Preparation method of copolymerization condensation resin

A condensed resin and copolymerization technology is applied in the field of preparation of co-condensed resin for rubber, which can solve the problems of long viscosity retention time, insufficient retention and high cost, and achieve the effects of simple production process, improved adhesion and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

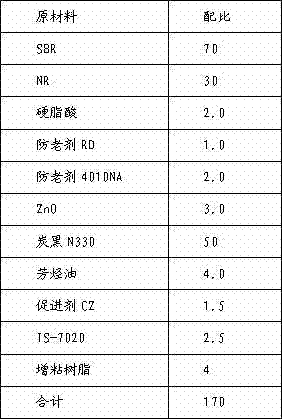

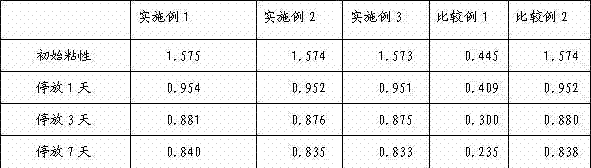

Embodiment 1

[0029] Put 225g of p-tert-butylphenol, 28g of morpholine and 3.5g of the catalyst triethylamine into a 1000ml four-necked flask equipped with a stirring device, a reflux condenser, a liquid addition device, a receiving device and a thermometer. Start stirring. When the temperature is between 60°C and 75°C, slowly add 156.6g of 37% formaldehyde. At this time, it is an exothermic reaction. Control the temperature between 90°C and 100°C to maintain the reaction for 1 hour, and then add resorcinol 12g, react for another 1 hour, the reaction is over, the reflux condenser is switched to the receiving state, heated to increase the temperature, start dehydration recovery, when the temperature reaches 160℃, build a vacuum, continue dehydration and free phenol under reduced pressure, at 185~210 The reaction is maintained at °C until the softening point reaches the requirement, 15 g of paraffin wax is added and stirred uniformly to obtain the resin of the present invention. The softening ...

Embodiment 2

[0031] Put 225g of p-tert-butylphenol, 28g of morpholine and 3.5g of the catalyst triethylamine into a 1000ml four-necked flask equipped with a stirring device, a reflux condenser, a liquid addition device, a receiving device and a thermometer. Start stirring. When the temperature is between 60°C and 75°C, slowly add 156.6g of 37% formaldehyde. At this time, it is an exothermic reaction. Control the temperature at 90°C to 100°C to maintain the reaction for 1 hour, then add 12g of m-cresol and react again. After 1 hour, the reaction is over, the reflux condenser is switched to the receiving state, the temperature is increased, and the dehydration recovery is started. When the temperature reaches 160°C, a vacuum is established, and the dehydration and free phenol are continued under reduced pressure, and the reaction is maintained at 185-210°C. Until the softening point reaches the requirement, 15 g of paraffin wax is added and stirred evenly to obtain the resin of the present inv...

Embodiment 3

[0033] Put 309 g of p-tert-octylphenol, 28.8 g of morpholine and 6.5 g of the catalyst triethylamine into a 1000 ml four-necked flask equipped with a stirring device, a reflux condenser, a liquid addition device, a receiving device and a thermometer, and heat to dissolve, Then start stirring. When the temperature is 80℃~85℃, 160.5g 37% formaldehyde is slowly added dropwise. At this time, it is an exothermic reaction. Control the temperature at 90℃~100℃ to maintain the reaction for 1 hour, and then add 16.5g resorcinol After reacting for another 1 hour, the reaction is over, the reflux condenser is switched to the receiving state, the heating is increased, and the dehydration recovery is started. When the temperature reaches 160°C, a vacuum is established, and the dehydration and free phenol are continued under reduced pressure at 160~195°C. The reaction is maintained until the softening point reaches the requirement, and 19 g of paraffin wax is added and stirred evenly to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com