Preparation method of mixed phenolic rosin modified phenolic resin

A technology of rosin modification and phenolic resin, which is applied in the field of preparation of rosin phenolic resin. It can solve the problems of insufficient viscosity, short fixation time, and small viscosity value, and achieve uniform molecular weight distribution, high softening point, and prevent splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

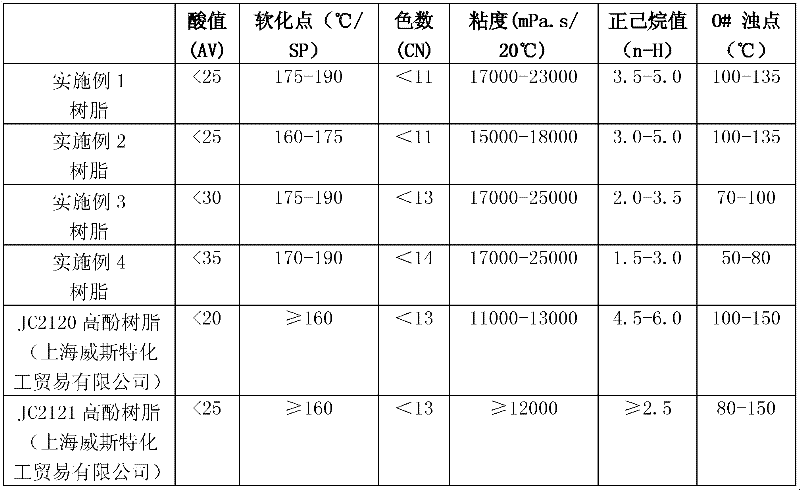

Examples

Embodiment 1

[0023] 1), put 90 parts by weight of xylene into the reaction kettle, start to heat up, add 200 parts by weight of p-tert-octylphenol, 400 parts by weight of p-tert-butylphenol, and nonylphenol of 30 parts by weight, and keep the temperature in the kettle Stir at 55°C for 10 minutes, then add 180 parts by weight of formaldehyde with a mass concentration of 92%, then add 4 parts by weight of lye and 80 parts by weight of water in sequence, raise the temperature to 95°C, and the heating rate is 1.0°C / min. Insulate and react until the viscosity of the reactant in the reactor is 18,000 mPa.s, cool to 70°C, take it out, and obtain the condensation liquid;

[0024] 2), the rosin of 2000 weight parts is dropped into reactor, is heated up to 175 ℃, successively adds the glycerol of 35 weight parts, the pentaerythritol of 180 weight parts and the mass concentration is 0.3 weight part of sulfuric acid solution of 10%, continues to heat up to 265 ℃, heat preservation reaction, until the ...

Embodiment 2

[0026] 1), put 150 parts by weight of xylene into the reaction kettle, start to heat up, add 180 parts by weight of p-tert-octylphenol, 300 parts by weight of p-tert-butylphenol, and nonylphenol of 20 parts by weight, and keep the temperature in the kettle Stir at 60°C for 5 minutes, then add 200 parts by weight of formaldehyde with a mass concentration of 96%, then add 2 parts by weight of lye and 100 parts by weight of water in sequence, raise the temperature to 90°C, and the heating rate is 1.0°C / min. Insulate and react until the viscosity of the reactant in the reactor is 16,000 mPa.s, cool to 70°C, take it out, and obtain the condensation liquid;

[0027] 2), the rosin of 1800 weight parts is dropped into reactor, is heated up to 180 ℃, successively adds the glycerol of 25 weight parts, the pentaerythritol of 140 weight parts and the mass concentration is 0.1 weight part of sulfuric acid solution of 15%, continues to heat up to 270 ℃, heat preservation reaction, until the...

Embodiment 3

[0029] 1), put 120 parts by weight of xylene into the reaction kettle, start to heat up, add 190 parts by weight of p-tert-octylphenol, 500 parts by weight of p-tert-butylphenol, and 50 parts by weight of nonylphenol, keep the kettle Stir at 60°C for 10 minutes, then add 200 parts by weight of formaldehyde with a mass concentration of 94%, then add 8 parts by weight of lye and 20 parts by weight of water in sequence, raise the temperature to 95°C, and the heating rate is 1.0°C / min. Insulate and react until the viscosity of the reactant in the reactor is 19,000 mPa.s, cool to 65°C, take it out, and obtain the condensation liquid;

[0030] 2), the rosin of 1500 weight parts is dropped into reactor, is heated up to 185 ℃, adds successively the glycerol of 30 weight parts, the pentaerythritol of 190 weight parts and the mass concentration is 0.2 weight part of sulfuric acid solution of 10%, continues to heat up to 275 ℃, heat preservation reaction, until the acid value of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com