Method for extracting scandium and other rare earths from zirconium oxychloride waste acid solution

A technology of zirconium oxychloride and waste acid solution, which is applied in the field of extracting scandium and other rare earths, can solve the problems that the purity level of scandium oxide needs to be improved, and does not involve the recovery, extraction and utilization of rare earths, so as to reduce the loss of scandium, reduce investment, and process A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

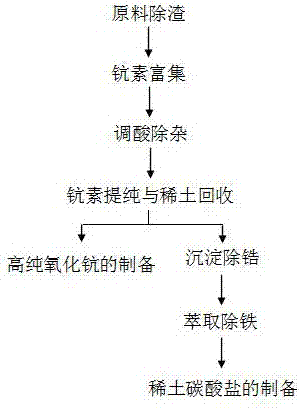

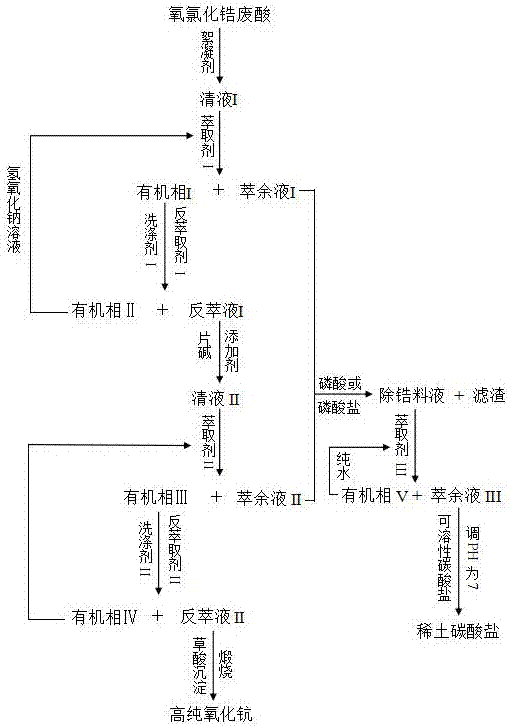

[0035] A method for extracting scandium and other rare earths from zirconium oxychloride waste acid solution, see figure 1 , figure 2 , including the following steps:

[0036] (1) Flocculation and impurity removal: filter the concentrated zirconium oxychloride waste acid solution with polyacrylamide (PMA) organic flocculant, and adjust the concentration of the slurry to facilitate plate and frame filter silicon slag to obtain clear liquid I;

[0037](2) Scandium enrichment: In a box-type mixing and settling tank, use extractant Ⅰ to perform 6-stage cascaded countercurrent extraction on clear liquid Ⅰ to obtain organic phase Ⅰ and raffinate Ⅰ, and raffinate Ⅰ contains about 15 pmm of scandium , the extraction rate was 97%; after 8 cascaded countercurrent washing of organic phase I with 6mol / L hydrochloric acid solution as detergent I, 25 cascaded countercurrent washing was carried out on organic phase I with 8 mol / L nitric acid solution as stripping agent I. Stage countercur...

Embodiment 2

[0046] A method for extracting scandium and other rare earths from zirconium oxychloride waste acid liquid, comprising the following steps:

[0047] (1) Flocculation and impurity removal: filter the concentrated zirconium oxychloride waste acid solution with polyacrylamide (PMA) organic flocculant, and adjust the concentration of the slurry to facilitate plate and frame filter silicon slag to obtain clear liquid I;

[0048] (2) Scandium enrichment:

[0049] (2-1) Enrichment stage extraction: Weigh 600ml of clear liquid Ⅰ (the clear liquid Ⅰ contains scandium 0.7g / L, iron 20 g / L, titanium 15 g / L, zirconium 25 g / L, rare earth 10 g / L ), the acidity is 3.5~5mol (the original acid material is used directly, no need to adjust the acidity), put it into a 1000ml pear-shaped separatory funnel, add 200ml of extraction agent Ⅰ, compared to O / A=1:3, extract at room temperature for 5min and then separate phase, to obtain the loaded organic phase I and the aqueous raffinate I. After equili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com