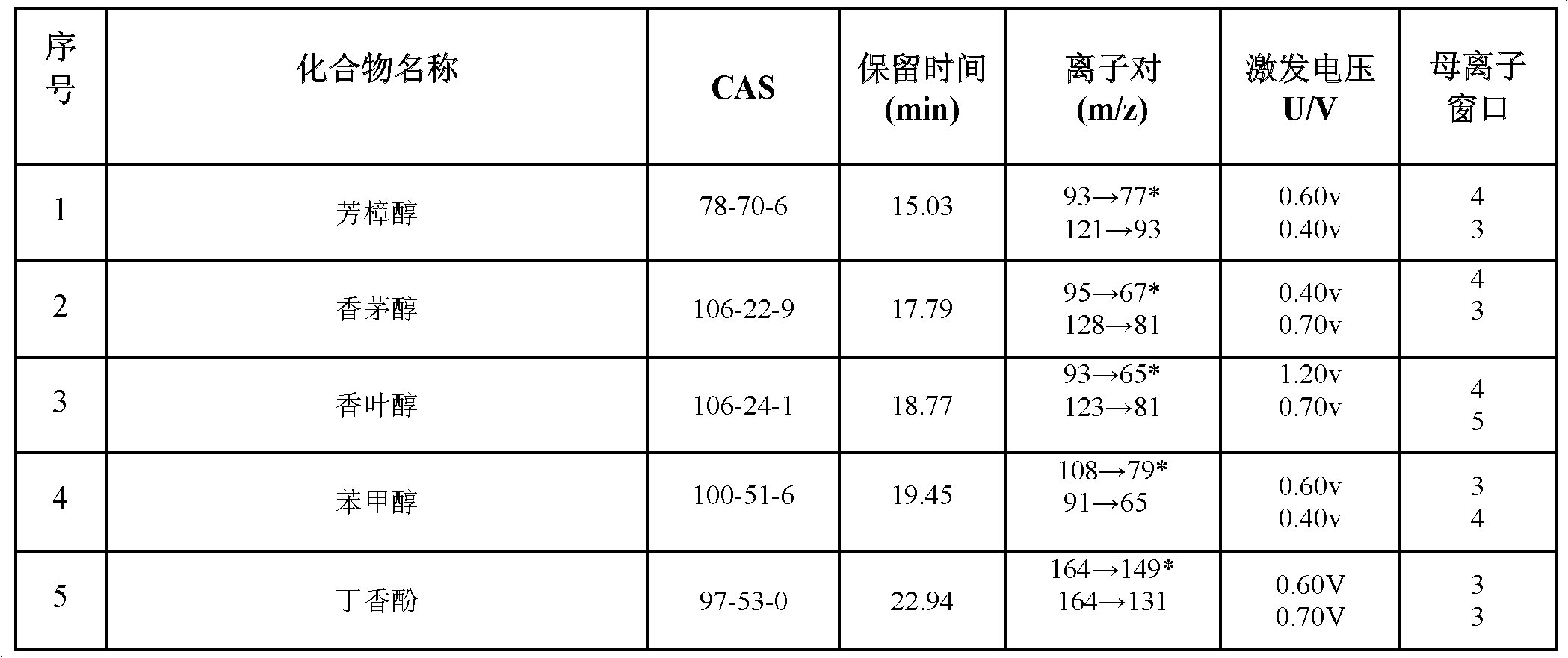

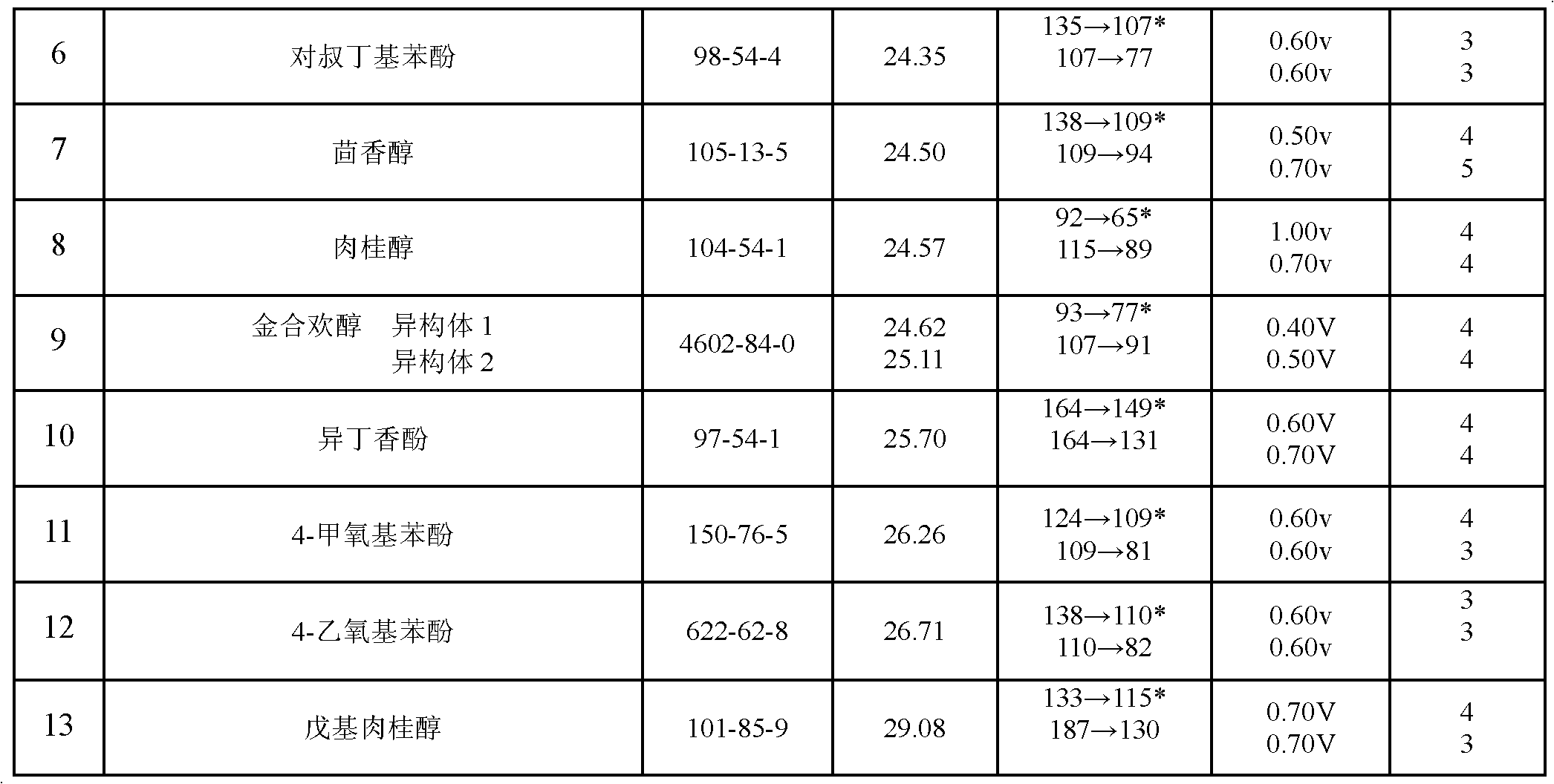

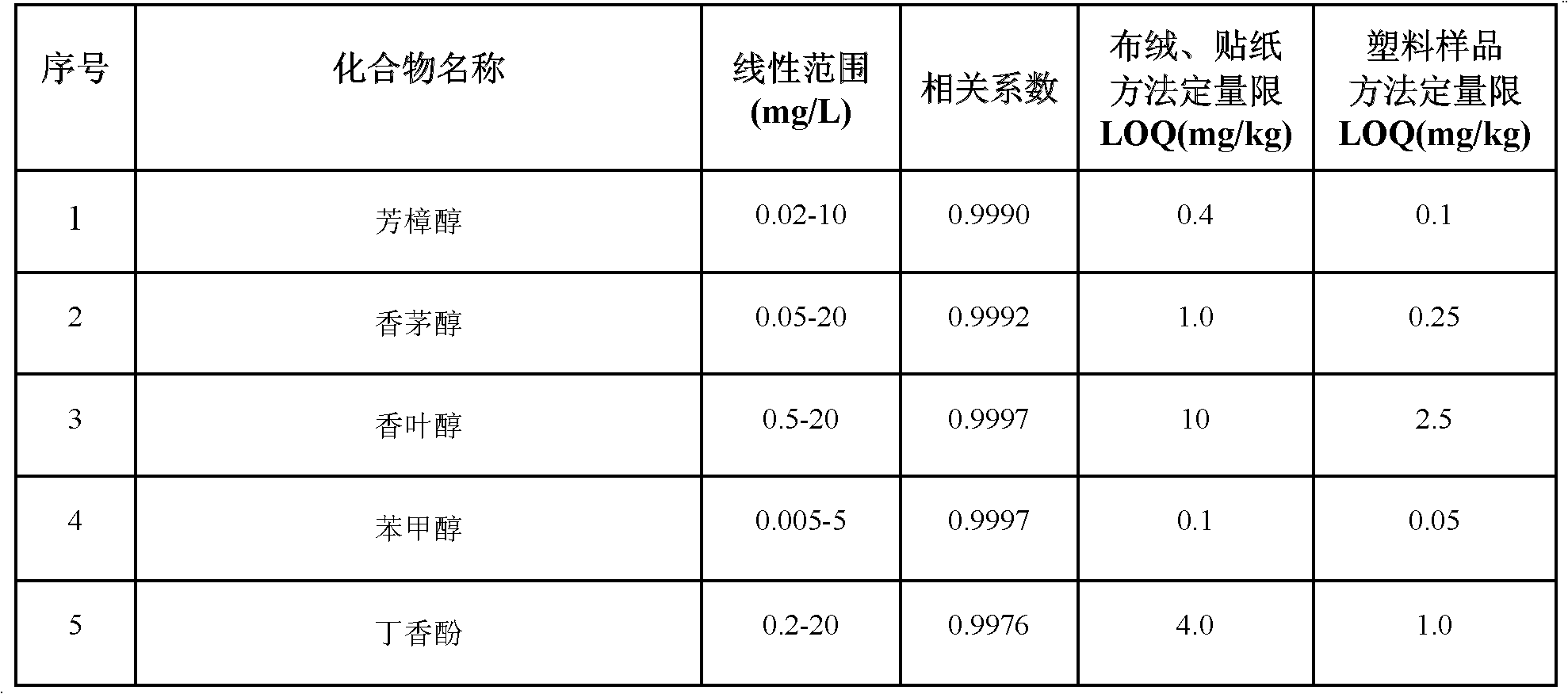

Method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in toy

InactiveCN103105438AApplicable AnalysisHigh sensitivityComponent separation4-MethoxyphenolIsoeugenol

The invention relates to a method for simultaneously detecting residual amounts of 13 phenolic alcohol sensitization aromatics in a toy. The method realizes simultaneous detection of 13 phenolic alcohol sensitization aromatics such as benzyl alcohol, linalool, 4-methoxyphenol, citronellol, geraniol, 4-ethoxyphenol, anise alcohol, p-tert-butylphenol, cinnamyl alcohol, eugenol, isoeugenol, amylcinnamyl alcohol and farnesol in a toy for the first time by the gas chromatography-ion trap tandem mass spectrometry technology, and fills the technical gap. The method can be used for detecting plush toys, paster toys and plastic toys (prepared from ABS, PVC and PS materials), and has a wide application range and strong applicability. The ion trap tandem mass spectrometry realizes qualification and quantification by two-stage mass spectrometry MS / MS and thus the method has good qualification and quantification effects on a toy sample having a complex matrix.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

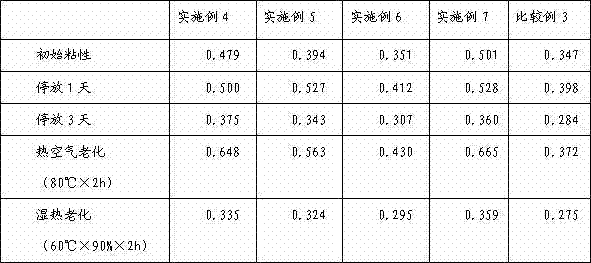

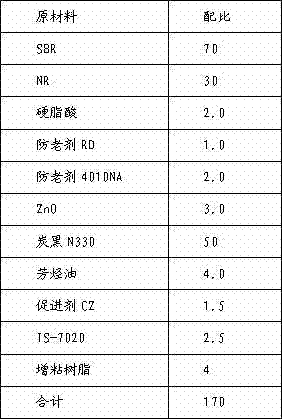

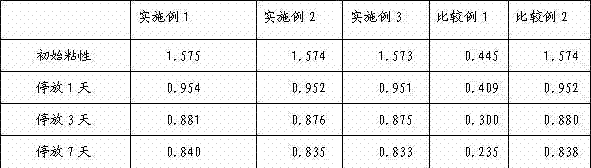

Preparation method of copolymerization condensation resin

The invention discloses a preparation method of copolymerization condensation resin. The preparation method is characterized by comprising the following steps of: 1) putting para-position alkylphenol and other phenols, aldehydes, amines and catalysts, and carrying out reaction for 1-5 hours at the temperature of 60-160 DEG C; and 2) after the reaction is finished, carrying out distillation and concentration, and maintaining the temperature to be 140-220 DEG C until the temperature of a softening point is 90-145 DEG C. The preparation method disclosed by the invention has the beneficial effects that firstly the copolymerization condensation resin prepared by adopting the preparation method disclosed by the invention has improved adhesiveness and the viscosity retention rate is excellent, the copolymerization condensation resin also has the effect of enhancing a bonding force between rubber and a framework material, and the tackifying effect of the copolymerization condensation resin is equivalent to that of p-tert-butylphenol acetylene resin and is better than that of the existing alkylphenol formaldehyde tackifying resin; and secondly a production process is simple, and industrial production is easy to achieve.

Owner:徐川大

Multifunctional crude oil tank farm treating agent

ActiveCN103275753AReduce contentReduce dirty oil contentDewatering/demulsification with chemical meansDiethylene glycol monobutyl etherSolubility

The invention relates to a multifunctional crude oil tank farm treating agent which is prepared by the following raw materials in percentage by weight: 55%-65% of a modified polyether demulsifying agent, 10%-15% of a synergist, 3%-5% of a dispersant and 20%-30% of a solvent, wherein the modified polyether demulsifying agent is one or a plurality of nonyl phenolic resin polyether, nonyl phenol aldehyde resin polyether, tertiary butyl phenolic resin polyether and tertiary butyl phenol amine aldehyde resin polyether polymerized by nonyl phenol, m-dinonylphenol or p-tert-butylphenol as an initiator, or a condensation product of the nonyl phenol, the m-dinonylphenol, the p-tert-butylphenol, vinylamines and methanal as the initiator with propylene epoxide and ethylene oxide; the synergist is a non-ionic surface active agent; the dispersant is polyacrylic acid or polyacrylamide; and the solvent is one or a plurality of diethylene glycol monobutyl ether, terpene or naphtha. The multifunctional crude oil tank farm treating agent is suitable for pretreating of various types of temporary stored or long-term stored crude oil entering the tank farm. A product has oil solubility, and the usage amount is low.

Owner:沈红新 +1

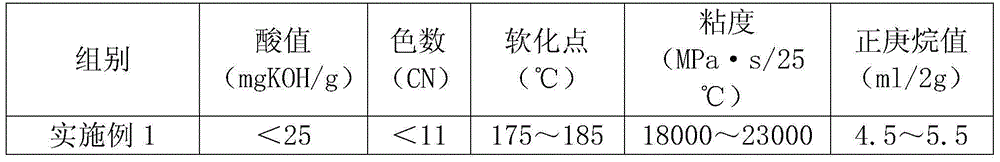

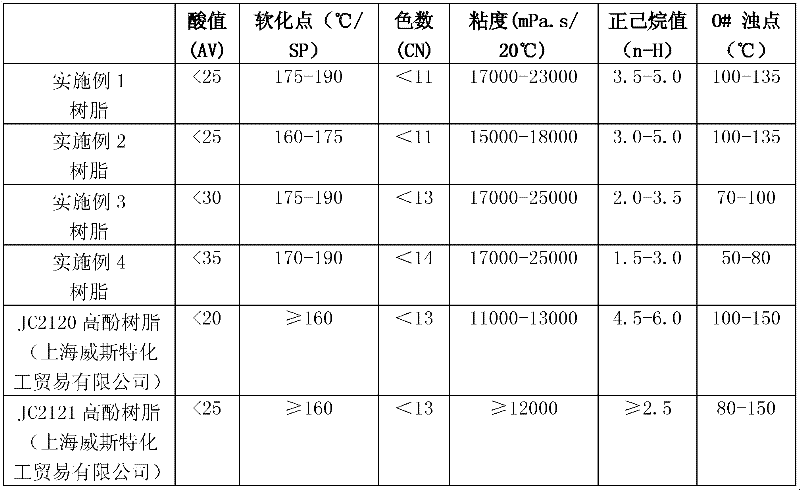

Preparation method for vegetable oil modified rosin phenolic resin

The invention provides a preparation method for vegetable oil modified rosin phenolic resin. The preparation method comprises the following steps of firstly, feeding rosin into a reaction kettle, raising the temperature to be 180DEG C, adding vegetable oil, continuously raising the temperature to be 210 to 215DEG C and keeping the temperature for 1 to 1.5 hours, and carrying out addition reaction; secondly, feeding pentaerythritol and magnesium oxide into the reaction kettle, reducing the temperature to be 160 to 170DEG C, feeding dodecylphenol and p-tert-butylphenol according to the mole ratio of 1:1.01 to 1.03, then continuously reducing the temperature to be 120 to 130DEG C, feeding paraformaldehyde according to the mole ratio of phenol to aldehyde being 1:2.0 to 2.1, and keeping the temperature for 2 to 2.5 hours; thirdly, raising the temperature in the reaction kettle to be 260 to 270DEG C, keeping the temperature, carrying out esterification reaction until an acid value is smaller than 25mgKOH / g, and carrying out reduced pressure distillation to obtain a low-boiling-point substance, namely the vegetable oil modified rosin phenolic resin. The resin prepared by the preparation method provided by the invention has the advantages of high viscosity, good solubility, high molecular weight, uniformity in distribution and suitability for offset lithography of ink.

Owner:桂林兴松林化有限责任公司

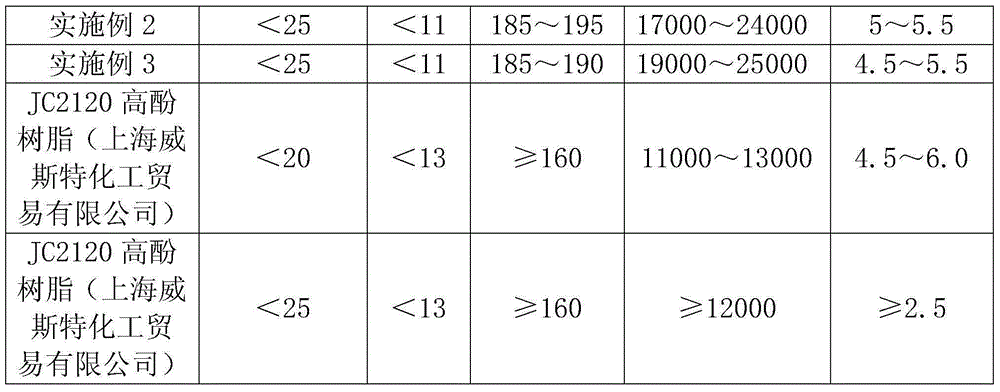

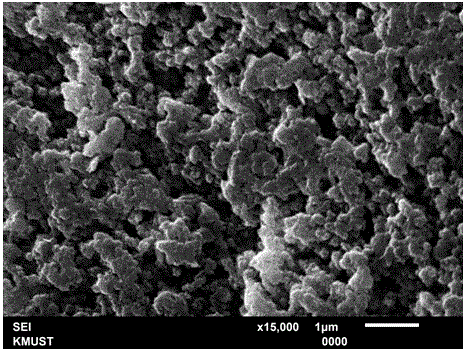

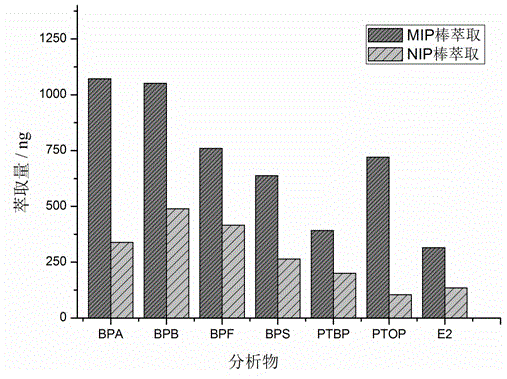

Preparation method of molecular imprinting sorptive extraction stirring bar by using alternative template

InactiveCN104923191AWith detachableSolve wear and tearOther chemical processesPreparing sample for investigationWater bathsFunctional monomer

The invention relates to a preparation method of a molecular imprinting sorptive extraction stirring bar by using an alternative template, belonging to the technical field of analytical chemistry and sample pretreatment. The method includes firstly using p-tert-butylphenol as a template molecule, dissolving the template molecule and a functional monomer in a solvent, uniformly mixing by ultrasound and standing, then adding a crosslinking agent and an initiator to obtain an assembly solution, and removing oxygen by ultrasound; injecting the assembly solution into a glass capillary with an inner diameter of 1.4mm, then inserting into a glass capillary with an outer diameter of 1.0mm, performing water bath heating for polymerization, removing the larger glass capillary, taking out the small glass capillary, cutting into appropriate length with a blade, inserting a iron core and sealing ends, sleeving silicon tubes on both ends, and cleaning with methanol, to obtain the molecular imprinting sorptive extraction stirring bar using p-tert-butylphenol as the alternative template. The obtained stirring bar can be applied to extraction analysis of trace amount of environmental estrogen bisphenol A in a water sample.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of mixed phenolic rosin modified phenolic resin

The invention discloses a preparation method of mixed phenolic rosin modified phenolic resin. Under the alkaline conditions, p-tert-octyl phenol, p-nonylphenol and p-tert-butylphenol react with formaldehyde to obtain a mixed phenolic solvent type phenolic resin condensation product, and in the presence of a catalyst, the condensation product undergoes rosin modification and mixed polyalcohol esterification to form the phenolic resin. The mixed polyalcohol comprises glycerol and pentaerythritol. The prepared phenolic resin is high in softening point and good in viscosity, the miscibility of a solvent is good, the color is light, the molecular weight distribution is uniform, and the phenolic resin is suitable for manufacture of printing ink and is suitable for components of ink for offset printing or intaglio printing.

Owner:桂林兴松林化有限责任公司

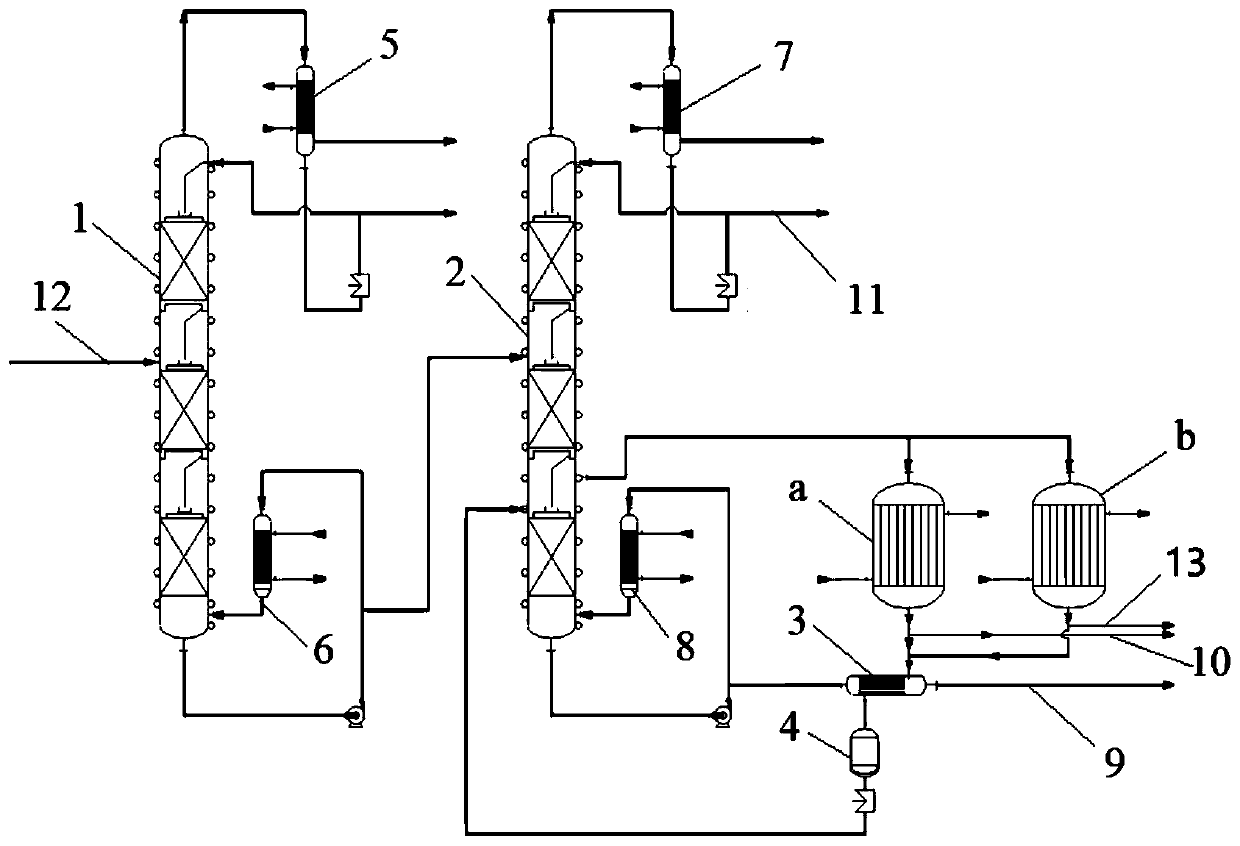

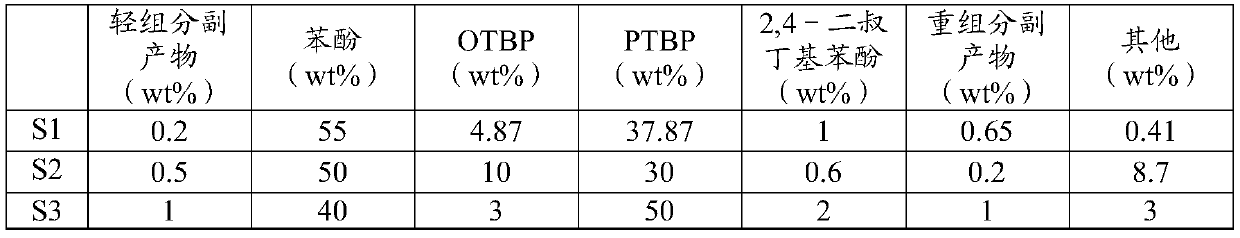

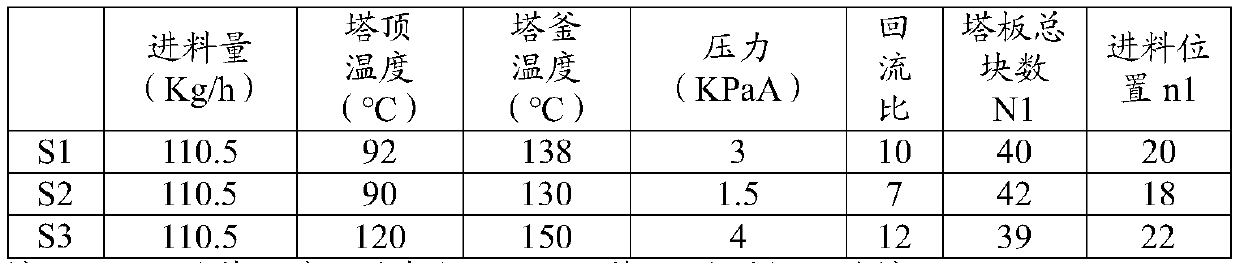

Method of producing o-tert-butyl phenol and p-tert-butyl phenol through combination of rectification and crystallization

ActiveCN110746276ARealize industrialized continuous productionReduce equipmentOrganic chemistryOrganic compound preparationTert butyl phenolP-tert-Butylphenol

The invention discloses a method of producing o-tert-butyl phenol and p-tert-butyl phenol through combination of rectification and crystallization. The method comprises the steps that (1) an alkylatedproduct flow obtained through a reaction between phenol and isobutene is input into a first rectifying tower for rectification treatment, a first tower top material which contains the phenol and a light-component byproduct is extracted from the tower top, and a first tower bottom material which contains the o-tert-butyl phenol, the p-tert-butyl phenol and a heavy-component byproduct is extractedfrom the tower bottom; (2) the first tower bottom material is input into a second rectifying tower for rectification treatment, an OTBP product is extracted from the tower top, a second side-line material which contains the p-tert-butyl phenol is extracted from a side line, and a second tower bottom material which contains 2,4-di-tert-butyl phenol and a heavy-component byproduct is extracted fromthe tower bottom; and (3) the second side-line material is input into a crystallization unit, so that the p-tert-butyl phenol in the second side-line material is cooled and crystallized, and after impurities are separated, the temperature is increased for fusing and discharging to obtain a PTBP product. According to the method, through coupling of the rectification technology and the crystallization technology, the problem of eutectic point limitation can be broken, and the product purity is effectively improved.

Owner:WANHUA CHEM GRP CO LTD

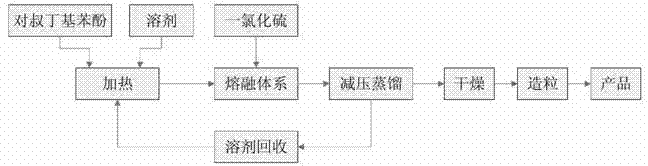

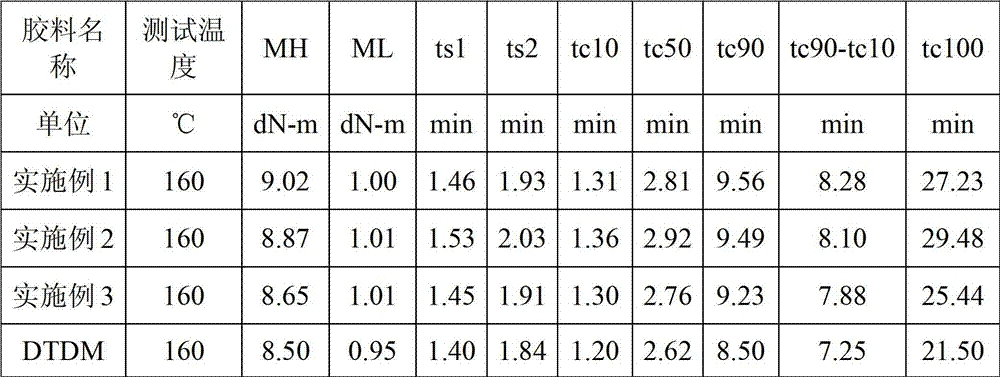

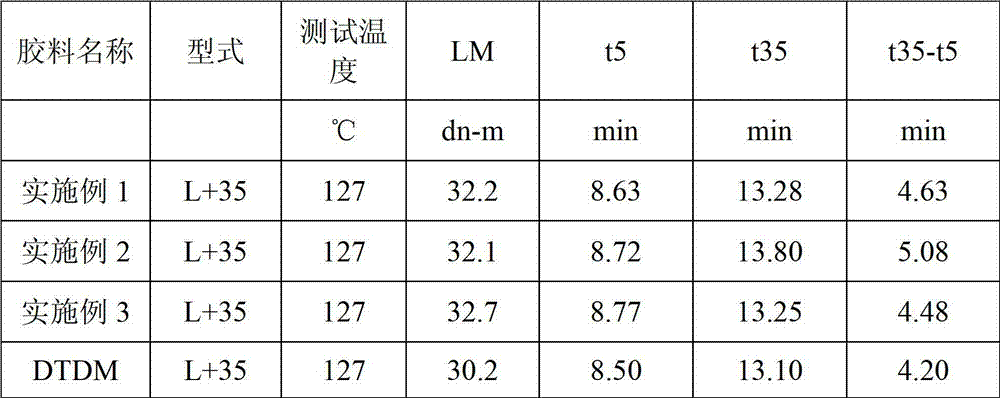

Preparation process of P-tert-butylphenol disulphide vulcanilzer

InactiveCN102964282AEasy to operateLow equipment requirementsHydropoly/poly sulfide preparationAlkaneBisulfide

The invention relates to a preparation process of P-tert-butylphenol disulphide vulcanilzer and belongs to the technical field of preparation methods of rubber auxiliary. The P-tert-butylphenol disulphide vulcanilzer is synthesized by reaction of P-tert-butylphenol and sulphur chloride in liquid phase alkane solvent, the P-tert-butylphenol disulphide vulcanilzer is heated in the solvent until solid is completely dissolved, sulphur chloride is dropwise added into a system, reduced pressure distillation is directly carried out after reaction is completely finished, and the solid after distillation is directly subjected to pelleting, so that the target product is obtained. The preparation process provided by the invention is easy to operate, equipment requirement is low, production cycle is short, and the alkane is used for substituting trichloro ethylene to be taken as reaction solvent, so that the preparation process provided by the invention is environment-friendly, safe and applicable to industrial production.

Owner:阳谷华泰(北京)新材料科技有限公司

Anti-tear cable material used for high-speed railway motor train unit and preparation method of anti-tear cable material

The invention discloses an anti-tear cable material used for a high-speed railway motor train unit and a preparation method of the anti-tear cable material. The anti-tear cable material used for the high-speed railway motor train unit comprises the following raw materials in parts by weight: 67 to 89 parts of polyurethane rubber, 22 to 36 parts of styrene-butadiene rubber, 15 to 25 parts of thermoplastic polyester elastic bodies, 4 to 8 parts of vinyl silicone oil, 17 to 26 parts of fumed silica, 3 to 6 parts of cadmium carbonate, 2 to 3 parts of lauroyl peroxide, 1.5 to 2.5 parts of triallyl isocyanurate, 1 to 2 parts of ammonium benzoate, 3 to 5 parts of poly-alpha-olefin, 5 to 10 parts of tert-butyl phenolic tackifying resin, 2 to 4 parts of triethylhexanoin, 10 to 15 parts of methylpentachlorostearate, 14 to 18 parts of carbon nano tubes, 10 to 15 parts of a diopside powder, 1 to 2 parts of 4,4'-dithiodimorpholine, 0.5 to 1 part of P-tert-butylphenol, and 20 to 25 parts of a composite flame retardant. The cable material provided by the invention combines the advantages of the raw materials such as the polyurethane rubber, the styrene-butadiene rubber, and the thermoplastic polyester elastic bodies, the tearing strength of a conventional cable material is improved, and the cable material is enabled to have excellent tear resistance, has the effect of bearing relatively great mechanical external force, and has the advantages of excellent chemical stability, heat resistance and age resistance, and long service life.

Owner:ANHUI KANGLIYA CO LTD

Treatment method of water polluted by mercury

ActiveCN104150634AReduce mercury levelsProcessing speedWater contaminantsMultistage water/sewage treatmentHydrogen SulfateP-tert-Butylphenol

The invention relates to the field of water treatment, and in particular relates to a treatment method of water polluted by mercury. The method comprises the following steps: (1) regulating the pH value of mercury-containing sewage to be 6-6.5, and adding sodium alcohol ether sulfate and sodium hypochlorite into the mercury-containing sewage, wherein the additive amount of sodium alcohol ether sulfate accounts for 1-2 times of the mass concentration of mercury in the sewage, and the additive amount of sodium hypochlorite accounts for 3-5 times of the mass concentration of mercury in the sewage; (2) regulating the pH value of the sewage to be 8-9, and then adding poly p-tert-butylphenol disulfide, ferrous sulfide and sodium hydrogen sulfate into the sewage under the conditions that the mass ratio of p-tert-butylphenol disulfide to ferrous sulfide to sodium hydrogen sulfate is (1-2) to (2-4) to 5, and the mass concentration of poly p-tert-butylphenol disulfide in the sewage is 1-5%; (3) then adding a flocculating agent, calcium oxide and alkylphenol polyoxyethylene into the sewage under the conditions that the mass ratio of the flocculating agent to calcium oxide to alkylphenol polyoxyethylene is 1 to 3 to 2, and the additive quantity of the flocculating agent is 0.1-0.3% of the quantity of the sewage; (4) standing the sewage for 3-5 days in a separation tank, and then performing solid-liquid separation; (5) adsorbing the separated sewage by adopting an activated carbon absorber, and then discharging the sewage.

Owner:ZHEJIANG OCEAN UNIV

Synthetic method of novel tackifying resin

The invention relates to a synthetic method of a novel tackifying resin. By adopting the synthetic method, phenolic hydroxyl is partially or completely removed; and a new substituent group with larger steric effect is led in, so as to synthesize the novel tackifying resin with a brand-new structure. The resin has better water-resisting property than p-tert-Butylphenol formaldehyde resin, octyl phenolic resin, modified alkyl phenolic resin, tertiary phenol acetylene resin, rosin modified phenolic resin, petroleum resin, terpene resin and the like, can prevent tearing, and can be widely applied to the industries such as plastic, paint, and adhesive, and has better economic benefit and market prospect.

Owner:于文明

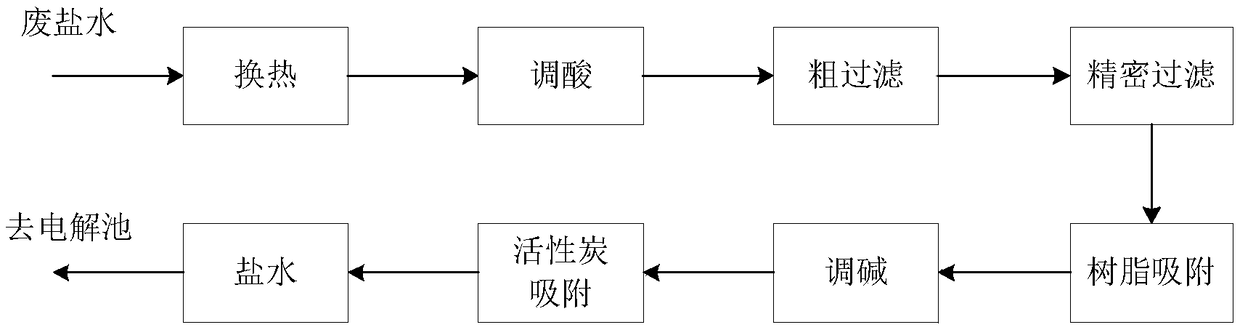

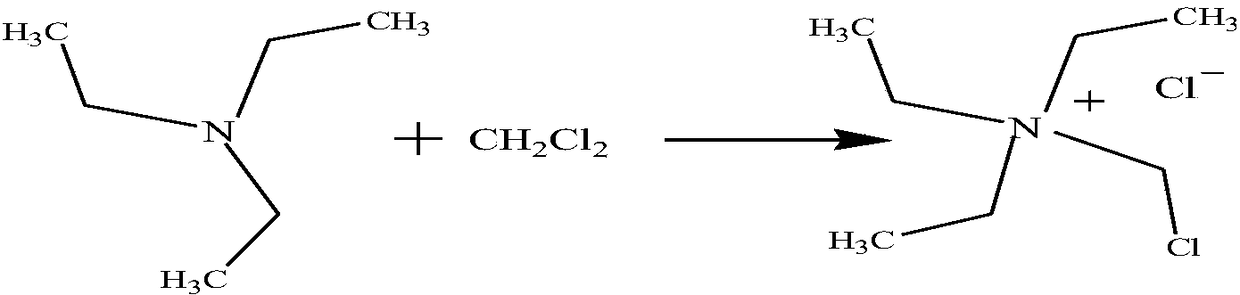

Treatment method for waste salt water generated in production process of polycarbonate

InactiveCN109231544AAchieving zero emissionsSolve pollutionWater contaminantsTreatment involving filtrationAlkali ionsP-tert-Butylphenol

The invention relates to a treatment method for waste salt water generated in the production process of polycarbonate. The treatment method comprises the following steps: the temperature of the wastesalt water generated in the production process of the polycarbonate PC and containing bisphenol A, p-tert-butylphenol and quaternary ammonium salt is regulated to 20-60 DEG C by a heat exchanger, thenthe waste salt water is introduced into an acid-regulating kettle, and the pH value is regulated to 1-4; then trace suspended solids are removed by a coarse filter and a precise filter, and the wastesalt water is conveyed to a high-position groove; the waste salt water flows into macroporous resin adsorbing columns by gravity to be adsorbed, then enters an alkaline-regulating kettle, and the pHvalue is regulated to 10-14; finally, the waste salt water enters active-carbon adsorbing columns to be adsorbed. The treatment method has the beneficial effects that phenolic organic matters in the waste salt water of the PC can be completely removed, and most of quaternary ammonium salt is removed; in the treated salt water, the content of the quaternary ammonium salt is less than 1ppm, the content of TOC (Total Organic Carbon) is less than 10ppm and the content of TN (Total Nitrogen) is less than 3ppm; as a raw material, the treated salt water can be used for a process for preparing causticsoda by a chlor-alkali ion membrane, and can not cause increase of voltage of an electrolytic cell, so that sodium chloride and water in the waste salt water can be recycled, and the recycling of thematerials is realized.

Owner:QINGDAO UNIV OF SCI & TECH +2

Jacket with high wear resistance and for underground-rail cable and preparation method of jacket

The invention discloses a jacket with high wear resistance and for an underground-rail cable and a preparation method of the jacket. The preparation method comprises the following steps: nano-silica and an emulsifier are mixed, the mixture is heated in a water bath at 50-60 DEG C, a dispersing agent is added after the water bath heating is performed for 1-1.5 h, centrifugal treatment is performed after the water bath heating is performed continuously at 70-80 DEG C for 30-40 min, filter residues obtained after filtering are washed and dried, and nano-filler M is obtained; the nano-filler M, a silane coupling agent KH560, ethyl alcohol and water are mixed, then first heat treatment and second heat treatment are performed respectively, and modified nano-filler N is obtained; the nano-filler N, polyethylene, epoxy resin, cellulose nitrate, p-tert-butylphenol formaldehyde resin, acrylic resin and ethyl acetate are mixed, and the jacket is obtained after extrusion molding. The problems of poorer wear resistance and the like of a common jacket are solved.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

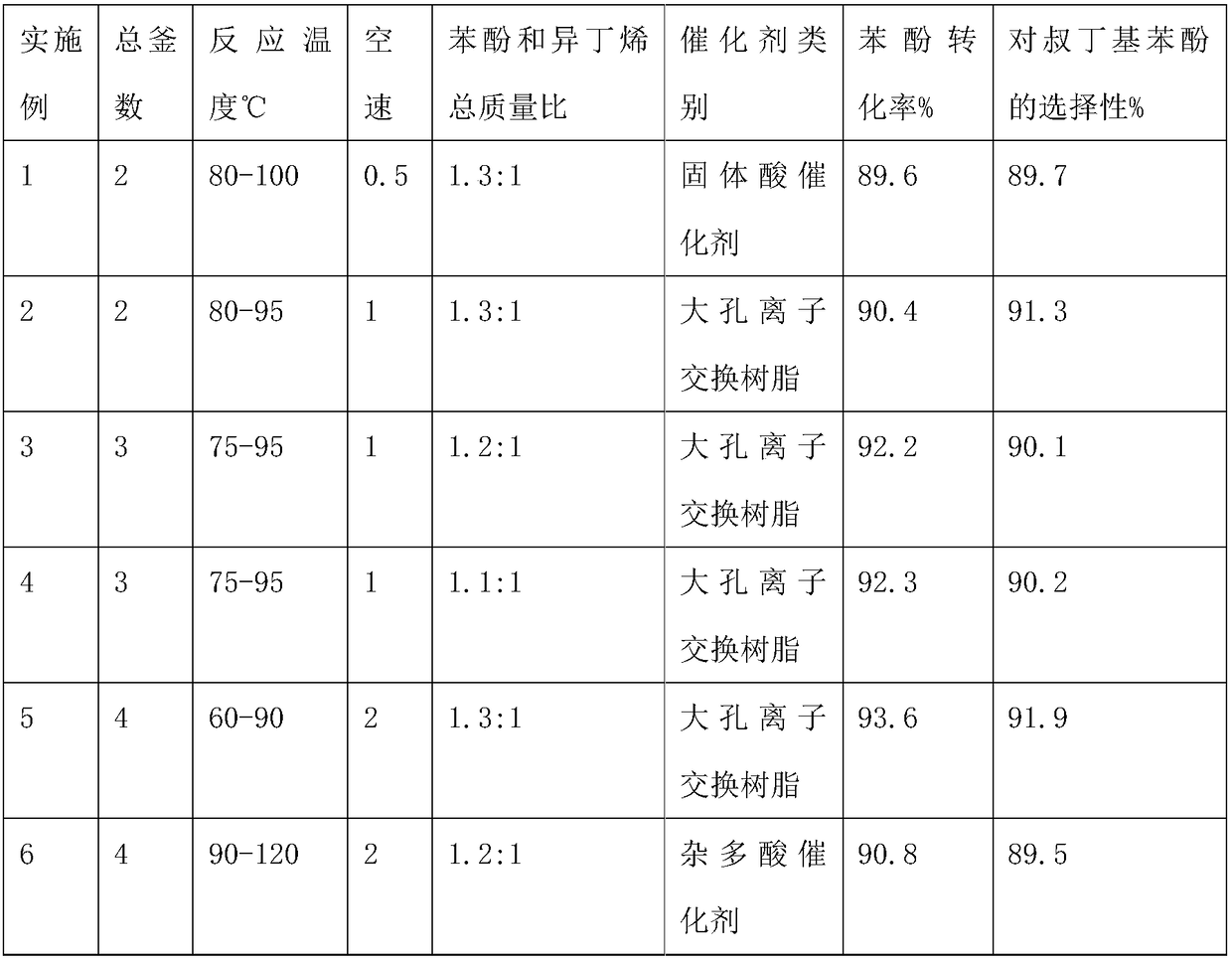

Industrial continuous process for preparation of p-tert-butylphenol

InactiveCN108558611AGood choiceImprove conversion rateOrganic chemistryOrganic compound preparationP-tert-ButylphenolWastewater

The invention discloses an industrial continuous process for preparation of p-tert-butylphenol. According to the process, phenol and isobutene are used as raw materials and allowed to pass through a fixed-bed reactor under the action of a catalyst, wherein continuous operation via multiple tandem kettles is carried out in the fixed-bed reactor; phenol is added from a first kettle; isobutene is added in a manner of multi-kettle continuous introduction; a reaction device is directly connected with a rectification device for separation of the raw materials and a product; the raw materials are returned to a catalytic tower for continuous operation; and the product is directly connected with a product storage tank after rectification. The method has the beneficial effects of good selectivity, high conversion rate, high yield, and almost no wastewater during production.

Owner:QINGDAO UNIV

Preparation method of rosin modified phenolic resin

The invention discloses a preparation method of rosin modified phenolic resin, and relates to the technical field of phenolic resin. The preparation method includes the steps that phenol and aluminum chloride anhydrous are added to a reaction still, temperature rises, polymerized formaldehyde is added while the solution is stirred, the solution is adjusted to be alkaline, temperature rises, and reaction is conducted, wherein the phenol is one or more of cresol, P-tert-butylphenol and dodecylphenol; rosin is added for modification, temperature rises, and reaction is conducted; polyhydric alcohols and metaphosphoric acid are added, and temperarure rise and reaction are conducted in stages, wherein polyhydric alcohols are one or more of pentaerythritol, xylitol and sorbitol. The rosin modified phenolic resin is good in viscosity, better in oil solubility, high in softening point, and suitable for planographic or intaglio printing ink.

Owner:GUANGXI ZHONGCHANG RESIN

Special cable for oil platform

InactiveCN106380647AImprove mechanical propertiesExcellent hot air aging performanceRubber insulatorsMelamine phosphatePolyvinyl chloride

The invention discloses a special cable for an oil platform. The special cable comprises a cable core and a sheath, wherein a modified nitrile rubber composite material is prepared from the following raw materials in parts by weight: 100 parts of nitrile rubber, 38 to 43 parts of ethylene propylene diene rubber, 2 to 5 parts of ethylene-vinyl acetate, 2 to 8 parts of chlorinated polyethylene, 0.5 to 2 parts of stearic acid, 0.5 to 3 parts of zinc oxide, 1 to 2 parts of p-tert-butylphenol-formaldehyde resin, 0.5 to 2 parts of DCBP, 0.5 to 1.5 parts of trimethylol-propane trimethacrylate, 3 to 15 parts of silicon aluminum carbon black, 2 to 10 parts of nanosilicon dioxide, 3 to 15 parts of aedelforsite, 3 to 15 parts of polyvinyl chloride, 1 to 5 parts of melamine phosphate, 2 to 10 parts of 6-chloro-N,N-diethyl-1,3,5-triazine-2,4-diamine, 10 to 30 parts of phosphorus silicon and nitrogen fire retardants, 1 to 2.5 parts of diethylene glycol distearate, 1 to 3 parts of 2-deoxy-2,2 difluoro-pentofuranose-1-ketone-3,5-dibenzoate, 1 to 3 parts of anti-aging agents, 0.5 to 2 parts of accelerants and 0.5 to 2 parts of silane coupling agents. The special cable for the oil platform provided by the invention has the advantages that the mechanical property is excellent; the aging-resistant and low-temperature-resistant performance is good; the fire-resistant and oil-resistant performance is excellent.

Owner:重庆三峡电线电缆科技股份有限公司

Method for manufacturing phenol resin using ion exchange resin as catalyst

The present invention discloses a method for synthesizing phenol resin ion exchange resin as catalyst. Said method includes: using 5% hydrochloric acid to treat macroporous cation exchange resin, when the exchange equivalent determined is 3.0-5.0 mg equivalent / g, using lots of distilled water to wash exchanged resin to neutrality, filtering and removing free water, pouring the resin into disk, drying at 90-120 deg.C in drying over for stand-by; mixing phenols of phenol, bisphenol A and p-tert-butylphenol, etc. and aldehydes of formaldehyde and acetaldehyde, etc. according to the mole ratio of1:0.5-1:2, and under the catalysis of the hydrogen-type macroporous cation exchange resin according to weight percentage of 15-50%, in the presence of solvent toluene or xylene or in non-solvent system.

Owner:夏红元

Rubber material for motor cushion block

InactiveCN105482198AImprove hydrophobicityImprove mechanical propertiesRubber materialHexamethylenetetramine

The invention discloses a rubber material for a motor cushion block. The rubber material is prepared from, by weight, 40-80 parts of nitrile butadiene rubber, 15-30 parts of cis-rich butadiene rubber, 30-40 parts of isoprene rubber, 1-3 parts of zinc oxide, 0.5-1.5 parts of magnesium oxide, 1.5-2.5 parts of p-tert-butylphenol-formaldehyde resin, 0.5-1.2 parts of accelerant CZ, 0.5-1.5 parts of hexamethylenetetramine, 40-50 parts of carbon black, 20-40 parts of calcined clay, 15-35 parts of nano-vermiculite, 10-30 parts of modified nano-montmorillonite, 5-15 parts of glass fiber, 10-30 parts of heavy calcium carbonate, 5-12 parts of grain graphite, 1-3 parts of antiager 4010NA, 1-3 parts of antiager IPPD, 1-3 parts of antiager D and 1-3 parts of coal tar. The rubber material is good in hydrophobic performance and mechanical performance, resistant to high temperature and ageing and long in service life.

Owner:崇夕山

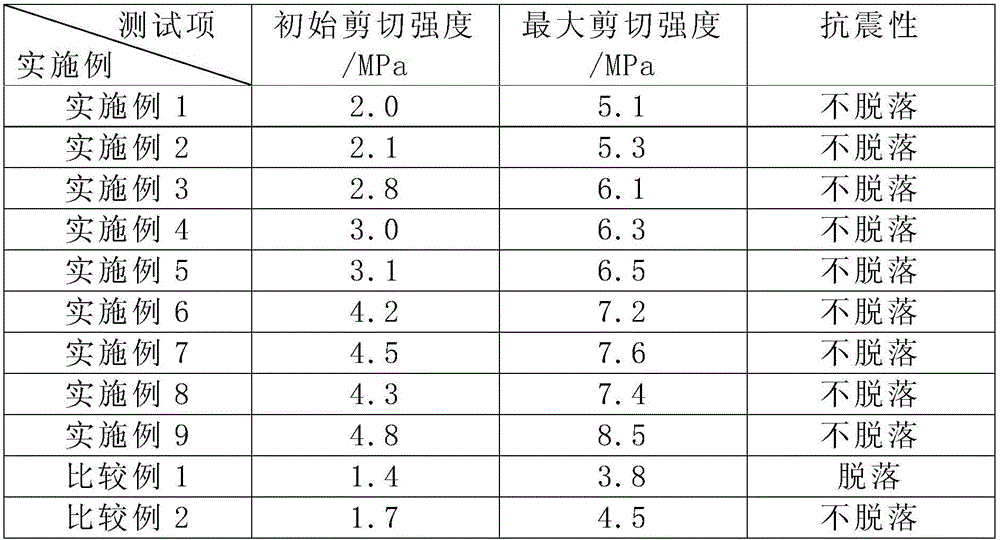

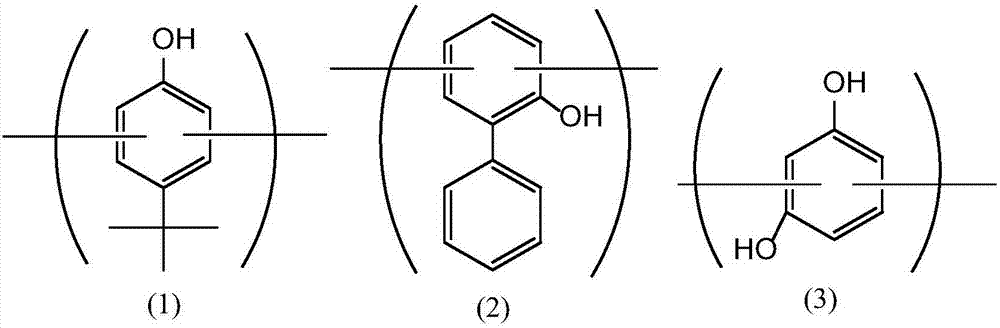

Cocondensate and method for producing same, and rubber composition containing cocondensate

Provided are: a cocondensate having a softening point of 150 DEG C or lower and containing a structural unit derived from p-tert-butylphenol, a structural unit derived from o-phenylphenol, and a structural unit derived from resorcin; a method for producing the cocondensate by reacting a mixture of p-tert-butylphenol and o-phenylphenol with formaldehyde in the presence of an alkali, and then performing reaction with a 0.8-fold molar quantity or more of resorcin with respect to the total amount of p-tert-butylphenol and o-phenylphenol; and a rubber composition containing the cocondensate.

Owner:TAOKA CHEM COMPANY

Aqueous high-strength nail-free adhesive

ActiveCN106753094AImprove composite bond strength performancePlay a role in thickeningMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesP-tert-ButylphenolButadiene-styrene rubber

The invention relates to an aqueous high-strength nail-free adhesive, belongs to the technical field of adhesive materials, and aims to solve the problems of environment pollution and low adhesiveness. The aqueous high-strength nail-free adhesive comprises the following components in parts by weight: 65-75 parts of a styrene-butadiene-styrene copolymer, 100-120 parts of silane, 75-85 parts of terpene resin, 45-55 parts of C9 petroleum resin, 8.0-10 parts of p-tert-butylphenol phenol-formaldehyde resin, 100-120 parts of rosin glycerin ester, 280-300 parts of an organic solvent, 120-150 parts of a plasticizer and 30-40 parts of packing. The aqueous high-strength nail-free adhesive provided by the invention is free of chloroprene rubber, good in environmental-friendliness, relatively good in temperature resistance and high in adhesive strength.

Owner:台州密得邦粘合材料有限公司

Anti-cracking pattern conveyor belt

InactiveCN104672535AImprove corrosion resistanceImprove oxidation resistanceConveyorsMethacrylateProcess loss

The invention discloses an anti-cracking pattern conveyor belt. The anti-cracking pattern conveyor belt is characterized in that the anti-cracking pattern conveyor belt comprises the following raw material components in parts by weight: 25 to 35 parts of isoprene rubber, 25 to 35 parts of EPDM, 10 to 20 parts of polypropylene, 5 to 6 parts of trichloroethylene, 3 to 5 parts of stearic acid, 6 to 8 parts of white factice, 8 to 12 parts of carbon black N375, 7 to 9 parts of silicon oxide, 2 to 3 parts of super tackifying agent HMT, 4 to 6 parts of sulfur, 1 to 2 parts of a foaming agent, 0.6 to 0.8 part of DCP, 3 to 4 parts of rosin resin, 0.5 to 0.8 part of modifier magnesium methacrylate and 4 to 5 parts of p-tert-Butylphenol formaldehyde resin. According to the anti-cracking pattern conveyor belt, the advantages of the rubber raw material such as good corrosion resistance and good oxidation resistance can be reserved, the shrinkage property, the cracking resistance and the stability can be greatly improved; on the premise that the process viscosity is not reduced, the production efficiency is improved, the process loss is reduced, and the application range in the field of high precision can be greatly enlarged.

Owner:QINGDAO ALLPOLY CONVEYOR BELT

Abrasion-resistant base compound for solid tyres of heavy trucks

The invention belongs to the technical field of rubber production, and particularly relates to an abrasion-resistant base compound for solid tyres of heavy trucks. The abrasion-resistant base compound for the solid tyres of the heavy trucks comprises raw materials in parts by weight as follows: natural rubber, carbon black N339, aromatic oil, poly-2,3,4-trimethyl-1,2-dihydroquinoline, N-(1,3-dimethyl)-N'-phenyl-p-phenylenediamine, zinc stearate, N-tert-butylbenzothiazole-2-sulfenamide, tetramethyl-thiuram sulfide, sulfur, an anti-scorching agent and P-tert-butylphenol formaldehyde resin. The base compound has the higher modulus and the good abrasion resistance, and meanwhile, the base compound is better in reversion resistance and low in hysteresis loss.

Owner:盐城易宝路轮胎有限公司

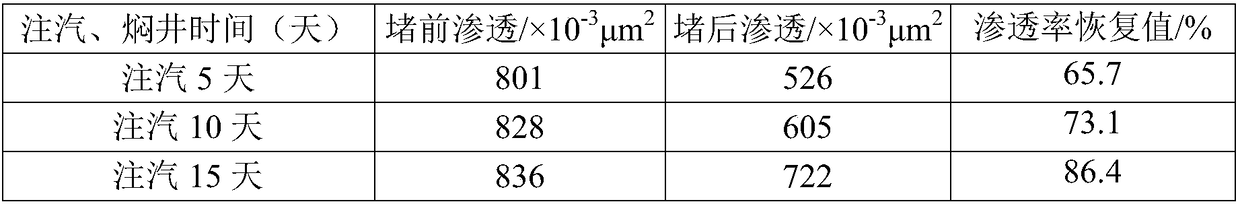

Degradable shielding protective agent as well as preparation method and application thereof

ActiveCN108059952AHigh temperature resistantHigh strengthDrilling compositionCelluloseP-tert-Butylphenol

The invention provides a degradable shielding protective agent as well as a preparation method and application thereof. The degradable shielding protective agent is prepared from the following materials: polyanionic cellulose, acid amide-modified starch copolymer YX-I, asphalt, coal gangue powder, lignite, sulphonated methyl phenolic resin, quaternary ammonium type cationic starch ether, propyleneglycol segmented polyether F38, p-tert-butylphenol LY-I, potassium polyacrylate and the balance of water. The degradable shielding protective agent can be used for temporarily blocking a well for high-temperature thick oil reservoir. The invention further provides a preparation method for the degradable shielding protective agent. The protective agent is degradable, is easy to prepare, is controllable in cross-linking time, has strong blocking performance and high temperature resistance, does not contaminate the oil reservoir, and has no impact on dehydration of a combined station.

Owner:PETROCHINA CO LTD

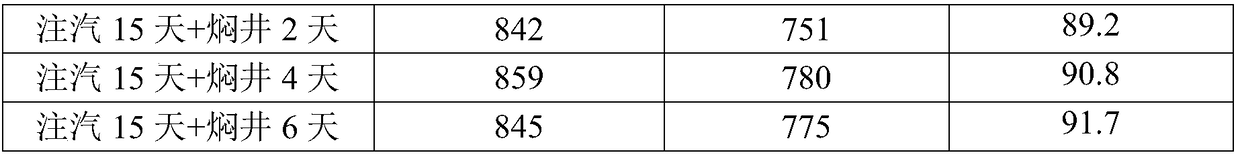

Rubber composition for tire

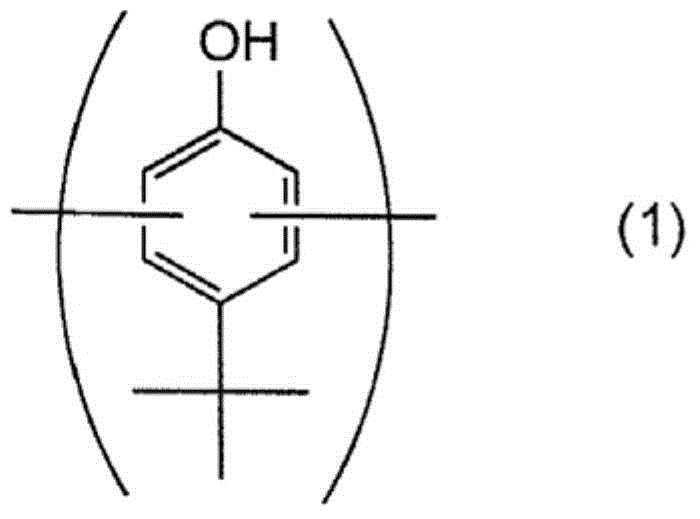

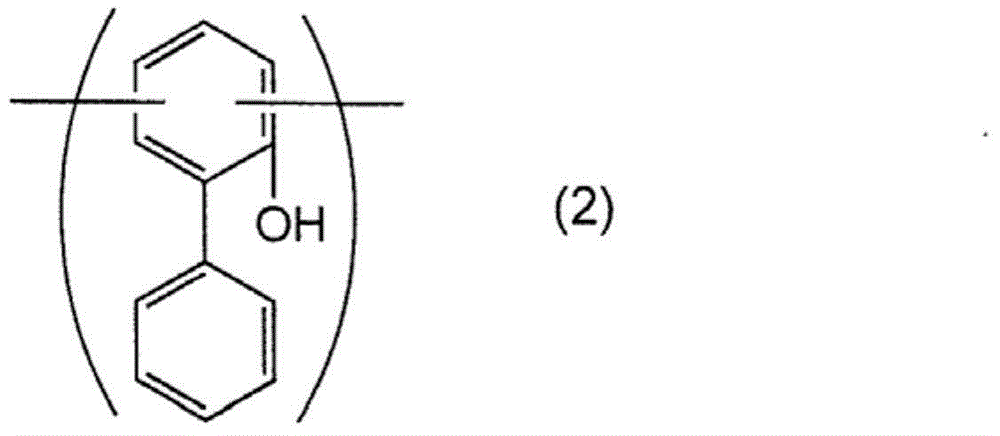

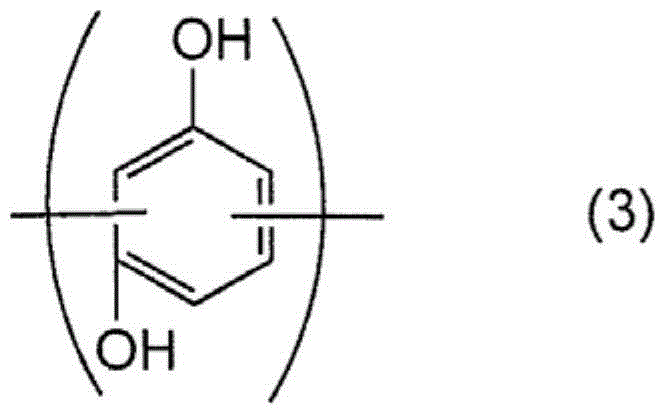

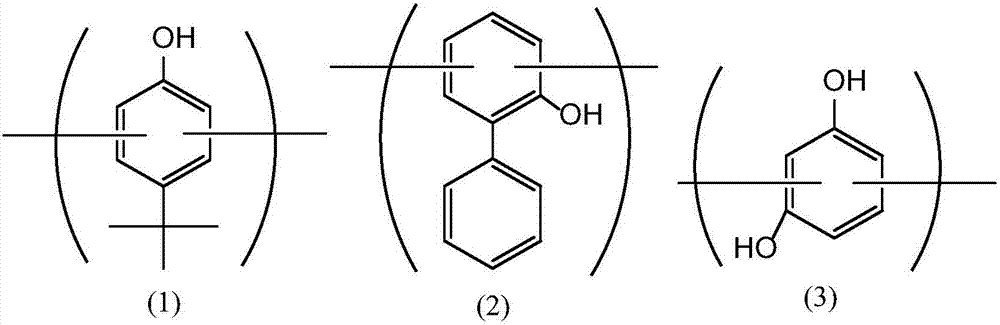

This rubber composition for a tire is obtained by blending a rubber component (A), zinc oxide (B), and a co-condensate (C) that has a softening point of 150 DEG C or less and that contains a p-tert-butylphenol-derived constituent unit represented by formula (1), an o-phenylphenol-derived constituent unit represented by formula (2), and a resorcinol-derived constituent unit represented by formula (3). The nitrogen adsorption specific surface area (N2SA) of the zinc oxide (B) according to the BET method is 6-110 m<2> / g. The blending amount of the zinc oxide (B) is 5-13 parts by mass with respect to 100 parts by mass of the rubber component (A). The blending amount of the co-condensate (C) is 0.1-10 parts by mass with respect to 100 parts by mass of the rubber component (A). The co-condensate (C) can be used as a replacement for p-tert-octylphenol and p-nonylphenol, has a softening point that is lower than the maximum temperature in a rubber processing step, and has excellent dispersibility in rubber.

Owner:BRIDGESTONE CORP

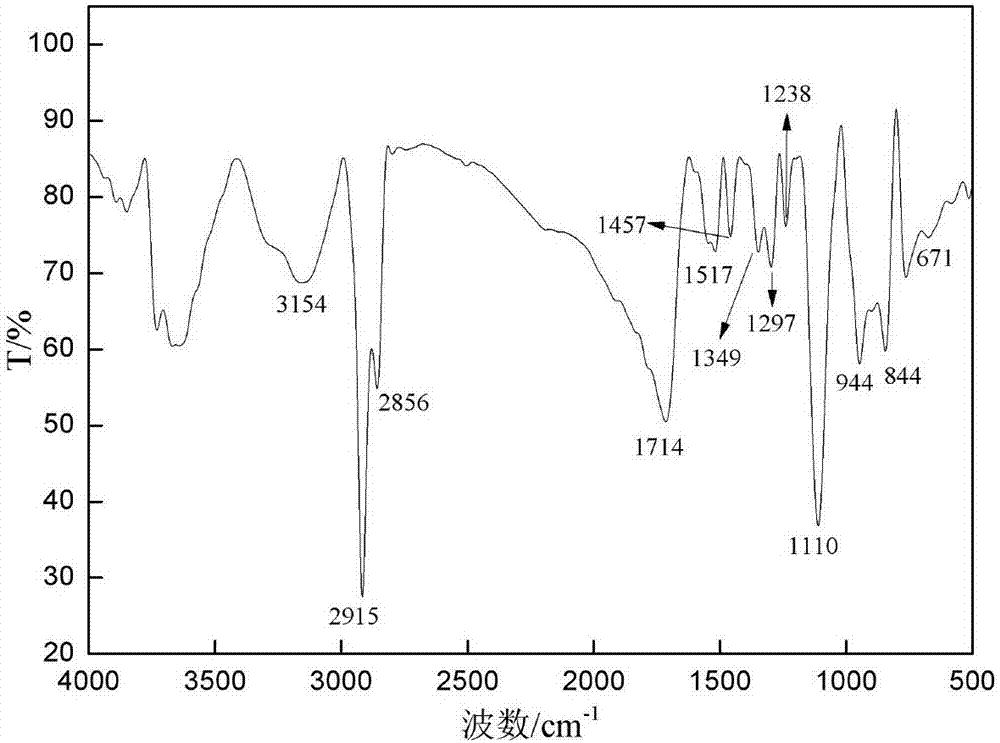

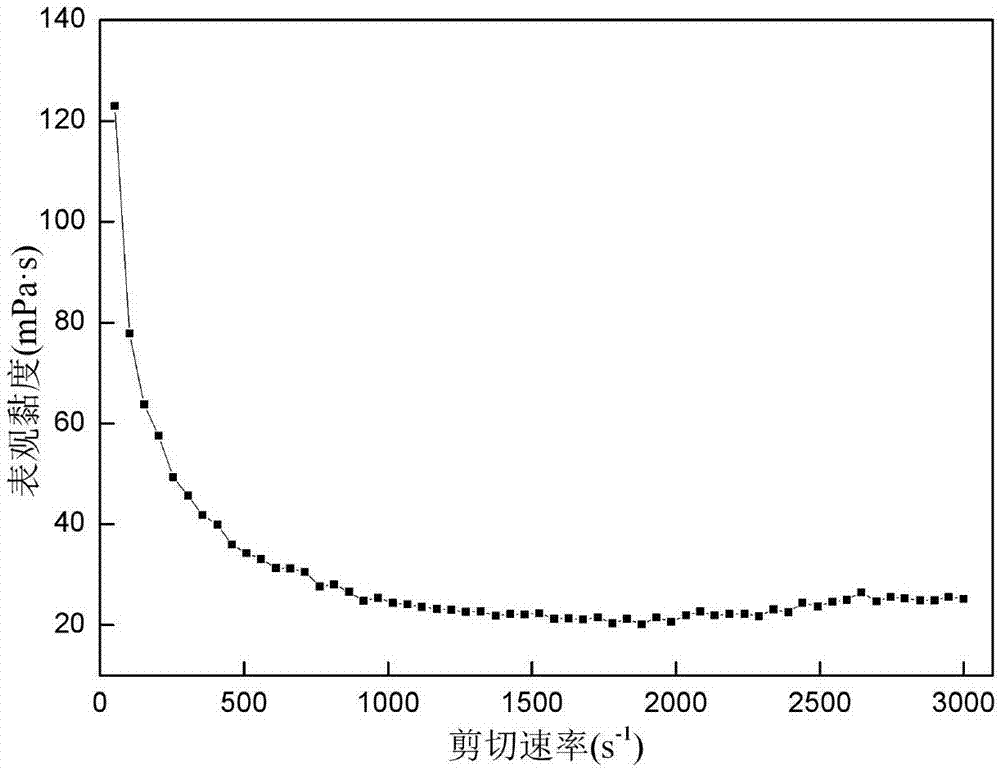

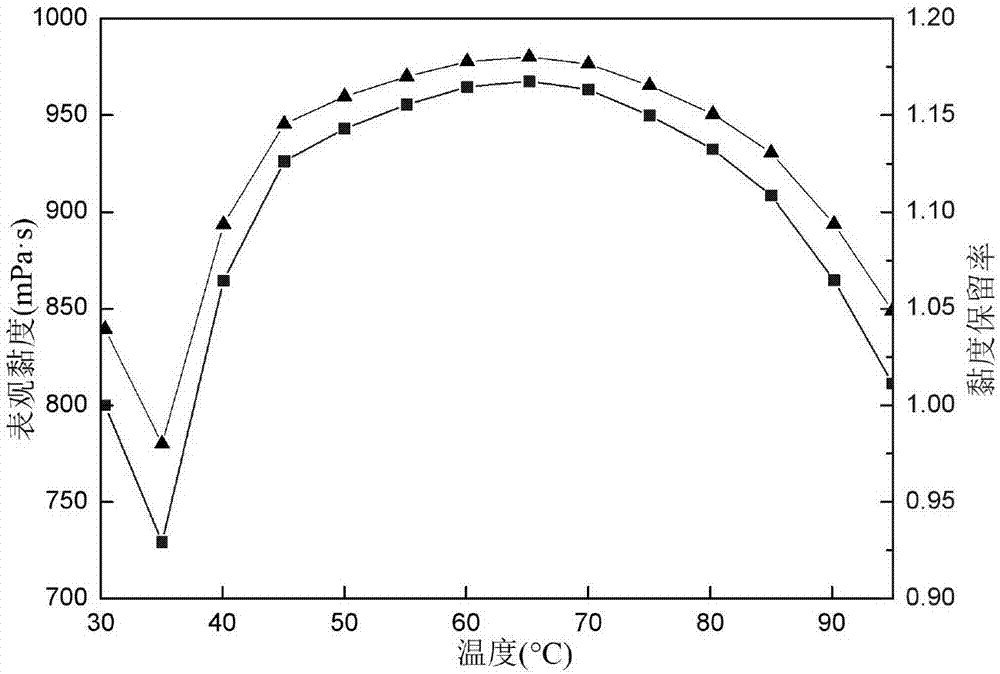

Hydrophobic associated polymer containing sulfonating calixarene and preparation method thereof

ActiveCN107459606AThe principle of the preparation method is reliableSimple methodOrganic compound preparationSulfonic acids salts preparationP-tert-ButylphenolDouble bond

The invention discloses a hydrophobic associated polymer containing sulfonating calixarene. The hydrophobic associated polymer is prepared from reaction monomer acrylamide, acrylic acid, vinyl modified sulfonated calixarene and vinyl modified fatty alcohol-polyoxyethylene ether through polymerization reaction. A preparation method comprises the steps that p-tert-butylphenol and formaldehyde are firstly used for preparing p-tert-butyl calix [4] arene, then p-tert-butyl is removed in anhydrous methylbenzene to obtain calix [4] arene, concentrated sulfuric acid is utilized to sulfonate calix [4] arene, and sulfonated calix [4] arene is obtained, methyl acryloyl chloride is utilized to introduce double bonds to the sulfonated calix [4] arene through vinylation, and the vinyl modified sulfonated calix [4] arene performs polymerization reaction with acrylamide, acrylic acid and vinyl modified fatty alcohol-polyoxyethylene ether to prepare the hydrophobic associated polymer containing the sulfonated calix [4] arene. The heat and salt resistance, viscosifying capacity and shearing resistance of the hydrophobic associated polymer containing the sulfonated calix [4] arene are remarkably improved, and the hydrophobic associated polymer has a wide application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Manufacturing method for hexafluoropropylene oxide modified phenolic resin grinding wheel

ActiveCN106217274AImprove heat resistanceNo pollutionAbrasion apparatusGrinding devicesFiberCarbon fibers

The invention relates to a manufacturing method for a hexafluoropropylene oxide modified phenolic resin grinding wheel, and belongs to the technical field of resin grinding wheel manufacturing. The manufacturing method comprises the following steps of: mixing and heating p-tert-butylphenol formaldehyde resin and methyl alcohol, and separately adding ferric nitrate, nickel nitrate and pre-treated carbon fibers to obtain mixed materials; burning, crushing and dissolving the mixed materials into acetone to obtain a mixed solution; ball-milling substances such as silicon carbide and bauxite, adding the ball-milled materials into the mixed solution to stir, and adding the prepared hexafluoropropylene oxide modified phenolic resin, stirring to obtain a material mixture; and finally, curing the material mixture to obtain the hexafluoropropylene oxide modified phenolic resin grinding wheel. The hexafluoropropylene oxide modified phenolic resin grinding wheel manufactured by the manufacturing method is high in heat resistance at a temperature of 370 DEG C or higher, and has grinding efficiency being 0.11-0.15kg / min; and in the production process, the environment is not polluted, so that the manufacturing method is environmentally friendly.

Owner:唐山市名鲨五金磨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com