Cooking-free mochi and preparation method thereof

A technology of no-cooking and mochi, applied in the field of pastry, can solve problems such as energy consumption and time consumption, and achieve the effects of reduced investment, soft and glutinous taste, and better edible taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

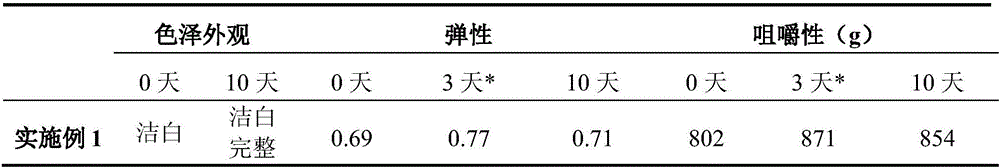

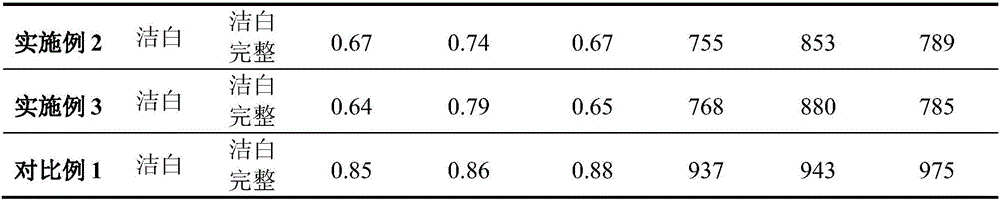

Examples

Embodiment 1

[0051] (1) Add 15.55kg of first-grade soybean oil (Yihai Kerry Arowana) into the premix mixing tank, then pass 16kg of refined castor sugar, pregelatinized glutinous rice flour (5% by mass on a dry basis) through Brabender Measuring instrument, viscosity 400BU, Henan Huangguo Grain Industry Co., Ltd. product) 7.5kg, acetylated distarch adipate (dry basis of 5% by mass is measured by Brabender instrument, viscosity 1800BU, French Roquette product ) 7kg, sodium alginate (viscosity 500mPa s) 1.3kg, maltodextrin (DE value 16) 3kg, sodium starch octenyl succinate (viscosity 450mPa s) 0.6kg, molecularly distilled monoglyceride (HLB value 3.9 ) 0.4kg, carrageenan (viscosity 80mPa·s) 0.3kg, anhydrous citric acid 0.15kg, potassium sorbate 0.05kg were put into it, stirred at 80rpm for 5min until the powder was evenly dispersed, and the mixed material ① was obtained;

[0052] (2) Add 21 kg of sterile distilled water to the mixed material ① prepared in step (1) at a rotating speed of 80 r...

Embodiment 2

[0057] (1) Add 35kg of first-grade soybean oil (Yihai Kerry Arowana) into the premix mixing tank, then pass 13.59kg of refined castor sugar, pregelatinized glutinous rice flour (5% by mass on a dry basis) through Brabender Measuring instrument, viscosity 450BU, Henan Huangguo Grain Industry Co., Ltd. product) 6.5kg, acetylated distarch adipate (dry basis of 5% by mass percentage is measured by Brabender instrument, viscosity 2600BU, French Roquette product ) 6kg, sodium alginate (viscosity 800mPa s) 1.1kg, maltodextrin (DE value 12) 1kg, sodium starch octenyl succinate (viscosity 900mPa s) 0.4kg, molecularly distilled monoglyceride (HLB value 5.3 ) 0.2kg, carrageenan (viscosity 150mPa·s) 0.1kg, anhydrous citric acid 0.05kg, potassium sorbate 0.01kg into it, and stirred at 100rpm for 5min until the powder is evenly dispersed to obtain the mixture ①;

[0058] (2) Add 15 kg of sterile distilled water to the mixed material ① prepared in step (1) at a rotating speed of 100 rpm, and...

Embodiment 3

[0063] (1) Add 25kg of first-grade soybean oil (Yihai Kerry Arowana) into the premix mixing tank, then pass 15kg of refined castor sugar, pregelatinized glutinous rice flour (5% by mass on a dry basis) through a Brabender instrument Determination, viscosity 420BU, product of Henan Huangguo Grain Industry Co., Ltd.) 7kg, acetylated distarch adipate (dry basis of 5% by mass is measured by Brabender instrument, viscosity 2200BU, French Roquette product) 6.57 kg, sodium alginate (viscosity 650mPa·s) 1.2kg, maltodextrin (DE value 14) 2kg, sodium starch octenyl succinate (viscosity 750mPa·s) 0.5kg, molecularly distilled monoglyceride (HLB value 4.5) 0.3kg, 0.2kg of carrageenan (viscosity 120mPa·s), 0.1kg of anhydrous citric acid, and 0.03kg of potassium sorbate were put into it, and stirred at 90rpm for 5min until the powder was evenly dispersed to prepare the mixture ①;

[0064] (2) Add 18 kg of sterile distilled water to the mixed material ① prepared in step (1) at a rotating spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com