Patents

Literature

52 results about "Acetylated distarch adipate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetylated distarch adipate (E1422), is a starch that is treated with acetic anhydride and adipic acid anhydride to resist high temperatures. It is used in foods as a bulking agent, stabilizer and a thickener.

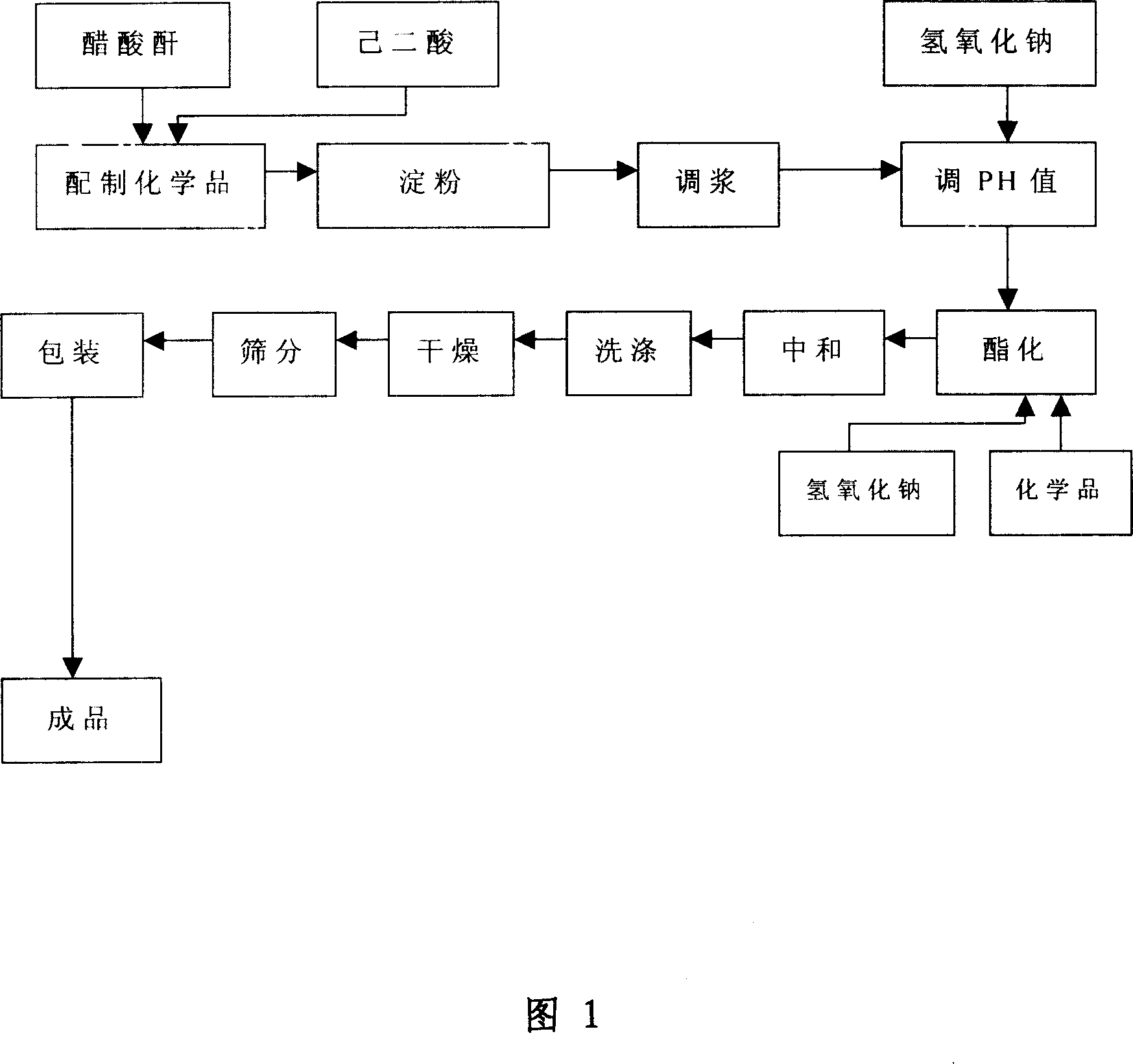

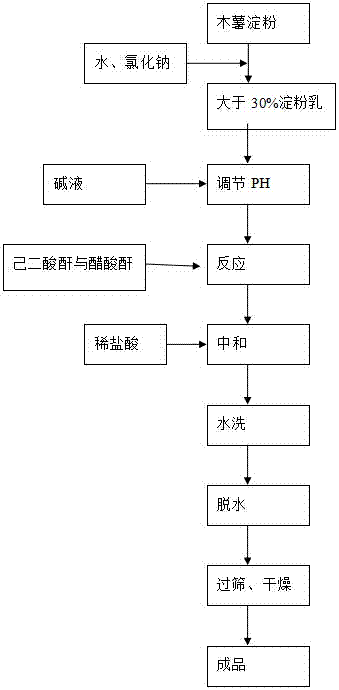

Method of preparing acetylated distarch adipate

Owner:四平帝达变性淀粉有限公司

Radish and sirloin essence and preparation method thereof

InactiveCN104041790AGood compositionGood contentFood ingredient as thickening agentFood thermal treatmentFlavorSodium Glutamate

The invention discloses radish and sirloin essence and a preparation method thereof. The radish and sirloin essence is prepared from following raw materials: a radish and sirloin flavor heat reactant, table salt, white granulated sugar, sodium glutamate, hydrolyzed vegetable protein, acetylated distarch adipate and a sirloin meat aroma base, wherein the radish and sirloin flavor heat reactant is prepared from following components: beef zymolyte, animal fat, ox bone clear soup, light soy sauce, a yeast extract, amino acid, glucose, xylose, smashed red onion, smashed ginger, cinnamon powder, star aniseed powder, glycerol monostearate and water; the beef zymolyte is prepared from following components: beef, alkaline hydrolyzed protease, flavor protease, water and table salt. According to the radish and sirloin essence, under the precondition of not adding radishes, the aroma of the prepared radish and sirloin essence is natural and vivid, is mellow and rich and has a lasting aroma; the preparation method is simple in process and easy to operate.

Owner:广东江大和风香精香料有限公司

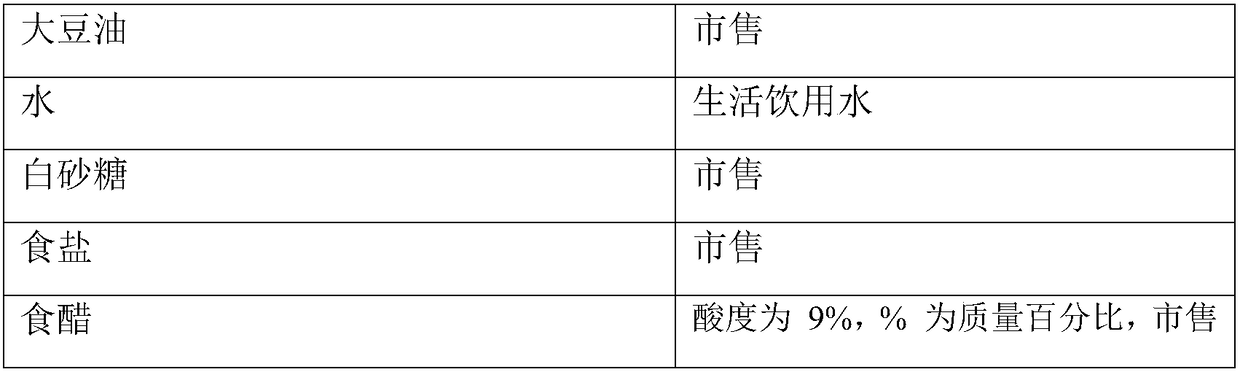

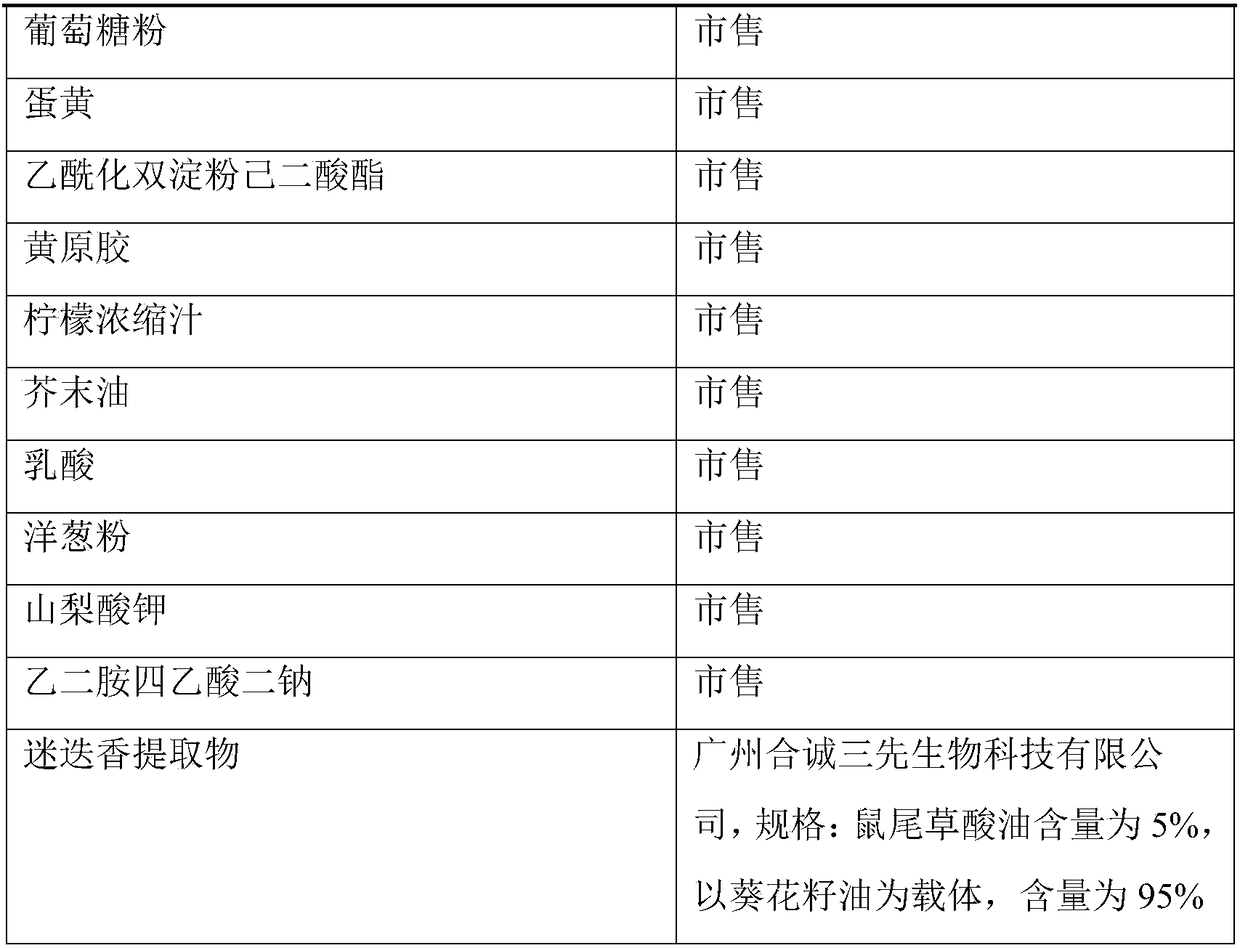

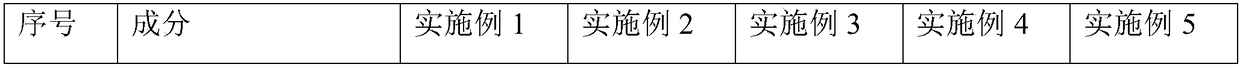

Anti-oxidation yolk low-fat salad dressing and making method thereof

The invention discloses anti-oxidation yolk low-fat salad dressing and a making method thereof. The salad dressing comprises the following raw materials in parts by weight of 200-300 parts of soybeanoil, 300-400 parts of water, 100-130 parts of white granulated sugar, 10-12 parts of table salt, 50-60 parts of vinegar, 30-40 parts of glucose powder, 20-30 parts of yolk, 20-40 parts of acetylated distarch adipate, 2-3 parts of xanthan gum, 2-3 parts of lemon condensed juice, 0.1-0.5 part of mustard oil, 0.1-0.5 part of lactic acid, 0.1-0.5 part of onion powder, 0.1-0.4 part of potassium sorbate, 0.01-0.04 part of ethylenediamine tetraacetic acid disodium salt, and 0.1-0.2 part of a rosemary extract (supercritical carbon dioxide extraction method). The prepared salad dressing is good in mouth feel, good in color and good in anti-oxidation property.

Owner:GUANGZHOU HAODAO FOOD CO LTD

Tomato ketchup and its preparation method

The invention relates to the technical field of seasoning processing, specifically to tomato ketchup and its preparation method. The tomato ketchup comprises the following components: by weight, 40-50 of concentrated ketchup, 4-5% of white sugar, 2-4% of acetylated distarch adipate, 0.3-0.6% of salt, 0.05-0.18% of edible acetic acid, 0.05-0.2% of vitamin C, 0.05-0.12% of cochineal, 0.03-0.08% of potassium sorbate, and 40-50% of water. The preparation method of the tomato ketchup comprises the following steps: Step 1, preparing a dissolved solution; Step 2, heating and adding a self-made thickening liquid; Step 3, carrying out gelatinization; Step 4, stirring materials; Step 5, boiling; and Step 6, cooling and adding auxiliary materials. The tomato ketchup has advantages of rich tomato flavor, soft mouthfeel, high nutritive value, anti-cancer efficacy, good stability, excellent quality and long shelf life.

Owner:DONGGUAN YONGYI FOODS

Frozen yoghurt and preparation method thereof

InactiveCN105613733AReduces the possibility of crystallizationHigh sweetnessMilk preparationLactaseAdditive ingredient

The invention discloses frozen yoghurt and a preparation method thereof. Formula of the frozen yoghurt comprises the following ingredients in percentage by weight: 25-35% of total solids, 4-10% of greases, 4-6% of milk proteins, 13-21% of non-fat milk solids, and milk accounting for all the remaining percentages; moreover, the formula of the frozen yoghurt comprises the following ingredients as stabilizers in parts by weight: 8-15 parts of acetylated distarch adipate ester, 15-25 parts of lactalbumin powder, 15-25 parts of pectin, 15-25 parts of sodium alginate and 3-10 parts of monoglyceryl fatty acid ester and / or diglycerol fatty acid ester; the stabilizer accounts for 0.5-2.5% of the total weight of the frozen yoghurt; and the formula of the frozen yoghurt further comprises lactase which accounts for 0.01-.0.05% of the total weight of the frozen yoghurt. The invention also provides a preparation method of the frozen yoghurt. The frozen yoghurt can be stored in a freezing environment of 18 DEG C below zero for a long time. The frozen yoghurt can be eaten as an ice cream in a frozen state; and the frozen yoghurt has the flavor of the yoghurt and the taste of the ice cream.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

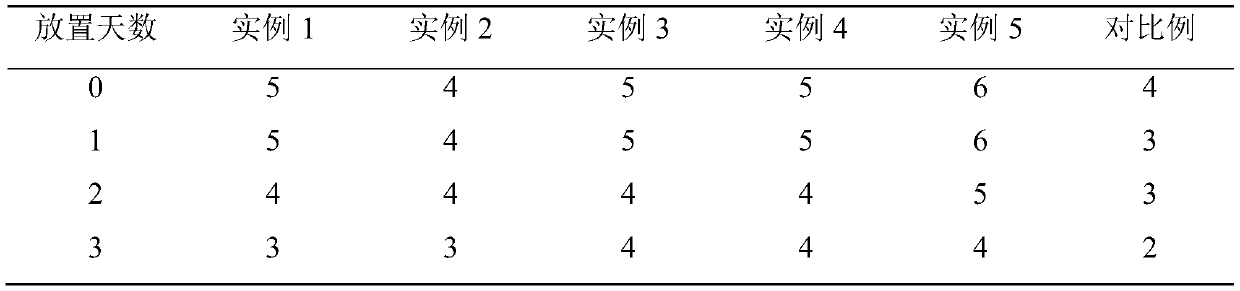

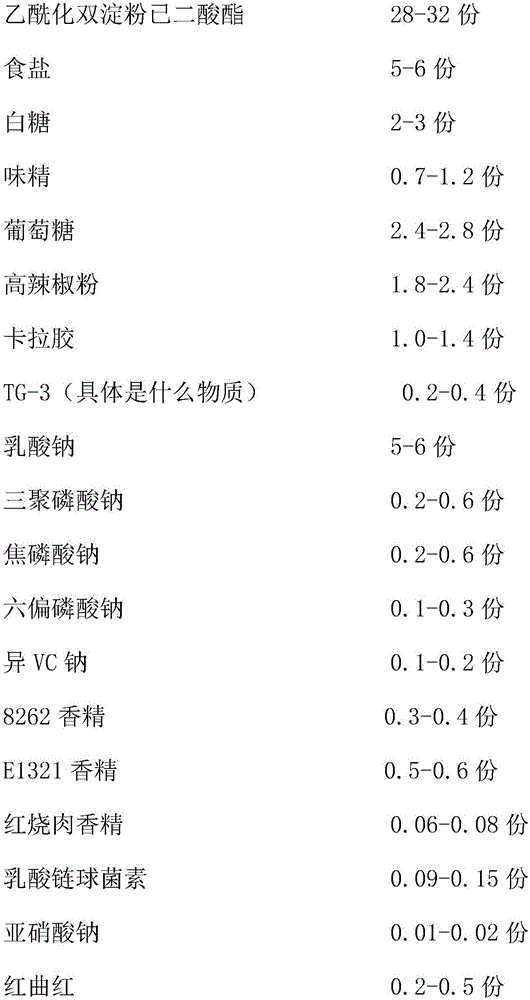

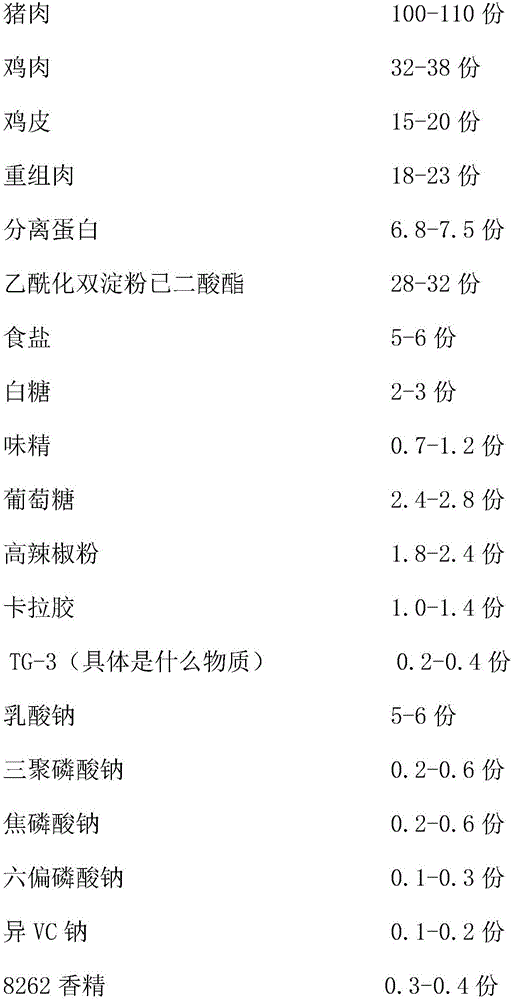

Spicy roasted sausage

The invention discloses a spicy roasted sausage and a preparation method thereof. According to the innovation point, the spicy roasted sausage is characterized by comprising pork, chicken, chicken skin, restructured meat and other auxiliary materials. The preparation method comprises the preparation flow of raw meat treatment, saline water preparation, primary rolling, secondary rolling, filling, drying, smoking, stewing, cooling, packaging, secondary sterilization, secondary cooling and storage. By adding high-chili powder and acetylated distarch adipate into the roasted sausage, the roasted sausage tastes unique and is compact and elastic in meat quality.

Owner:NANTONG YUTU GROUP

High-strength ceramic bowl and preparation method thereof

The invention discloses a high-strength ceramic bowl and a preparation method thereof. The high-strength ceramic bowl is prepared from the following raw materials in parts by weight: 31-43 parts of white clay, 22-34 parts of emery, 16-28 parts of attapulgite, 14-23 parts of rectorite, 12-18 parts of diabase, 4-7 parts of carbon nano tubes, 3-6 parts of magnesium borate whiskers, 2-3 parts of ferric citrate, 4-8 parts of magnesium silicate, 6-9 parts of polyethyleneglycol, 5-7 parts of acetylated distarch adipate, 3-5 parts of carboxymethylcellulose sodium, 4-6 parts of cane molasses and 5-10 parts of nano antimicrobial gent. The added emery, carbon nano tubes and magnesium borate whiskers are compounded as a strengthening body to not only remarkably improve the hardness and the strength of the ceramic bowl but also improve the wear resistance, the acid and alkali corrosion resistance and the high-temperature resistance of the ceramic bowl. The prepared ceramic bowl is larger than or equal to 1280 N in breaking strength, larger than or equal to 35 MPa in rupture modulus, high in strength, excellent in thermal stability, resistant to acid and alkali corrosion and durable, thereby meeting the market demands.

Owner:安徽省含山瓷业股份有限公司

A kind of radish sirloin essence and preparation method thereof

InactiveCN104041790BRealistic aromaRich and rich aromaFood ingredient as thickening agentFood thermal treatmentAdipateAcetylated distarch adipate

The invention discloses radish and sirloin essence and a preparation method thereof. The radish and sirloin essence is prepared from following raw materials: a radish and sirloin flavor heat reactant, table salt, white granulated sugar, sodium glutamate, hydrolyzed vegetable protein, acetylated distarch adipate and a sirloin meat aroma base, wherein the radish and sirloin flavor heat reactant is prepared from following components: beef zymolyte, animal fat, ox bone clear soup, light soy sauce, a yeast extract, amino acid, glucose, xylose, smashed red onion, smashed ginger, cinnamon powder, star aniseed powder, glycerol monostearate and water; the beef zymolyte is prepared from following components: beef, alkaline hydrolyzed protease, flavor protease, water and table salt. According to the radish and sirloin essence, under the precondition of not adding radishes, the aroma of the prepared radish and sirloin essence is natural and vivid, is mellow and rich and has a lasting aroma; the preparation method is simple in process and easy to operate.

Owner:广东江大和风香精香料有限公司

Corn antistaling agent

The invention relates to a corn antistaling agent comprising the following components in parts by weight: 0.3-1 percent of nitrite, 10-30 percent of tea polyphenol, 5-15 percent of ferric chloride, 3-8 percent of acetylated distarch adipate, 20-50 percent of disodium hydrogen phosphate and 60-90 percent of water. In the invention, the corn antistaling agent is prepared from the raw material including the nitrite, the tea polyphenol, the ferric chloride, the acetylated distarch adipate and the disodium hydrogen phosphate, therefore, the freshness date of corn can be effectively prolonged, the release period is long, the freshness date of the corn reaches as long as about 8 months, the original taste and the mouth feel of the corn can be effectively kept and the nutrition consumption is reduced. The invention has low raw material cost, simple process and convenience in use.

Owner:苏威

Quick-frozen coarse cereal dumplings and preparation method thereof

InactiveCN110122757AImprove toughnessAvoid breakingFood freezingFood coatingQuick FreezeFreezing thawing

The invention discloses quick-frozen coarse cereal dumplings, comprising wrappers and stuffing; the wrappers are prepared from the following raw materials in parts by weight: 98-102 parts of wheat core flour, 3-6 parts of acetate modified starch, 3-5 parts of oxidized hydroxypropyl starch, 1-3 parts of acetylated distarch adipate, 0.4-0.6 part of a dumpling improver, 0.4-0.6 part of table salt, 7-32 parts of coarse cereal flour, 1.5-3 parts of vital gluten and 47-64 parts of water. The acetate modified starch, the acetylated distarch adipate and the oxidized hydroxypropyl starch are compoundedto prepare the wrappers, the acetate modified starch has very good aging resistance, water-retaining property and film-forming property, the acetylated distarch adipate is high in aging resistance and freeze-thaw stability; the oxidized hydroxypropyl starch has stronger elasticity, water-retaining property and aging resistance, and the acetate modified starch, the acetylated distarch adipate andthe oxidized hydroxypropyl starch have a synergistic effect when being added into the wrappers so as to form a dense network structure and a good surface film on the surface of each wrapper, so that the moisture loss can be effectively reduced, toughness of the wrappers is enahnced, and the wrappers are prevented from cracking.

Owner:河南创新研霖食品科技有限公司

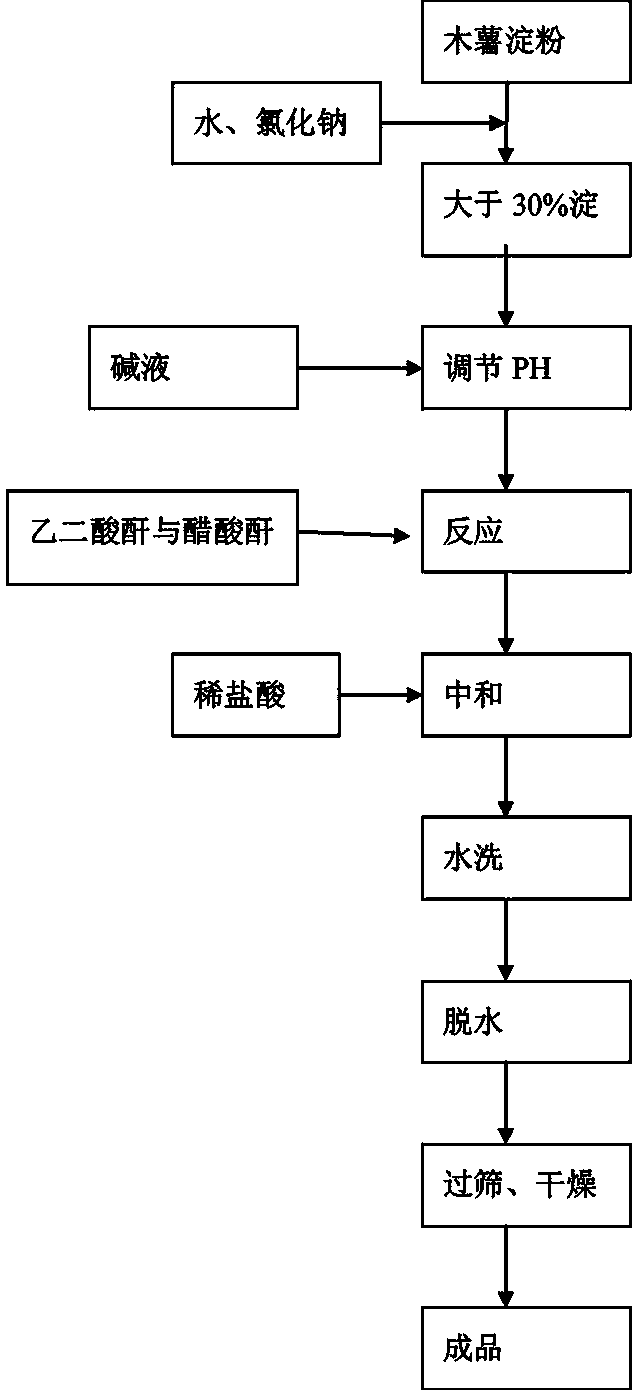

Preparation method of acetylated distarch adipate starch

The invention provides a preparation method of acetylated distarch adipate starch. The preparation method is characterized by comprising the following steps: preparing starch milk, adding alkaline liquor, stirring, adding oxalic anhydride and acetic anhydride for reaction after vacuumizing, washing, dehydrating and drying after neutralization, and discharging the materials. According to the preparation method of acetylated distarch adipate starch, oxalic anhydride is difficultly converted into oxalic acid by heating and vacuum conditions, and even partial oxalic anhydride which has been converted into oxalic acid also reacts to generate oxalic anhydride, thereby ensuring the efficient crosslinking reaction.

Owner:DONGGUAN DONGMEI FOOD

Environmentally-friendly textile sizing agent

The invention discloses an environmentally-friendly textile sizing agent which is prepared from the following components in parts by weight: 3 to 9 parts of chitosan, 2 to 8 parts of a crease resistant agent, 15 to 20 parts of maleic anhydride, 2 to 6 parts of dibutyl diacrylate, 0.5 to 1.5 parts of bentonite, 2 to 6 parts of waterborne copolymer ether ester, 5 to 12 parts of acetylated distarch adipate, 5 to 15 parts of acrylamide, 4 to 9 parts of butyl acrylate, 2 to 6 parts of vinyl acetate, 1 to 2 parts of an initiator, 0.8 to 1.5 parts of a catalyst, 2 to 6 parts of calcium chloride, 5 to10 parts of deionized water and 5 to 10 parts of modified starch. By adding the chitosan and the modified starch, textile fiber can be effectively puffed and loosened, so that the sizing percentage of a fabric is increased; by adding the bentonite, the intensity and the toughness of a sizing film can be greatly improved. By reasonable control over the contents of all the components of the sizingagent and preparation process conditions, the prepared textile sizing agent is stable in viscosity, excellent in chemical stability and thermal stability, and easy to size and desize; sizing agent wastewater is easy to treat; the sizing film performance and the sizing performance are high; the hygroscopic reviscosity is low; the environmentally-friendly textile sizing agent is green and environmentally friendly, and can avoid environmental pollution.

Owner:福泉曼易思纺织有限公司

Instant cold noodles and making method

PendingCN112385768ASolve the problem of not being able to industrializeSolve the problem of fast foodFood ingredient as thickening agentFood preservationSodium acetateSodium phosphates

The invention discloses instant cold noodles and a making method, and mainly relates to the field of instant cold noodles and making methods. The raw materials of the instant cold noodles comprise flour paste and auxiliary materials in the weight ratio of (10-8):1, and the auxiliary materials comprise the following components in parts by weight: 200-400 parts of xanthan gum, 100-300 parts of gellan gum, 200-300 parts of guar gum, 100-300 parts of sodium polyacrylate, 100-200 parts of sodium tripolyphosphate, 200-300 parts of sodium hexametaphosphate, 50-150 parts of carboxymethyl cellulose, 1500-3000 parts of acetylated distarch adipate, 400-600 parts of soybean lecithin, 10-80 parts of potassium sorbate, 10-80 parts of nisin, 0.1-10 parts of natamycin, 10-100 parts of sodium dehydroacetate, 0.1-20 parts of azodicarbonamide, 500-1000 parts of polydimethylsiloxane emulsion and 1000-5000 parts of edible glycerol. The instant cold noodles and the making method have the beneficial effectsthat the standardized production of cold noodle production can be realized, the production period is shortened, a relatively long shelf life is obtained, and the frozen cold noodles can be eaten afterbeing heated.

Owner:济南迎辉生物科技有限公司

Genuine sausage and preparation method thereof

PendingCN109907249AGood nutritional ratioIncrease elasticitySausage casingsMonosodium glutamateSodium phosphates

The invention relates to the field of sausages, in particular to a genuine sausage and a preparation method thereof. The genuine sausage comprises meat stuffing and a casing, the meat stuffing comprises pork, shrimps, fine fat, monosodium glutamate, white granulated sugar, edible salt, acetylated distarch adipate, sodium tripolyphosphate, sodium hexametaphosphate and sodium phosphate. The casing comprises, by weight, seaweed polysaccharide sulfide, tylorrhynchus extract fish skin collagen, konjac gum, sodium carboxymethyl cellulose, hydroxy propyl distarch phosphate and glycerol. The preparedsausage is excellent in elasticity and good in nutritive proportion, and the casing has good elasticity, flexibility and air permeability.

Owner:福建御冠食品有限公司

Modified starch for producing bean curd skins for chafing dish

InactiveCN108433094AImprove toughnessGood toughness, good rehydration when shabu-shabuFood ingredientsCheese manufactureAcetic anhydrideSodium starch

The invention discloses modified starch for producing bean curd skins for a chafing dish. The modified starch consists of acetylated distarch adipate and sodium starch octenyl succinate, wherein the acetylated distarch adipate is prepared through the following steps of compounding glutinous corn starch and tapioca starch in the proportion of the glutinous corn starch to the tapioca starch being 1to 1 into 40% starch milk, adjusting pH with sodium hydroxide of which the concentration is 5%, raising the temperature, adding acetic anhydride adipic anhydride mixed liquor of which the mass is 5% of that of the glutinous corn starch and tapioca starch, then performing rotational flow washing, performing dehydration, performing drying, performing crushing and performing packaging; and the sodiumstarch octenyl succinate is prepared through the steps of compounding the tapioca starch into 40% starch milk, adjusting pH with sodium hydroxide of which the concentration is 3%, raising the temperature, adding octenyl succinic anhydride of which the mass is 3% of that of the tapioca starch, then performing rotational flow washing, performing dehydration, performing drying, performing crushing,and performing packaging. Compared with conventional bean curd skins, the bean curd skins made from the modified starch disclosed by the invention have the advantages that after the modified starch isadded, the bean curd skins are easy to shape, not liable to break and good in toughness, and during instant-boiling of the chafing dish, the bean curd skins are good in rehydration properties, resistant to cook, fine and smooth in mouth feel and soft.

Owner:诸城兴贸玉米开发有限公司

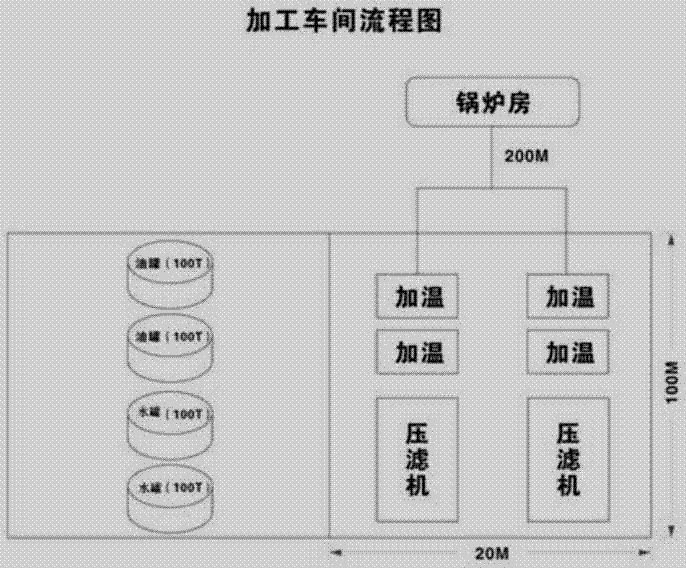

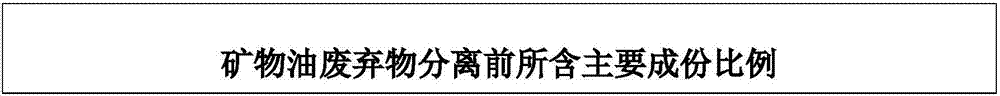

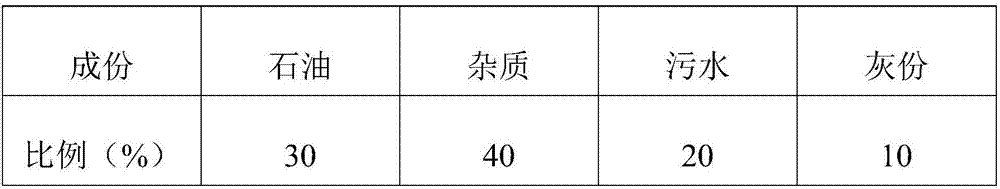

Environmental-protection treatment technology of mineral oil waste

ActiveCN106905993AReduce oil contentSimple processDewatering/demulsification with chemical meansHydrocarbon oils treatmentWaste treatmentAdipate

The invention discloses a mineral oil waste treatment process: (1) processing of chemical agents: heating to 400 DEG C with a demulsifier, polyacrylamide, cassava acetylated distarch adipate starch and sodium silicate to dissolve and react for 1 h so as to form a transparent liquid, and barreling for later use; (2) putting mineral oil waste into a heating tank, adding a medicament according to the ratio of 1 ton of the mineral oil waste to 0.5% of the medicament, heating to about 80 DEG C and fully stirring, demulsifying and decomposing the mineral oil waste, precipitating for 2 h, extracting crude oil, extruding wastewater and impurities by a filter press, filtering out moisture, and forming powdery solids from the impurities. Oil and impurities processed by the technology are all tested through a professional testing agency and all reach the discharge standard of national requirements.

Owner:诗茵(海南)环保科技有限公司

Tempura

InactiveCN107788407AStrong water absorptionImprove water absorptionMeat/fish preservation using chemicalsProtein food ingredientsBiotechnologyMonosodium glutamate

The invention discloses tempura. The tempura is prepared from raw materials in parts by weight as follows: 15-20 parts of chicken breast, 15-20 parts of chicken skin, 15-20 parts of fish paste, 5-10 parts of protein pulp, 2-3 parts of onion, 1-2 parts of corn grains, 5-8 parts of carrots, 10-15 parts of acetylated distarch adipate, 5-10 parts of starch acetate, 5-10 parts of corn starch, 5-10 parts of hydropropyl distarch phosphate, 2-3 parts of salt, 1-2 parts of monosodium glutamate and 1-2 parts of sugar. The starch acetate and hydropropyl distarch phosphate have higher water absorption andcan remarkably increase the water absorption of the product, so that the yield of the product can be increased by 1%-2%. Traditional tempura is prone to cracking, separation and the like after beingfrozen and thawed about 5 times in stability tests, and the tempura produced from the components with the method has those phenomena after being frozen and thawed 10 times.

Owner:诸城兴贸玉米开发有限公司

Tomato dice seasoning and preparation method thereof

InactiveCN109105853ARich tomato flavorRich flavorFood ingredient functionsMonosodium glutamateAdipate

The invention relates to a seasoning and a preparation method thereof, especially to a tomato dice seasoning and a preparation method thereof The tomato dice seasoning comprises, by weight, 20 to 30%of catsup, 25 to 35% of tomato dices, 1.5 to 2% of acetylated distarch adipate, 4 to 10% of white granulated sugar, 4 to 10% of salt, 2 to 4% of chickens' extract, 2 to 4% of monosodium glutamate, 2 to 5% of soybean oil, 0.5 to 1% of sesame oil, 1 to 2% of extract yeast, 1 to 5% of chicken essence paste, 0.1 to 0.5% of spices, 0.1 to 0.5% of disodium 5'-ribonucleotide and 10 to 20% of drinking water. The invention has the following beneficial effects: (1) the tomato dice seasoning provided by the invention has rich tomato flavor and soft taste; (2) the tomato dice seasoning has agreeable sour-sweet taste, can easily whet the appetite and better presents the rich taste of dishes; and (3) the preparation method of the invention is simple in process, low in production cost and applicable to mass production.

Owner:贾帅强

A kind of preparation method of acetylated distarch adipate starch

The invention provides a preparation method of acetylated distarch adipate starch. The preparation method is characterized by comprising the following steps: preparing starch milk, adding alkaline liquor, stirring, adding oxalic anhydride and acetic anhydride for reaction after vacuumizing, washing, dehydrating and drying after neutralization, and discharging the materials. According to the preparation method of acetylated distarch adipate starch, oxalic anhydride is difficultly converted into oxalic acid by heating and vacuum conditions, and even partial oxalic anhydride which has been converted into oxalic acid also reacts to generate oxalic anhydride, thereby ensuring the efficient crosslinking reaction.

Owner:DONGGUAN DONGMEI FOOD

Composite coating flour for frying and preparation method thereof

InactiveCN107751977AImprove adhesionGood film formingFood coatingOrganic compound food ingredientsCarboxymethyl starchCassava (food)

The invention discloses composite coating flour for frying and a preparation method thereof. The composite coating flour for the frying is prepared from the following raw materials in parts by weight:5 to 10 parts of corn starch, 5 to 10 parts of cassava starch, 10 to 20 parts of oxidized starch, 50 to 60 parts of cross-linking starch, 5 to 10 parts of acetylated distarch adipate, 5 to 10 parts of carboxymethyl starch, 0.8 to 1.2 parts of table salt and 0.8 to 1.2 parts of spice. The composite coating flour for the frying has the following beneficial effects that the coating flour has greaterbonding force and higher film-forming property, high-temperature expansibility and stability through compounding, so that the flour can have good binding and cohesive force, the coating flour can beprevented from falling off, a pickling material and water can be prevented from excessive losing when frying is performed, and golden appearance and good crispness are provided; food is crisp on outside, tender in inside, and juicy after being fried; the food does not collapse and become soft when the food is stored; the oil absorption rate is reduced, and the saturated fat intake of a human bodyis reduced.

Owner:诸城兴贸玉米开发有限公司

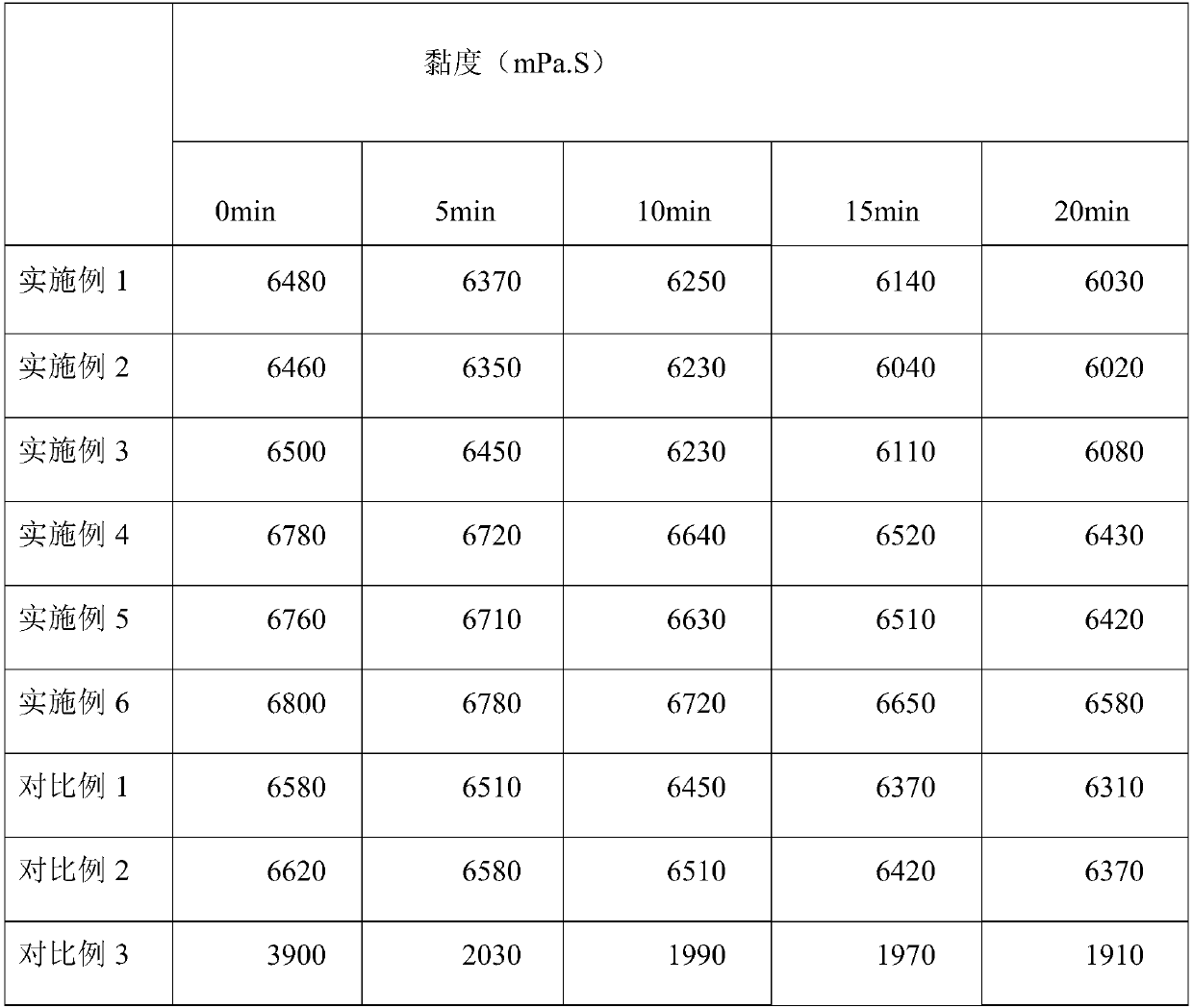

Preparation technology of acetylated distarch adipate

The invention discloses a preparation technology of acetylated distarch adipate. The preparation technology comprises the following steps: step one, adding starch into rice bran oil for reacting at the temperature of 100 to 110 DEG C for 20 to 30 min, stirring at the rotate speed of 300 to 400 rpm for 35 to 45 min, then carrying out washing, centrifuging and drying, then feeding the mixture into afeeding pool, then adding water to prepare a starch emulsion, and then adding pectin. According to the preparation technology, the rice bran oil has various active ingredients such as fatty acids, agreat number of hydroxide radicals are generated at the temperature of 100 to 110 DEG C, the hydroxide radicals are combined with starch, the esterification efficiency of starch and acetic anhydride and the cross-linking efficiency of adipic acid are improved, simultaneously, the viscosity of the starch emulsion can be improved through the added pectin, and the cross-linking efficiency of starch in the subsequent cross-linking process is improved.

Owner:GUANGXI GAOYUAN STARCH

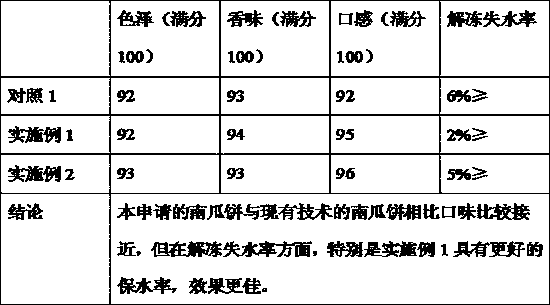

Quick-frozen pumpkin pie

The invention discloses a quick-frozen pumpkin pie, which is prepared from the following raw materials by mass in parts: 100 parts of pumpkin puree, 100 parts of chicken breast, 20 parts of green pepper, 20 parts of green Chinese onion, 20 parts of acetylated distarch adipate starch, 10 parts of ice water, 22 parts of carrots, 10 parts of salt, 15 parts of sugar, 4 parts of monosodium glutamate, 4parts of spices and 1 part of essence. The acetylated distarch adipate starch and the chicken breast are added into the pumpkin pie to improve the nutritional value of the pumpkin pie as well as thetaste of the product, the pumpkin nutrition is not lost, at the same time, the nutrition of the chicken breast is provided, and the pumpkin nutrition and the chicken breast nutrition enhance each other, so that current customer demands for maximum reasonable food nutrition is satisfied.

Owner:SHANDONG HUACHANG FOOD TECH

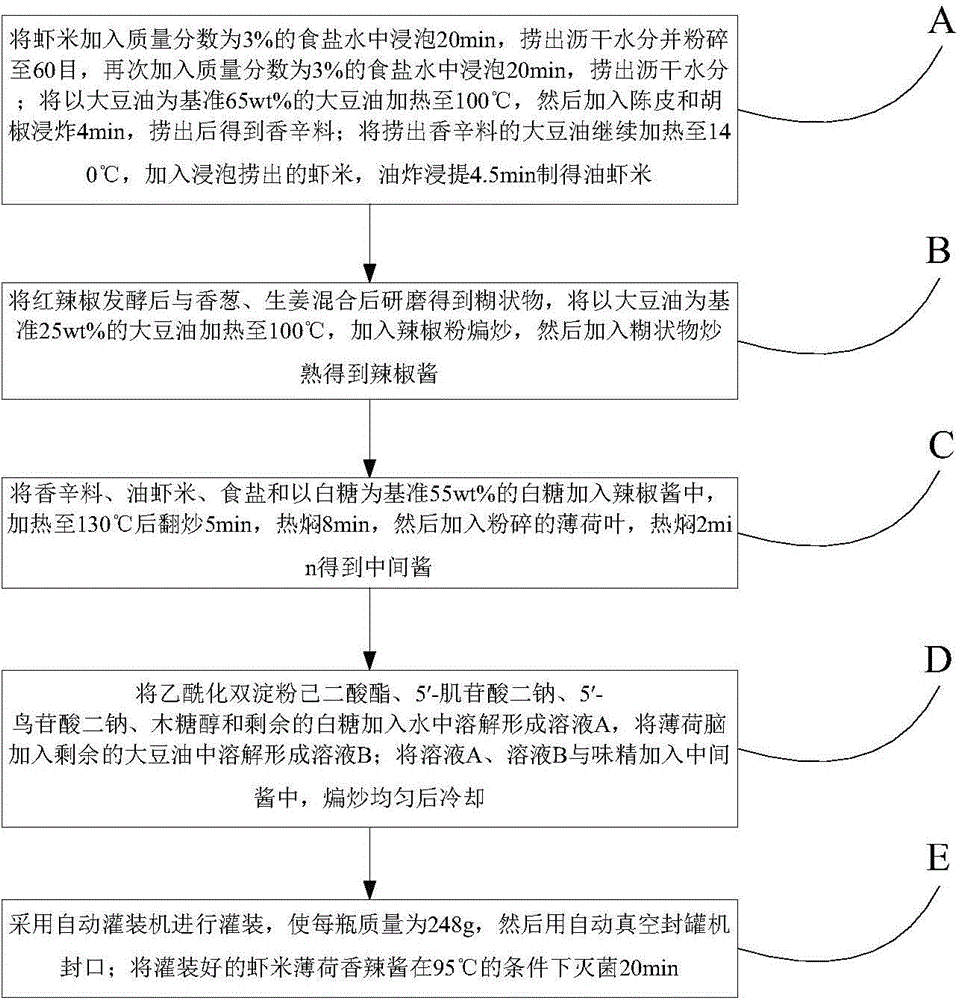

Hot and spicy sauce with dried peeled shrimp and mint and preparation method of hot and spicy sauce

ActiveCN104872621ARich food cultureVast business potentialFood preparationMonosodium glutamateMenthol

The invention discloses a hot and spicy sauce with dried peeled shrimp and mint. The hot and spicy sauce with dried peeled shrimp and mint is prepared from the following raw materials in parts by weight: 45-55 parts of dried peeled shrimp, 175-185 parts of red pepper, 9-13 parts of mint leaves, 85-100 parts of soybean oil, 1-1.5 parts of monosodium glutamate, 1-1.5 parts of chive, 0.5-1 part of ginger, 2-3 parts of chilli powder, 0.5-1 part of black pepper, 0.5-1 part of pericarpium citri reticulatae, 0.1-0.4 part of menthol, 2.5-3.2 parts of white sugar, 0.02-0.08 part of xylitol, 1-3.5 parts of salt, 0.2-0.9 part of acetylated distarch adipate, 0.4-0.8 part of disodium 5'-Inosinate and 0.4-0.8 part of guanosine-5'-monophosphat. The invention also discloses a preparation method of the hot and spicy sauce with dried peeled shrimp and mint. The prepared hot and spicy sauce with dried peeled shrimp and mint is chewy, smooth, nutritive and healthy, and is cold and spicy in taste.

Owner:芜湖市老兵坛子食品有限公司

Fresh-keeping cold noodle improver

InactiveCN109924388AImprove the defects that are prone to aging and hardeningImprove textureFood preservationPhosphateGluten

The invention provides a fresh-keeping cold noodle improver which consists of, by weight, the following raw materials: one or both of acetylated distarch phosphate or acetylated distarch adipate: 75%-90% of hydroxypropyl distarch phosphate, 2%-15% of trehalose and 2%-5% of high gluten flour. The fresh-keeping cold noodle improver is used for preparing cold noodles, contains components with betteranti-aging effect, can effectively improve the defect that the cold noodles are easy to age and harden, improves the texture and mouthfeel of the cold noodles, and enables the cold noodles to have a longer shelf life. Industrial production of the cold noodle can also be promoted.

Owner:无锡威尔森淀粉工业有限公司

Spicy roasted sausage

InactiveCN106616476AUniform colorGood lookingFood ingredient as taste affecting agentHot peppersAcetylated distarch adipate

The invention discloses a spicy roasted sausage and a preparation method thereof. The spicy roasted sausage is characterized by being prepared from pork, chicken, chicken skin, restructured meat and other auxiliary materials; and the preparation process comprises the steps of raw material meat treatment, saline water preparation, primary rolling and rubbing, secondary rolling and rubbing, filling, drying, fumigating and cooking, cooling and packaging, secondary sterilization, secondary cooling and storing. By adding highly-spicy hot pepper powder and acetylated distarch adipate into the roasted sausage, the roasted sausage is unique in taste and compact and elastic in meat texture.

Owner:NANTONG BOTAI ART PATTERN DESIGN CO LTD

Quick-frozen salmon egg dumplings

InactiveCN109170639AFull of nutritionRich in nutritional valueFood coatingFood ingredient functionsAnimal scienceThreadfin bream

Quick-frozen salmon egg dumplings consist of the following raw materials in parts by mass: 350 parts of salmon surimi, 100 parts of golden threadfin bream surimi, 100 parts of seawater AA surimi, 100parts of pork fat, 15 parts of garlic, 25 parts of ginger, 25 parts of acetylated distarch adipate starch, 100 parts of ice water, 2 parts of compound phosphate, 3 parts of seafood marinade, 12 partsof salt, 15 parts of sugar, 4 parts of MSG, 6 parts of spices, and 0.75 part of flavored fragrant oil. The quick-frozen salmon egg dumplings are rich in nutrients and rich in unsaturated fatty acids.The protein of the quick-frozen salmon egg dumplings contains 18 kinds of amino acids (including 8 kinds of essential amino acids), and the protein content of the quick-frozen salmon egg dumplings issignificantly higher than that of other products.

Owner:SHANDONG HUACHANG FOOD TECH

Compound thickening agent for fish tofu

InactiveCN107616484AStrong water absorptionImprove water absorptionFood sciencePhosphatePhosphoric acid

The invention discloses a compound thickening agent for fish tofu. The compound thickening agent is characterized by being prepared from the following raw materials by percentage: 98-99% of modified starch, 0.5-1% of xanthan gum and 0.5-1% of konjac gum, wherein every 1% of the modified starch is prepared from the following raw materials by a weight ratio: 16-23% of acetylated distarch phosphate,16-17% of acetylated distarch adipate, 10-12% of hydroxypropyl distarch phosphate, 23-25% of starch acetate and 28-30% of starch phosphate. After the compound thickening agent for the fish tofu is used, the water absorption of the product is obviously improved, so that the product yield is increased; the compound thickening agent can increase the product yield by 2-3%. The compound thickening agent provided by the invention can improve the taste of the fish tofu, enhance the water-absorbing property and water-retaining property of the fish tofu, and improve the elasticity of the fish tofu. After the compound thickening agent is used, the freezing resistance and boiling fastness of the fish tofu can be improved, and the shelf life of the fish tofu can be prolonged.

Owner:诸城兴贸玉米开发有限公司

Snow pear and loquat flavored fermented milk and preparation method thereof

PendingCN113491288AAvoid flavor effectsHigh clarityMilk preparationOther dairy technologyBiotechnologyFruit juice

The invention provides snow pear and loquat flavored fermented milk and a preparation method thereof. The preparation method comprises the following steps that snow pears and loquats are boiled, blanched, pulped, subjected to ultrasonic treatment and enzymolysis, a carboxymethyl chitosan / activated clay compound is added, clarification treatment is carried out to obtain mixed fruit juice, the mixed fruit juice is mixed with raw milk and a compound stabilizer, and degassing, homogenizing, sterilizing, and fermenting are carried out to obtain the snow pear and loquat flavored fermented milk. The compound stabilizer is prepared from agar and acetylated distarch adipate, the base material is prepared from 0.5%-1% of the mixed fruit juice, and the weight ratio of the snow pears to the loquats is (8: 2) to (6: 4). The snow pear and loquat flavored fermented milk is prepared by the preparation method. The snow pear and loquat flavored fermented milk is high in stability, uniform in texture and relatively good in flavor and taste.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

A kind of tomato sauce and preparation method thereof

The invention relates to the technical field of seasoning processing, specifically to tomato ketchup and its preparation method. The tomato ketchup comprises the following components: by weight, 40-50 of concentrated ketchup, 4-5% of white sugar, 2-4% of acetylated distarch adipate, 0.3-0.6% of salt, 0.05-0.18% of edible acetic acid, 0.05-0.2% of vitamin C, 0.05-0.12% of cochineal, 0.03-0.08% of potassium sorbate, and 40-50% of water. The preparation method of the tomato ketchup comprises the following steps: Step 1, preparing a dissolved solution; Step 2, heating and adding a self-made thickening liquid; Step 3, carrying out gelatinization; Step 4, stirring materials; Step 5, boiling; and Step 6, cooling and adding auxiliary materials. The tomato ketchup has advantages of rich tomato flavor, soft mouthfeel, high nutritive value, anti-cancer efficacy, good stability, excellent quality and long shelf life.

Owner:DONGGUAN YONGYI FOODS

Environmentally-friendly textile sizing agent and preparation method thereof

The invention discloses an environmentally-friendly textile sizing agent and a preparation method thereof. The environmentally-friendly textile sizing agent is prepared from the following components:3 to 9 parts of chitosan, 2 to 8 parts of a crease resistant agent, 15 to 20 parts of maleic anhydride, 2 to 6 parts of dibutyl diacrylate, 0.5 to 1.5 parts of bentonite, 2 to 6 parts of waterborne copolymer ether ester, 5 to 12 parts of acetylated distarch adipate, 5 to 15 parts of acrylamide, 4 to 9 parts of butyl acrylate, 2 to 6 parts of vinyl acetate, 1 to 2 parts of an initiator, 0.8 to 1.5parts of a catalyst, 2 to 6 parts of calcium chloride, 5 to 10 parts of deionized water and 5 to 10 parts of modified starch. By adding the chitosan and the modified starch, textile fiber can be effectively puffed and loosened, so that the sizing percentage of a fabric is increased; by adding the bentonite, the intensity and the toughness of a sizing film can be greatly improved. By reasonable control over the contents of all the components of the sizing agent and preparation process conditions, the prepared textile sizing agent is stable in viscosity, excellent in chemical stability and thermal stability, and easy to size and desize; sizing agent wastewater is easy to treat; the sizing film performance and the sizing performance are high; the hygroscopic reviscosity is low; the environmentally-friendly textile sizing agent is green and environmentally friendly, and can avoid environmental pollution.

Owner:福泉曼易思纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com