Method of producing o-tert-butyl phenol and p-tert-butyl phenol through combination of rectification and crystallization

A technology of p-tert-butylphenol and o-tert-butylphenol, which is applied in the field of chemical separation, can solve the problems of easy adhesion of amorphous substances, easy growth of impurities into the crystal lattice, and decrease in product purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 (S1)

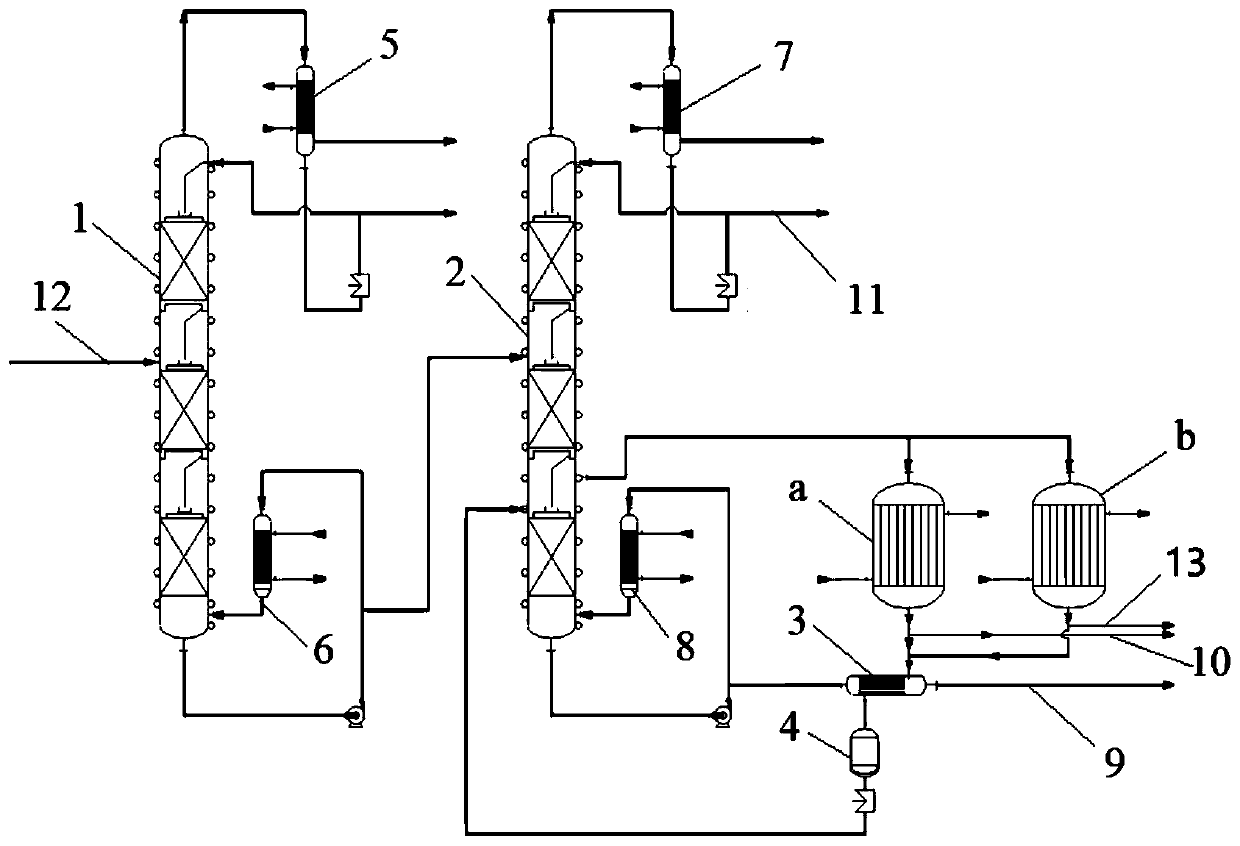

[0037] Such as figure 1 Shown, a kind of rectification and crystallization are used to produce the method for o-tert-butylphenol and p-tert-butylphenol, comprising the following steps:

[0038] (1) The alkylation product obtained by the alkylation reaction of phenol and isobutene is fed into the first rectification tower 1 through the fifth pipeline 12 for rectification treatment, so that the phenol and light components with a boiling point less than 110°C are contained therein The by-product is separated from o-tert-butylphenol and p-tert-butylphenol; when the top temperature of the first rectification tower 1 reaches 92°C and the bottom temperature reaches 138°C, the The first overhead material including phenol and light component by-products with a boiling point less than 110°C is extracted from the top of the tower, part of the first overhead material is refluxed after being condensed by the first condenser 5, and the remaining part is returned to ...

Embodiment 2 and 3

[0042] Embodiment 2 and 3 (S2 and S3)

[0043] The steps of Examples 2 and 3 are the same as in Example 1. The composition of the alkylation product stream is shown in Table 1, the operating conditions of the first rectifying tower 1 are shown in Table 2, and the operating conditions of the second rectifying tower 2 are shown in Table 3.

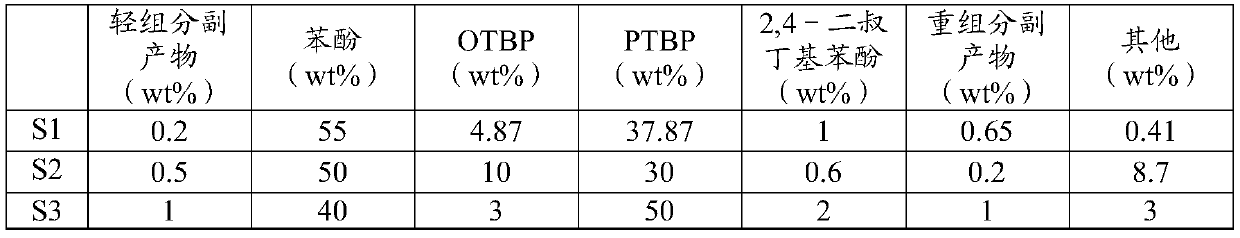

[0044] The composition of the alkylation product stream in Table 1 S1-3 and the content of each composition

[0045]

[0046] Process conditions of the first rectifying tower in table 2 S1-3

[0047]

[0048] Note: The feeding position refers to the feeding of the first rectification column at the n1th tray from top to bottom.

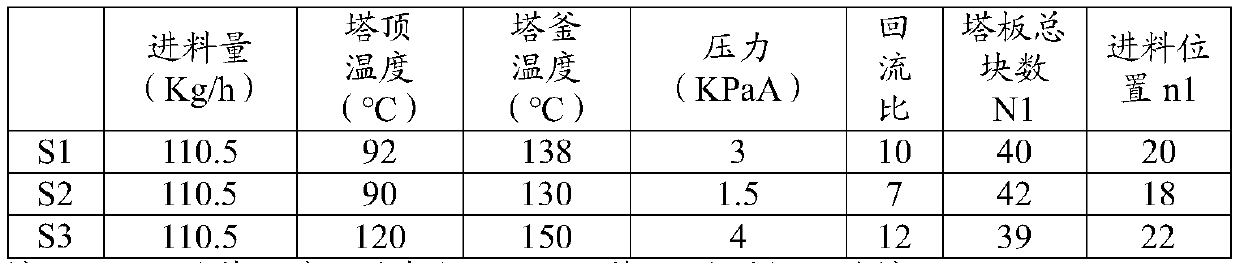

[0049] Process conditions of the second rectifying tower in table 3 S1-3

[0050]

[0051] Note: The meanings of n2, n3 and n4 are similar to n1.

[0052] Process conditions of the four treatment processes in the crystallization unit in Table 4 S1-3

[0053]

[0054] Examples 1-3 all can obtain o-tert-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com