Rubber composition for tire

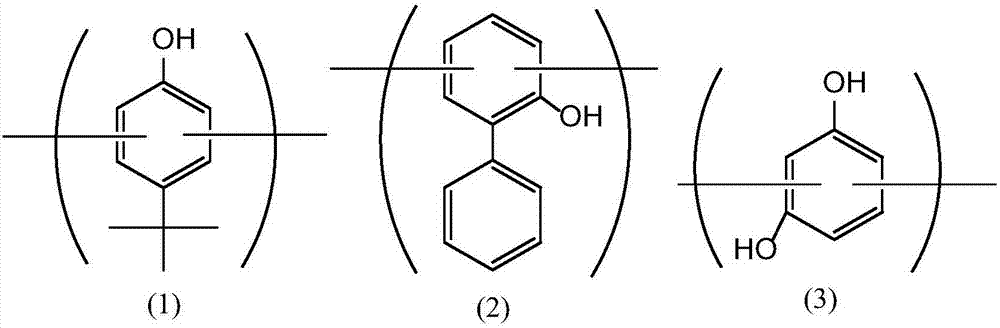

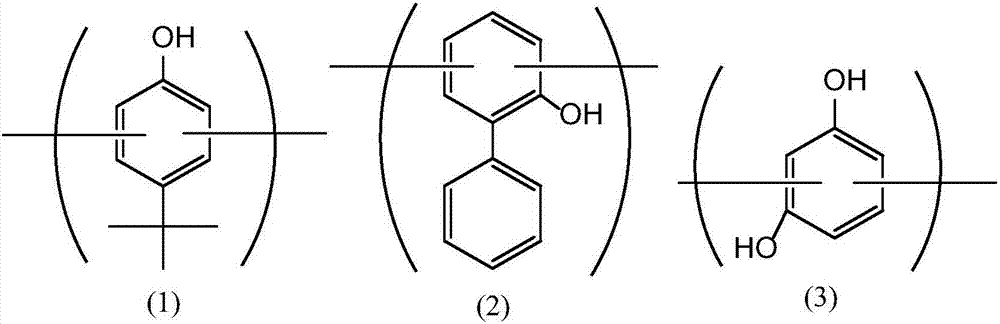

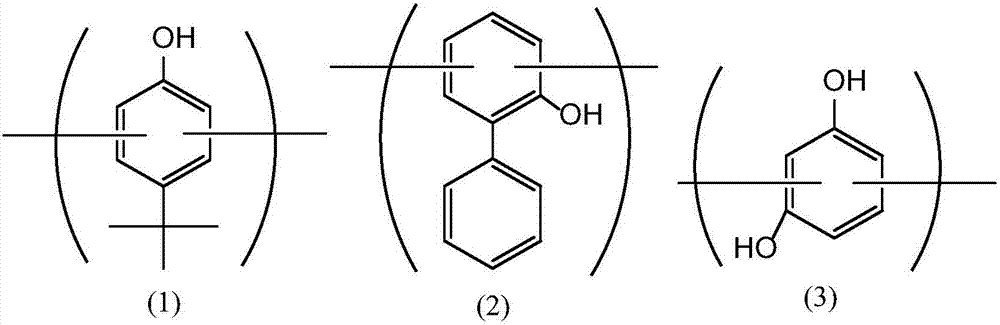

一种橡胶组合物、轮胎的技术,应用在特殊轮胎、轮胎零部件、运输和包装等方向,能够解决可能性变高等问题,达到初始粘接性和湿热粘接性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0134] [Preparation of Rubber Composition for Tires]

[0135] The rubber composition for tires of this embodiment can be obtained by mixing the aforementioned various components and additives using a kneader, for example, an open kneader such as a roller or a closed kneader such as a Banbury mixer. Machine to mix.

[0136] Specifically, the rubber composition for tires of this embodiment can be obtained by kneading the rubber component (A), zinc oxide (B) and cocondensate (C) in the first stage of kneading, and then They are produced by mixing them with vulcanizing agents and vulcanization accelerators.

[0137] In a stage preceding the final stage of kneading, a part or all of the vulcanization accelerator may be added and kneaded, and in the final stage of kneading, the vulcanization agent and the remaining vulcanization accelerator may be mixed to produce a composition. In this case, as a vulcanization accelerator to be added in a stage prior to the final stage of kneadin...

Embodiment

[0142] The present invention is described in more detail with reference to Examples and Comparative Examples given below, but the present invention is not limited thereto.

[0143] [Evaluation method of cocondensate]

[0144] The cocondensate was analyzed and its physical properties were evaluated as follows.

[0145] (a) Measurement of the average molecular weight of the cocondensate

[0146] The average molecular weight of the cocondensate was calculated by the gel permeation chromatography (GPC) used for analysis under the following conditions using the following equipment, and calculated the weight average molecular weight in terms of styrene.

[0147] Instrument used: HLC-8220GPC (manufactured by Tosoh Corporation)

[0148] Column: TSK Guard Column SUPER HZ-L (manufactured by Tosoh Corporation)

[0149] +TSK-GEL SUPER HZ1000(4.6mmφ×150mm)

[0150] +TSK-GEL SUPER HZ2500(4.6mmφ×150mm)

[0151] +TSK-GEL SUPER HZ4000(4.6mmφ×150mm)

[0152] Column temperature: 40°C

[0...

manufacture example 1

[0184] 97.3g (1.2mol) of formalin with a purity of 37%, 15.0g (0.10mol) of p-tert-butylphenol, 85.0g (0.50mol) of o-phenylphenol and 75.4g of toluene were sequentially added to the equipment equipped with reflux Four-neck split flask with condenser and thermometer. Next, this was heated to an internal temperature of 45° C., and 20 g (0.12 mol) of a 24% aqueous sodium hydroxide solution was added and stirred until the exotherm ceased. After confirming that the exotherm had ceased, this was heated to an internal temperature of 65° C. and kept at this temperature for 2 hours. This was then reheated to an internal temperature of 80° C. and held for a further 4 hours.

[0185] After the reaction, this was cooled to an internal temperature below 65° C., and neutralized with 49 g of water and 7.55 g (1.13 mol) of oxalic acid dihydrate added thereto, and then after adding 22.6 g of toluene, this was left as it was. Set aside, and remove the aqueous layer.

[0186] 62.7 g (0.57 mol)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com