Preparation process of P-tert-butylphenol disulphide vulcanilzer

A technology for the preparation of p-tert-butylphenol, which is applied in the field of preparation of rubber additives, can solve the problems of high production cost, high cost, and long reaction time, and achieve the effects of low equipment requirements, short production cycle, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

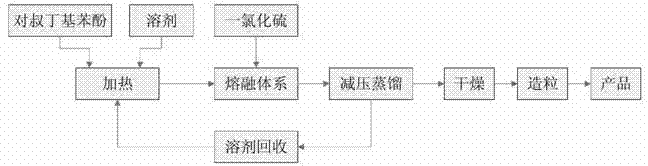

Method used

Image

Examples

Embodiment 1

[0018] The preparation method of p-tert-butylphenol disulfide (TB710) adopts the following steps:

[0019] Add 15 g of p-tert-butylphenol and 2 ml of petroleum ether into a 100 ml four-neck glass flask equipped with a stirring, thermometer and constant pressure dropping funnel, and stir to raise the temperature until the solid is completely dissolved. Add 13.5g of sulfur monochloride dropwise through the dropping funnel, control the drop rate, drop it in about 30 minutes, absorb the tail gas with dilute lye, continue the reaction until the reaction has no gas release and reach the end of the reaction, the reaction temperature is 100-140°C , from the initial dissolution to the completion of the reaction, the temperature gradually increased in this range. The alkane solvent was recovered by distillation under reduced pressure in the system, and the next mother liquor was used mechanically. The remaining brown viscous liquid after distillation was granulated to obtain a brown sol...

Embodiment 2

[0021] The preparation method of rubber vulcanizing agent (TB710) adopts the following steps:

[0022] Add 300 g of p-tert-butylphenol and 400 ml of petroleum ether into a 1000 ml four-neck glass flask equipped with a stirring, thermometer and constant pressure dropping funnel, stir and heat up until the solid is completely dissolved. Add 297g of sulfur chloride dropwise through the dropping funnel, and control the dropping rate. After about 2.0 hours, the tail gas is absorbed with dilute lye. After the dropwise addition, continue the reaction until the reaction has no gas release and reaches the end of the reaction. The reaction temperature is 100-140°C. From the initial dissolution to the completion of the reaction, the temperature gradually increases in this range. The linear alkane solvent was recovered by distillation under reduced pressure for the next mother liquor to be used mechanically to obtain a brown viscous liquid, which was released while hot and granulated to o...

Embodiment 3

[0024] The preparation method of rubber vulcanizing agent (TB710) adopts the following steps:

[0025] Add 150 g of p-tert-butylphenol and 150 ml of petroleum ether into a 500 ml four-neck glass flask equipped with a stirring, thermometer and constant pressure dropping funnel, stir and heat up until the solid is completely dissolved. Add 162g of sulfur chloride dropwise through the dropping funnel, control the drop rate, drop it in about 1.5 hours, absorb the tail gas with dilute lye, continue the reaction until the reaction has no gas release, and then reach the end of the reaction. From the initial dissolution to the completion of the reaction, the temperature gradually increases within this range. , Distilled under reduced pressure to recover the linear alkane solvent for the next mother liquor to be applied mechanically to obtain a brown viscous liquid and release it while hot for granulation to obtain a brown solid with a yield ≥ 98%, a softening point of 90°C, and a sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com