A method for purifying folic acid

A folic acid, acid wet technology, applied in the field of folic acid synthesis, to achieve the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: folic acid crude product is synthesized

[0057] 1. Raw materials for folic acid synthesis:

[0058] N-p-aminobenzoyl-L glutamic acid (ammonia one), 2,4,5-triamino-6-hydroxypyrimidine sulfate (ammonia two), trichloroacetone, sodium metabisulfite, sodium carbonate.

[0059] 2. The reaction equation of folic acid synthesis:

[0060]

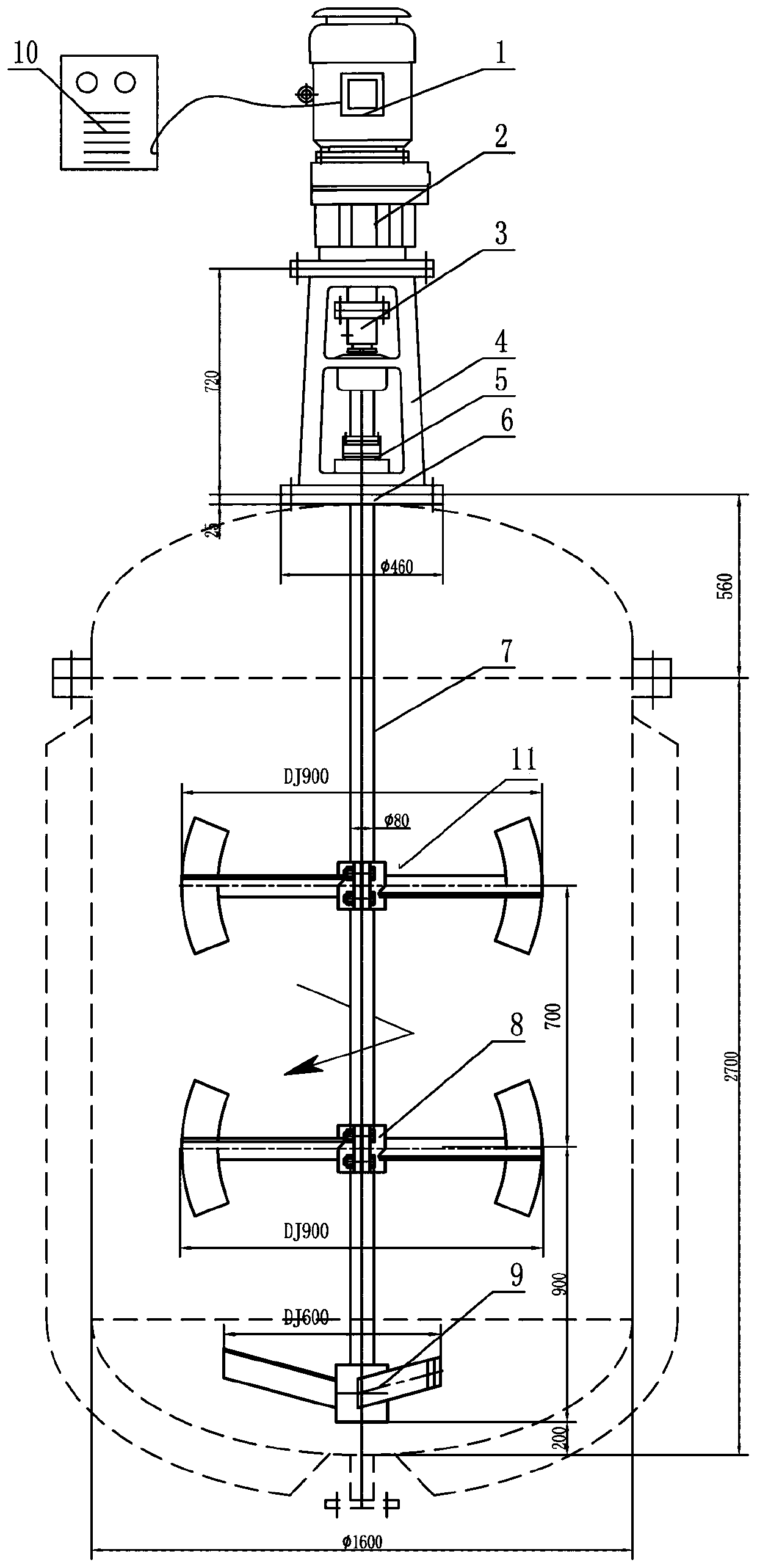

[0061] 3. The structure of the reaction tank for the synthesis of folic acid

[0062] The structural design of the reaction tank for the synthesis of folic acid in this embodiment is as follows: figure 1 with Figure 5 Shown:

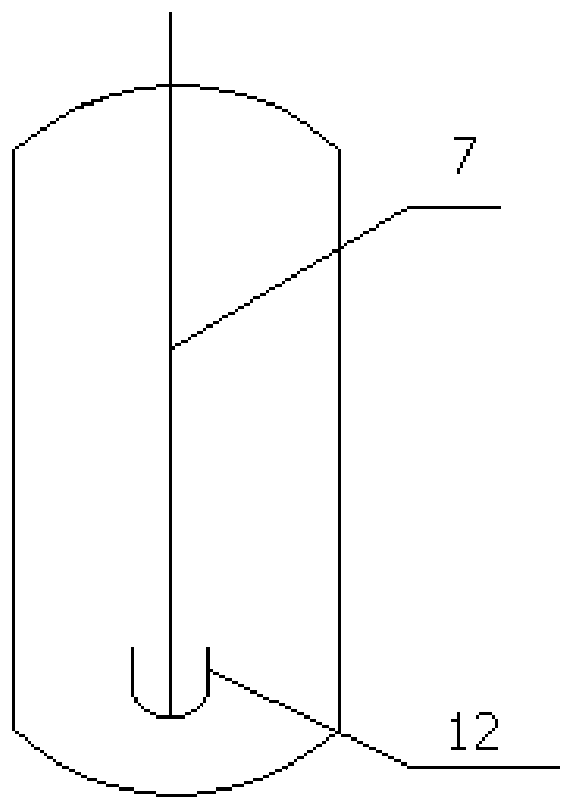

[0063] A reaction tank for folic acid synthesis, including container, motor 1 (Y7.5KW-4P), reducer 2 (RF97-85rpm), coupling 3 (GT60 / 65), frame 4 (DJ65), installation Bottom cover 5 (R460-25), mechanical seal 6 (212-80), stirring shaft 7 Upper agitator 11 (ACJ900), middle agitator 8 (ACJ900), lower agitator 9 (HCQ600), frequency converter 10 (Y7.5KW).

[0064] The container is an enamel kettle ...

Embodiment 2

[0140] The purification method of embodiment 2 folic acid

[0141] (1) acid-dissolving: drop into about 800Kg of folic acid crude product prepared in the prepared embodiment 1 in the acid-dissolving tank, then slowly add 30wt% dilute sulfuric acid (unit liter) in the acid-dissolving tank, the amount of adding acid is Ensure that the crude folic acid can be completely dissolved, and start stirring after adding the acid until the crude product is completely dissolved and no lumps appear. Then add about 6200L of drinking water, stir for 10 minutes and then let it stand for 30 minutes, then pour the rested material into the plate and frame filter press, and the filter cake is the acid extract.

[0142] (2) Alkali dissolution: Add 2000L of drinking water to the alkali dissolution reaction tank, start stirring, open the jacket steam valve of the alkali dissolution tank for heating, when the temperature in the tank reaches about 70°C, add about 90Kg of acid extract, and continue heat...

Embodiment 3

[0149] Embodiment 3: the purification method of folic acid

[0150] The folic acid wet product prepared by the method of Example 2 (concrete stenoic acid content: 0.6%) is hot-washed, and the specific steps are as follows:

[0151] After refining and pressing, add 850L of purified water to the refining tank, raise the temperature to 60°C and start refining and stirring, put 250L CP hydrochloric acid into the refining tank, and then pump it into the refining plate frame to wash the folic acid wet fine product for about 15 minutes. Immediately after washing, use 4000 liters of pure water at 70°C in another refining tank to continue washing for 40 minutes, and then obtain the finished product of folic acid.

[0152] The statistical results obtained from multiple batches of production show that the folic acid content in the finished folic acid product is less than 0.2 wt%, and the success rate is about 95%. That is, 100 batches of production can successfully prepare folic acid wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com