Preparation method for vegetable oil modified rosin phenolic resin

A technology for modifying rosin phenolic resin and vegetable oil, which can be used in inks, household utensils, applications, etc. It can solve the problems of good solubility and high viscosity, and achieve good solubility, high softening point, and high viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1) Put rosin into the reaction kettle, raise the temperature to 180°C, add soybean oil, the weight ratio of rosin to soybean oil is 100:5, continue to heat up to 210°C and keep it warm for 1 hour to carry out the addition reaction;

[0014] 2) Add pentaerythritol and magnesium oxide to the reaction kettle, the molar ratio of rosin to pentaerythritol is 1:1.1, cool down to 160°C, and add dodecylphenol and p-tert-butyl in a molar ratio of 1:1.01 Phenol, then continue to cool down to 120°C, then add paraformaldehyde at a ratio of phenol-formaldehyde molar ratio of 1:2.0, and keep warm at this temperature for 2 hours;

[0015] 3) Raise the temperature in the reactor to 260° C. and keep warm to carry out esterification reaction until the acid value is less than 25 mgKOH / g, and distill off the low boilers under reduced pressure to obtain the vegetable oil modified rosin phenolic resin.

Embodiment 2

[0017] 1) Put rosin into the reaction kettle, heat up to 180°C, add linseed oil, the weight ratio of rosin to linseed oil is 100:30, continue to heat up to 215°C and keep it warm for 1.5h to carry out the addition reaction;

[0018] 2) Add pentaerythritol and magnesium oxide to the reaction kettle, the molar ratio of rosin to pentaerythritol is 1:1.3, cool down to 170°C, and add dodecylphenol and p-tert-butyl in a molar ratio of 1:1.03 Phenol, then continue to cool down to 130°C, then add paraformaldehyde at a ratio of phenol-formaldehyde molar ratio of 1:2.1, and keep warm at this temperature for 2.5h;

[0019] 3) Raise the temperature in the reactor to 270° C. and keep warm to carry out esterification reaction until the acid value is less than 25 mgKOH / g, and distill off low boilers under reduced pressure to obtain vegetable oil modified rosin phenolic resin.

Embodiment 3

[0021] 1) Put rosin into the reaction kettle, heat up to 180°C, add castor oil, the weight ratio of rosin to castor oil is 100:20, continue to heat up to 213°C and keep it warm for 1.3h to carry out the addition reaction;

[0022] 2) Add pentaerythritol and magnesium oxide to the reaction kettle, the molar ratio of rosin to pentaerythritol is 1:1.2, cool down to 165°C, and add dodecylphenol and p-tert-butyl in a molar ratio of 1:1.02 Phenol, then continue to cool down to 125°C, then add paraformaldehyde at a ratio of phenol-formaldehyde molar ratio of 1:2.05, and keep warm at this temperature for 2.2h;

[0023] 3) Raise the temperature in the reactor to 265° C. and keep warm to carry out esterification reaction until the acid value is less than 25 mgKOH / g, and distill off low boilers under reduced pressure to obtain vegetable oil modified rosin phenolic resin.

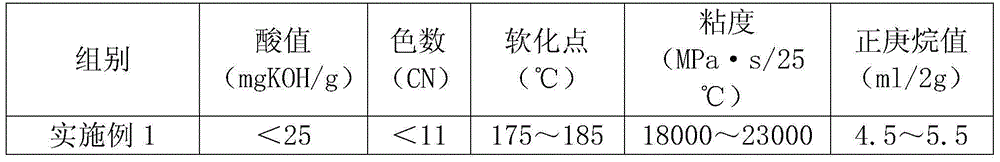

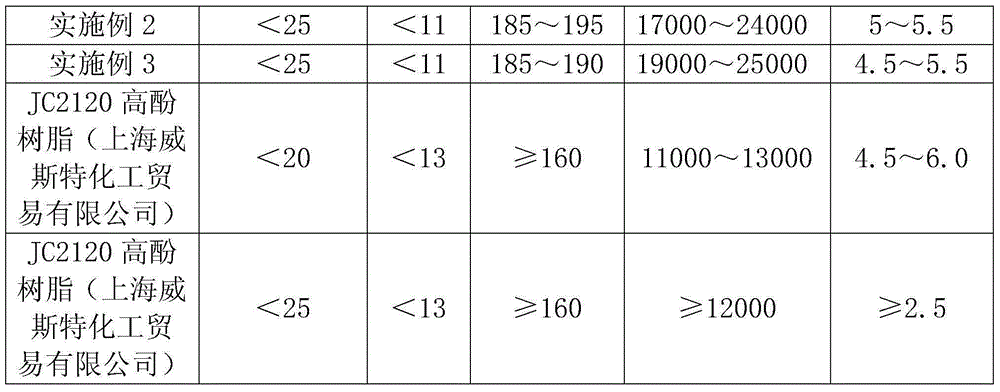

[0024] The resin of embodiment 1~3 is compared with existing resin as follows:

[0025]

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com